-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 25. 2025, 12:00:07

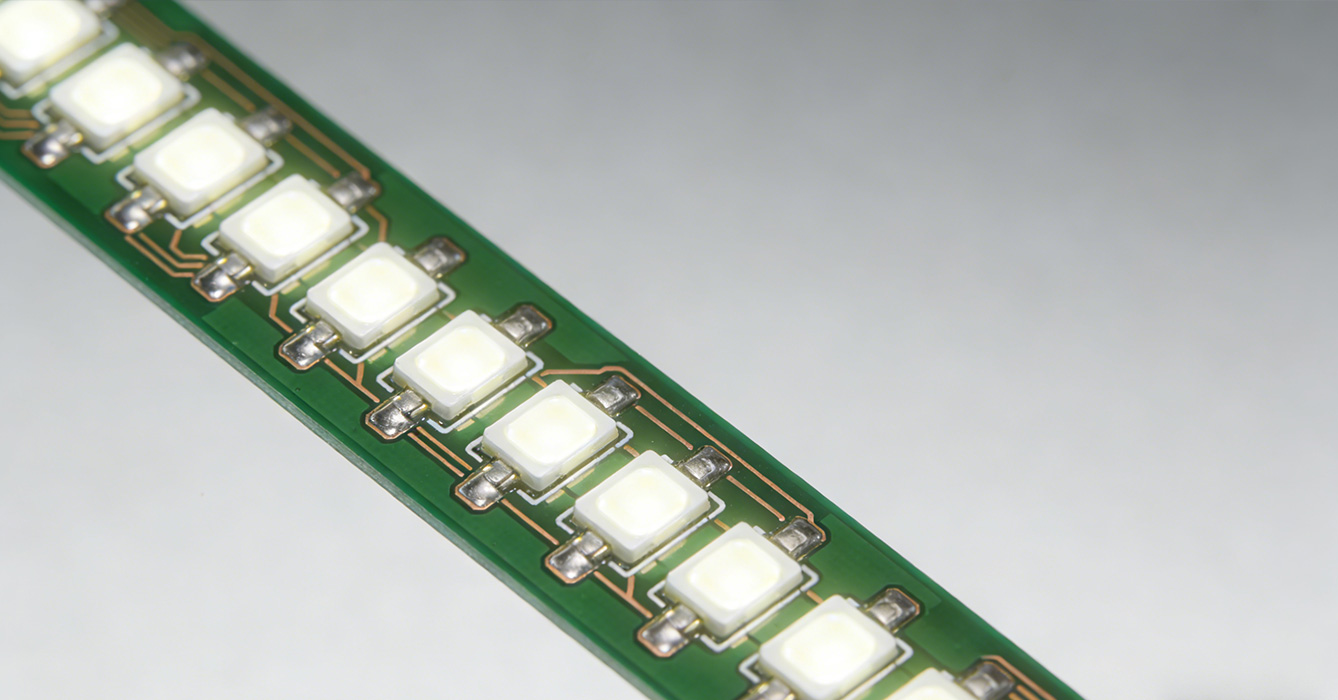

As the global lighting industry shifts toward intelligence, energy efficiency, and miniaturization, LED Lighting FPCB (Flexible Printed Circuit Board) has emerged as a core component driving innovation in lighting design and performance. Unlike rigid printed circuit boards that limit lighting form factors, LED Lighting FPCB combines flexibility, lightweight design, and excellent thermal conductivity, making it adaptable to a wide range of lighting applications—from compact smart home fixtures to large-scale urban landscape projects. This versatile component not only optimizes the structural design of LED lighting products but also enhances energy efficiency and service life, becoming an indispensable part of modern lighting ecosystems. For lighting designers, product developers, and facility operators, understanding the value and application of LED Lighting FPCB is key to creating competitive lighting solutions. This article explores the core advantages, diversified application scenarios, implementation guidelines, and future trends of LED Lighting FPCB, highlighting its pivotal role in shaping the future of intelligent lighting.

Traditional lighting substrates, such as rigid PCBs and metal core PCBs (MCPCBs), face significant limitations in meeting the evolving needs of modern LED lighting systems. Rigid PCBs are inflexible, restricting the design of lighting products to regular shapes and preventing adaptation to curved or irregular installation surfaces—such as the contoured edges of smart home ceiling lights or the curved surfaces of architectural decorative lighting. This inflexibility limits creative lighting designs and reduces the applicability of LED lighting in complex environments.

Another critical drawback is the trade-off between thermal performance and weight. While MCPCBs offer better heat dissipation than standard rigid PCBs, they are heavy and bulky, increasing the overall weight of lighting products. This is a major disadvantage for applications requiring lightweight solutions, such as portable lighting devices or ceiling-mounted fixtures that require minimal structural support. Additionally, traditional substrates often have higher energy loss due to poor circuit conductivity, reducing the overall energy efficiency of LED lighting systems. LED Lighting FPCB addresses these limitations by integrating flexibility, lightweight design, and efficient thermal management, revolutionizing the design and performance of LED lighting products.

LED Lighting FPCB offers four key advantages that make it superior to traditional lighting substrates, enabling broader application and better performance:

- Exceptional flexibility and design freedom: The inherent flexibility of LED Lighting FPCB allows it to be bent, folded, or twisted into various shapes, supporting innovative lighting designs that were previously impossible with rigid substrates. Lighting designers can create thin, curved, or even wearable lighting products—such as flexible LED strips for interior decoration, curved panel lights for architectural contours, or lightweight headlamps for outdoor activities. This flexibility also simplifies installation by conforming to the shape of the installation surface, reducing the need for custom brackets.

- Lightweight and space-saving: LED Lighting FPCB is significantly lighter and thinner than traditional rigid PCBs and MCPCBs, making it ideal for applications where weight and space are critical. For example, in smart home lighting fixtures, the lightweight design reduces the load on ceiling structures, while the thin profile allows for sleeker, more minimalist product designs. In portable lighting devices, such as flashlights or camping lights, the reduced weight enhances portability.

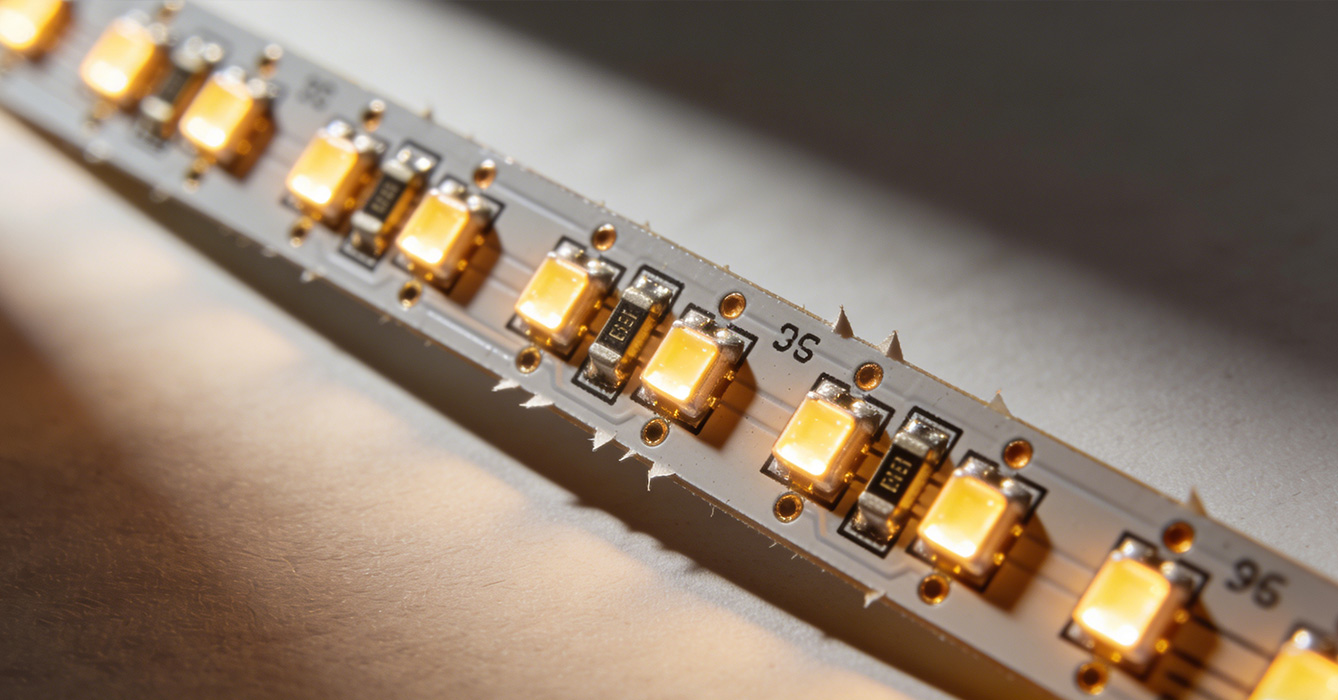

- Efficient thermal management: High-quality LED Lighting FPCB uses polyimide substrates with excellent thermal conductivity, effectively dissipating heat generated by LED chips. Efficient heat dissipation prevents LED overheating, which is a major cause of reduced LED lifespan and performance degradation. This thermal advantage ensures stable operation of LED lighting systems even in high-power or long-duration applications, extending product service life and reducing maintenance costs.

- Cost-effectiveness and scalability: LED Lighting FPCB can be mass-produced with high precision, reducing manufacturing costs for large-scale applications. The simplified design also reduces the number of components required, lowering assembly costs. Additionally, LED Lighting FPCB supports scalable circuit designs, allowing for easy customization of lighting products to meet different power and brightness requirements without significant changes to the manufacturing process.

LED Lighting FPCB's versatility enables its application across a wide range of lighting sectors, from residential and commercial to industrial and public infrastructure:

- Smart home lighting: In smart homes, LED Lighting FPCB is used in a variety of fixtures, including flexible LED strips for under-cabinet lighting, curved panel lights for living rooms, and thin recessed lights for bedrooms. Its flexibility allows for seamless integration into furniture and architectural elements, while its lightweight design supports easy installation. Additionally, the efficient thermal management ensures long-term reliability of smart lighting products that are often left on for extended periods.

- Urban landscape and architectural lighting: LED Lighting FPCB is ideal for large-scale landscape and architectural lighting projects, such as bridge contour lighting, building facade lighting, and park decorative lighting. Its flexibility allows it to follow the curved lines of bridges and buildings, creating dynamic and visually appealing lighting effects. The lightweight design also simplifies installation on tall buildings and complex structures, reducing construction costs and safety risks.

- Industrial automation lighting: In industrial environments, such as factories and warehouses, LED Lighting FPCB is used in high-bay lights, machine vision lighting, and safety lighting. Its efficient thermal management ensures stable performance in high-temperature industrial settings, while its flexibility allows for customization to fit the specific dimensions of industrial equipment. The lightweight design also reduces the load on industrial machinery and structures.

- Portable and wearable lighting: Portable lighting devices, such as flashlights, camping lights, and headlamps, benefit greatly from LED Lighting FPCB's lightweight and flexible design. The thin profile allows for compact product designs, while the flexibility enables folding or adjustable lighting angles. Wearable lighting products, such as safety vests with integrated LED lights or LED armbands, also rely on LED Lighting FPCB for its comfort and conformability to the body.

To maximize the performance and reliability of LED Lighting FPCB in lighting applications, follow these essential implementation guidelines:

- Select the right substrate material: Choose LED Lighting FPCB with substrate materials that match the application requirements. For high-temperature environments, such as industrial lighting, select polyimide substrates with high thermal resistance. For low-cost, general-purpose applications, such as residential lighting, standard polyimide substrates are sufficient. Ensure the substrate material has good adhesion to copper foil to prevent circuit failure.

- Optimize circuit design for thermal efficiency: Design the circuit layout of LED Lighting FPCB to maximize heat dissipation. This includes minimizing the length of high-current traces, using appropriate trace widths to reduce resistance and heat generation, and placing thermal vias in areas with high heat concentration. Avoid overcrowding components to allow for adequate air circulation.

- Ensure proper installation and protection: During installation, avoid over-bending or stretching the LED Lighting FPCB, as this can damage the circuit and substrate. Use appropriate mounting accessories, such as adhesive tapes or clips, to secure the FPCB in place without causing stress. For outdoor or humid environments, use LED Lighting FPCB with waterproof coatings and sealed connectors to prevent moisture intrusion.

- Test for reliability and performance: Conduct thorough testing of LED Lighting FPCB before mass production, including thermal testing, flexibility testing, and electrical performance testing. Test the lighting system under real-world conditions to ensure it meets the required brightness, energy efficiency, and service life. Regularly inspect and maintain the lighting system to detect any issues with the FPCB, such as circuit damage or coating degradation.

Driven by technological advancements and market demand, LED Lighting FPCB is poised to evolve toward greater intelligence, integration, and sustainability:

- Integration with smart sensing and control: Future LED Lighting FPCB will integrate sensors (such as motion sensors, light sensors, and temperature sensors) and control chips directly onto the flexible substrate, enabling intelligent adaptive lighting. For example, lighting systems can automatically adjust brightness based on ambient light levels or occupancy, enhancing energy efficiency and user experience.

- Development of high-density and miniaturized designs: As LED technology advances toward Mini/Micro LED, LED Lighting FPCB will develop higher circuit density and smaller line widths to support the integration of more LED chips in a smaller space. This will enable ultra-thin, high-resolution lighting products, such as transparent LED displays and micro-LED wearables.

- Adoption of eco-friendly materials and processes: In response to global sustainability initiatives, manufacturers will increasingly use eco-friendly materials, such as recyclable polyimide and lead-free copper foil, in LED Lighting FPCB production. Energy-efficient manufacturing processes, such as laser etching and low-temperature curing, will also become more prevalent, reducing the environmental impact of FPCB production.

In conclusion, LED Lighting FPCB is a versatile and essential component that is transforming the modern lighting industry. Its flexibility, lightweight design, efficient thermal management, and cost-effectiveness make it suitable for a wide range of applications, from smart homes to urban landscapes. By following proper implementation guidelines, lighting designers and developers can fully leverage the advantages of LED Lighting FPCB to create innovative, high-performance lighting solutions. As technology evolves, LED Lighting FPCB will continue to integrate intelligence and sustainability, playing an increasingly important role in the development of energy-efficient and user-centric lighting systems. For anyone involved in the lighting industry, understanding and embracing LED Lighting FPCB is a key step toward staying competitive in the rapidly evolving market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB