-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 09. 2025, 18:50:03

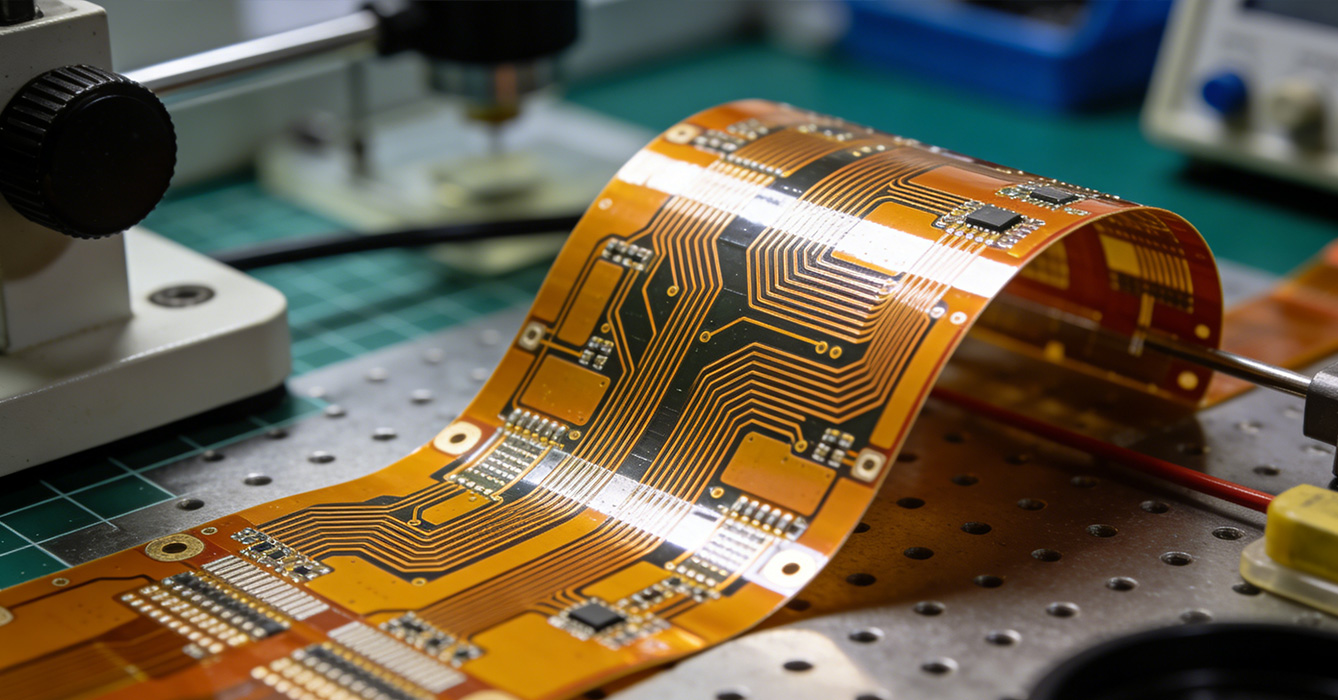

In the fast-evolving global electronics industry, the performance and versatility of flexible printed circuits (FPCs) have become decisive factors in product innovation. A professional FPC manufacturer distinguishes itself through cutting-edge material innovation and tailored engineering capabilities, going beyond standardized production to deliver high-performance, application-specific FPC solutions. Unlike generic component suppliers, leading FPC manufacturers prioritize R&D in advanced materials and precision engineering, enabling them to address the unique challenges of emerging electronic applications—from wearable devices to industrial IoT sensors. For electronics brands striving to gain a competitive edge, partnering with an FPC manufacturer that excels in material innovation and customization is essential to unlocking product potential and meeting evolving market demands.

The core competitiveness of top FPC manufacturers lies in their continuous breakthroughs in material science, which lay the foundation for FPCs with superior performance and broader applicability:

- Next-Generation Substrate Materials: Leading manufacturers invest heavily in developing advanced substrate materials beyond traditional polyimides. This includes high-thermal-conductivity substrates for heat-intensive applications (e.g., automotive electronics), ultra-thin flexible substrates for wearable devices, and low-dielectric-constant materials for high-frequency communication FPCs. These innovative substrates balance flexibility, durability, and functional performance, enabling FPCs to adapt to extreme operating conditions.

- High-Performance Conductive & Adhesive Materials: To enhance signal integrity and mechanical reliability, FPC manufacturers adopt high-purity copper foils, silver-paste conductive materials, and advanced adhesive systems. High-purity copper reduces signal loss and improves current-carrying capacity, while specialized adhesives prevent delamination even under repeated bending or temperature fluctuations. For harsh environments, corrosion-resistant conductive materials ensure long-term FPC performance in humid, chemical-exposed settings.

- Eco-Friendly & Sustainable Materials: Aligning with global sustainability trends, forward-looking FPC manufacturers integrate eco-friendly materials into their product lines. This includes bio-based polyimides derived from renewable resources, recyclable conductive materials, and water-based adhesives with low VOC emissions. These sustainable materials not only reduce environmental impact but also meet the strict green certification requirements of global electronics brands.

A professional FPC manufacturer stands out through its ability to provide customized engineering solutions, adapting FPC designs to the specific requirements of diverse electronic products:

- Application-Specific Design Optimization: Manufacturers work closely with customers to understand the operational context of their products, optimizing FPC designs for factors such as space constraints, mechanical stress, and signal transmission needs. For example, for wearable devices, they design ultra-compact, lightweight FPCs with minimal thickness; for industrial sensors, they develop ruggedized FPCs with reinforced structures and EMI shielding.

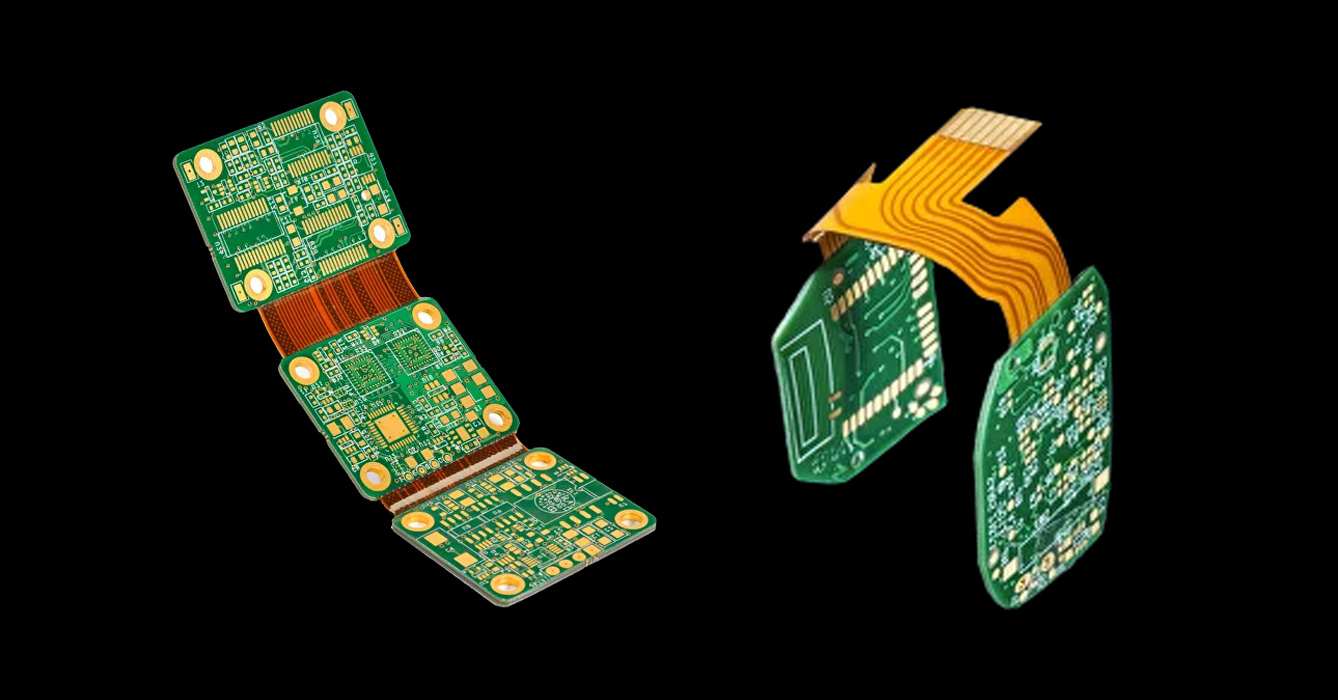

- Complex Structure Design & Integration: Beyond basic flexible circuits, manufacturers excel in designing complex FPC structures such as rigid-flex combinations, multi-layered circuits, and integrated component layouts. Rigid-flex FPCs, which combine flexible and rigid segments, are ideal for devices requiring both flexibility and structural stability (e.g., foldable smartphones, medical devices). Integrated component layouts reduce the number of parts, simplifying assembly and improving product reliability.

- Rapid Prototyping & Iterative Engineering: To accelerate customers’ product development cycles, FPC manufacturers offer rapid prototyping services supported by advanced EDA (Electronic Design Automation) tools. They can quickly produce functional FPC prototypes, enabling customers to validate design feasibility and iterate on performance improvements. This iterative engineering process ensures that the final FPC solution fully meets the product’s technical goals.

Top FPC manufacturers implement rigorous quality engineering processes and reliability validation protocols to ensure their customized solutions meet the highest industry standards:

- Comprehensive Performance Testing: Custom FPCs undergo targeted testing based on their application scenarios, including flex endurance cycling, thermal cycling, humidity aging, signal integrity analysis, and mechanical stress testing. For automotive and medical applications, additional tests such as vibration resistance, salt spray resistance, and biocompatibility validation are conducted to ensure compliance with industry-specific requirements.

- Precision Manufacturing Control: Advanced manufacturing technologies such as laser etching, automated lamination, and AI-driven optical inspection (AOI) ensure the precision and consistency of customized FPCs. Laser etching enables ultra-fine circuit patterns for high-density designs, while AI-driven AOI detects micro-defects that may affect performance. Strict process control ensures that even small-batch customized orders meet the same quality standards as mass-produced products.

- Global Quality Compliance: Manufacturers comply with international standards such as IPC-6012/2221 for FPC quality, RoHS/REACH for environmental protection, and industry-specific certifications (e.g., IATF 16949 for automotive, ISO 13485 for medical). This compliance ensures that customized FPC solutions can be seamlessly integrated into customers’ global product lines.

Forward-looking FPC manufacturers maintain a proactive R&D focus, exploring new material applications and engineering approaches to support emerging electronic technologies:

- Flexible Electronics & Wearable Tech: Investing in R&D for ultra-thin, stretchable FPCs that can conform to human skin or irregular surfaces, supporting the growth of wearable health monitors, smart clothing, and flexible displays.

- High-Speed Communication & 6G Readiness: Developing FPCs with low signal loss and high EMI resistance to support the high-frequency, high-speed data transmission requirements of 6G technology and next-generation IoT devices.

- Advanced Medical & Implantable Devices: Exploring biocompatible, hermetically sealed FPC solutions for implantable medical devices, such as pacemakers and neural sensors, where long-term reliability and biocompatibility are critical.

In conclusion, an FPC manufacturer’s advanced material innovation and customized engineering capabilities are key enablers of electronic product innovation. By leveraging cutting-edge materials, tailoring designs to specific applications, and ensuring rigorous quality validation, these manufacturers empower electronics brands to bring innovative, reliable products to market. As the electronics industry continues to evolve toward miniaturization, flexibility, and sustainability, the strategic value of partnering with an FPC manufacturer that prioritizes innovation and customization will only grow, making it a critical asset for brands aiming to lead in their respective markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB