-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 19. 2025, 12:01:21

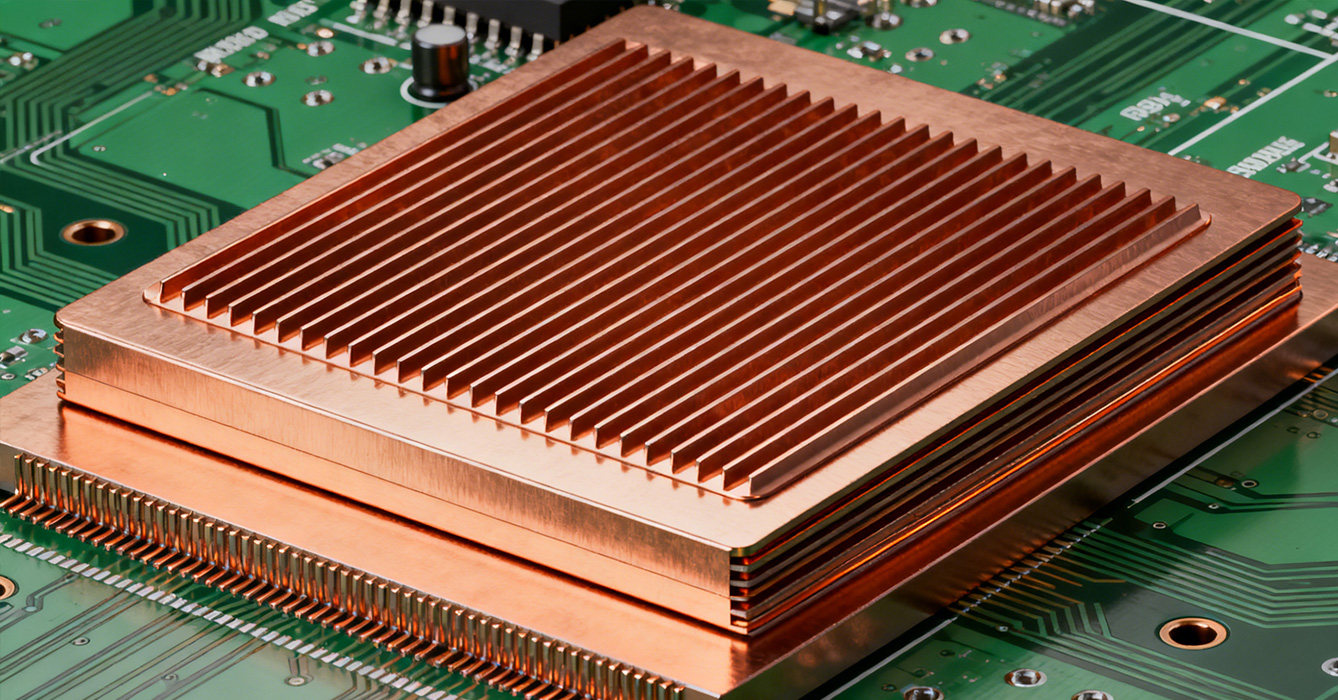

High Thermal Sinkpad Copper Core has emerged as a game-changing solution for addressing the thermal challenges of modern high-power electronic systems. By leveraging copper’s exceptional thermal conductivity and integrating a specialized sinkpad structure, this technology delivers unmatched heat dissipation capabilities while maintaining electrical isolation and mechanical stability. As electronic devices continue to shrink in form factor while handling increasing power densities—from industrial power converters to advanced lighting systems—High Thermal Sinkpad Copper Core provides a critical pathway to prevent overheating, extend component lifespans, and ensure reliable performance. This article explores the core advantages, design principles, manufacturing breakthroughs, key applications, and future innovations of this advanced thermal management solution.

The superiority of High Thermal Sinkpad Copper Core stems from its unique material properties and structural design, addressing the limitations of traditional metal-core PCBs.

Copper’s inherent thermal conductivity far exceeds that of alternative materials like aluminum, enabling rapid heat transfer away from high-power components. Unlike standard metal-core PCBs, which rely on a dielectric layer that limits heat flow, High Thermal Sinkpad Copper Core features a direct thermal path (DTP) structure. This design allows the component’s thermal pad to make direct contact with the copper core, eliminating intermediate thermal barriers and maximizing heat dissipation efficiency. The result is significantly lower thermal resistance, ensuring uniform heat distribution and minimizing hotspots that can degrade performance or cause premature failure. This thermal superiority is particularly critical in applications where even small temperature increases can lead to substantial reductions in component reliability.

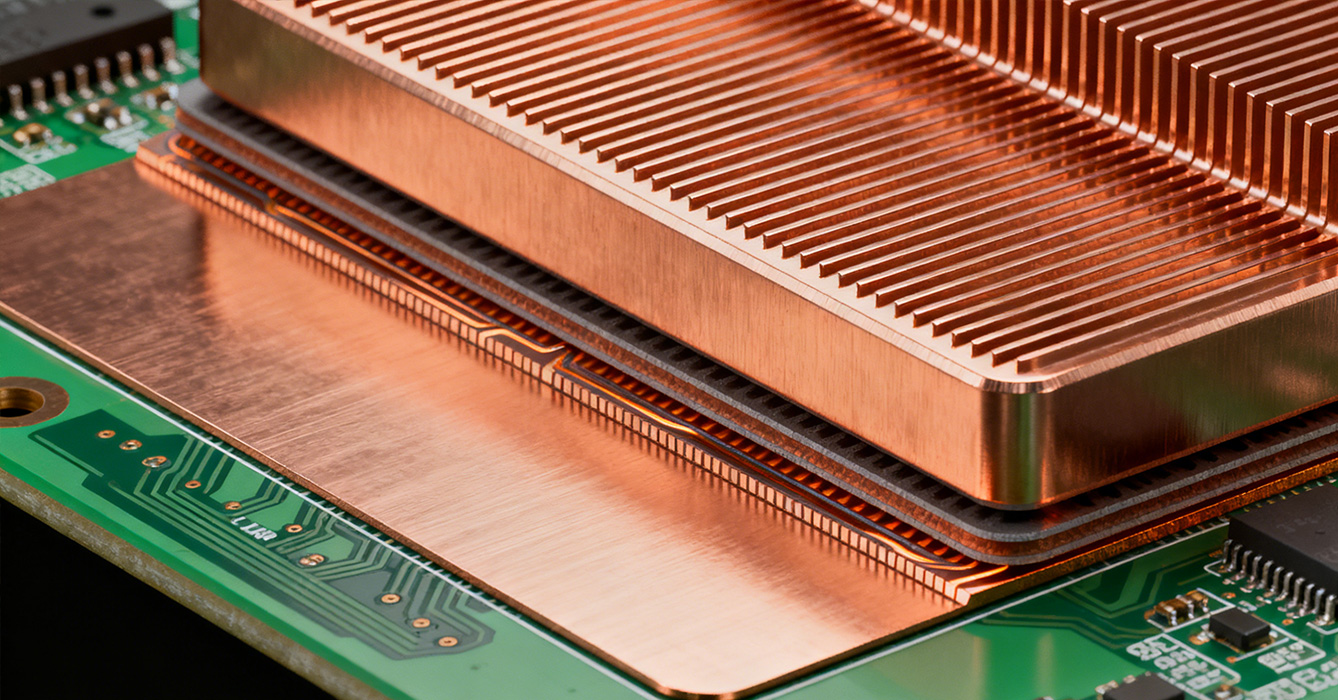

A defining feature of High Thermal Sinkpad Copper Core is its thermoelectric separation architecture, which isolates electrical circuits from the thermal conduction path. The copper core functions exclusively as a heat-dissipating medium, while the circuit traces are positioned on a separate dielectric layer, maintaining electrical insulation without compromising thermal performance. This separation prevents electrical interference and ensures that heat generated by active components is channeled directly to the copper core, rather than being trapped by conductive layers. For high-power components such as LEDs and semiconductors, this design minimizes lumens depreciation and extends operational lifespans by keeping junction temperatures within safe limits.

Mechanical Rigidity and Durability

Copper’s inherent structural rigidity provides High Thermal Sinkpad Copper Core with exceptional mechanical stability, making it suitable for harsh operating environments. The robust copper core resists warping and deformation caused by thermal cycling, vibration, and physical stress—common challenges in industrial and automotive applications. Unlike more flexible materials, copper’s high density and strength ensure the sinkpad maintains its structural integrity over extended periods, even under extreme temperature fluctuations. This durability translates to reduced maintenance costs and improved long-term reliability for electronic systems operating in demanding conditions.

Maximizing the effectiveness of High Thermal Sinkpad Copper Core requires careful design considerations that balance thermal efficiency, electrical performance, and manufacturability.

Designers prioritize creating unobstructed thermal pathways from heat-generating components to the copper core. This involves strategically placing the sinkpad’s convex copper pedestal directly beneath critical components, ensuring intimate contact for efficient heat transfer. The size and shape of the copper core are tailored to the application’s thermal requirements, with larger surface areas allocated for high-power devices to enhance heat spreading. Additionally, integrating thermal interface materials (TIMs) between the component and copper core fills micro-irregularities, further improving heat transfer efficiency without compromising electrical isolation.

While pure copper is the standard for High Thermal Sinkpad Copper Core, material selection must align with specific application needs. High-purity copper is preferred for maximum thermal conductivity, as impurities can significantly reduce heat transfer capabilities. For applications requiring a balance of thermal performance and cost efficiency, copper-graphene composites are emerging as a viable alternative, leveraging graphene’s enhanced thermal properties to boost heat dissipation while maintaining copper’s structural advantages. The dielectric layer material is also critical, with high-temperature-resistant polymers selected to ensure electrical insulation and prevent delamination under elevated operating temperatures.

High Thermal Sinkpad Copper Core is often paired with external cooling solutions to further enhance thermal performance. The copper core’s flat, uniform surface provides an ideal interface for heat sinks, fans, or liquid cooling systems, enabling efficient heat transfer to the ambient environment. In compact designs where space is limited, the copper core itself can act as a primary heat dissipator, eliminating the need for additional cooling components and simplifying system integration. This flexibility makes High Thermal Sinkpad Copper Core suitable for a wide range of applications, from small-form-factor consumer electronics to large-scale industrial systems.

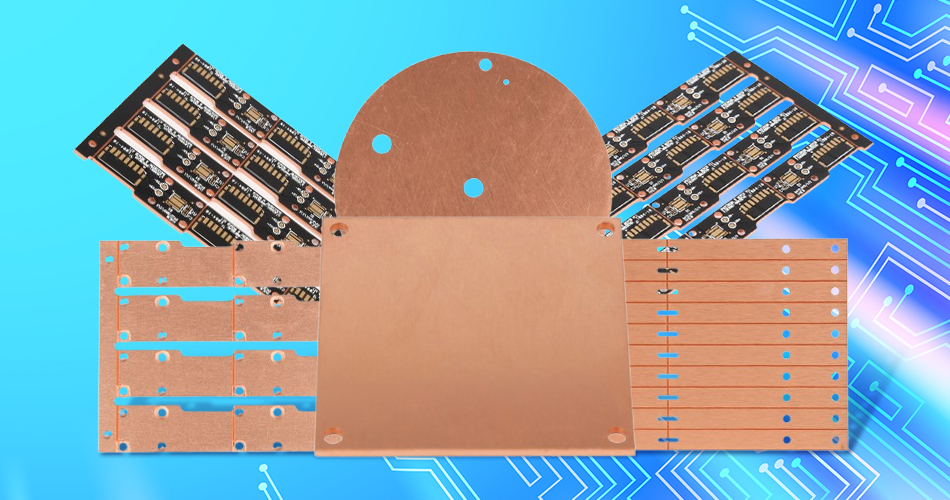

Producing High Thermal Sinkpad Copper Core requires specialized manufacturing processes to address the unique properties of copper and ensure precision and reliability.

Manufacturing High Thermal Sinkpad Copper Core demands tight tolerances to achieve the required thermal and electrical performance. Key processes include precision etching to create the thermoelectric separation structure and controlled bonding of the dielectric layer to the copper core. Drilling and routing operations must be executed with extreme accuracy to avoid damaging the copper core or compromising thermal pathways. Advanced techniques such as laser drilling are increasingly used to achieve micro-scale features, ensuring optimal component placement and thermal contact. These precision processes require specialized equipment and skilled labor, distinguishing High Thermal Sinkpad Copper Core production from standard PCB manufacturing.

Copper’s high density and conductivity present unique manufacturing challenges, including potential warping during high-temperature processes and difficulty in achieving uniform dielectric bonding. To address these issues, manufacturers employ advanced temperature control during curing and bonding stages, preventing thermal stress and ensuring structural integrity. Additionally, surface treatment technologies such as immersion gold or ENEPIG coatings are applied to enhance solderability and corrosion resistance, extending the product’s operational lifespan. Quality control measures, including X-ray inspection and thermal performance testing, are critical to verifying the integrity of the thermal path and ensuring compliance with application requirements.

High Thermal Sinkpad Copper Core is gaining traction across diverse industries where thermal management is a critical success factor.

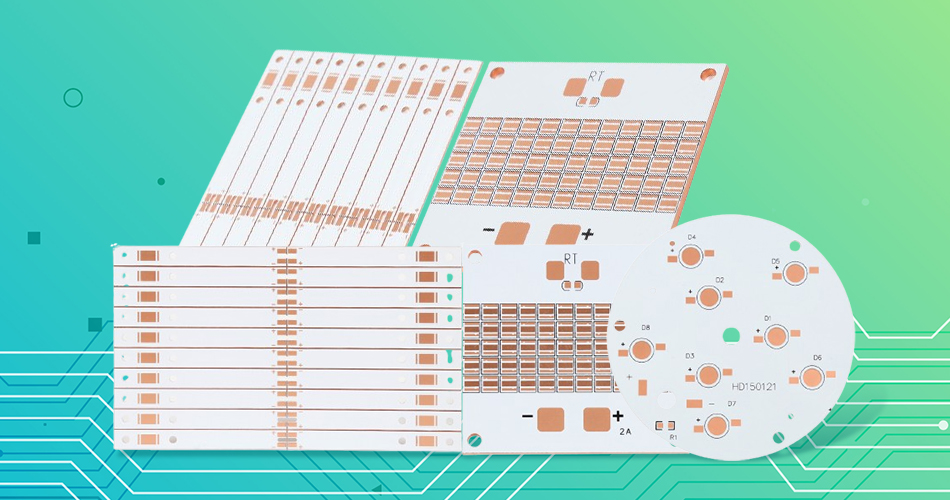

The lighting industry relies heavily on High Thermal Sinkpad Copper Core for high-power LEDs, including stadium floodlights, automotive headlights, and industrial lighting. The technology’s ability to dissipate heat efficiently minimizes lumens depreciation, extending LED lifespans and maintaining brightness over time. For COB (Chip-on-Board) LED packages, the direct thermal path design ensures uniform heat distribution across the entire chip array, preventing premature failure and ensuring consistent performance.

Industrial power converters, inverters, and motor drives operate at high power levels, generating significant heat that must be managed effectively. High Thermal Sinkpad Copper Core provides the thermal conductivity required to cool power semiconductors such as IGBTs and diodes, ensuring reliable operation in harsh industrial environments. The technology’s mechanical durability also makes it suitable for vibration-prone applications, reducing downtime and maintenance costs.

In automotive applications, High Thermal Sinkpad Copper Core is used in electric vehicle (EV) powertrains, battery management systems (BMS), and advanced driver-assistance systems (ADAS). The technology’s ability to withstand extreme temperature fluctuations and vibration makes it ideal for under-hood environments, where components are exposed to harsh conditions. By efficiently cooling power electronics, High Thermal Sinkpad Copper Core contributes to improved EV efficiency and extended battery range.

The evolution of High Thermal Sinkpad Copper Core is shaped by ongoing advancements in materials science and manufacturing technology, with several key trends emerging.

The development of copper-based composite materials is enhancing the performance of High Thermal Sinkpad Copper Core. Graphene-enhanced copper cores, for example, offer even higher thermal conductivity while reducing weight, making them suitable for weight-sensitive applications such as aerospace and portable electronics. Other composites, such as copper-tungsten, combine copper’s thermal conductivity with tungsten’s high-temperature stability, expanding the technology’s applicability to extreme environments.

As electronic devices continue to shrink, High Thermal Sinkpad Copper Core is evolving to support higher component densities. Advanced manufacturing techniques enable smaller, more precise sinkpad structures, allowing for the integration of multiple high-power components on a single board without compromising thermal performance. This miniaturization trend is critical for applications such as wearable electronics and compact industrial sensors, where space is at a premium.

The industry is increasingly focusing on sustainable manufacturing processes for High Thermal Sinkpad Copper Core. This includes the use of recycled copper materials, eco-friendly dielectric layers, and energy-efficient manufacturing techniques to reduce environmental impact. Additionally, the thermoelectric separation design facilitates easier recycling of components and materials at the end of the product’s lifecycle, supporting circular economy principles.

High Thermal Sinkpad Copper Core represents a pivotal advancement in thermal management for high-power electronic systems, offering unmatched heat dissipation capabilities, mechanical durability, and design flexibility. By leveraging copper’s exceptional thermal conductivity and integrating a thermoelectric separation structure, this technology addresses the critical challenge of managing increasing power densities in compact devices. From high-power lighting to electric vehicles and industrial systems, High Thermal Sinkpad Copper Core is enabling the next generation of reliable, high-performance electronics. As materials and manufacturing techniques continue to advance, this solution will play an increasingly vital role in powering the technologies of the future, ensuring efficient thermal management without compromising performance or reliability.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB