-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 29. 2025, 13:06:04

In today's fast-paced technological world, electronics are at the heart of innovation. From smartphones to medical devices, the demand for electronic products is ever-increasing. But how do these complex gadgets make their way from a concept to a finished product? This is where Electronics Manufacturing Services (EMS) come into play. In this guide, we'll explore what EMS is, its importance, and how it can benefit your business.

Electronics Manufacturing Services, or EMS, refer to a range of services provided by companies that specialize in designing, manufacturing, testing, and distributing electronic components and assemblies for original equipment manufacturers (OEMs). Essentially, EMS providers act as the backbone of the electronics industry, enabling businesses to bring their products to market efficiently and cost-effectively.

EMS encompasses a broad spectrum of services, including:

Design Services: EMS providers often assist in the design and development of electronic products. This can include circuit design, prototyping, and design for manufacturability (DFM) analysis.

Manufacturing Services: This involves the production of electronic components and assemblies. It includes processes like surface mount technology (SMT), through-hole technology, and more.

Testing Services: Ensuring product quality is crucial. EMS providers offer various testing services to verify the functionality and reliability of electronic products.

Logistics and Distribution: EMS companies often handle the logistics of delivering finished products to market, streamlining the supply chain for OEMs.

Contract Electronics Manufacturing (CEM) is a subset of EMS, focusing specifically on manufacturing electronic components on behalf of OEMs. CEM providers handle the production process, allowing OEMs to concentrate on their core business activities such as product development and marketing.

Cost Efficiency: By outsourcing manufacturing, companies can save on capital investments in equipment and facilities. This allows them to allocate resources to other critical areas.

Scalability: CEM providers offer the flexibility to scale production up or down based on demand, ensuring that businesses can adapt to market changes without the burden of excess inventory.

Expertise and Innovation: CEM companies bring specialized knowledge and experience to the table, often resulting in improved product quality and faster time-to-market.

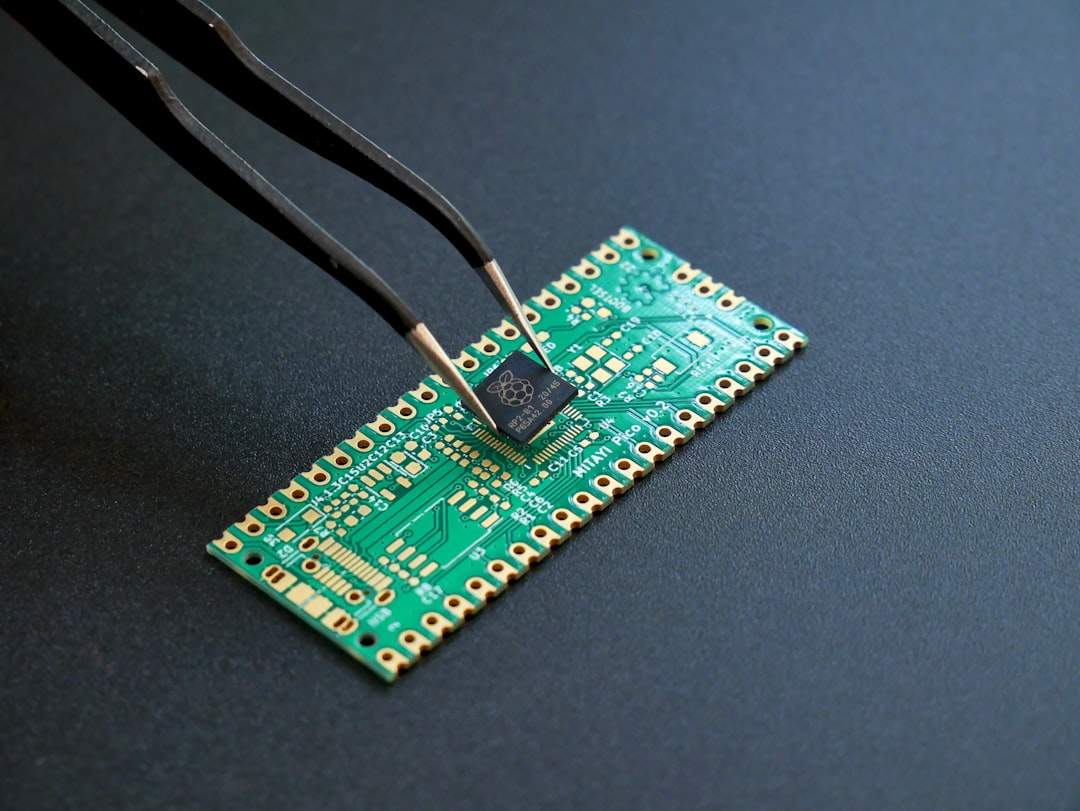

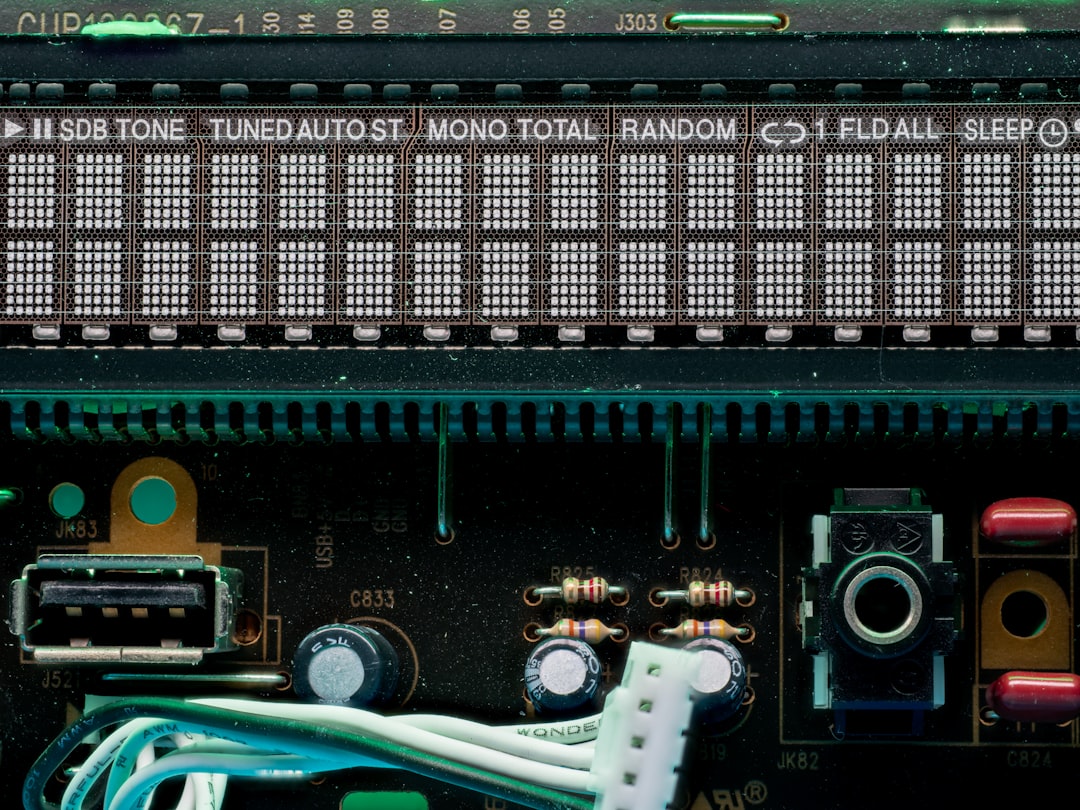

Printed Circuit Board (PCB) assembly is a crucial step in the electronics manufacturing process. PCBs form the backbone of most electronic devices, serving as the platform on which components are mounted and connected.

PCB assembly involves several steps, including:

Solder Paste Application: A solder paste is applied to the PCB to prepare it for component placement.

Component Placement: Using automated machines, components are accurately placed on the PCB.

Soldering: The board is heated to melt the solder paste, securing the components in place. Techniques like reflow soldering or wave soldering are commonly used.

Inspection and Testing: Once assembled, the PCB undergoes rigorous inspection and testing to ensure functionality and quality.

Precision and Reliability: Professional PCB assembly services offer high precision, reducing the risk of errors and ensuring that products meet quality standards.

Cost Savings: By leveraging the expertise and equipment of PCB assembly providers, companies can avoid the costs associated with in-house assembly.

Faster Turnaround: Experienced PCB assembly services can significantly reduce production times, helping businesses meet tight deadlines and get products to market faster.

Choosing the right EMS provider is a critical decision that can significantly impact your business's success. Here are some factors to consider:

Look for a provider with a proven track record in your industry. A reputable EMS provider will have a history of successful projects and satisfied clients.

Ensure that the provider has the necessary equipment and expertise to handle your specific manufacturing needs. This includes capabilities in PCB assembly, testing, and quality control.

Quality is paramount in electronics manufacturing. Verify that the EMS provider follows industry standards and has a robust quality assurance process in place.

Effective communication is essential for a successful partnership. Choose a provider that values collaboration and keeps you informed throughout the manufacturing process.

Electronics Manufacturing Services play a pivotal role in the development and production of electronic products. Whether you're a startup looking to bring a new device to market or an established company seeking to optimize your manufacturing process, EMS providers offer the expertise and resources needed to succeed.

By understanding the components of EMS, the benefits of contract electronics manufacturing, and the importance of PCB assembly services, you can make informed decisions that drive your business forward. With the right partner, you can focus on innovation and growth, leaving the complexities of manufacturing to the experts.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB