-

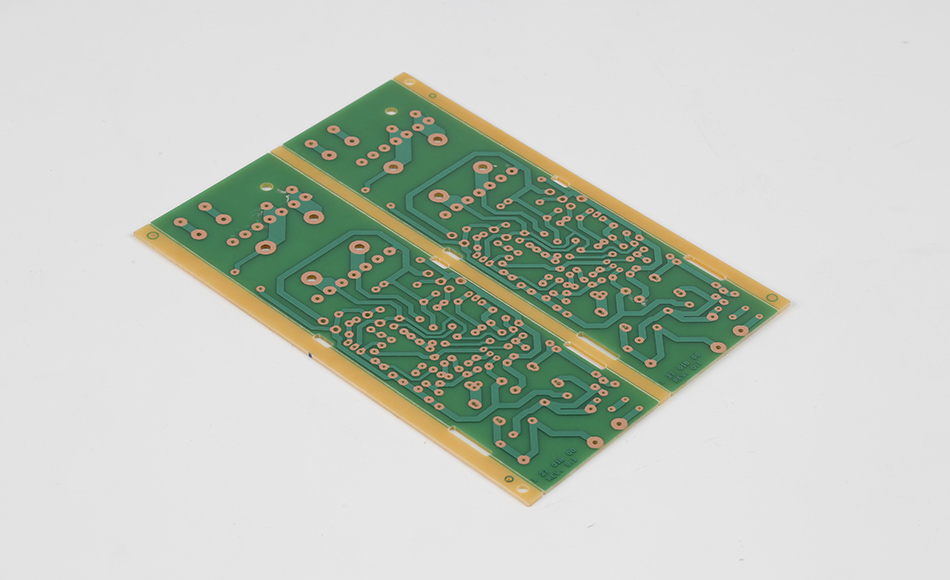

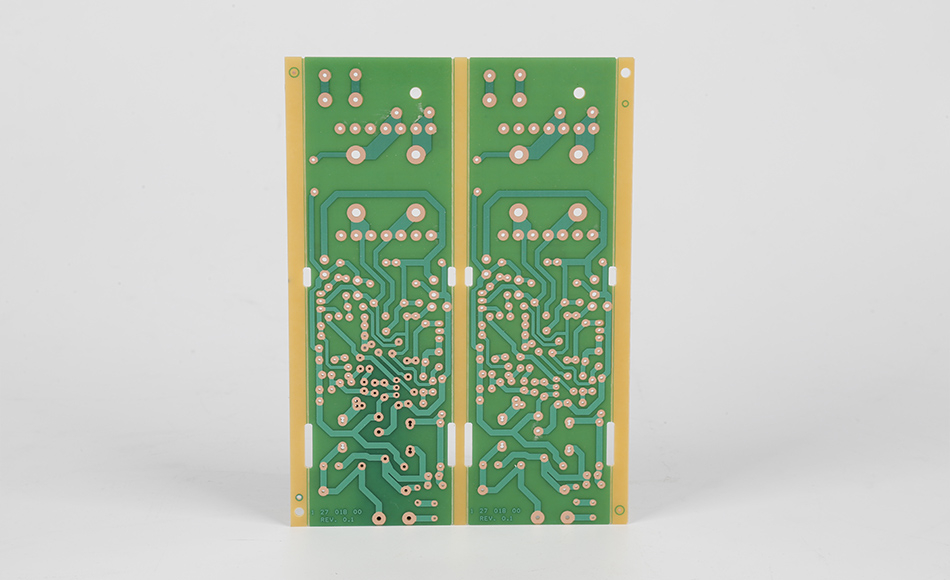

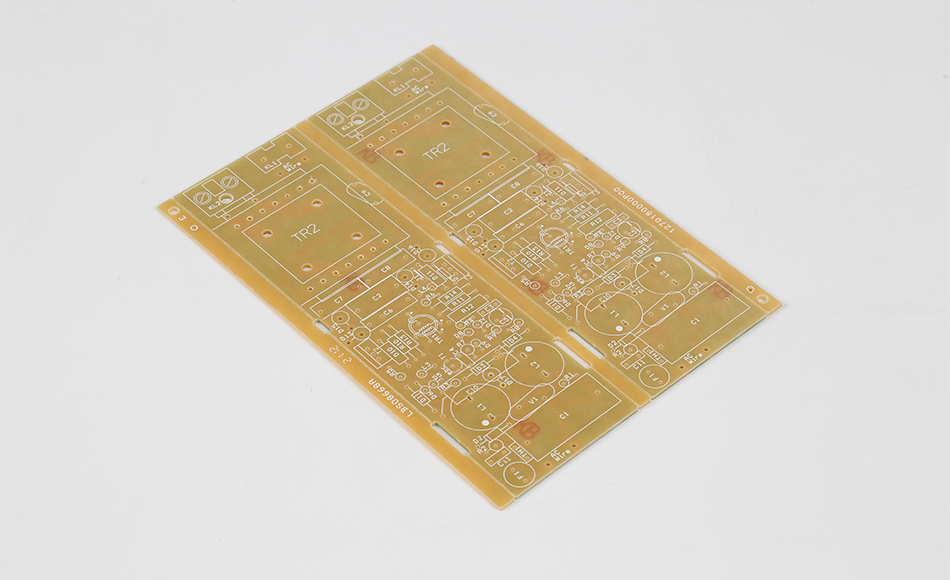

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 30. 2025, 14:54:44

High Brightness CEM3 LED Backlight Boards are indispensable for display systems needing strong visibility in tough conditions—outdoor billboards, industrial control panels, medical diagnostic monitors, and automotive HUDs. Unlike standard brightness boards (300–500 nits), high brightness variants (800+ nits) demand more from their substrate: managing heat from dense LED arrays, maintaining uniform light across large surfaces, and retaining mechanical stability under prolonged high-power use.

CEM3 stands out as an ideal substrate, balancing three key needs: thermal resilience for high-power LED heat, dielectric stability for consistent current (critical for brightness uniformity), and cost-effectiveness vs. specialized substrates like MCFR4 or ceramic. Standard CEM3 struggles with high brightness—suffering thermal degradation, uneven light, or premature failure—but optimized High Brightness CEM3 boards fix these gaps via material tweaks, design adjustments, and integration with complementary components.

This article explores the unique technical challenges of high brightness LED backlighting, how CEM3 is tailored to overcome them, real-world applications, and future trends—providing actionable insights for engineers and manufacturers building high-visibility, durable displays.

High brightness (800+ nits) operation brings three interrelated challenges for CEM3 boards: increased thermal stress, stricter light uniformity demands, and enhanced reliability requirements—more acute than in standard brightness systems, requiring targeted solutions.

High brightness comes from higher-power LEDs (1–3W each) or denser arrays (more LEDs per area)—both boosting heat generation. A 1000-nit outdoor display may use 200+ 2W LEDs, generating 400W of heat over 1m². This heat risks:

Thermal Degradation: Standard CEM3’s epoxy softens/degrades above 105°C, reducing insulation resistance and warping boards. Warping misaligns LEDs, causing hot spots and poor display quality.

LED Lifespan Cut: LEDs are temperature-sensitive—every 10°C higher junction temp halves lifespan (per Arrhenius equation). Without good heat dissipation, high-power LEDs in CEM3 boards may fail in 10,000–15,000 hours, vs. 30,000+ hours in cooled systems.

Trace Resistance Rise: Copper traces on CEM3 have higher resistance at high temps, causing voltage drops. This reduces LED current, leading to brightness dips and uneven output.

High brightness displays (55+ inch billboards, 32-inch medical monitors) need strict uniformity (brightness variation <5%) for consistent visibility. CEM3 boards struggle with this due to:

LED Pitch Variation: Dense arrays need precise placement (±0.1mm tolerance). Standard CEM3 has surface irregularities (Ra >1.0μm) causing misalignment, leading to 8–12% brightness variation.

Light Reflection Loss: High brightness relies on efficient PCB reflection. Standard CEM3’s matte surface absorbs 15–20% of light, reducing brightness and creating uneven reflection.

Current Distribution Issues: Uneven current flow (from trace resistance or poor routing) means edge LEDs get less current than central ones, causing "edge dimming."

High brightness displays often run 24/7 (outdoor billboards, industrial monitors) or in harsh environments (automotive HUDs, medical devices), requiring CEM3 boards to meet stricter reliability standards:

Environmental Resistance: Outdoor displays face UV, moisture, and -40°C to 60°C swings. Standard CEM3 yellows under UV (reducing light transmission) or absorbs moisture (increasing thermal resistance).

Mechanical Durability: Automotive/industrial displays endure 10–500 Hz vibration and shock. High-power LED arrays add weight to CEM3 boards, raising risk of trace cracking or LED detachment.

Long-Term Stability: Medical/aviation displays need 5+ years of consistent brightness/color. Standard CEM3 degrades over time, causing 10% brightness drift (3 years) or ΔE >3.0 color shift—unacceptable for critical use.

To tackle high brightness challenges, High Brightness CEM3 boards need targeted optimizations in material formulation, PCB design, and integration with cooling/optical components—boosting thermal performance, uniformity, and reliability without losing CEM3’s cost edge.

Enhancing CEM3’s thermal properties is key to managing high-power LED heat. Key tweaks:

Thermally Conductive Fillers: Boron nitride (BN) or aluminum nitride (AlN) in CEM3’s epoxy raises in-plane conductivity by 40–50% (0.3 → 0.45–0.5 W/m·K). This spreads heat from LED pads to board edges, cutting hot spot temps by 15–20°C. A 1000-nit outdoor display with filled CEM3 saw LED junction temps drop from 75°C to 62°C, extending lifespan to 35,000 hours.

High-Tg Epoxy Resin: Epoxy with Tg 140–150°C (vs. 120–130°C standard) prevents warping at high temps. A high-Tg CEM3 board in a 24/7 industrial monitor kept flatness (<0.5mm warpage) after 10,000 hours, vs. 1.2mm for standard CEM3.

Low-Moisture Additives: Hydrophobic agents reduce CEM3’s moisture absorption to <1.0% (24h boiling water), down from 1.5–2.0% standard. This keeps thermal conductivity stable (±3% variation) in humid outdoor environments, avoiding 10–15% conductivity loss in standard CEM3.

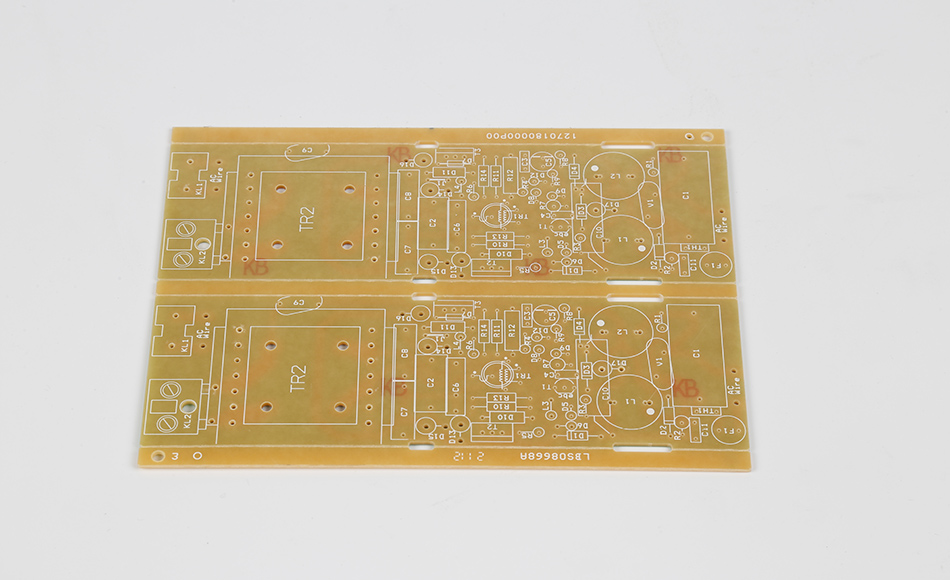

Design adjustments ensure consistent light output across large CEM3 boards:

Precision LED Pad Placement: Laser etching (±0.05mm tolerance) for pads ensures uniform 0.5–1.0mm pitch, cutting brightness variation to <4%. A 55-inch outdoor billboard using this design saw variation drop from 11% to 3.8%, meeting industry standards.

Light-Reflective Finishes: White solder mask (reflectivity >90%) on CEM3 cuts light absorption by 50% vs. standard matte finishes. This boosts brightness by 8–10% and eliminates "dark spots" from uneven absorption.

Star-Shaped Power Routing: Central power input with equal-length branches to each LED ensures uniform current. For a 32-inch medical monitor (150 LEDs), this reduced current variation from 8% to 2%, fixing edge dimming for diagnostic imaging.

Complementary parts enhance High Brightness CEM3 performance, addressing thermal/optical challenges:

Thermal Interface Materials (TIMs): Graphite sheets (150 W/m·K) attached to CEM3’s back transfer heat to external sinks. An 800-nit automotive HUD using this cut board temp by 22°C, keeping LED color shift ΔE <1.5 in under-hood environments.

Diffuser Films/Light Guides: Micro-prism diffuser films (120° diffusion angle) paired with CEM3 ensure uniform light across displays. A 43-inch industrial panel using this hit 95% uniformity, up from 85% with CEM3 alone.

Vibration-Damping Mounts: Silicone dampers (damping coefficient 0.8) for automotive/industrial CEM3 boards reduce vibration stress. A high brightness automotive HUD with these mounts had no trace cracking/LED detachment after 100,000 km road tests, vs. 5% failure for standard mounts.

High Brightness CEM3 boards are tailored to industry-specific needs, using optimized thermal/optical/reliability properties to solve sector challenges. Below are key applications.

Outdoor displays need 800–1500 nits to compete with sunlight, plus UV/moisture/temp swing resistance. High Brightness CEM3 meets these needs by:

UV/Moisture Resistance: UV-stabilized resin prevents yellowing (90% light transmission after 2 years outdoors) and hydrophobic additives reduce moisture absorption, keeping thermal stability in rain/humidity.

Large-Format Design: CEM3 supports 2m×1m panels, cutting splices in big billboards. This reduces splice-point brightness variation from 15% to 4%.

Cost-Effectiveness: High Brightness CEM3 costs 30–40% less than MCFR4, ideal for high-volume signage. A global display maker reported 25% lower PCB costs switching from MCFR4 to optimized CEM3, with no performance loss.

Medical monitors need 600–1000 nits for accurate imaging, plus ΔE <1.5 color accuracy and 5+ year reliability. High Brightness CEM3 delivers by:

Color Stability: Low-moisture CEM3 and uniform current prevent color shift. A 32-inch ultrasound monitor with optimized CEM3 kept ΔE <1.2 for 4 years, meeting FDA imaging requirements.

Low EMI: CEM3’s stable Dk (±2% variation) reduces interference with sensitive medical gear. Unlike MCFR4 (EMI spikes), High Brightness CEM3 meets EN 60601-1 EMI standards.

Sterilization Compatibility: CEM3 resists alcohol cleaners (common in hospitals), keeping reflectivity/strength after 10,000+ cleanings.

Automotive displays need 500–800 nits for daytime visibility, plus vibration/temp cycle (-40°C to 85°C)/fluid resistance. High Brightness CEM3 adapts by:

Thermal Cycle Resistance: High-Tg CEM3 (145°C) and reinforced edge plating withstand 1000+ cycles (-40°C to 85°C) with no delamination/trace cracking, exceeding automotive’s 800-cycle requirement.

Fluid Resistance: CEM3’s epoxy resists engine oil, coolant, and brake fluid. A HUD board exposed to oil for 500 hours had no change in thermal conductivity/strength.

Compact Design: 0.6–0.8mm thin-core CEM3 fits tight automotive enclosures (10mm HUD thickness limits), cutting display size by 20% vs. MCFR4.

As display tech evolves, High Brightness CEM3 boards adapt to meet demands for higher brightness, miniaturization, and sustainability. Key trends:

Mini LED (0.2–1mm) enables 1500+ nits and local dimming, ideal for premium displays (8K TVs, pro monitors). High Brightness CEM3 evolves to support this by:

Ultra-Fine Pitch Pads: Laser drilling creates 0.15–0.2mm pads for dense Mini LED arrays (1000+ LEDs/m²), ensuring alignment and uniformity.

Micro-Thermal Vias: 0.2mm vias under each Mini LED boost through-plane conductivity by 60%, managing dense array heat. A 1500-nit 8K TV with this design kept LED junction temps <60°C, extending lifespan to 40,000 hours.

Local Dimming Circuits: Thin-film transistors (TFTs) on CEM3 enable local dimming, cutting power use by 30% while maintaining ultra-high brightness.

Display makers prioritize sustainability, driving High Brightness CEM3 to adopt green practices:

Recycled Materials: 30% recycled glass fiber (from end-of-life wind blades) in CEM3 cuts carbon footprint by 25%, with no thermal/mechanical loss.

Bio-Based Epoxy: Plant-derived epoxy (castor oil-based) replaces petroleum resin, retaining high-Tg/low moisture absorption and biodegrading at end-of-life.

Energy-Efficient Production: Solar-powered curing ovens for CEM3 lamination cut manufacturing energy use by 40% vs. gas-fired ovens, aligning with carbon neutrality goals.

Smart displays need dynamic brightness adjustment (dimming in low light). High Brightness CEM3 integrates:

Embedded Light Sensors: Thin-film ambient light sensors (ALS) in CEM3 enable real-time adjustment, cutting power use by 25–30% for outdoor displays (dusk dimming) and automotive HUDs (sunlight adaptation).

IoT Monitoring: Wireless sensors on CEM3 track temp, brightness, and current, enabling remote maintenance. A smart outdoor display network using this cut unplanned downtime by 50% via predictive LED failure alerts.

High Brightness CEM3 LED Backlight Boards solve high-visibility display challenges—thermal stress, light uniformity, reliability—via material optimization, design tweaks, and component integration. Unlike MCFR4 or ceramic, they balance performance and cost, making them ideal for outdoor displays, medical monitors, automotive HUDs, and more.

Real-world use shows their value: lower costs, longer lifespan, and consistent performance in harsh environments. As Mini LED, sustainability, and smart control reshape displays, High Brightness CEM3 will keep evolving—delivering higher brightness, efficiency, and eco-friendliness.

For engineers and manufacturers, High Brightness CEM3 is a strategic choice: it balances tech performance and cost, enabling high-quality, durable displays that meet today’s and tomorrow’s market demands. As high-visibility displays grow across industries, optimized CEM3 will remain foundational to display innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB