-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 25. 2025, 10:50:02

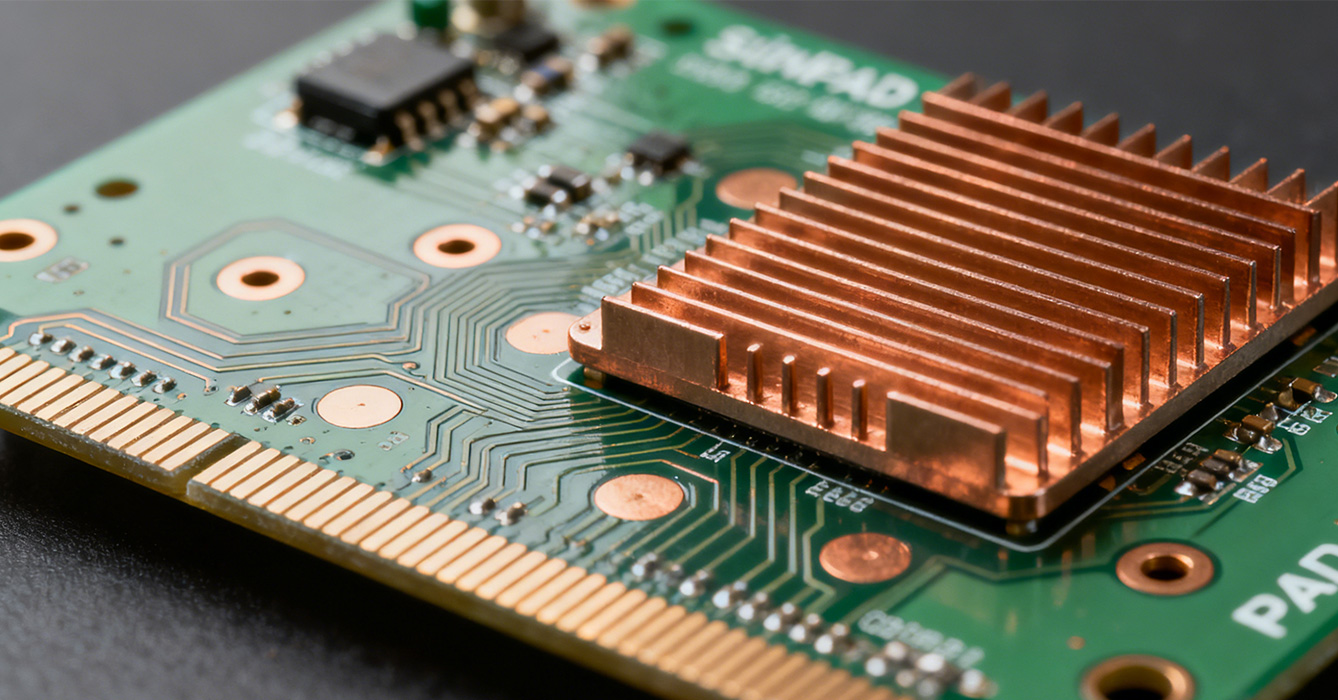

As electronic devices evolve toward higher power densities and smaller form factors, thermal management has evolved from a secondary consideration to a critical design pillar. Sinkpad PCB has emerged as a definitive solution, redefining how heat is managed in high-power systems by integrating dedicated thermal sink structures directly into the PCB architecture. Unlike conventional PCBs that rely on external cooling solutions, Sinkpad PCB merges electrical functionality with thermal efficiency, addressing the core challenge of dissipating concentrated heat without compromising design flexibility or reliability. This makes it an indispensable component for industries ranging from consumer electronics to industrial automation and beyond.

At the heart of Sinkpad PCB’s performance is its integrated thermal sink design. These dedicated sink regions are engineered to establish direct thermal contact with high-heat components, creating a streamlined path for heat transfer away from sensitive junctions. Unlike discrete heat sinks that add size and require additional assembly steps, sinkpads are part of the PCB itself—eliminating air gaps and reducing thermal resistance. This direct integration ensures that heat is rapidly distributed across the board’s substrate, preventing the formation of hotspots that can degrade component performance, cause premature failure, or limit operational efficiency. For high-power devices operating at sustained loads, this translates to consistent performance and extended service life.

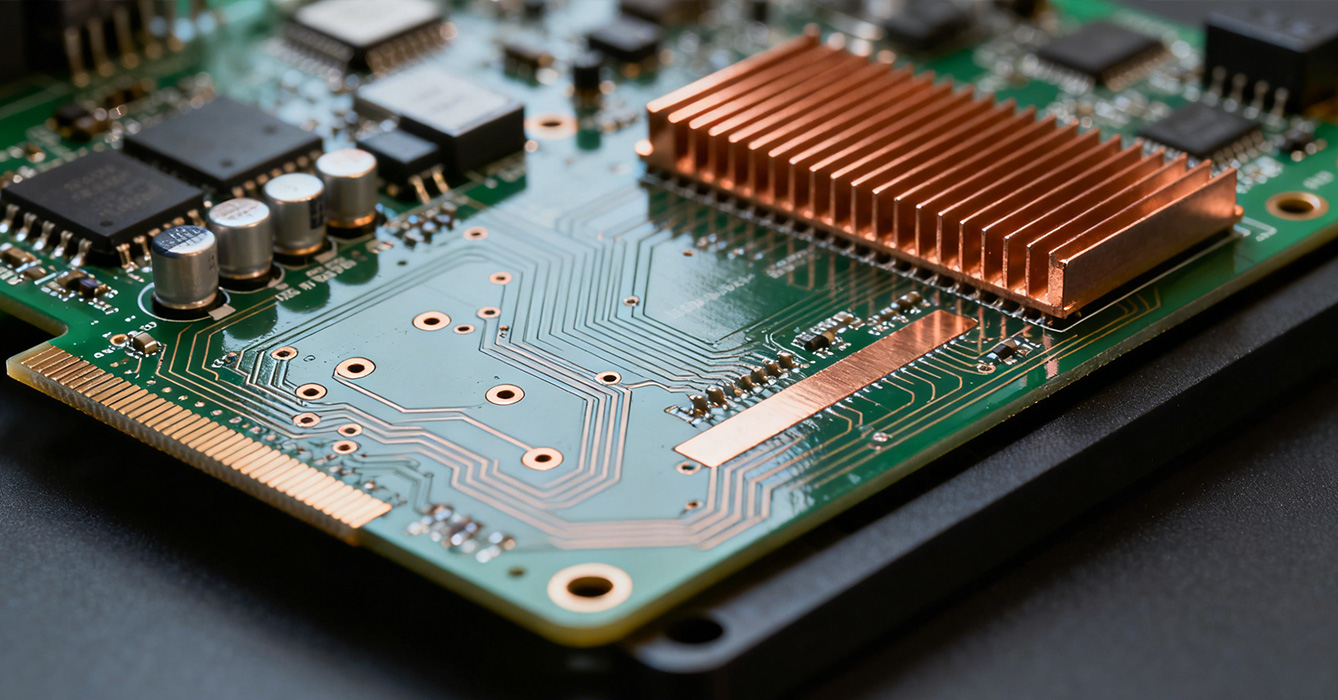

One of the most significant benefits of Sinkpad PCB is its ability to support compact, power-dense designs. By eliminating the need for external heat sinks or bulky thermal interfaces, engineers gain greater flexibility to optimize device size and weight. This is particularly valuable in applications where space is at a premium, such as portable electronics, automotive on-board systems, and miniaturized industrial sensors. Additionally, Sinkpad PCB’s design allows for seamless integration of high-power components alongside delicate signal circuits, thanks to the separation of thermal and electrical pathways. This eliminates the traditional trade-off between power handling and circuit complexity, enabling the development of more advanced, multifunctional devices.

Sinkpad PCB’s versatility lies in its ability to address unique thermal and design requirements across diverse industries. In high-power LED lighting, it enables the creation of brighter, more energy-efficient fixtures by managing the intense heat generated by dense LED arrays—without the need for unsightly external cooling. In industrial power electronics, it provides reliable thermal management for motor drives, inverters, and power modules operating in harsh, high-temperature environments. For electric vehicles, Sinkpad PCB plays a critical role in battery management systems and powertrain electronics, where thermal stability directly impacts safety and performance. Even in precision applications like medical devices, its consistent thermal performance ensures the reliability of life-critical systems.

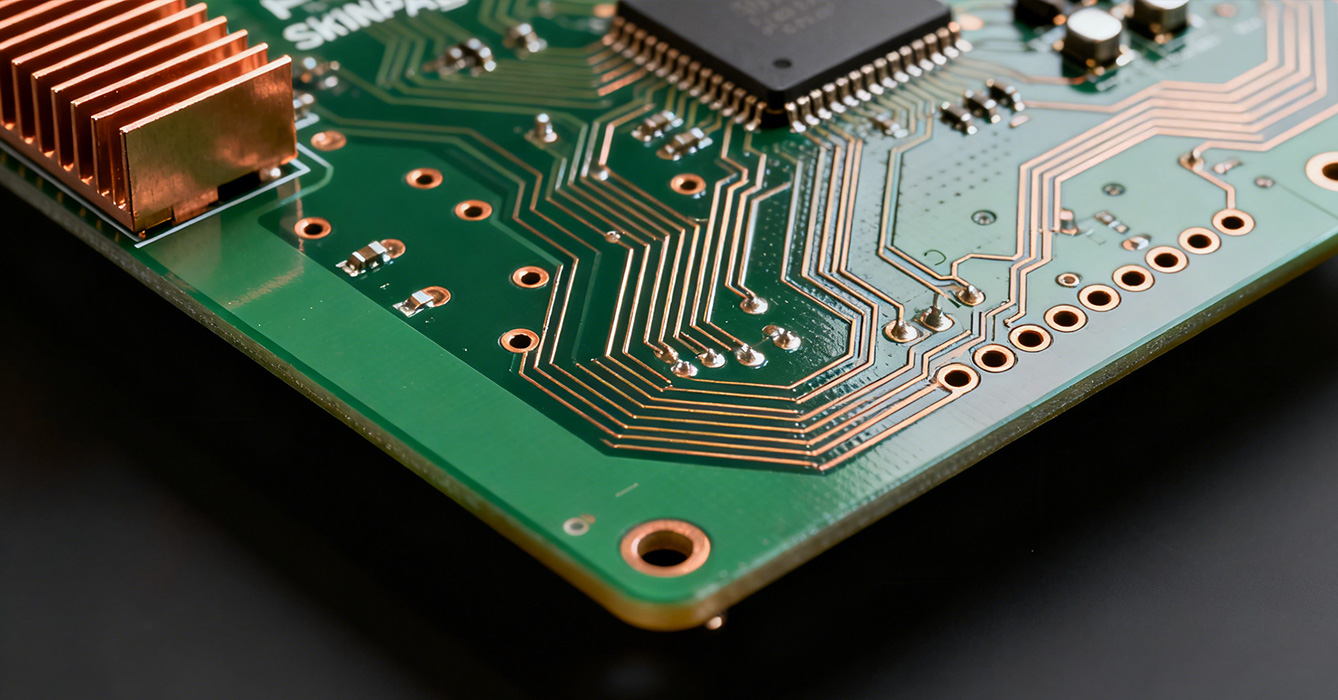

Beyond its thermal capabilities, Sinkpad PCB delivers enhanced mechanical and electrical reliability. The integrated sink structures reinforce the PCB’s rigidity, reducing the risk of warpage or damage caused by thermal cycling—a common issue in high-power electronics. This structural stability ensures that solder joints remain intact and components stay properly aligned, even under extreme temperature fluctuations or vibration. Additionally, the separation of thermal and electrical paths minimizes the risk of electrical interference, ensuring clean signal transmission and reducing the likelihood of system malfunctions. For manufacturers, this translates to lower failure rates, reduced maintenance costs, and improved customer trust in end products.

Sinkpad PCB also aligns with the growing industry focus on sustainability. Its integrated design reduces the number of components required in device assembly, lowering material consumption and simplifying manufacturing processes. By optimizing thermal efficiency, it minimizes energy waste associated with overheating, contributing to more energy-efficient electronic systems. Furthermore, Sinkpad PCB is compatible with lead-free manufacturing processes and environmentally friendly surface finishes, ensuring compliance with global sustainability standards. This makes it a responsible choice for manufacturers aiming to reduce their environmental footprint while delivering high-performance products.

As the demand for power-dense, compact electronic devices continues to grow, Sinkpad PCB stands as a foundational technology that addresses the industry’s most pressing thermal and design challenges. Its ability to integrate thermal management directly into the PCB architecture, support compact designs, and deliver reliable performance across diverse applications makes it a key enabler of next-generation electronics. For engineers and manufacturers seeking to push the boundaries of what’s possible, Sinkpad PCB is more than a component—it’s a strategic solution that drives innovation, enhances reliability, and supports sustainable design practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB