-

- PCB TYPE

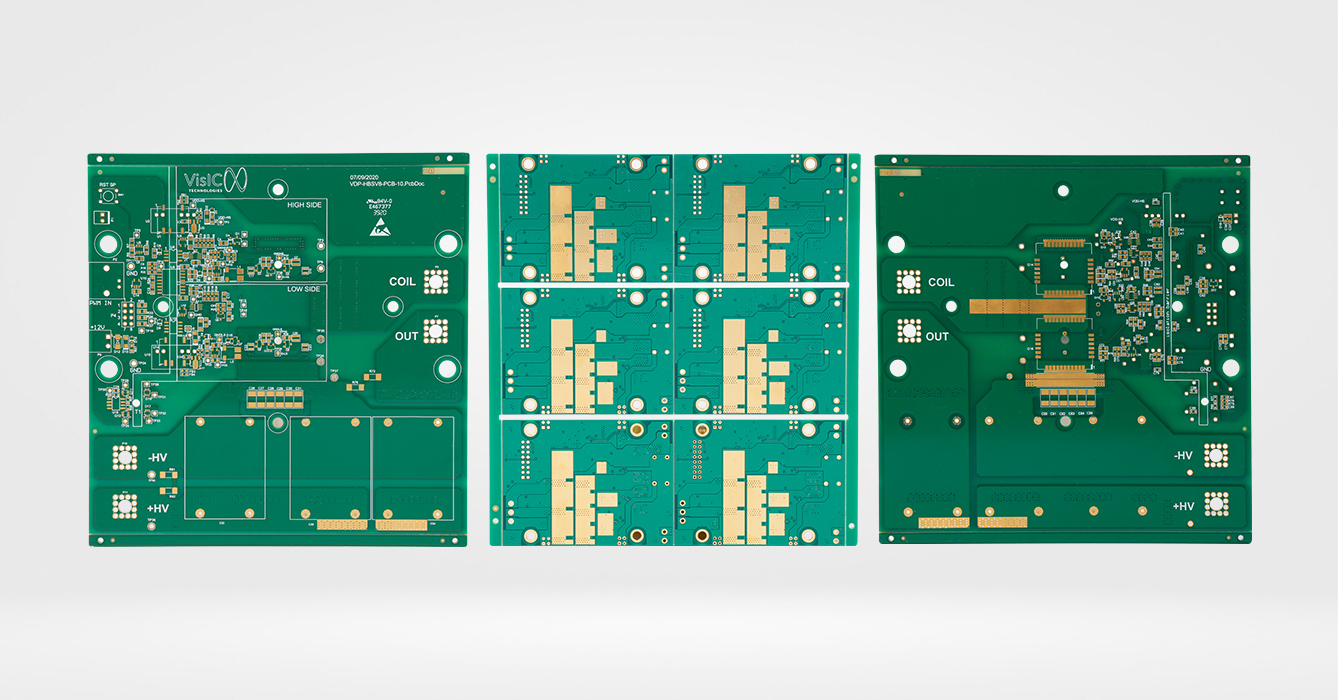

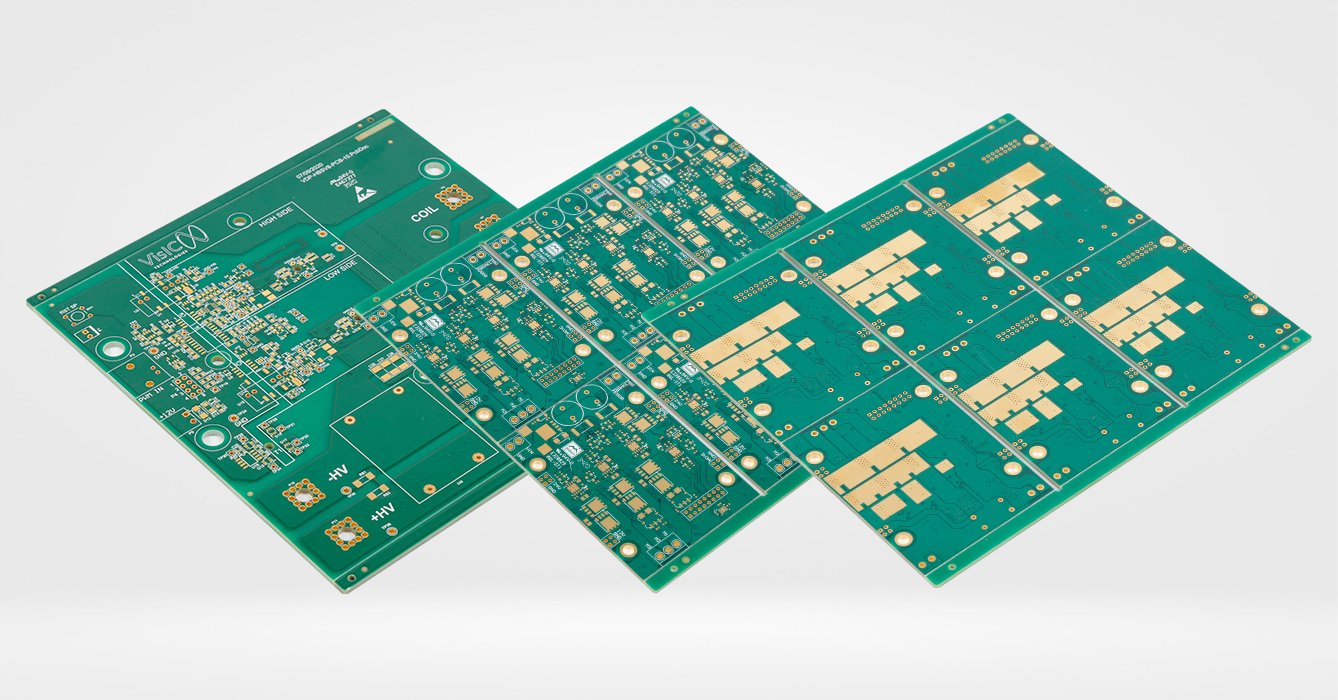

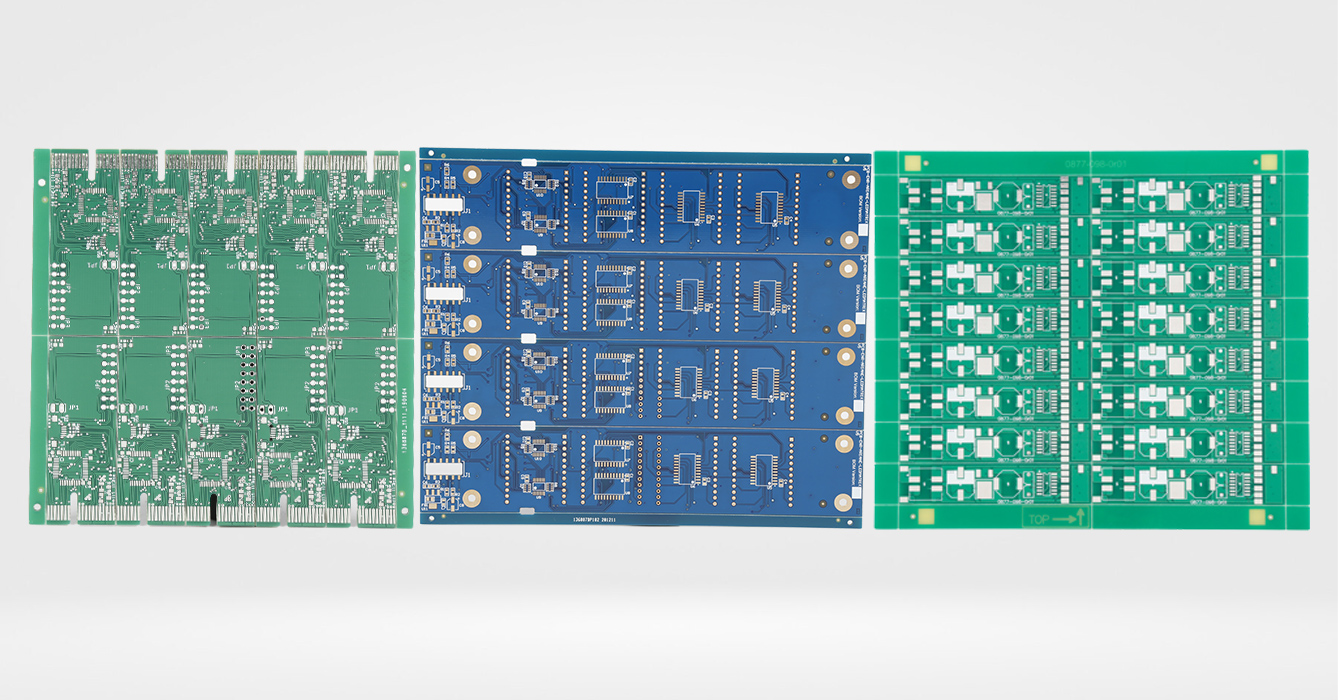

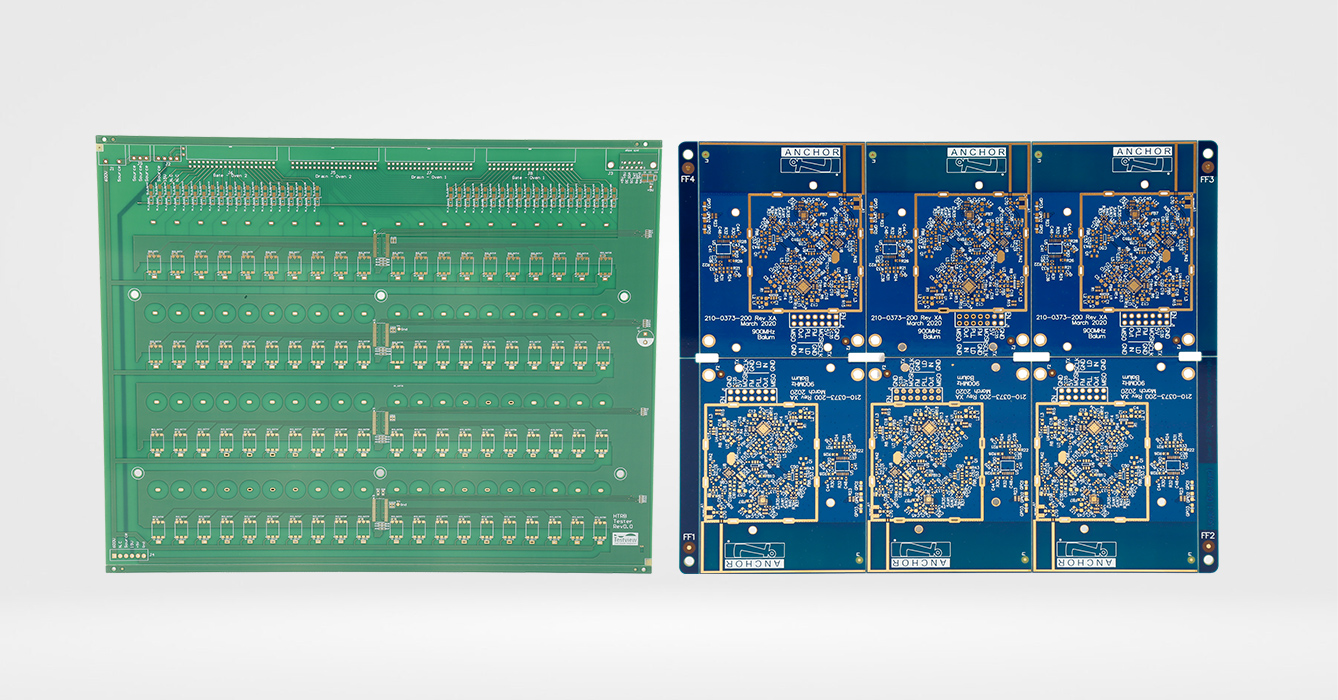

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 04. 2025, 11:51:24

In the landscape of printed circuit board (PCB) materials, the fr4 pcb datasheet emerges as a fundamental reference for engineers, manufacturers, and designers seeking to understand the most widely used substrate in the electronics industry. FR4, a glass-reinforced epoxy laminate, has become the backbone of modern electronics due to its unique blend of electrical insulation, mechanical robustness, thermal stability, and cost-effectiveness. The fr4 pcb datasheet is more than a mere list of specifications; it is a detailed guide that unpacks how this material performs under diverse conditions, from the rigors of manufacturing processes to the demands of end-use environments. This article explores the technical depth of the fr4 pcb datasheet, offering insights into its composition, properties, applications, and advancements, all while highlighting its role as a critical tool for informed decision-making in PCB design and production.

The fr4 pcb datasheet begins by establishing FR4 as a thermoset composite, classified under copper-clad laminates (CCLs). The "FR" in its name denotes "flame-retardant," a key safety attribute derived from additives that prevent sustained combustion—a feature rigorously tested and documented in the datasheet. Unlike generic laminates, FR4’s structure is a precisely engineered matrix designed to balance multiple performance criteria.

At the heart of FR4 is an epoxy resin system, typically based on bisphenol-A, which acts as both a binder and an electrical insulator. The datasheet explains that this resin is often modified with brominated compounds to enhance flame retardancy, though newer formulations may use phosphorus-based alternatives to meet stricter environmental standards. Interwoven within the resin are layers of E-glass fiber, a type of alumino-borosilicate glass woven into fabrics of varying densities. The datasheet emphasizes that the choice of weave—from fine 1080 patterns to thicker 7628 weaves—directly impacts properties such as mechanical strength and dielectric performance. Thicker weaves improve rigidity but can increase signal loss at high frequencies, a trade-off the datasheet helps designers evaluate.

The datasheet also clarifies that FR4 is not a one-size-fits-all material. It exists in multiple variants, each tailored to specific applications: standard FR4 for general-purpose use, high-Tg variants for elevated temperature environments, and low-Dk (dielectric constant) versions for high-frequency applications. This diversity is a cornerstone of FR4’s versatility, as highlighted in the datasheet’s section on material classification.

A detailed breakdown of FR4’s composition in the datasheet reveals how each component contributes to its overall performance:

Epoxy Resin Matrix: The primary binding agent, responsible for adhesion between layers, electrical insulation, and chemical resistance. The datasheet notes that resin formulation varies by grade: standard FR4 uses bisphenol-A epoxies, while high-Tg variants incorporate novolac hardeners to increase thermal stability. The curing process, often specified in the datasheet, involves heating the resin to 170–190°C under pressure to form a cross-linked polymer network, ensuring structural integrity.

Glass Fiber Reinforcement: E-glass fibers provide mechanical rigidity and dimensional stability, resisting warpage during manufacturing and operation. The datasheet explains that fiber weave density affects properties like flexural strength and moisture absorption—thicker weaves offer higher strength but may trap more moisture. The fiber-to-resin ratio is carefully controlled, typically around 50–60% by weight, to balance strength and processability.

Copper Foil: Bonded to the laminate surface, copper forms the conductive circuit traces. The datasheet distinguishes between electrodeposited (ED) copper, with a rough surface for strong adhesion, and rolled copper, which offers better ductility for flexible-rigid PCBs. Copper thickness ranges from 0.5 oz to 4 oz, with the datasheet advising thicker foils for high-current applications to reduce resistance and heat buildup.

Additives: Flame retardants (e.g., tetrabromobisphenol A) to meet UL94 V-0 standards; silica fillers to reduce thermal expansion; and silane coupling agents to strengthen the bond between glass fibers and resin, minimizing delamination risks. The datasheet may also note UV stabilizers in some formulations for outdoor applications, preventing resin degradation from sunlight.

The fr4 pcb datasheet devotes significant attention to physical properties, which influence manufacturability and long-term reliability:

Density: Typically 1.8–2.0 g/cm³, balancing structural robustness with weight efficiency—critical for aerospace and portable electronics. The datasheet notes that density variations are minimal across batches, ensuring consistent handling during manufacturing.

Thickness and Tolerance: Available in thicknesses from 0.031 inches (0.79 mm) to 0.250 inches (6.35 mm), with tolerances of ±5% to ±10%. The datasheet emphasizes that tight tolerances are essential for impedance-controlled designs, where even minor thickness variations can disrupt signal integrity.

Surface Characteristics: FR4’s surface is often roughened to enhance adhesion with copper and subsequent finishes (e.g., ENIG, HASL). The datasheet describes surface roughness parameters (e.g., Ra values) that ensure compatibility with different plating processes.

Moisture Absorption: Standard FR4 absorbs ≤0.15% of its weight in water (per IPC-4101), a value that increases slightly in humid environments. The datasheet highlights low-moisture variants (≤0.12%) for outdoor or marine applications, where moisture can degrade electrical performance.

Color: Naturally amber or brown, though black FR4 is available for light-sensitive applications like camera modules. The datasheet notes that color does not affect mechanical or electrical properties but can impact thermal absorption in high-heat environments.

As an insulating material, FR4’s electrical properties are paramount, and the datasheet provides detailed insights into how it behaves under varying electrical conditions:

Dielectric Constant (Dk): A measure of the material’s ability to store electrical energy. Standard FR4 has a Dk of 4.2–4.7 at 1 MHz, with the datasheet showing that Dk increases with frequency (e.g., 4.5–5.0 at 10 GHz). For high-frequency applications, low-Dk variants (3.8–4.2) are recommended, as noted in specialized sections of the datasheet.

Dissipation Factor (Df): Indicates energy loss as heat. Standard FR4 has a Df of ≤0.02 at 1 MHz, rising with temperature and frequency. The datasheet advises low-Df FR4 (≤0.015) for high-speed signals (e.g., 10 Gbps Ethernet) to minimize signal degradation.

Dielectric Strength: ≥20 kV/mm (per ASTM D149), ensuring resistance to arcing in high-voltage applications like power supplies. The datasheet notes that dielectric strength decreases slightly with moisture absorption, emphasizing the need for proper sealing in humid environments.

Insulation Resistance: Volume resistivity ≥10¹⁴ Ω·cm and surface resistivity ≥10¹³ Ω, ensuring minimal leakage current. The datasheet includes data showing how these values hold up in humidity tests (85°C/85% RH), confirming reliability in damp conditions.

Signal Propagation: The datasheet calculates signal speed in FR4 (≈1.5 ns per inch for 50Ω microstrip traces), a critical metric for timing-sensitive designs. It warns that Dk variations across the laminate can cause signal skew, making material consistency vital for multi-layer PCBs.

FR4’s mechanical strength ensures it survives manufacturing processes and operational loads, as detailed in the datasheet:

Tensile Strength: ≥400 MPa along the fiber direction, with lower values transverse to the weave. This anisotropy is highlighted in the datasheet, guiding designers to align critical components with the fiber direction in vibration-prone applications (e.g., automotive).

Flexural Strength: ≥500 MPa at room temperature, dropping to ≥300 MPa at 125°C. The datasheet notes that high-Tg FR4 retains higher flexural strength at elevated temperatures, making it suitable for industrial ovens or engine compartments.

Peel Strength: ≥1.0 N/mm for 1 oz copper (per IPC-TM-650 2.4.8), ensuring copper traces stay bonded during soldering and thermal cycling. The datasheet emphasizes that peel strength decreases with temperature, a factor to consider in high-heat applications.

Impact Resistance: Charpy impact strength ≥15 kJ/m², making FR4 resistant to drops and shocks—important for consumer electronics. The datasheet compares this to other materials, showing FR4’s advantage over brittle ceramics in rugged environments.

Dimensional Stability: Minimal size change with temperature or humidity (≤0.1% under normal conditions). The datasheet explains that stability is critical for multi-layer PCBs, where layer misalignment can cause short circuits or open traces.

Thermal properties dictate FR4’s performance in high-temperature environments, and the datasheet provides comprehensive data:

Glass Transition Temperature (Tg): The temperature at which epoxy shifts from rigid to rubbery. Standard FR4 has a Tg of 130–140°C, with mid-Tg (150–160°C) and high-Tg (≥170°C) variants available. The datasheet stresses that Tg should be 20–30°C higher than the maximum operational temperature to avoid dimensional instability.

Decomposition Temperature (Td): ≥300°C for standard FR4, ensuring compatibility with lead-free soldering (peak ~260°C). High-Tg FR4 has a higher Td (≥320°C), as noted in the datasheet, making it suitable for rework-intensive applications.

Thermal Conductivity: 0.2–0.3 W/m·K for standard FR4, limiting heat dissipation from high-power components. The datasheet highlights thermally enhanced variants (0.5–0.8 W/m·K) with ceramic fillers, bridging the gap with metal-core PCBs.

Coefficient of Thermal Expansion (CTE): Anisotropic, with in-plane CTE of 12–18 ppm/°C (below Tg) and z-axis CTE of 60–80 ppm/°C (below Tg). The datasheet explains that low-CTE FR4 (z-axis ≤60 ppm/°C) reduces via cracking in thermal cycling, ideal for automotive underhood PCBs.

The fr4 pcb datasheet offers practical guidance for manufacturing processes, ensuring optimal results:

Lamination: Press temperatures of 170–190°C, pressures of 200–400 psi, and cycle times of 60–90 minutes. High-Tg FR4 requires longer cycles (90–120 minutes) for full curing, as specified in the datasheet.

Drilling: Carbide bits are recommended for small vias (≤0.1 mm) to avoid burring. The datasheet suggests speeds of 20,000–60,000 RPM and feed rates of 0.1–0.3 mm/rev, with coolant to prevent resin softening.

Routing: CNC routers achieve tolerances of ±0.05 mm (standard) or ±0.025 mm (precision). The datasheet emphasizes sharp bits to prevent edge chipping, especially in thin laminates.

Surface Preparation: Desmearing removes resin smears from drilled holes, while micro-etching roughens copper for better adhesion of solder mask. The datasheet details chemical and plasma treatment options for different applications.

The datasheet confirms FR4’s adherence to global standards, ensuring reliability and interoperability:

IPC-4101: Classifies FR4 into types based on performance, with Type 1 for general use and Type 2 for high-performance variants. The datasheet references specific test methods (e.g., IPC-TM-650) for validating properties.

UL 94: Rated V-0, with the datasheet including test results showing self-extinguishing within 10 seconds and no flaming drips—a requirement for consumer and industrial electronics.

IEC 61249: Ensures compliance with environmental regulations (e.g., RoHS), restricting hazardous substances. The datasheet notes bromine-free options for regions with strict environmental protection laws.

MIL-PRF-31032: Military specification for high-reliability PCBs, requiring tight tolerances and enhanced thermal cycling resistance. The datasheet includes test data for aerospace and defense applications.

Rigorous testing, as outlined in the datasheet, ensures FR4 meets specifications:

Thermal Cycling: 28 cycles of -55°C to +125°C (per IPC-TM-650 2.6.7) to check for delamination or via cracking. The datasheet reports minimal degradation in tested samples.

Solder Float Test: Immersion in 260°C solder for 10 seconds to verify resistance to blistering, confirming compatibility with lead-free processes.

Flammability Testing: UL 94 vertical burn tests validate the V-0 rating, with the datasheet including videos or images of test results for transparency.

Moisture Resistance: Pressure cooker tests (121°C, 100% RH, 2 atm) for 24–96 hours, with the datasheet showing minimal impact on electrical and mechanical properties.

The datasheet highlights FR4’s versatility across industries, while acknowledging its boundaries:

Consumer Electronics: Smartphones, laptops, and TVs use standard FR4 for cost-effectiveness. The datasheet notes that thin laminates (0.031–0.062 inches) are preferred for slim designs.

Industrial Control: Motor drives and PLCs use mid-Tg FR4 to withstand 125°C operational temperatures. The datasheet recommends low-CTE variants for industrial sensors with wide temperature swings.

Telecommunications: Routers and base stations use low-Dk FR4 to minimize signal loss at 1–10 GHz. The datasheet compares performance with specialized high-frequency materials, noting FR4’s cost advantage.

Automotive: Cabin electronics use mid-Tg FR4, while underhood components require high-Tg, low-CTE variants. The datasheet includes data from automotive-specific tests (e.g., IATF 16949 compliance).

Limitations: The datasheet candidly notes that FR4 is unsuitable for extreme environments (e.g., aerospace with -55°C to +125°C cycling) or ultra-high-power applications (e.g., 100W+ LEDs), where polyimide or metal-core PCBs perform better.

The fr4 pcb datasheet explores evolving FR4 technologies to meet emerging needs:

Eco-Friendly FR4: Bromine-free flame retardants and bio-based resins reduce environmental impact, with the datasheet highlighting compliance with EU regulations.

High-Frequency FR4: Modified resins and optimized weaves achieve Dk values as low as 3.3, targeting 5G and radar applications. The datasheet compares these to PTFE-based materials, emphasizing cost and processability advantages.

Thermally Enhanced FR4: Ceramic-filled formulations (e.g., Panasonic R-1787) boost thermal conductivity to 0.8–1.0 W/m·K, reducing heat sinks in mid-power devices. The datasheet includes thermal imaging data showing improved heat dissipation.

3D-Printable FR4: Experimental inks allow 3D printing of FR4 structures, enabling complex geometries. The datasheet outlines early test results, noting potential for custom heat sinks and sensor housings.

The fr4 pcb datasheet is an indispensable resource that bridges theoretical material science with practical application. By detailing FR4’s composition, properties, and performance under diverse conditions, it empowers engineers to select the right variant, optimize designs, and ensure PCB reliability. As electronics continue to advance, FR4 evolves alongside them—remaining the material of choice for most applications while pushing boundaries in sustainability, frequency performance, and thermal management. The datasheet, in turn, remains a dynamic document, reflecting these innovations and ensuring stakeholders can harness FR4’s full potential in an ever-changing technological landscape.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB