-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 18. 2025, 16:22:47

In mission-critical sectors such as aerospace, industrial control, and new energy vehicles, the performance stability of electronic components directly determines operational safety and efficiency. High Reliability Flex PCB Board emerges as a core solution, engineered to withstand extreme environmental stresses while maintaining consistent electrical and mechanical performance. Unlike standard flexible PCBs designed for consumer electronics, this specialized circuit board integrates robust structural designs, high-performance materials, and rigorous quality control processes. For manufacturers operating in high-stakes industries, adopting High Reliability Flex PCB Board is not only a technical necessity but also a strategic guarantee to minimize downtime, reduce maintenance costs, and ensure compliance with industry-specific safety standards.

The exceptional reliability of High Reliability Flex PCB Board is rooted in targeted design optimizations that address potential failure points in conventional flexible circuits:

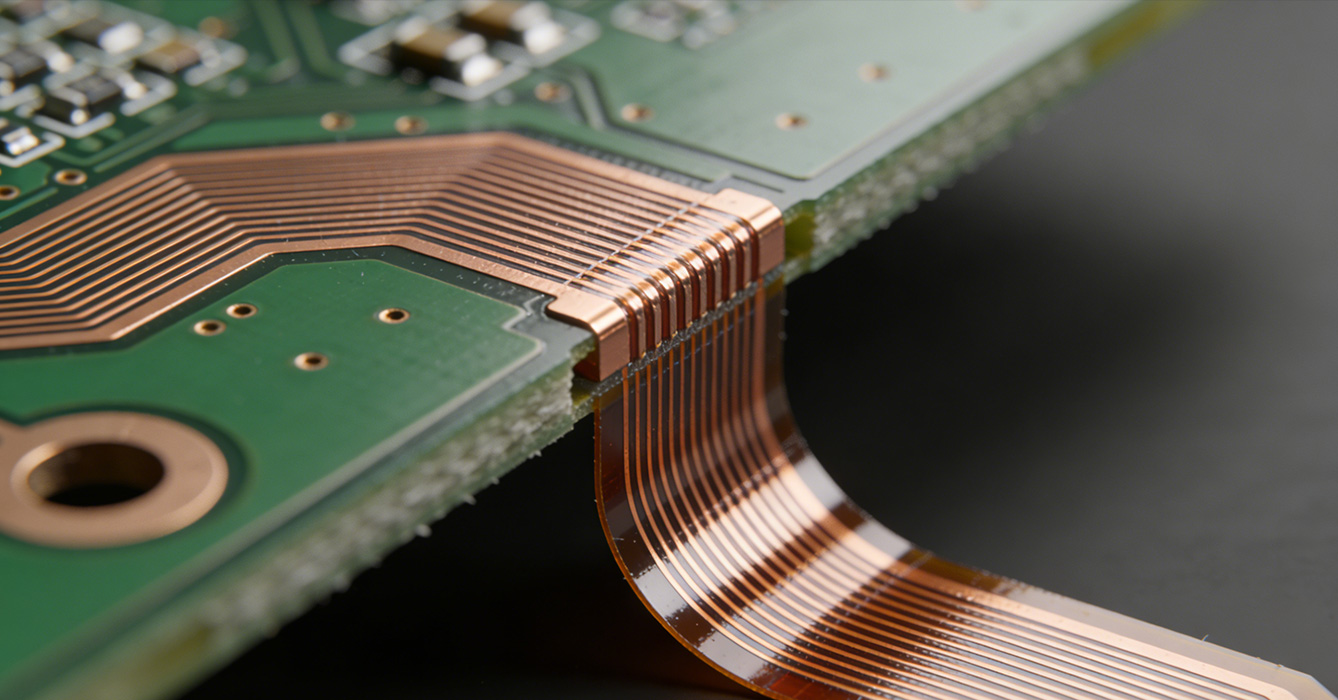

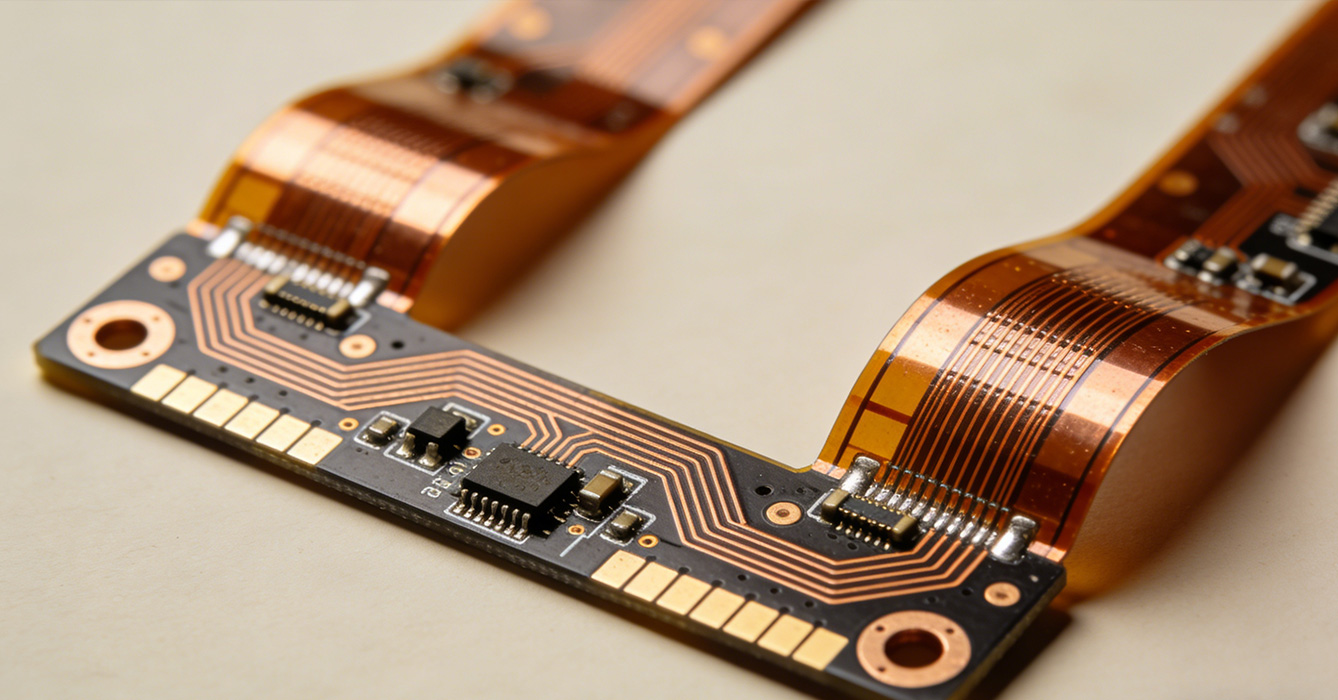

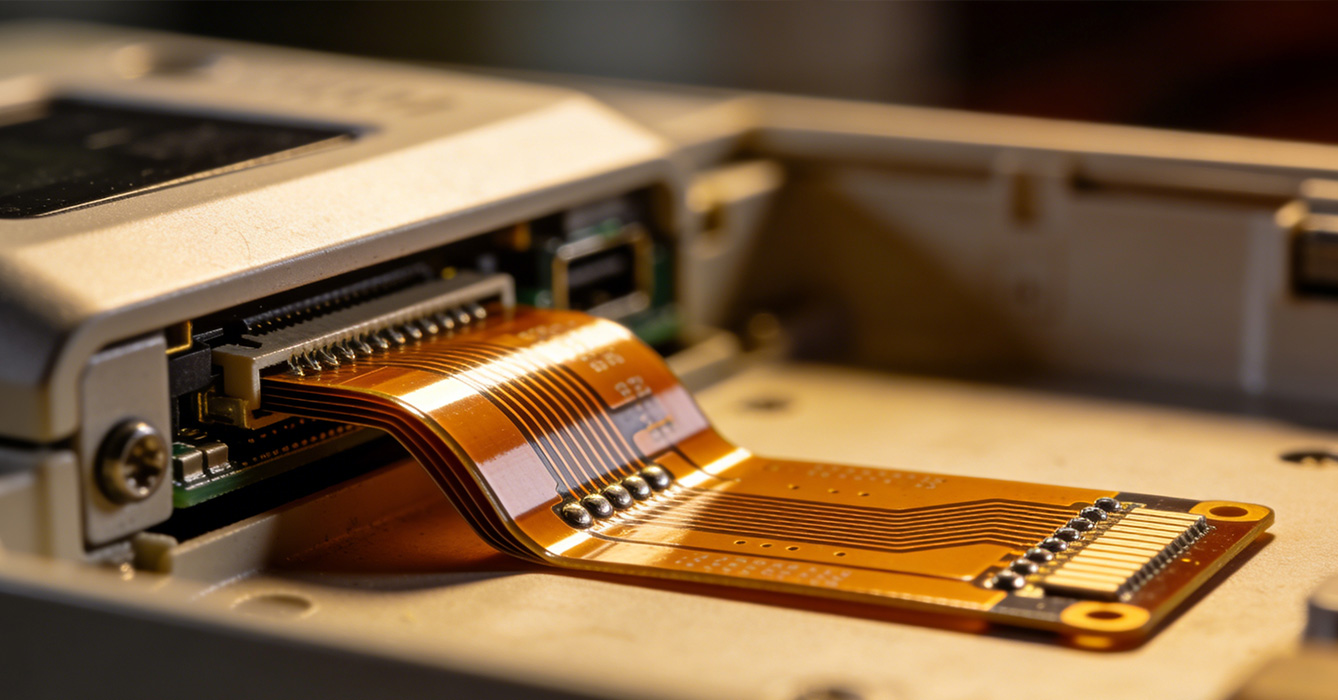

- Rigid-Flex Hybrid Design for Structural Stability: A key design innovation is the integration of rigid and flexible substrates into a single hybrid assembly. Rigid sections provide structural support for component mounting and heat dissipation, while flexible segments enable dynamic bending and compact packaging. This design minimizes the need for connectors and wiring harnesses, reducing potential failure points caused by vibration-induced wear or poor connections. The seamless integration of rigid and flexible regions ensures mechanical integrity even under repeated flexing, making it ideal for devices requiring both structural stability and design adaptability.

- Reinforced Conductive Pathways & Solder Joints: High Reliability Flex PCB Board features optimized conductive trace designs and reinforced solder joints to enhance current-carrying capacity and mechanical resilience. Trace widths and spacing are engineered to distribute stress evenly, while solder joints undergo advanced bonding processes such as laser soldering with nitrogen protection to improve adhesion and reduce voids. Additionally, protective overlays and coverlays are applied to critical trace areas, shielding them from environmental contaminants and mechanical damage.

To meet the demands of harsh operating conditions, High Reliability Flex PCB Board incorporates specialized technologies for environmental adaptation:

- High-Temperature & Corrosion-Resistant Materials: Substrates are constructed from high-grade polyimide (PI) or ceramic-filled polymers that exhibit excellent thermal stability, capable of withstanding continuous operating temperatures ranging from extreme cold to high heat. Conductive layers use oxygen-free copper with anti-oxidation surface treatments such as electroless nickel immersion gold (ENIG), enhancing resistance to corrosion, humidity, and chemical exposure. These material selections ensure stable performance in aerospace, marine, and industrial environments where temperature fluctuations and corrosive agents are prevalent.

- Shock & Vibration Mitigation: The board design incorporates stress-absorbing structures and damping materials to withstand high levels of shock and vibration. Flexible segments are engineered with optimized bend radii to avoid material fatigue, while rigid sections are reinforced to prevent component displacement. This vibration resistance is critical for applications such as automotive powertrain systems, industrial robots, and aerospace equipment, where mechanical stress can otherwise lead to solder joint fractures or circuit discontinuities.

High Reliability Flex PCB Board undergoes stringent testing protocols to validate its performance and ensure compliance with industry standards:

- Endurance & Environmental Testing: Comprehensive testing includes flexural endurance testing (in accordance with IPC standards) to evaluate performance under repeated bending, as well as environmental chamber testing for temperature cycling, humidity resistance, and salt spray exposure. Shock and vibration testing simulate real-world operating conditions, verifying the board’s ability to withstand mechanical stress without performance degradation. These tests ensure that the board meets the reliability requirements of mission-critical applications.

- Quality Assurance & Traceability: Manufacturers implement strict quality control processes throughout production, including automated optical inspection (AOI) for circuit defects and X-ray inspection for solder joint integrity. Full traceability is maintained for all raw materials and production steps, with detailed documentation supporting compliance with industry standards such as AS9100 for aerospace and IATF 16949 for automotive applications. This level of quality assurance ensures consistent reliability across production batches.

High Reliability Flex PCB Board is essential for applications where failure is not an option, enabling innovation in high-stakes industries:

- Aerospace & Defense: In spacecraft, satellites, and military aircraft, the board’s ability to withstand extreme temperatures, radiation, and vibration ensures reliable operation of navigation systems, communication modules, and avionic controls. Its lightweight and compact design also supports weight reduction goals critical for aerospace applications.

- Industrial Control & Automation: Industrial robots, process control systems, and oil & gas exploration equipment rely on High Reliability Flex PCB Board to maintain performance in harsh factory environments, including high temperatures, dust, and chemical exposure. The board’s durability reduces unplanned downtime, improving production efficiency and safety.

- New Energy Vehicles: In electric vehicle powertrains and battery management systems (BMS), the board withstands high temperatures, vibration, and electrical stress, ensuring stable power distribution and battery performance. Its reliability is critical for enhancing the safety and lifespan of electric vehicles.

The development of High Reliability Flex PCB Board is evolving toward enhanced performance and intelligent functionality to meet growing industry demands:

- Advanced Material Innovation: Research is focused on developing next-generation materials such as carbon fiber-reinforced polyimides, which offer superior strength-to-weight ratios and thermal conductivity. These materials further enhance the board’s ability to withstand extreme environments while reducing weight.

- Smart Health Monitoring: Future designs will integrate embedded sensors to monitor the board’s operational status, including temperature, vibration, and electrical performance. This real-time health monitoring enables predictive maintenance, alerting operators to potential issues before they lead to failure.

- Enhanced Manufacturing Precision: The adoption of AI-driven manufacturing and inspection technologies will further improve production precision and quality control, ensuring consistent reliability even for complex rigid-flex designs. This advancement supports the growing demand for high-reliability solutions in emerging high-tech sectors.

In conclusion, High Reliability Flex PCB Board is a critical enabler of stable operation in mission-critical and extreme environments, combining robust design, advanced materials, and rigorous testing. Its unique capabilities support innovation across aerospace, industrial control, and new energy vehicle sectors, where reliability is paramount. As industries continue to push the boundaries of operating conditions, the role of High Reliability Flex PCB Board will become increasingly vital, driving advancements in safety, efficiency, and performance in high-stakes applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB