-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 15. 2025, 20:13:12

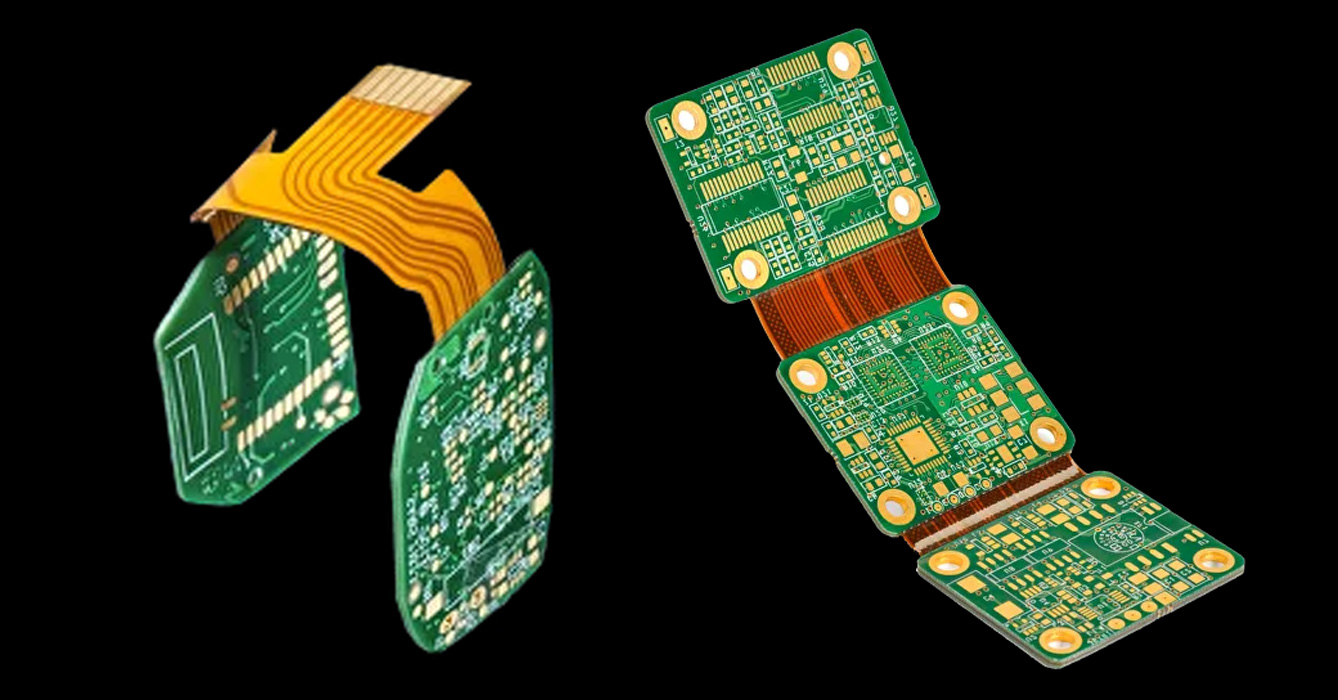

As electronic devices evolve toward miniaturization, flexibility, and multi-functionality, Flexible PCB (FPC) has become a core component supporting industrial upgrading in consumer electronics, automotive electronics, and medical devices. The traditional manufacturing model of FPC, however, has long been plagued by challenges such as low production efficiency, high defect rates, and difficulty in balancing mass production and customization. In recent years, advanced manufacturing technologies represented by laser welding and roll-to-roll production have brought revolutionary changes to the FPC industry. These innovations not only solve the core pain points of traditional manufacturing but also enable FPC to meet the diverse needs of emerging applications. For electronics manufacturers, understanding the advanced manufacturing trends of Flexible PCB is crucial to improving product competitiveness and seizing market opportunities.

The upgrading of FPC manufacturing processes focuses on solving the pain points of traditional technologies such as mechanical damage, thermal deformation, and complicated procedures, driving the industry toward high precision, high efficiency, and low defect rates:

- Laser Welding Technology: Precision Solution for Assembly Challenges: Traditional contact welding technologies (such as manual soldering and reflow soldering) easily cause mechanical damage and thermal deformation to the flexible substrate of FPC. Laser welding, with its non-contact operation and micro-area heating characteristics, fundamentally avoids these problems. It achieves micron-level positioning accuracy, controls the heat-affected zone within an extremely small range, and ensures the structural integrity and performance stability of FPC during the welding process. In addition, laser welding uses high-purity nitrogen protection instead of flux, realizing clean and residue-free welding, which greatly improves the long-term reliability of FPC and meets the strict requirements of high-end fields such as medical electronics and aerospace.

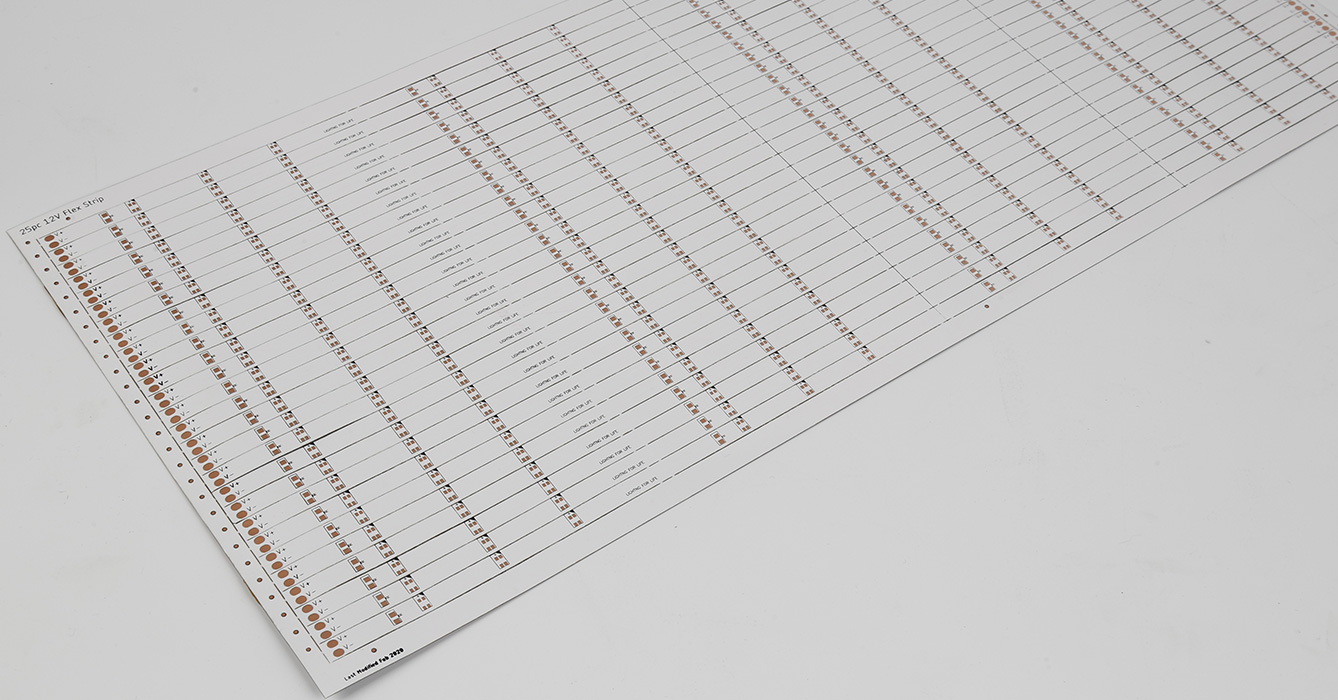

- Roll-to-Roll Production: Enabling Efficient Mass Customization: The traditional sheet-to-sheet production method of FPC has limitations such as cumbersome processes and difficulty in producing ultra-long products. The roll-to-roll production technology transforms FPC manufacturing into a continuous and automated process, greatly simplifying the production flow. This technology can realize the customization of "infinitely long" FPC products, meeting the needs of customers for assembling different lengths of electronic components. At the same time, it significantly reduces labor costs and material waste, improving production efficiency while achieving cost optimization. For industries such as LED lighting that require large-scale and customized FPC applications, roll-to-roll production has become a core driving force for capacity upgrading.

Advanced manufacturing technologies have broken the inherent contradiction between mass production and customization in FPC manufacturing, enabling suppliers to provide flexible solutions for different industry scenarios:

- Large-Scale Production Efficiency Enhancement: Roll-to-roll production lines integrate multiple processes such as electroplating, lamination, and anti-oxidation, realizing continuous operation of the entire production process. Compared with traditional production methods, the number of processes is significantly reduced, and the labor demand is greatly decreased, which effectively improves the consistency and stability of mass-produced FPC products. This efficiency advantage makes FPC better adapt to the large-scale supply needs of consumer electronics such as smartphones and wearable devices.

- Flexible Customization Capability Upgrade: While realizing mass production, advanced manufacturing technologies also support personalized customization of FPC. For example, laser welding technology can quickly adjust welding parameters according to the size and structure of different FPC products, adapting to the production of small-batch and multi-variety products. The roll-to-roll production line can flexibly adjust product length and specification settings to meet the customized needs of special fields such as automotive electronic modules and medical implantable devices. This synergy of mass production and customization has expanded the application boundaries of FPC.

Advanced manufacturing of FPC not only pursues efficiency but also focuses on improving product reliability through a series of technical guarantees:

- Precision Quality Control System: The integration of automated inspection technologies such as machine vision in the production process realizes real-time monitoring of FPC welding points,线路, and lamination quality. For example, in laser welding, high-resolution image recognition systems are used to ensure the accuracy of solder joint positioning, reducing short-circuit and open-circuit defects. In roll-to-roll production, online detection equipment is installed to timely find and eliminate quality problems such as line scratches and oxidation, ensuring the reliability of each batch of products.

- Clean Production Environment Construction: Advanced FPC manufacturing pays attention to clean production to avoid pollution affecting product performance. Laser welding uses nitrogen protection to prevent solder oxidation, and the entire production process of roll-to-roll production is carried out in a dust-free workshop. These measures ensure that FPC products have no residues and high surface cleanliness, meeting the high reliability requirements of high-end electronic equipment for core components.

With the continuous advancement of manufacturing technology, FPC will further empower the development of emerging industries through more intelligent and high-performance production methods:

- Intelligent Manufacturing Integration: The future FPC production line will realize full-process intelligent control through the integration of industrial Internet of Things, big data, and artificial intelligence technologies. Intelligent systems can automatically adjust production parameters according to product requirements, predict equipment failures, and further improve production efficiency and product quality stability.

- Adaptation to High-End Emerging Fields: As the demand for flexible electronics, wearable medical devices, and intelligent automotive systems grows, FPC manufacturing will develop in the direction of higher precision and more complex structures. Advanced manufacturing technologies will support the production of FPC with integrated functions such as sensing and energy storage, providing core component support for the upgrading of these emerging industries.

- Green and Low-Carbon Development: The FPC industry will further promote green manufacturing, optimize production processes to reduce energy consumption and material waste, and develop environmentally friendly materials and processes. This not only responds to global carbon neutrality requirements but also improves the sustainable development capacity of enterprises.

In conclusion, advanced manufacturing innovations are reshaping the development pattern of the Flexible PCB industry. Laser welding, roll-to-roll production, and other technologies have solved the core pain points of traditional manufacturing, realizing the balance between mass production efficiency and customization. With the continuous integration of intelligence and green development, Flexible PCB will play a more critical role in emerging industries, becoming a key driving force for the innovation and upgrading of the global electronics industry. For enterprises in the industrial chain, grasping the trend of advanced manufacturing technology is the key to winning the future market competition.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB