-

- PCB TYPE

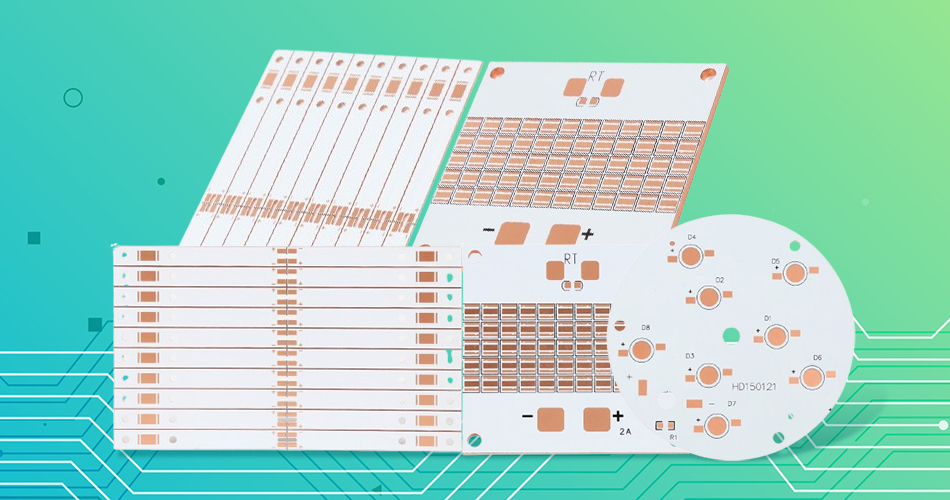

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 18. 2025, 13:59:11

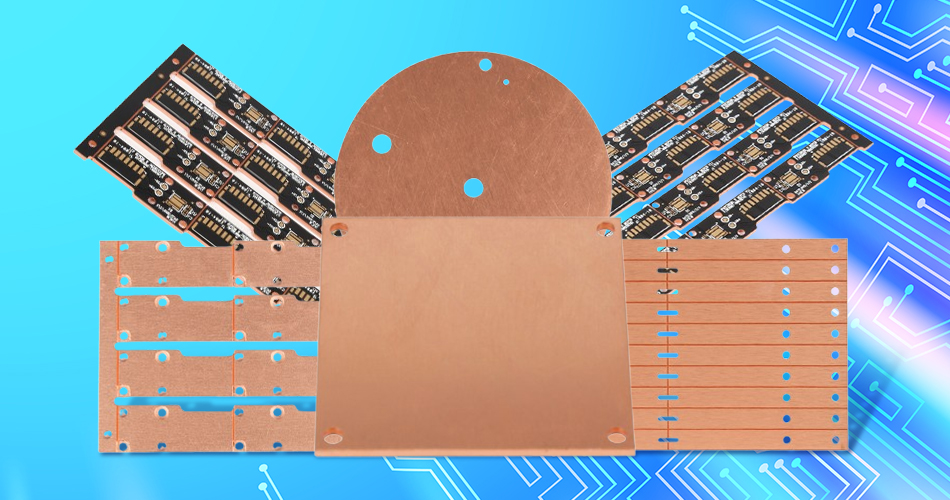

Sinkpad PCB has solidified its position as a cornerstone technology in modern electronics, bridging the gap between thermal management efficiency and structural reliability amid soaring demand for high-performance devices. As global electronics trends pivot toward AI-driven systems, electric mobility, and compact smart devices, sinkpad PCBs have evolved from specialized components to mainstream solutions, enabling the seamless operation of power-intensive applications. Unlike standard PCBs, sinkpad designs integrate dedicated metal layers that enhance heat dissipation while preserving signal integrity, addressing a critical pain point for engineers navigating miniaturization and power density challenges. This article explores the current market landscape, sustainable technology breakthroughs, key application drivers, and industry evolution shaping the future of sinkpad PCB.

The global sinkpad PCB market is experiencing robust expansion, fueled by converging demand from high-value electronics sectors and ongoing technological advancements.

Key end markets—including AI servers, NEV, and 5G infrastructure—are driving unprecedented growth for sinkpad PCBs. The explosive rise in AI server shipments, which surged by 68% year-over-year in 2025, has created substantial demand for sinkpad solutions capable of managing the thermal loads of high-density compute chips. Similarly, NEVs have emerged as a major growth engine, with PCB penetration exceeding 75% and per-unit value more than tripling compared to traditional vehicles, as sinkpad PCBs enable reliable operation of power electronics and battery management systems. 5G base station deployments further amplify demand, with next-generation stations requiring 40% more high-frequency PCB content than previous iterations, underscoring sinkpad technology’s role in supporting network densification.

The sinkpad PCB sector is witnessing a shift in global competitive dynamics, with Chinese manufacturers emerging as dominant players. By 2025, Chinese firms accounted for over 40% of the global market share, leveraging industrial chain clustering and cost optimization capabilities to capture high-value orders. The market is also experiencing consolidation, as top 10 manufacturers increased their combined market share to 52%, driven by investments in advanced manufacturing and technical expertise. This concentration reflects the growing importance of economies of scale and technological specialization in meeting the stringent requirements of high-performance electronics.

Sustainability has become a defining trend in sinkpad PCB development, with industry players prioritizing eco-friendly materials and processes to reduce environmental impact.

Recyclable Material Breakthroughs

Traditional PCBs pose significant environmental challenges due to non-recyclable plastic substrates and hazardous manufacturing byproducts. Recent innovations have addressed this issue, such as the development of vitrimer-based sinkpad PCBs that enable efficient material recovery. These advanced substrates can be dissolved in low-boiling-point solvents, allowing for the extraction of 98% of the polymer matrix, 100% of glass fibers, and 91% of processing solvents—all while preserving electronic components for reuse. Compared to conventional designs, these recyclable sinkpad PCBs reduce greenhouse gas emissions by 48% and carcinogenic pollutant release by 81%, aligning with global circular economy goals.

Manufacturing processes for sinkpad PCBs are also evolving toward sustainability, with technologies like liquid metal printing gaining traction. This innovative approach streamlines production from over a dozen steps to just two, eliminating multiple energy-intensive processes while reducing waste. Liquid metal inks, which exhibit high conductivity and strong adhesion, enable the rapid fabrication of sinkpad structures on a variety of substrates—including flexible and biodegradable materials—without compromising performance. These advancements not only lower environmental impact but also enhance production agility, supporting small-batch and customized sinkpad PCB requirements.

Sinkpad PCBs deliver tailored solutions across diverse high-stakes sectors, addressing unique operational challenges in each domain.

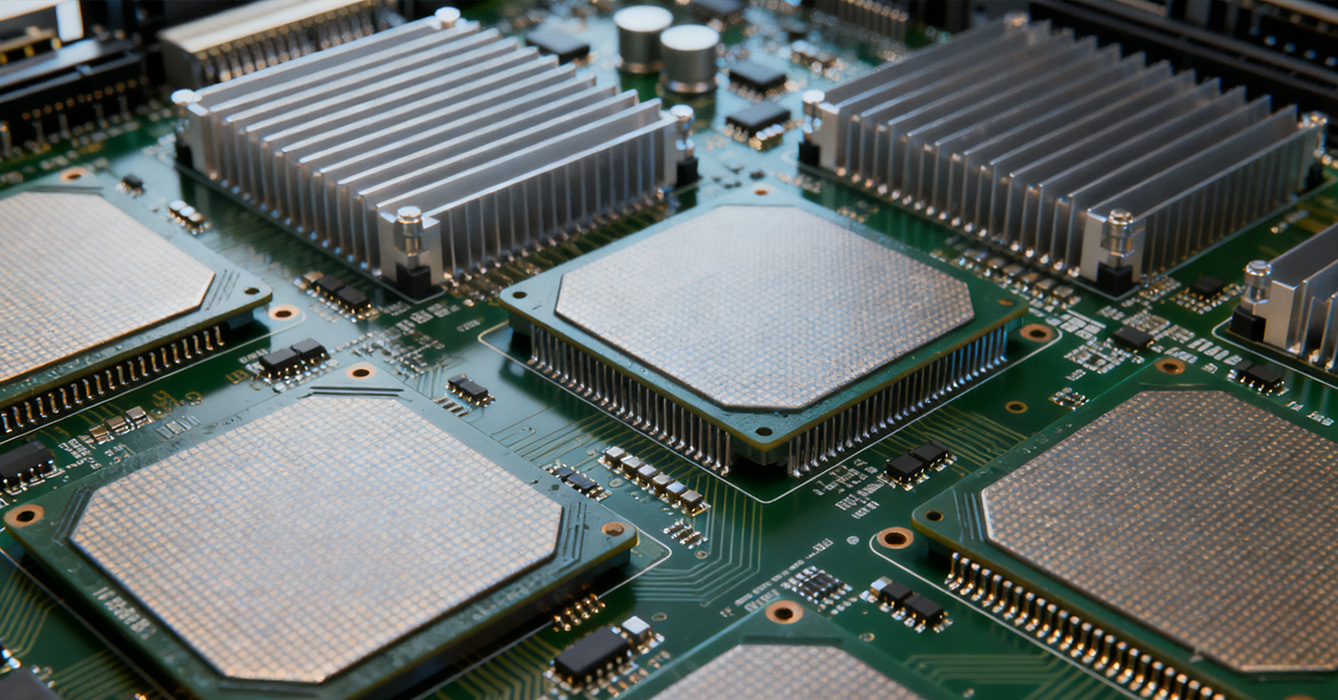

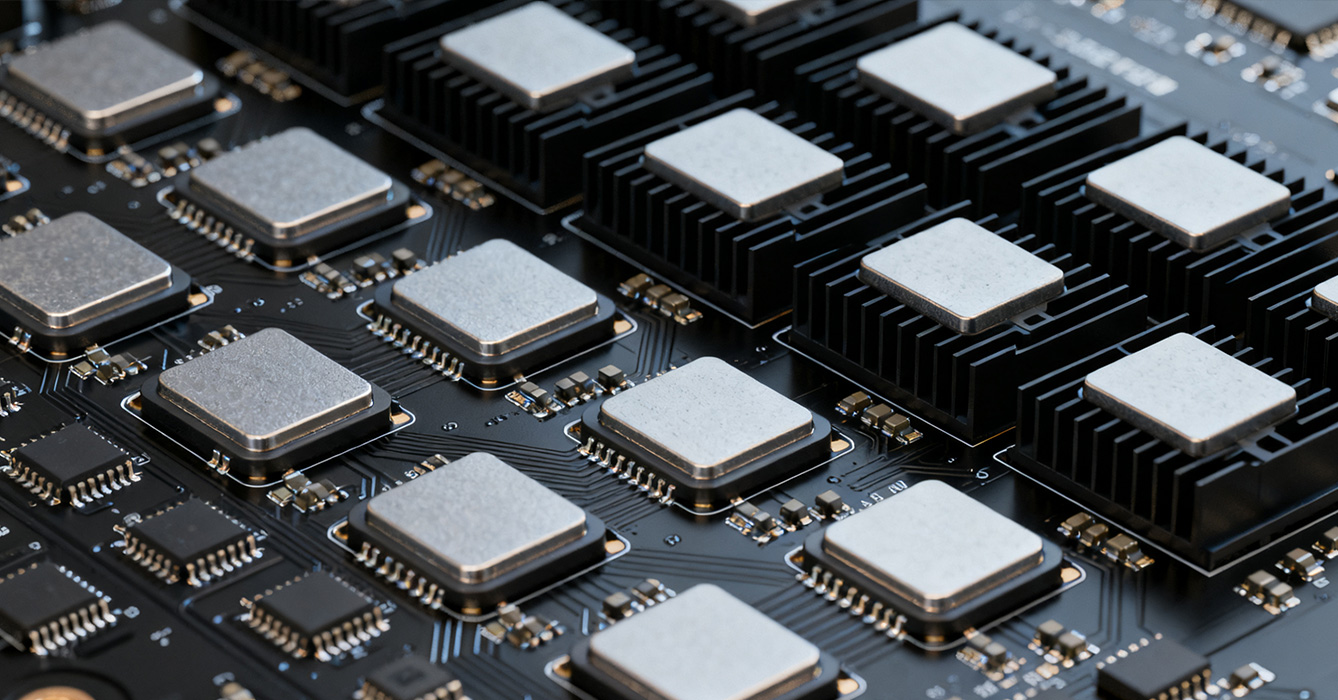

In AI and HPC environments, sinkpad PCBs play a mission-critical role in managing thermal density, which remains a primary bottleneck for compute performance. By integrating high-thermal-conductivity metal cores with optimized routing, sinkpad designs dissipate heat from neural processing units (NPUs) and graphics processing units (GPUs), preventing thermal throttling and extending component lifespan. This capability is particularly vital for data centers, where dense server racks generate concentrated heat loads, and reliability directly impacts operational uptime and energy efficiency.

Automotive applications demand sinkpad PCBs that balance thermal management, mechanical durability, and space efficiency. In electric vehicle powertrains, sinkpad technology cools power semiconductors and inverters, ensuring stable operation under extreme temperature fluctuations (-40°C to 125°C) and vibration. The compact design of sinkpad PCBs also supports vehicle lightweighting initiatives, a key priority for improving energy efficiency and extending driving range. As autonomous driving technology advances, sinkpad PCBs will further enable the integration of multiple sensors and processing units in space-constrained environments.

Industrial IoT (IIoT) devices operating in harsh environments rely on sinkpad PCBs for robust performance. These applications require resistance to dust, humidity, and temperature cycling, while maintaining efficient heat dissipation for edge computing components. Sinkpad designs provide the necessary thermal stability for real-time data processing in smart factories, enabling predictive maintenance and process optimization. The mechanical ruggedness of sinkpad PCBs also ensures reliability in vibration-prone industrial settings, reducing downtime and maintenance costs.

The evolution of sinkpad PCB technology will be shaped by three key trends: advanced material integration, design optimization, and expanding application scope. Graphene-enhanced substrates and composite metal cores will further improve thermal conductivity while reducing weight, enabling even more compact and efficient designs. AI-driven design tools will automate the optimization of sinkpad layouts, balancing thermal performance, signal integrity, and material usage to reduce development cycles. As applications expand into 6G communications, quantum computing, and wearable medical devices, sinkpad PCBs will continue to evolve, addressing increasingly complex thermal and mechanical challenges.

Sinkpad PCB technology stands at the intersection of performance, sustainability, and market demand, enabling the next generation of high-power, compact electronic systems. Driven by AI, automotive, and 5G applications, the market is experiencing robust growth while undergoing a sustainability transformation—powered by recyclable materials and eco-efficient manufacturing. As global competition intensifies and technological innovations accelerate, sinkpad PCBs will remain indispensable for engineers seeking to resolve thermal-electrical tradeoffs in cutting-edge electronics. The ongoing evolution of materials, processes, and design methodologies ensures that sinkpad PCB technology will continue to adapt to emerging challenges, solidifying its role as a critical enabler of technological progress in the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB