-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 15. 2025, 20:12:04

As global industries pursue high reliability, safety, and sustainability, Polyimide (PI) has emerged as a cornerstone high-performance polymer material, redefining the performance boundaries of components in extreme environments. Renowned for its exceptional thermal stability, chemical resistance, and structural versatility, Polyimide transcends the limitations of traditional materials, enabling innovations in energy storage, aerospace, protective equipment, and advanced electronics. Unlike conventional polymers that compromise on performance under harsh conditions, Polyimide maintains consistent functionality across wide temperature ranges and corrosive environments, making it indispensable for mission-critical applications. For industries striving to address safety challenges and achieve carbon neutrality goals, leveraging Polyimide’s unique properties and innovative forms has become a strategic imperative.

The adaptability of Polyimide is reflected in its diverse morphological forms, each tailored to specific industry needs through advanced manufacturing technologies:

- 1D to 3D Multiscale Manufacturing: Through precise process control and material compounding, Polyimide can be fabricated into 1D fibers, 2D films, and 3D aerogels or foam structures. For example, 1D Polyimide fibers exhibit high tensile strength and heat resistance, making them ideal for high-temperature filtration and advanced composite reinforcements. 3D Polyimide aerogels, with their ultra-low thermal conductivity and lightweight properties, are revolutionizing thermal insulation solutions in aerospace and energy systems.

- Composite Integration for Enhanced Performance: By combining Polyimide with inorganic materials such as silica or carbon nanomaterials, composite systems with synergistic properties are developed. These composites retain Polyimide’s inherent thermal stability while gaining enhanced mechanical strength or flame-retardant capabilities. Notably, recyclable Polyimide composite aerogels have been developed using “detachable” composite systems, achieving a balance between high performance and environmental sustainability.

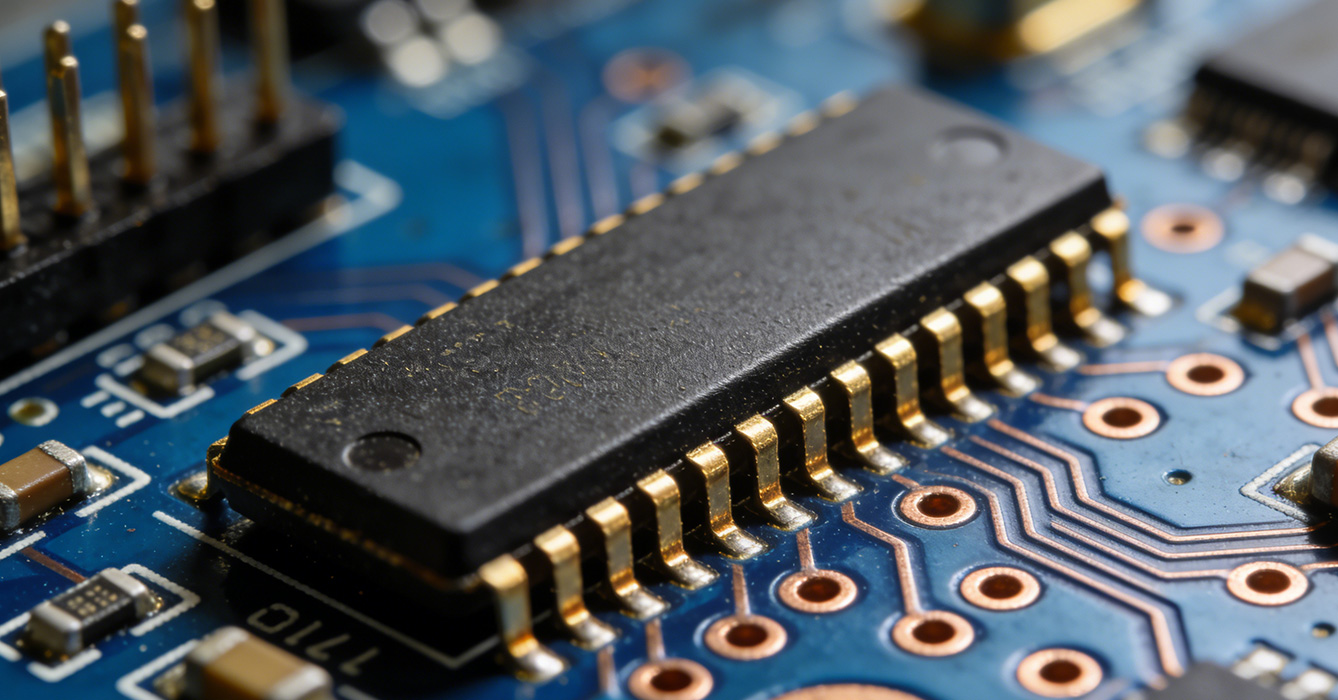

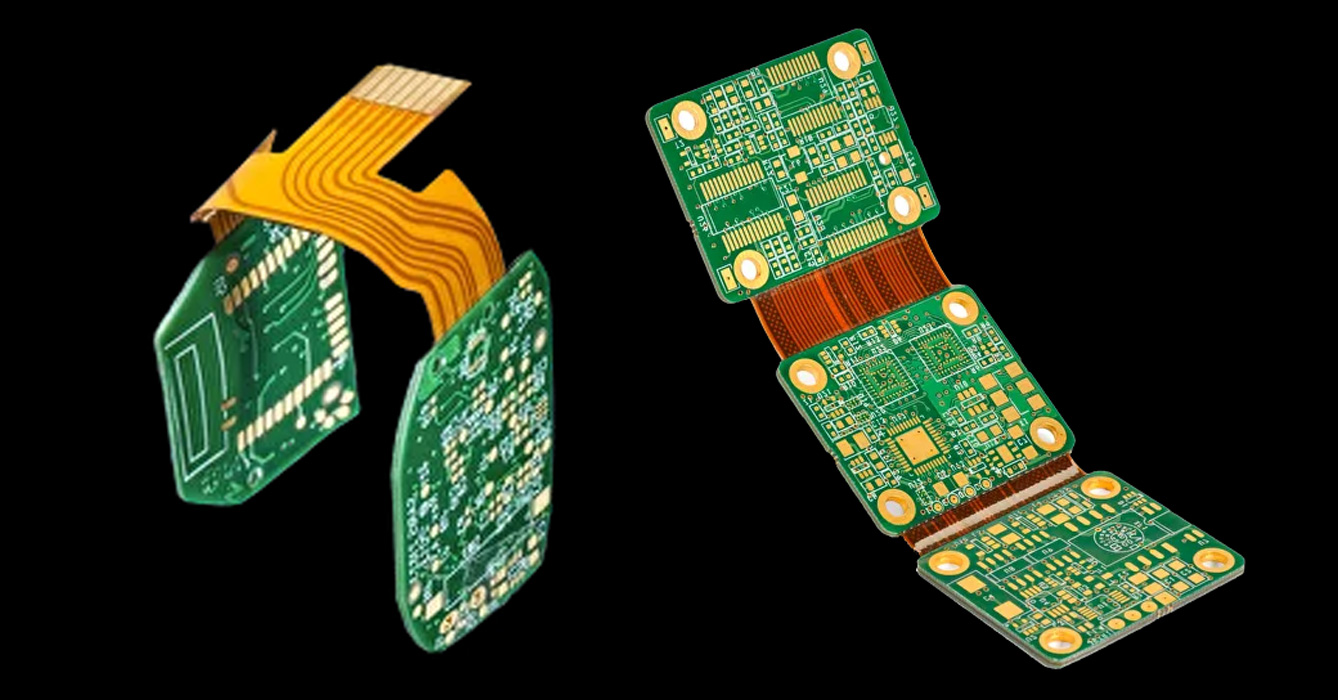

- Thin-Film Precision Engineering: Ultra-thin Polyimide films, processed through advanced casting technologies, offer exceptional flexibility and electrical insulation. These films are tailored for applications requiring miniaturization and high reliability, such as microelectronic components and battery safety barriers, where their thin profile and high dielectric strength enable compact, safe design solutions.

Polyimide plays a pivotal role in enhancing safety and reliability across key industries, addressing core pain points in extreme operating scenarios:

- New Energy Vehicle Battery Safety: In response to battery thermal runaway risks, Polyimide films and foams form a multi-layer thermal protection system in battery packs. They act as high-temperature barriers, blocking the spread of heat during thermal events and extending the response time for safety systems. Additionally, Polyimide’s low water absorption and chemical resistance prevent electrolyte corrosion, while its flexibility accommodates the dynamic conditions of automotive operation.

- Aerospace & Protective Equipment: In aerospace applications, Polyimide aerogels and composites provide lightweight, high-efficiency thermal insulation for spacecraft and aircraft, withstanding extreme temperature fluctuations and radiation. In protective equipment, such as fire-resistant clothing, Polyimide-based materials offer exceptional heat insulation and flame retardancy, safeguarding personnel in high-temperature environments.

- Electronics Thermal Management: As electronic devices become more compact and high-powered, Polyimide films with tailored thermal conductivity properties facilitate efficient heat dissipation. Their ability to maintain insulation performance at elevated temperatures ensures the reliability of microelectronic components, preventing overheating-related failures in advanced electronic systems.

Aligning with global sustainability trends, the Polyimide industry is advancing eco-friendly technologies to reduce environmental impact:

- Recyclable Polyimide Systems: Innovative “detachable” composite strategies enable the efficient recycling of Polyimide materials. These systems allow for the separation of Polyimide from composite components after use, facilitating material reuse and reducing waste. Such recyclable Polyimide aerogels maintain stable performance even after multiple recycling cycles, demonstrating great potential for sustainable applications.

- Green Synthesis Processes: Research is focused on developing low-toxicity monomer formulations and solvent-free polymerization methods for Polyimide production. These processes reduce volatile organic compound (VOC) emissions and energy consumption, aligning with carbon neutrality goals while maintaining the material’s high-performance characteristics.

- Energy-Efficient Manufacturing: Advanced processing technologies optimize the production of Polyimide forms, reducing material waste and energy input. For example, precision casting techniques for thin films minimize material loss, while low-temperature curing processes reduce energy consumption during fabrication.

The future development of Polyimide focuses on integrating smart functionalities and expanding industrial applicability:

- Smart Responsive Properties: Ongoing research aims to integrate temperature-sensitive or self-healing functionalities into Polyimide materials. Smart Polyimide films that change color in response to temperature fluctuations can provide real-time thermal monitoring, while self-healing composites can autonomously repair micro-damage, enhancing component lifespan.

- Cost Optimization for Mass Adoption: Advances in raw material synthesis and manufacturing scalability are driving down Polyimide production costs, enabling its adoption in broader industrial sectors beyond high-end applications. This includes consumer electronics, renewable energy, and automotive components, expanding its market impact.

- Cross-Industry Standardization: The establishment of unified global standards for Polyimide materials and their applications is accelerating, ensuring consistent quality and performance across industries. Standardization also facilitates cross-sector collaboration, promoting the development of innovative Polyimide-based solutions.

In conclusion, Polyimide’s morphological versatility, extreme environment adaptability, and sustainable innovation potential make it a critical enabler of industrial safety and progress. From battery safety systems to aerospace insulation and recyclable composites, Polyimide is reshaping the performance benchmarks of high-reliability materials. As technology advances toward smart integration and cost optimization, the strategic value of Polyimide will continue to grow, driving innovations across industries and contributing to a safer, more sustainable future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB