-

- PCB TYPE

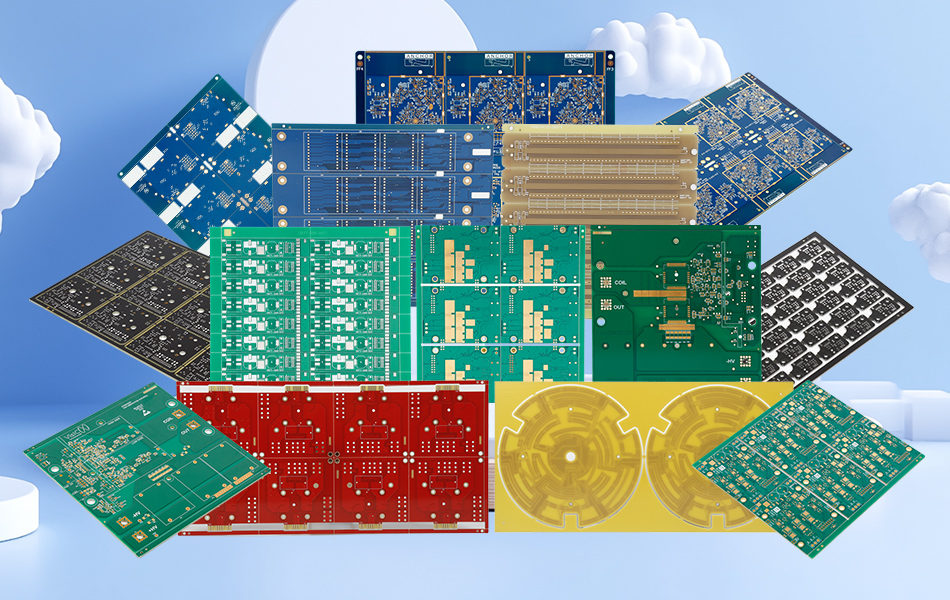

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 12. 2025, 11:54:40

In the era of 5G networks, satellite communications, and high-speed data transfer, High Frequency Hybrid PCB Material has emerged as a critical innovation, addressing the limitations of single-material substrates in handling ultra-fast signals. These hybrid materials combine the strengths of multiple specialized substrates—such as low-dielectric polymers, ceramic composites, and reinforced laminates—to deliver exceptional signal integrity, thermal stability, and mechanical durability at frequencies exceeding several gigahertz. Unlike traditional materials that excel in either electrical performance or manufacturability but not both, high frequency hybrids balance these attributes, making them indispensable for applications where signal loss, latency, and reliability are paramount. This article explores the composition, design principles, manufacturing processes, and applications of high frequency hybrid PCB materials, highlighting their role in powering the next wave of high-speed electronic systems.

High frequency hybrid PCB materials are engineered to overcome the core challenges of high-speed signal transmission: signal attenuation (loss), dispersion (distortion), and electromagnetic interference (EMI). These issues become increasingly problematic as frequencies rise, as traditional materials struggle to maintain signal integrity.

At their essence, high frequency hybrid materials integrate two or more base materials, each contributing unique properties:

Low-Dielectric Polymers: Materials like PTFE (polytetrafluoroethylene) or liquid crystal polymers (LCP) offer extremely low dielectric constant (Dk) and dissipation factor (Df), minimizing signal loss and ensuring efficient signal propagation. However, they often lack mechanical rigidity and may be difficult to process.

Ceramic Composites: Ceramic-filled substrates provide high thermal conductivity and stable dielectric properties across wide temperature ranges, making them ideal for managing heat in high-power components. They enhance dimensional stability but can be brittle and expensive.

Reinforced Laminates: Glass fiber-reinforced epoxy or cyanate ester resins add mechanical strength and reduce moisture absorption, improving durability in harsh environments. These materials offer better processability than pure polymers or ceramics but may have higher dielectric losses at extreme frequencies.

By combining these elements, high frequency hybrid materials create a substrate that minimizes signal loss, dissipates heat effectively, and withstands mechanical stress—critical for high-frequency applications like 5G base stations, radar systems, and aerospace communication modules.

The performance of high frequency hybrid PCB materials is defined by a set of interrelated properties, each tailored to support high-speed signal transmission:

The dielectric constant measures a material’s ability to store electrical energy. For high-frequency signals, a low and stable Dk (typically between 2.0 and 4.0) is essential, as it reduces signal delay and ensures consistent propagation velocity. Hybrid materials achieve this by blending low-Dk polymers with ceramic fillers that prevent Dk fluctuations due to temperature or frequency changes.

The dissipation factor quantifies energy loss as heat in a material. A low Df (often below 0.002 at high frequencies) minimizes signal attenuation, ensuring that signals retain their strength over longer distances. High frequency hybrids combine low-Df polymers with additives that suppress molecular vibrations, which are a primary source of energy loss at high frequencies.

High-frequency components, such as power amplifiers and transceivers, generate significant heat, which can degrade signal integrity and component performance. Hybrid materials integrate thermally conductive ceramics (like aluminum oxide or silicon nitride) to dissipate heat efficiently, preventing hotspots and maintaining stable dielectric properties.

At high frequencies, even minor dimensional changes—caused by temperature fluctuations or moisture absorption—can disrupt signal paths and introduce impedance mismatches. High frequency hybrids use glass fiber reinforcement or ceramic fillers to minimize expansion and contraction, ensuring the PCB retains its shape and signal integrity in varying environments.

Electromagnetic interference from adjacent components or external sources can corrupt high-frequency signals. Some hybrid materials incorporate conductive layers or fillers (such as carbon nanotubes or metal particles) to absorb or reflect EMI, enhancing signal purity without compromising dielectric performance.

Designing with high frequency hybrid materials requires a nuanced approach to maximize their performance while addressing their unique characteristics:

Impedance—resistance to signal flow—must be tightly controlled to prevent signal reflection and loss. High frequency hybrid materials’ dielectric properties (Dk) directly influence impedance, so designers must precisely calculate trace dimensions (width, thickness) and substrate thickness to achieve the target impedance (typically 50 ohms for RF applications). Even small variations in Dk due to material blending can affect impedance, requiring careful material selection and testing.

High-frequency signals are sensitive to trace geometry and placement. Designers must minimize trace length to reduce attenuation and avoid sharp bends, which cause signal reflection. Hybrid materials’ improved thermal conductivity allows for denser component placement, but this must be balanced with EMI concerns—traces carrying high-frequency signals should be separated from noisy components (like power supplies) or shielded using ground planes.

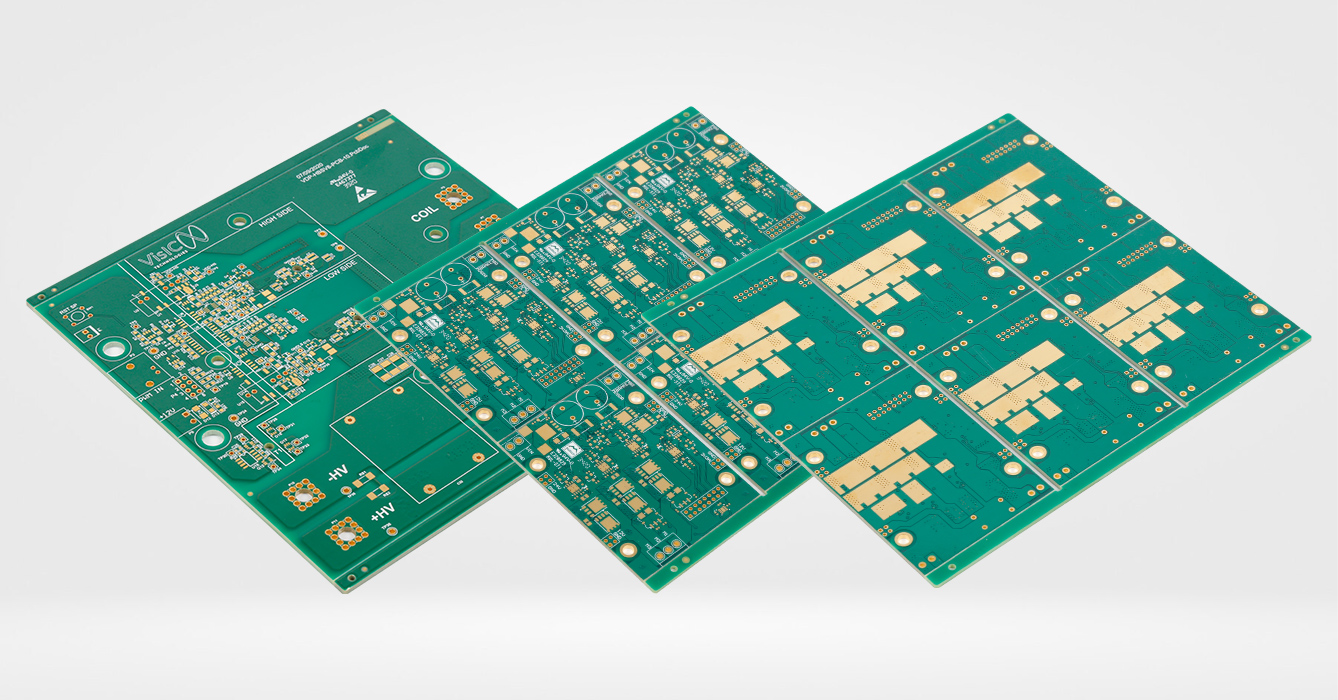

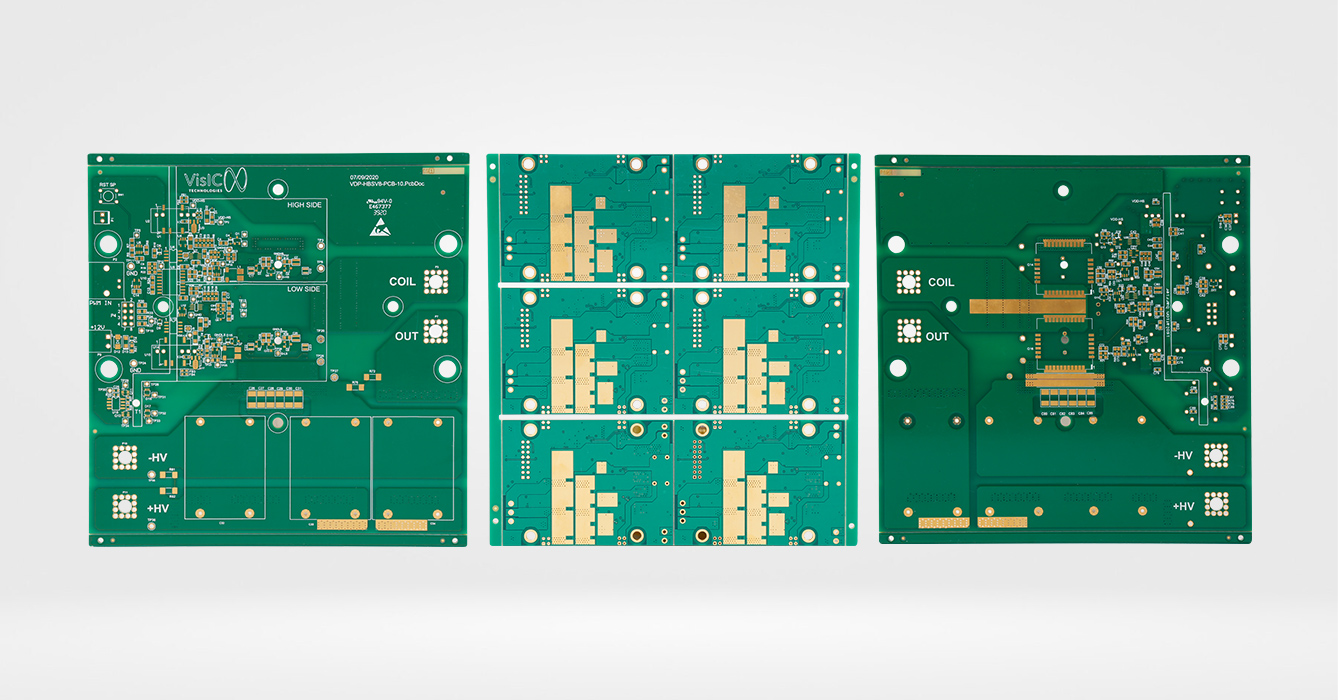

The layer stackup in hybrid PCBs is critical for managing signal integrity and thermal performance. Designers often use a “sandwich” structure: low-Dk polymer layers for signal traces, ceramic-filled layers for heat dissipation, and reinforced laminates for mechanical support. Ground planes are placed adjacent to signal layers to provide shielding and control impedance, while thermal vias connect high-heat components to thermally conductive layers.

Hybrid materials combine dissimilar substances, which can lead to adhesion issues or thermal expansion mismatches. Designers must ensure that the base materials and bonding agents are chemically compatible, preventing delamination during manufacturing or operation. Additionally, the coefficient of thermal expansion (CTE) of each layer should be matched as closely as possible to reduce stress during temperature cycles.

High frequency hybrid materials often require specialized manufacturing processes (e.g., laser drilling, plasma etching) to maintain precision. Designers must collaborate with manufacturers to understand material limitations—for example, some low-Dk polymers are sensitive to high temperatures during lamination, requiring adjusted curing parameters.

Producing PCBs with high frequency hybrid materials involves specialized techniques that balance precision with material compatibility:

The manufacturing process begins with preparing and blending the base materials. Low-Dk polymers are mixed with ceramic fillers or glass fibers in controlled proportions to achieve the desired dielectric and mechanical properties. This blending is often done using extrusion or calendaring processes to ensure uniform distribution of additives, which is critical for consistent performance.

Layers of the hybrid material are stacked with copper foil and bonded under heat and pressure. Unlike standard FR4 lamination, high frequency hybrids require precise control of temperature and pressure to avoid damaging heat-sensitive polymers or causing filler migration. Some materials use adhesive films with low dielectric loss to bond layers, ensuring strong adhesion without increasing signal attenuation.

Vias (holes connecting layers) are drilled using laser or mechanical methods, with laser drilling preferred for small vias in high-density designs. The via walls are plated with copper to ensure electrical continuity, but the plating process must be optimized to avoid damaging the hybrid material—for example, acidic plating solutions can degrade certain polymers, requiring protective coatings.

Copper layers are patterned using photolithography, with high-resolution masks to define fine traces (often less than 50 micrometers wide) required for high-frequency signals. Etching processes use milder chemicals to prevent material degradation, and plasma etching may be used for polymers that resist traditional chemical etching.

The finished PCBs undergo surface treatments (such as electroless nickel immersion gold) to protect copper traces and ensure reliable solder joints. Testing includes dielectric spectroscopy to verify Dk and Df at operating frequencies, thermal imaging to assess heat dissipation, and network analysis to measure signal loss and impedance.

High frequency hybrid PCB materials are enabling breakthroughs in industries requiring ultra-fast, reliable communication:

5G base stations and user equipment operate at millimeter-wave frequencies (24–40 GHz), where signal loss is significant. Hybrid materials minimize attenuation, allowing for longer signal ranges and higher data throughput. They also manage the heat generated by high-power RF amplifiers, ensuring stable performance in dense urban deployments.

Satellite transceivers and radar systems operate at frequencies up to 100 GHz, requiring materials with exceptional dielectric stability and radiation resistance. High frequency hybrids withstand the extreme temperature swings and vacuum environments of space, while their low signal loss enables reliable communication between satellites and ground stations.

Advanced driver-assistance systems (ADAS) and autonomous vehicles use radar (77–81 GHz) for object detection. Hybrid materials ensure precise signal propagation, improving detection accuracy and reducing false alarms. Their mechanical durability also makes them resistant to vibration and temperature changes in automotive environments.

High-frequency ultrasound and microwave imaging systems rely on low-loss materials to generate high-resolution images. Hybrid PCBs enable compact, portable devices with improved signal clarity, enhancing diagnostic capabilities in fields like cardiology and oncology.

High-speed interconnects in data centers (e.g., 100G/400G Ethernet) require materials that support multi-gigabit signals with minimal latency. Hybrid materials reduce signal loss in backplanes and switches, enabling faster data transfer between servers and improving overall network efficiency.

Compared to single-material substrates, high frequency hybrid materials offer several key benefits:

By combining low-Dk polymers, thermally conductive ceramics, and reinforced laminates, hybrids deliver superior signal integrity, thermal management, and durability—performance that no single material can match. This makes them ideal for the most demanding high-frequency applications.

Hybrid materials can be tailored to specific frequency ranges and environmental conditions by adjusting the ratio of base materials. For example, a design requiring higher thermal conductivity can incorporate more ceramic filler, while one prioritizing low signal loss can use more low-Dk polymer.

While high frequency hybrids are more expensive than standard FR4, they are often cheaper than pure ceramic or PTFE substrates. By using expensive materials (like ceramics) only where needed and reinforcing with lower-cost polymers, hybrids balance performance and cost.

The integrated thermal and electrical performance of hybrids eliminates the need for external heat sinks or EMI shields, reducing system size and weight. This is particularly valuable in aerospace and portable devices where space is constrained.

Despite their advantages, high frequency hybrid PCB materials face ongoing challenges:

Blending dissimilar materials can lead to adhesion issues or inconsistent performance. Research into new bonding agents and surface treatments is improving layer adhesion, while advanced mixing techniques ensure uniform filler distribution.

Specialized processes for hybrid materials increase production costs and lead times. Automation and process optimization—such as inline material testing and laser-based patterning—are reducing these barriers, making hybrids more accessible for mass production.

At terahertz frequencies (above 1 THz), even hybrid materials may suffer from significant signal loss. New material combinations, such as graphene-reinforced polymers, are being explored to extend performance into this emerging frequency range.

Many high frequency materials (like PTFE) are non-biodegradable and difficult to recycle. Manufacturers are developing bio-based polymers and recyclable ceramic composites to reduce environmental impact without sacrificing performance.

High Frequency Hybrid PCB Material represents a pivotal advancement in electronics, enabling the high-speed, reliable communication systems that underpin modern technology. By combining the strengths of low-dielectric polymers, thermally conductive ceramics, and reinforced laminates, these materials address the critical challenges of signal loss, heat management, and mechanical durability at ultra-high frequencies. From 5G networks to aerospace radar, their applications are transforming industries and driving innovation in connectivity. As research continues to improve material compatibility, manufacturing efficiency, and sustainability, high frequency hybrid PCB materials will play an even greater role in shaping the future of high-speed electronics, ensuring that next-generation systems can meet the demands of an increasingly connected world.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB