-

- PCB TYPE

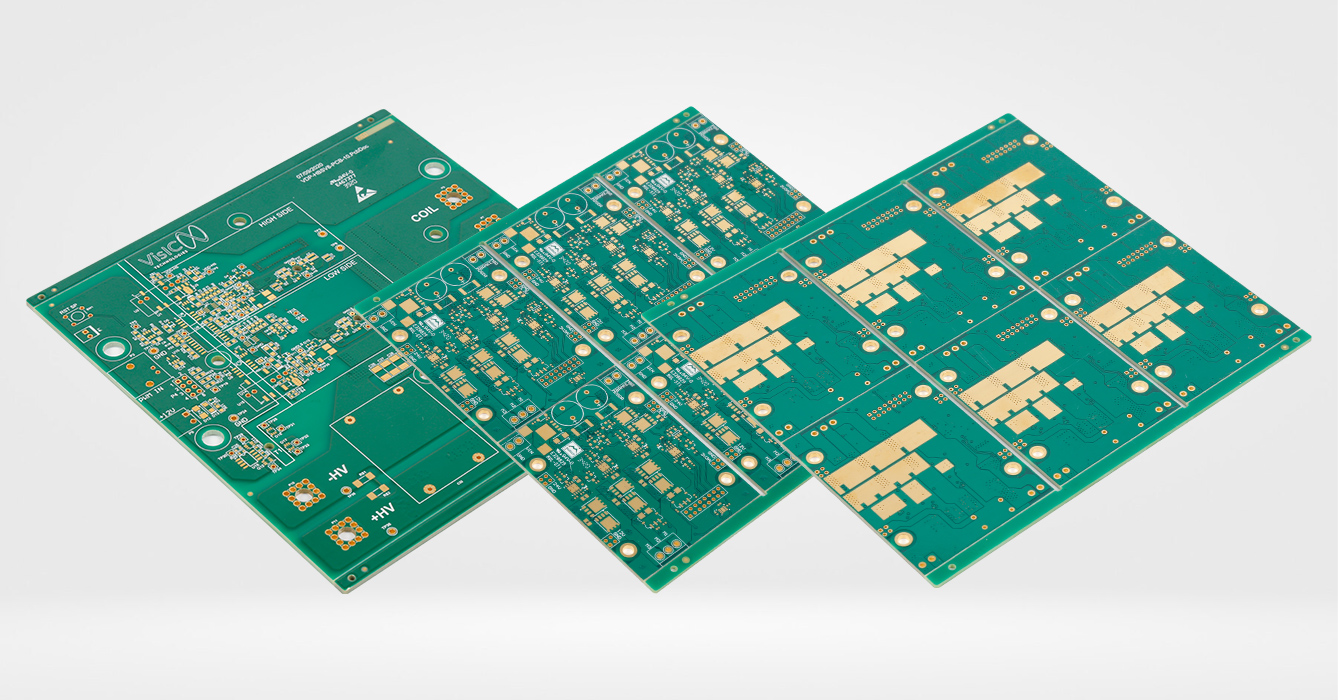

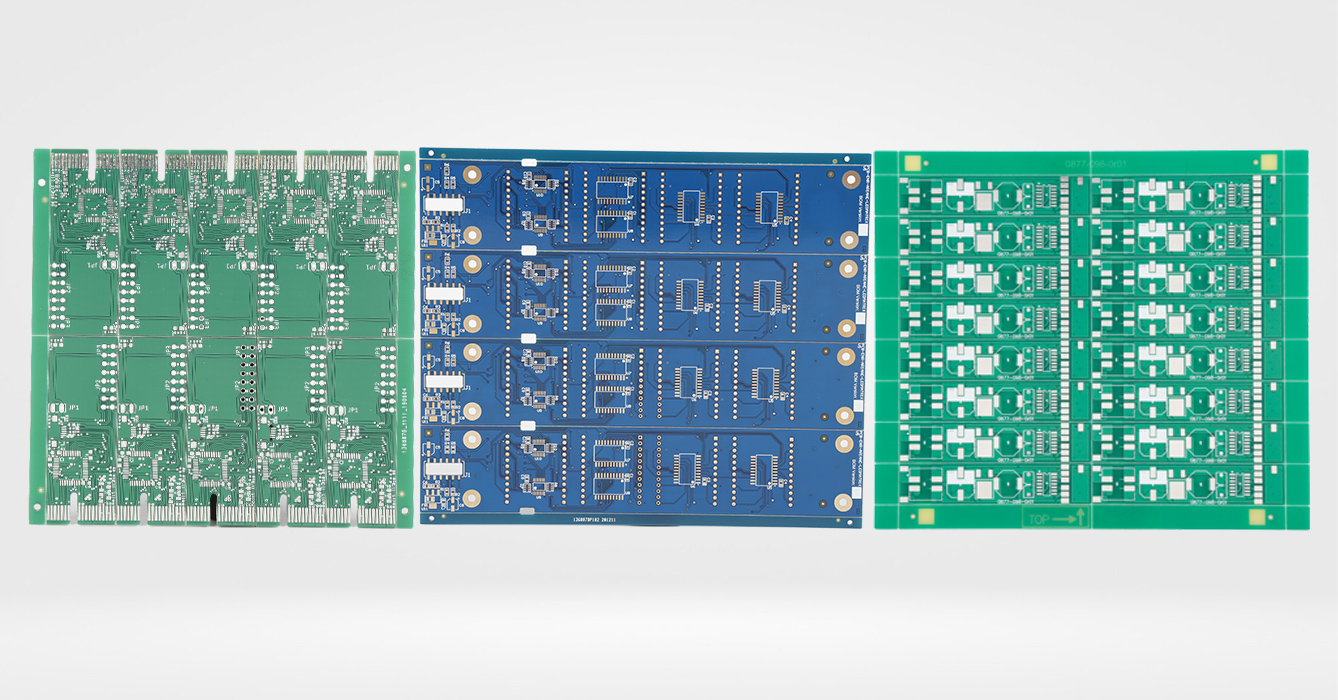

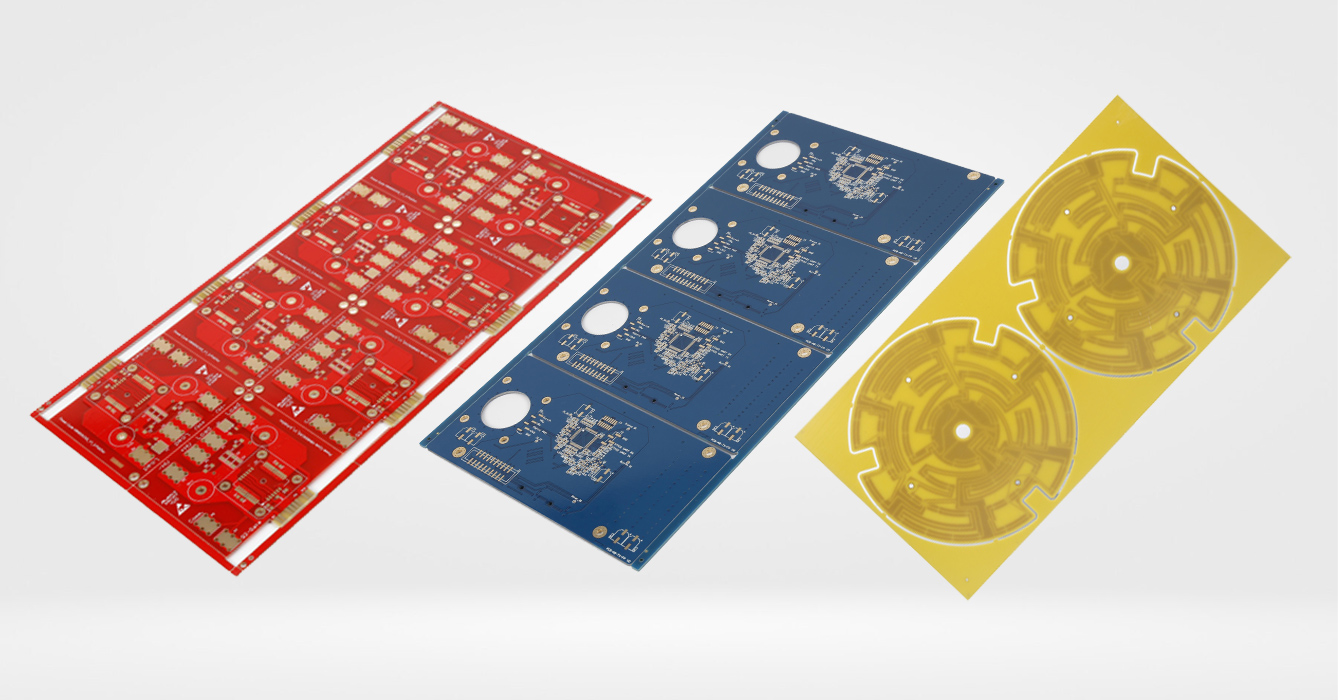

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 06. 2025, 09:29:08

In the complex supply chain of high-performance electronics, the role of a High TG FR4 PCB Manufacturer is pivotal in translating design specifications into reliable, heat-resistant circuit boards. High TG FR4 PCBs—defined by their glass transition temperature (Tg) of 150°C or higher—require specialized manufacturing processes, material sourcing, and quality control to meet the stringent demands of automotive, aerospace, and industrial applications. Unlike standard FR4 manufacturers, those specializing in high TG variants must master the nuances of advanced resin systems, precision lamination, and thermal testing to ensure the final product retains its integrity in extreme temperatures. This article explores the critical functions of a High TG FR4 PCB Manufacturer, from material selection and process optimization to quality assurance and industry compliance, highlighting how their expertise bridges the gap between design intent and real-world performance.

A High TG FR4 PCB Manufacturer distinguishes itself through specialized capabilities tailored to the unique properties of high TG laminates. These competencies ensure the final PCBs meet the thermal and mechanical requirements of high-reliability applications:

Material Sourcing Expertise: High TG FR4 relies on advanced epoxy resins (e.g., novolac-based) and high-performance glass fibers, which demand strict supplier qualification. Manufacturers establish partnerships with laminate producers (e.g., Isola, Rogers) to secure consistent batches with verified Tg values (150°C to 200°C) and low variability in dielectric properties. This ensures that every PCB starts with a substrate that meets design specifications.

Process Engineering for High TG Laminates: High TG resins require longer curing times and higher temperatures than standard FR4. Manufacturers invest in precision lamination presses capable of maintaining 190–220°C under controlled pressure (300–500 psi) for 120–180 minutes, ensuring full cross-linking of the resin matrix. This expertise prevents under-curing, which would compromise thermal stability, and over-curing, which can make the laminate brittle.

Quality Control for Thermal Performance: Beyond standard PCB inspections, High TG FR4 manufacturers implement specialized tests to verify Tg, such as differential scanning calorimetry (DSC) and thermal mechanical analysis (TMA). These tests confirm that the laminate retains its glassy state at the specified temperature, a critical validation for end-users in automotive and aerospace sectors.

High TG FR4 PCBs require modified manufacturing workflows to accommodate the material’s properties, with manufacturers focusing on three key stages:

Pre-Lamination Preparation: High TG laminates are more sensitive to moisture than standard FR4, so manufacturers implement strict drying protocols (80–100°C for 12–24 hours) before lamination. This prevents void formation caused by moisture vaporization during pressing, which can lead to delamination in high-temperature operation. Additionally, prepreg (bonding material) is selected to match the high TG core, ensuring compatible curing profiles and minimizing interfacial stress.

Lamination and Bonding: The lamination process for high TG FR4 involves a gradual temperature ramp (2–3°C per minute) to avoid thermal shock, followed by a prolonged dwell time at peak temperature to ensure resin flow and adhesion between layers. Manufacturers use computer-controlled presses with real-time monitoring of temperature and pressure, generating detailed process logs for traceability—a requirement for aerospace and military contracts.

Post-Lamination Processing: High TG FR4’s dense resin matrix requires specialized drilling and routing tools. Manufacturers use diamond-coated carbide bits and slower feed rates (0.08–0.15 mm/rev) to prevent resin smearing and edge chipping, which can compromise via integrity. After drilling, desmearing processes are extended (e.g., longer exposure to permanganate solutions) to remove resin residues from via walls, ensuring reliable copper plating.

A High TG FR4 PCB Manufacturer implements rigorous quality checks to validate thermal and mechanical performance, going beyond standard PCB testing:

Tg Verification: Each production lot undergoes DSC testing to measure the glass transition temperature, ensuring it meets the specified range (e.g., 170°C ±5°C). This test identifies batch-to-batch variations that could affect reliability.

Thermal Cycling Testing: Sample PCBs are subjected to 500–1,000 cycles of -55°C to +150°C, with post-test inspections using X-ray and ultrasonic scanning to detect delamination or via cracking. Manufacturers set pass/fail criteria based on end-use requirements, such as <1% via failure for automotive Grade 0 applications.

Mechanical Strength Testing: Peel strength tests (per IPC-TM-650 2.4.8) verify that copper traces remain bonded to the laminate after thermal aging (150°C for 1,000 hours). High TG FR4 requires a minimum peel strength of 1.0 N/mm for 1 oz copper, ensuring resistance to thermal stress in operation.

Electrical Performance at Elevated Temperatures: Network analyzers measure impedance stability at 125°C and 150°C, confirming that high TG FR4’s dielectric constant (Dk) remains within ±3% of its room-temperature value. This is critical for high-speed designs in 5G base stations and radar systems.

To serve regulated industries, High TG FR4 PCB Manufacturers pursue certifications that validate their ability to produce reliable, compliant products:

IPC-A-600 Class 3: This standard ensures PCBs meet the highest quality requirements for aerospace and military applications, with strict criteria for via fill, solder mask coverage, and freedom from defects. Manufacturers implement statistical process control (SPC) to maintain Class 3 compliance across production runs.

IATF 16949: For automotive clients, certification to IATF 16949 demonstrates adherence to quality management systems specific to automotive electronics. This includes traceability from raw materials to finished PCBs, and corrective action protocols for non-conformities—critical for components used in safety-critical systems like engine control units (ECUs).

AS9100: Aerospace manufacturers require AS9100 certification, which incorporates additional controls for traceability, risk management, and reliability testing. High TG FR4 PCB Manufacturers with AS9100 certification can supply PCBs for avionics, where failure in extreme temperatures could have catastrophic consequences.

UL 94 V-0: Compliance with UL’s flame retardancy standard is mandatory for most electronics. High TG FR4 manufacturers verify that their PCBs retain V-0 classification after thermal aging, ensuring safety in industrial and consumer applications.

High TG FR4 PCB Manufacturers offer tailored solutions to meet application-specific needs, leveraging their expertise in material science and process engineering:

Custom Tg Selection: Manufacturers work with clients to select the optimal Tg (150°C to 200°C) based on operational temperature ranges. For example, underhood automotive PCBs may use 170°C Tg, while downhole oil and gas tools require 200°C Tg to withstand extreme heat.

Layer Count and Stackup Design: High TG FR4’s rigidity allows for complex stackups (up to 30 layers) with thick copper (4–6 oz) for power distribution. Manufacturers assist clients in optimizing layer arrangements to enhance heat spreading and signal integrity, using simulation tools to predict thermal performance.

Surface Finish Options: Depending on soldering requirements and environmental exposure, manufacturers offer ENIG (Electroless Nickel Immersion Gold), immersion silver, or hard gold finishes. For high-temperature applications, ENIG is preferred for its oxidation resistance and compatibility with lead-free soldering processes (peak temperatures up to 260°C).

Thermal Management Features: Custom options include thermal vias filled with conductive epoxy, copper-inlaid heat sinks, and metal-core hybrid designs. These features, combined with high TG FR4’s inherent thermal stability, enable PCBs to dissipate heat in high-power applications like EV inverters and industrial motor drives.

High TG FR4 PCB Manufacturers manage complex supply chains to ensure reliability and on-time delivery, critical for clients in fast-paced industries like automotive and electronics:

Raw Material Inventory Management: To avoid delays, manufacturers maintain inventory of high TG laminates and prepregs, with strict rotation protocols to prevent moisture absorption. This is especially important for low-volume, high-mix production runs common in aerospace and defense.

Just-In-Time (JIT) Production: For automotive clients with JIT manufacturing systems, High TG FR4 PCB Manufacturers implement flexible production schedules and Kanban systems to deliver PCBs in sync with assembly lines. This reduces inventory costs for clients while ensuring parts are available when needed.

Global Distribution: Leading manufacturers operate facilities in regions with high demand (e.g., Asia, Europe, North America) to minimize lead times. They also partner with logistics providers experienced in shipping sensitive electronics, using climate-controlled packaging to protect high TG PCBs from moisture during transit.

Despite their expertise, High TG FR4 PCB Manufacturers navigate unique challenges inherent to producing high-performance laminates:

Material Cost Volatility: High TG resins and specialty glass fibers are more expensive than standard FR4 materials, with prices subject to fluctuations in raw material (e.g., bromine for flame retardants) and energy costs. Manufacturers mitigate this by entering long-term supply agreements with laminate producers.

Process Complexity: The extended curing times and specialized tooling required for high TG FR4 increase production costs and lead times. To remain competitive, manufacturers invest in automation (e.g., robotic handling, automated optical inspection) to improve efficiency without compromising quality.

Quality Control for Low-Volume Runs: Aerospace and defense clients often require small batches (10–100 PCBs) with strict quality criteria. Manufacturers adapt by implementing scalable testing protocols that maintain rigor while avoiding excessive costs for low-volume orders.

High TG FR4 PCB Manufacturers are adapting to industry trends to meet evolving demands for performance and sustainability:

Eco-Friendly High TG Formulations: Manufacturers are adopting bromine-free, phosphorus-based flame retardants in high TG resins to comply with EU RoHS and REACH regulations. These formulations maintain Tg and flame resistance while reducing environmental impact.

Additive Manufacturing Integration: Some manufacturers are exploring 3D printing of high TG epoxy structures for prototyping, enabling rapid iteration of complex designs (e.g., integrated heat sinks) before full-scale production. This reduces lead times for custom projects.

AI-Driven Process Optimization: Machine learning algorithms analyze lamination data (temperature, pressure, time) to predict and prevent defects, improving yield rates. AI also optimizes drilling parameters for high TG laminates, reducing tool wear and improving via quality.

Selecting a High TG FR4 PCB Manufacturer requires evaluating factors beyond basic manufacturing capabilities:

Technical Expertise: Look for manufacturers with in-house material scientists and process engineers who can advise on Tg selection, stackup design, and thermal management. This expertise is critical for resolving complex issues like signal integrity at high temperatures.

Certifications and Traceability: Prioritize manufacturers with IATF 16949, AS9100, and IPC-A-600 Class 3 certifications, as these indicate a commitment to quality. Traceability systems (e.g., batch tracking, process logs) are essential for automotive and aerospace clients.

Production Capacity and Flexibility: Ensure the manufacturer can scale production from prototypes to high-volume runs (10,000+ PCBs) while maintaining quality. Flexibility to accommodate design changes and tight deadlines is also important for time-sensitive projects.

Testing Capabilities: Verify that the manufacturer has in-house testing for Tg (DSC), thermal cycling, and signal integrity at elevated temperatures. This reduces reliance on third-party labs, speeding up validation and ensuring accountability.

Examples of High TG FR4 PCB Manufacturer projects highlight their impact on critical applications:

Automotive EV Battery Management Systems: A manufacturer collaborated with an EV OEM to produce 170°C Tg PCBs for BMS, incorporating thermal vias and 4 oz copper planes. The PCBs withstood 1,000 thermal cycles (-40°C to +150°C) with zero failures, meeting AEC-Q200 Grade 0 requirements.

Aerospace Engine Sensors: A certified AS9100 manufacturer produced 180°C Tg PCBs for engine vibration sensors, using ENIG finishes and hermetic sealing. The PCBs passed thermal vacuum testing and radiation exposure (100 kRad), ensuring reliability in space launch vehicles.

Industrial Furnace Controls: A manufacturer supplied 160°C Tg PCBs for furnace controllers, featuring thick copper traces and conformal coating. These PCBs operated continuously at 140°C for 5,000 hours without performance degradation, reducing maintenance costs for the end-user.

A High TG FR4 PCB Manufacturer plays a critical role in enabling electronics to perform in extreme thermal environments, combining material expertise, advanced manufacturing processes, and rigorous quality control to deliver reliable products. Their ability to navigate the complexities of high TG laminates—from lamination to testing—ensures that PCBs meet the demands of automotive, aerospace, and industrial applications. As electronics continue to push into higher temperature ranges, the expertise of High TG FR4 PCB Manufacturers will remain essential, bridging the gap between innovative designs and real-world reliability. By prioritizing technical competence, certifications, and customization capabilities, clients can partner with manufacturers to create high TG FR4 PCBs that thrive in the most challenging environments.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB