-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 10. 2025, 13:38:00

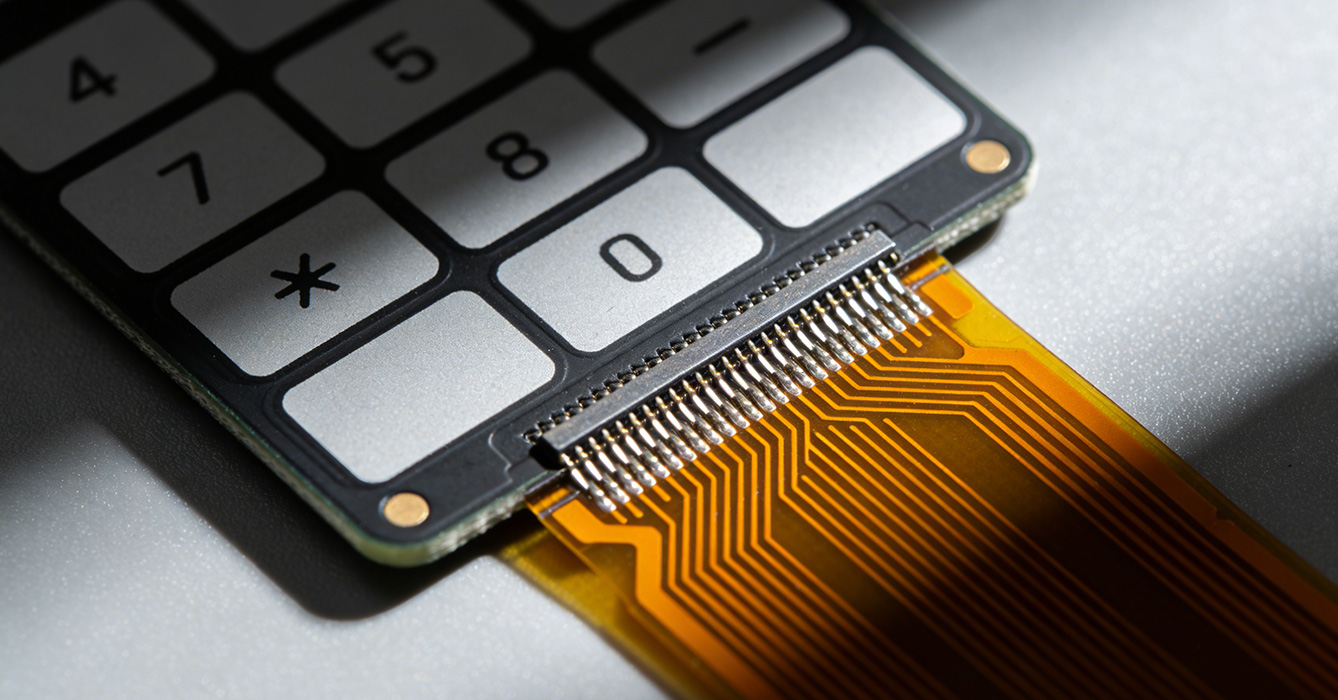

Keypads serve as critical human-machine interfaces across industrial control panels, consumer electronics, automotive dashboards, and medical devices, demanding flexible printed circuits (FPCs) that can withstand millions of按压 cycles while maintaining reliable signal transmission. A professional Durable Keypad FPC Manufacturer specializes in engineering FPCs tailored for the unique mechanical stress and environmental challenges of keypad applications. Unlike generic FPC manufacturers, these specialized providers focus on按压 durability, wear resistance, and consistent tactile feedback, ensuring FPCs remain functional even in high-frequency usage and harsh operating environments. For brands developing long-lasting, high-reliability keypads, partnering with a reputable Durable Keypad FPC Manufacturer is essential to delivering products that meet end-users’ expectations for longevity and performance.

The competitive edge of a top Durable Keypad FPC Manufacturer lies in its mastery of specialized technologies that enhance FPC resilience against the repeated mechanical stress of keypad operations:

- Press-Cycle Optimized Circuit Design: High-frequency keypad usage subjects FPCs to continuous bending and compression at contact points. Leading manufacturers use advanced EDA tools to design circuit layouts that disperse mechanical stress—such as curved trace routing around key contact areas, staggered component placement, and reinforced solder joints. This design minimizes the risk of circuit breakage or contact failure even after 10 million+按压 cycles, a benchmark for industrial and automotive keypad reliability.

- Wear-Resistant Material Integration: Keypad FPCs require surface materials that resist abrasion from repeated key presses and environmental contaminants. Manufacturers adopt specialized coverlay materials (e.g., high-hardness polyimide films, scratch-resistant coatings) and corrosion-resistant conductive materials (e.g., gold-plated contacts, alloy foils). These materials prevent contact oxidation, surface wear, and moisture ingress, ensuring consistent signal transmission and extending FPC lifespan in dusty, humid, or chemical-exposed environments.

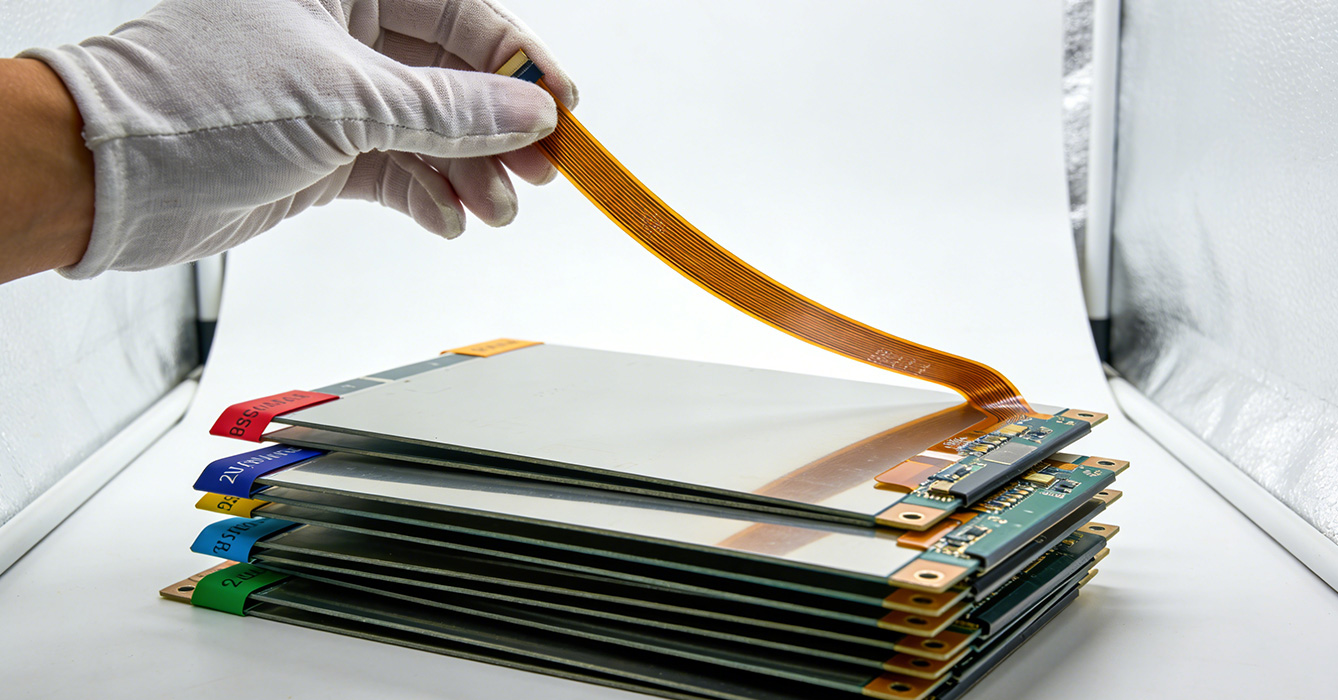

- Elastic Substrate & Tactile Feedback Synergy: Tactile feedback is critical for user experience, and FPCs play a role in maintaining consistent key responsiveness. Durable Keypad FPC Manufacturers select elastic substrate materials with excellent recovery properties, ensuring the FPC regains its shape after each press without permanent deformation. They also optimize substrate thickness and layer structure to balance flexibility and rigidity, supporting stable tactile feedback throughout the keypad’s service life.

A professional Durable Keypad FPC Manufacturer tailors solutions to the distinct durability and environmental requirements of different keypad use cases:

- Industrial Control Keypads: Industrial keypads operate in harsh environments (dust, vibration, chemical exposure) and require ultra-durable FPCs. Manufacturers develop ruggedized FPCs with sealed edge structures, chemical-resistant coatings, and enhanced mechanical reinforcement. These FPCs withstand extreme temperature fluctuations (-40°C to 85°C) and heavy-duty usage, ensuring reliable operation in factories, construction equipment, and mining controls.

- Consumer Electronics Keypads: For smartphones, remote controls, and gaming devices, FPCs must balance durability with slim form factors. Manufacturers design ultra-thin, lightweight FPCs with high-flex endurance and low-power consumption. They integrate compact contact structures to fit within narrow device spaces while supporting 1–5 million press cycles, aligning with consumer electronics’ lifespan expectations.

- Automotive Keypads: In-car keypads (infotainment systems, steering wheel controls) face temperature extremes, vibration, and UV radiation. Durable Keypad FPC Manufacturers produce automotive-grade FPCs compliant with IATF 16949 standards, using heat-resistant, flame-retardant materials. These FPCs resist automotive fluids (oil, coolant) and maintain performance during long-term vibration, ensuring safe and reliable user interaction while driving.

- Medical Device Keypads: Medical keypads (diagnostic equipment, patient monitors) require sterile, corrosion-resistant FPCs that withstand frequent disinfection. Manufacturers use biocompatible, chemical-resistant materials (e.g., medical-grade polyimides) and sealed designs to prevent contamination. These FPCs also support precise signal transmission for critical medical operations, with durability to withstand daily disinfection cycles.

To ensure FPCs meet the strict durability requirements of keypad applications, manufacturers implement comprehensive testing protocols:

- Accelerated Press-Cycle Testing: Using automated testing equipment, FPCs undergo millions of simulated key presses to validate mechanical durability. This testing measures contact resistance stability, substrate deformation, and circuit integrity, ensuring the FPC performs consistently throughout its intended service life.

- Environmental Stress Testing: Tests include thermal cycling (to simulate temperature extremes), humidity aging (to prevent moisture damage), salt spray testing (for corrosion resistance in industrial/automotive environments), and UV exposure testing (for in-car and outdoor keypads). These tests validate FPC performance in real-world operating conditions.

- Wear & Abrasion Testing: Using abrasion testers, manufacturers evaluate the resistance of FPC surfaces and contacts to repeated friction from key caps. This testing ensures the FPC does not suffer from surface wear or contact failure due to long-term usage.

Durable Keypad FPC Manufacturers act as strategic partners, supporting keypad brands through collaborative R&D and end-to-end services:

- Early-Stage Co-Design: Manufacturers participate in the early design phase of keypads, providing DFM (Design for Manufacturability) insights on FPC layout, material selection, and contact structure. They work closely with keypad designers to optimize FPC compatibility with key caps, tactile domes, and housing, ensuring durability does not compromise user experience.

- Rapid Prototyping & Iteration: To accelerate keypad development, manufacturers offer rapid prototyping services, delivering functional FPC prototypes within days. This enables brands to quickly validate durability and performance, iterate on design improvements, and shorten time-to-market.

- Mass Production Quality Assurance: During mass production, manufacturers use AI-driven optical inspection (AOI) and contact resistance testing to ensure consistent quality. Strict batch traceability systems track each FPC from raw material to delivery, enabling rapid resolution of any quality issues and ensuring reliability across large production runs.

In conclusion, a Durable Keypad FPC Manufacturer is a critical enabler of high-reliability keypad solutions, leveraging specialized durability technologies, scenario-specific customization, and rigorous testing to meet the demands of high-cycle usage and harsh environments. As keypads continue to be essential interfaces in industrial, automotive, and consumer electronics, the strategic value of partnering with a professional Durable Keypad FPC Manufacturer will remain prominent for brands aiming to deliver long-lasting, user-centric products. Their ability to balance durability, performance, and design flexibility makes them indispensable in the keypad innovation ecosystem.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB