-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 18. 2025, 16:23:51

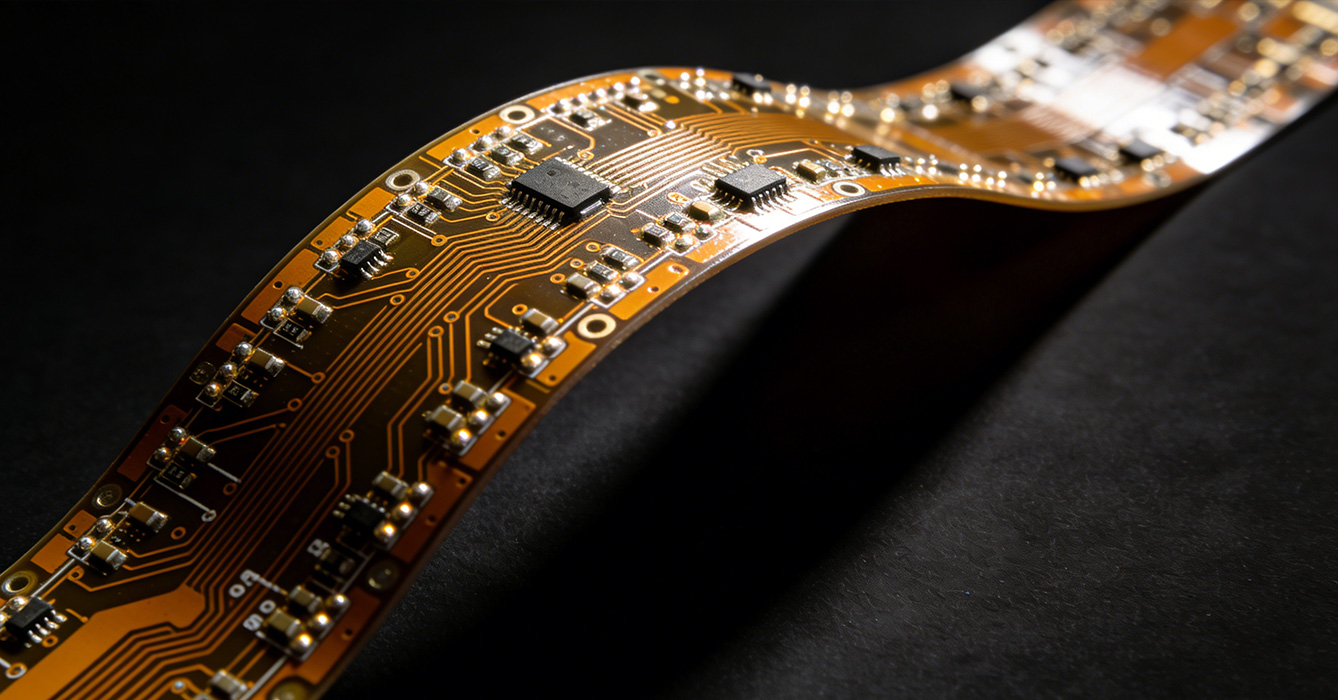

In the era of precision electronics, the quality of flexible PCB boards directly determines the performance, lifespan, and safety of end products. Quality Flexible PCB Board, distinguished by rigorous quality control throughout the entire production lifecycle, has become a core requirement for manufacturers across consumer electronics, medical devices, and automotive industries. Unlike low-cost flexible PCBs that prioritize cost over performance, Quality Flexible PCB Board integrates premium materials, precision manufacturing, and comprehensive quality verification to ensure consistent electrical and mechanical performance. For electronics brands, adopting Quality Flexible PCB Board is not only a means to reduce product failure rates and maintenance costs but also a key strategy to enhance brand reputation and gain a competitive edge in global markets.

The superior quality of Quality Flexible PCB Board is built on a systematic quality control system that covers every stage of the product lifecycle, eliminating potential defects at the source:

- Quality-Oriented Design Phase: Quality control begins with the design stage, where engineers conduct thorough DFM (Design for Manufacturability) analysis to optimize circuit layouts, trace widths, and bend radius. This analysis ensures that the design is not only functional but also compatible with high-precision manufacturing processes, reducing the risk of defects such as trace breakage or short circuits. Simulation tests are also performed to verify the board’s performance under real-world operating conditions, ensuring that the design meets the quality requirements of target applications.

- Real-Time Quality Monitoring in Production: During manufacturing, advanced automated inspection technologies are deployed to monitor quality in real time. Automated Optical Inspection (AOI) systems detect subtle circuit defects such as open circuits, short circuits, and missing solder, while X-ray inspection ensures the integrity of hidden solder joints and internal structures. Statistical Process Control (SPC) is applied to track key production parameters, enabling timely adjustments to avoid process deviations. These measures ensure that every unit of Quality Flexible PCB Board meets consistent quality standards.

- Rigorous Post-Production Verification & Traceability: After production, each batch of Quality Flexible PCB Board undergoes comprehensive performance testing, including electrical continuity testing, insulation resistance testing, and flex endurance testing. Full traceability is maintained for all raw materials and production processes, with detailed records of material suppliers, production dates, and test results. This traceability system not only facilitates quick troubleshooting in case of quality issues but also supports compliance with global quality standards and customer audit requirements.

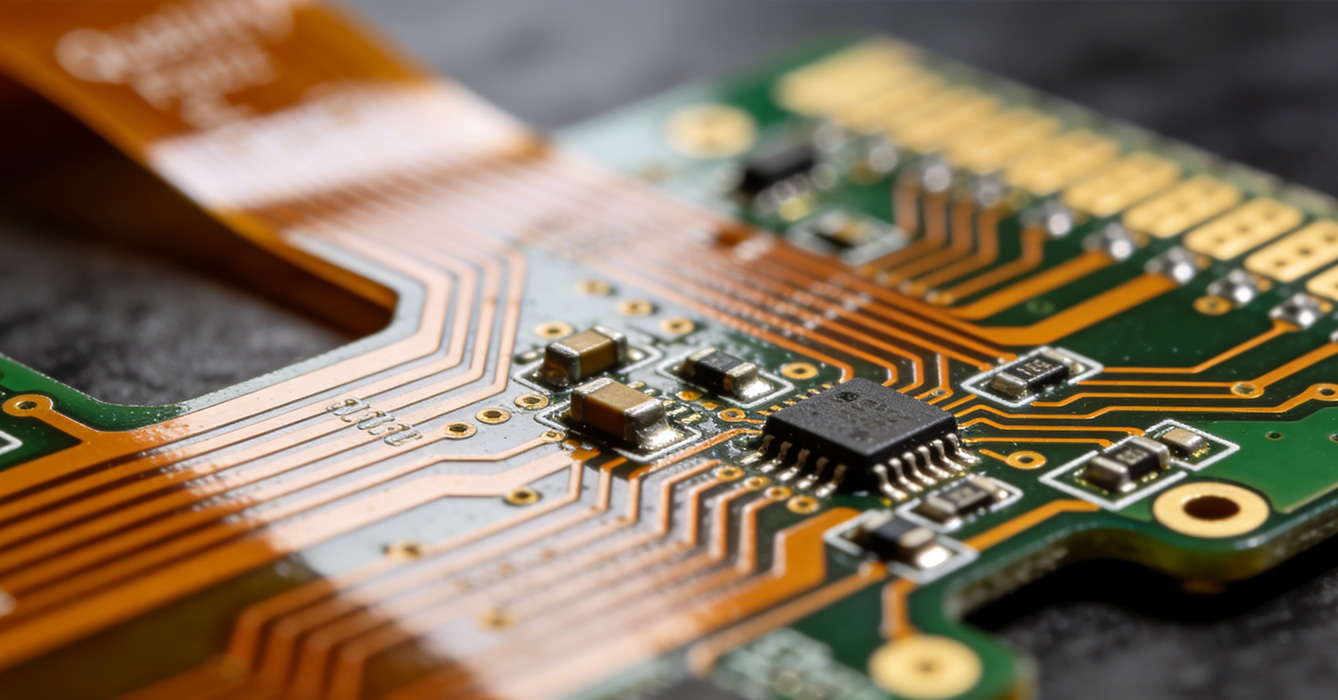

The quality of flexible PCB boards is inherently linked to the selection of materials and manufacturing processes, and Quality Flexible PCB Board adheres to strict criteria in both aspects:

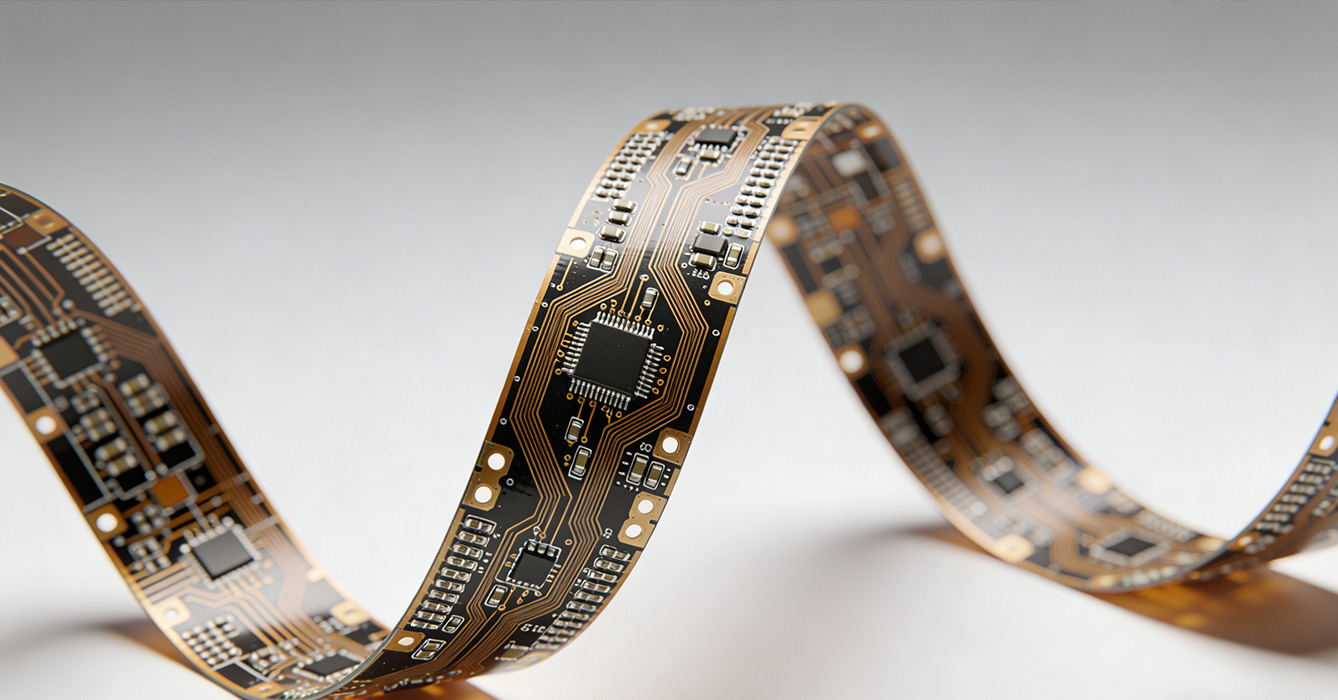

- Premium Substrate & Conductive Materials: High-grade materials are selected to ensure long-term reliability. Substrates use high-purity polyimide (PI) with excellent thermal stability and mechanical strength, avoiding low-quality substrates that may degrade under temperature fluctuations or repeated bending. Conductive layers adopt oxygen-free copper foil with uniform thickness, ensuring stable electrical conductivity and resistance to oxidation. Surface treatments such as Electroless Nickel Immersion Gold (ENIG) or Organic Solderability Preservatives (OSP) are applied to enhance solderability and corrosion resistance.

- Precision Manufacturing Processes: Quality Flexible PCB Board adopts advanced manufacturing processes to ensure dimensional accuracy and structural integrity. Precision laser drilling technology is used for via formation, ensuring uniform via size and accurate positioning. Advanced soldering processes such as reflow soldering with nitrogen protection reduce solder defects and improve joint strength. Additionally, strict control of cleaning processes ensures that no residual flux or contaminants remain on the board, preventing electrical failures caused by pollution.

Quality certification is a key guarantee for Quality Flexible PCB Board to gain market recognition and meet global regulatory requirements:

- Compliance with Global Quality Standards: Quality Flexible PCB Board complies with international quality standards such as IPC-2223 (for flexible printed circuits) and ISO 9001 (quality management system). For industry-specific applications, it also meets specialized standards, such as IATF 16949 for automotive electronics and ISO 13485 for medical devices. These certifications demonstrate the board’s compliance with rigorous quality requirements and enable it to enter global markets smoothly.

- Building Customer Trust & Brand Value: Consistent quality performance helps manufacturers of Quality Flexible PCB Board build long-term trust with customers. By delivering products with low failure rates and stable performance, they support customers in improving the quality of their end products, thereby enhancing the customer’s brand reputation. In an increasingly competitive market, quality has become a core differentiator, and Quality Flexible PCB Board helps both manufacturers and customers gain a competitive advantage.

Quality Flexible PCB Board is widely used in applications where quality and reliability are critical:

- Consumer Electronics: In high-end smartphones, laptops, and wearable devices, Quality Flexible PCB Board ensures stable performance under frequent use and repeated bending. Its reliable electrical connections support the smooth operation of high-speed data transmission and complex functions, enhancing the user experience.

- Medical Devices: In medical equipment such as diagnostic devices and portable health monitors, Quality Flexible PCB Board meets strict biocompatibility and reliability requirements. Its stable performance ensures accurate data collection and transmission, supporting the safety and effectiveness of medical procedures.

- Automotive Electronics: In automotive infotainment systems, sensor modules, and lighting systems, Quality Flexible PCB Board withstands harsh automotive environments such as temperature fluctuations and vibration. Its high quality ensures the long-term reliability of automotive electronics, reducing the risk of vehicle malfunctions.

The development of Quality Flexible PCB Board is moving toward intelligent quality enhancement to meet the growing demand for high-quality electronics:

- AI-Driven Quality Prediction: The integration of artificial intelligence (AI) into quality control systems enables predictive analysis of potential quality issues. By analyzing production data and historical quality records, AI can identify patterns and predict defects before they occur, further improving production yield and product quality.

- Digital Twin for Quality Simulation: Digital twin technology is being applied to simulate the entire production process of flexible PCB boards. This allows manufacturers to optimize processes, detect potential quality risks, and verify quality performance in a virtual environment, reducing the need for physical testing and accelerating product development.

In conclusion, Quality Flexible PCB Board is the foundation of reliable electronic systems, with its superior quality built on a full-lifecycle quality control system, premium materials, and precision processes. It not only ensures the performance and safety of end products but also helps manufacturers build market trust and enhance competitiveness. As the electronics industry continues to pursue higher quality standards, the role of Quality Flexible PCB Board will become increasingly important, driving the development of high-quality, reliable electronic products worldwide.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB