-

- PCB TYPE

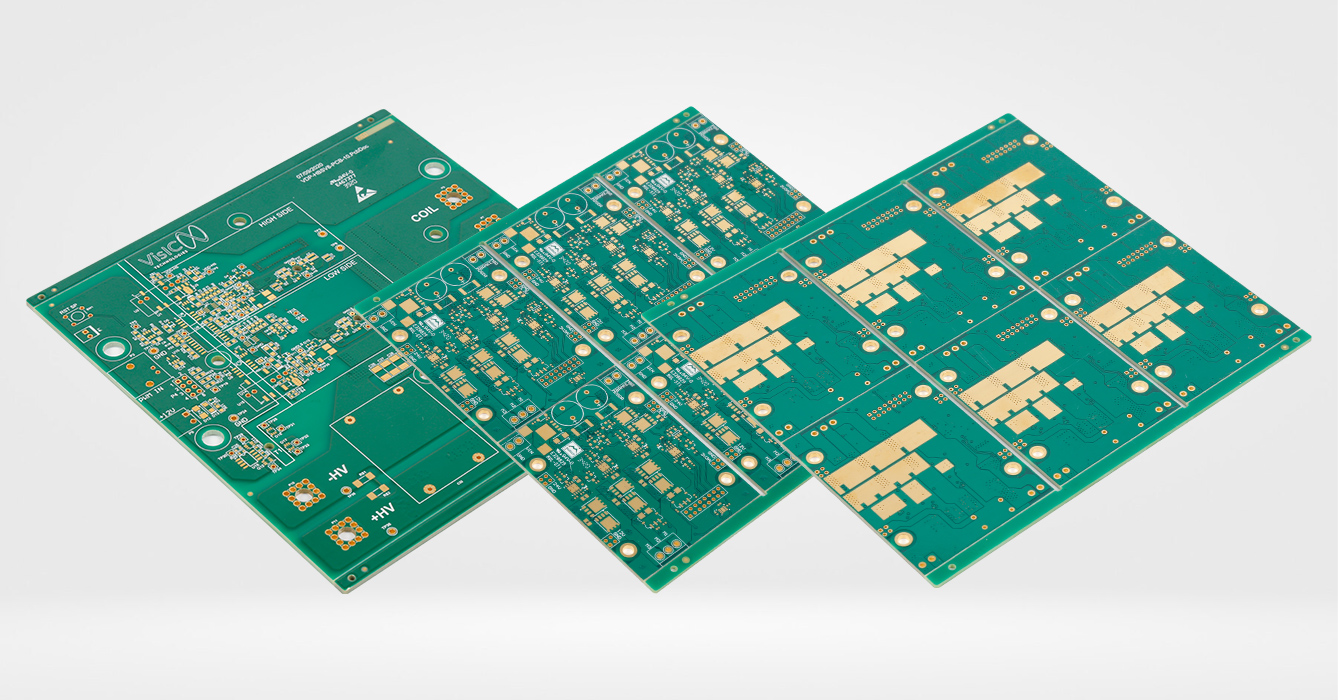

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 06. 2025, 09:21:26

In the realm of high-performance electronics, where operational temperatures often exceed 120°C, High Tg180 FR4 PCB Design has emerged as a critical solution for ensuring long-term reliability. Tg, or glass transition temperature, refers to the point at which epoxy resin shifts from a rigid, glassy state to a rubbery, flexible one—a transition that can compromise dimensional stability, signal integrity, and mechanical strength in PCBs. High Tg180 FR4, with a Tg of 180°C, is engineered to delay this transition, making it ideal for applications subjected to sustained high heat, such as automotive underhood systems, industrial ovens, and aerospace electronics. This article explores the nuances of High Tg180 FR4 PCB Design, from material selection and layout considerations to manufacturing synergies and application-specific optimizations, highlighting how intentional design choices leverage the material’s thermal resilience to prevent failures in extreme environments.

High Tg180 FR4 is a specialized laminate variant where the epoxy resin system is formulated to achieve a glass transition temperature of 180°C—50–60°C higher than standard FR4 (Tg 130–140°C). This elevated Tg is not merely a material property but a design enabler: it extends the range of temperatures where the PCB retains its rigid structure, mechanical strength, and electrical performance. For designers, this means greater flexibility to operate in environments with ambient temperatures up to 150°C, transient thermal spikes (e.g., during soldering or component operation), and prolonged exposure to heat without risking delamination, via cracking, or signal degradation.

Unlike mid-Tg FR4 (Tg 150–160°C), High Tg180 FR4 achieves its thermal resilience through a combination of advanced resin chemistry (e.g., novolac epoxy blends with dicyandiamide hardeners) and optimized fiber reinforcement (tighter E-glass weaves). These modifications create a denser cross-linked polymer network that resists softening at high temperatures, a characteristic that directly influences key design decisions—from layer stackup and trace routing to component placement and thermal management.

The unique properties of High Tg180 FR4 dictate specific design strategies, distinguishing it from standard FR4 or lower Tg variants:

Thermal Stability: With a Tg of 180°C, the material remains rigid in environments where standard FR4 would soften. This stability reduces dimensional change (≤0.1% at 150°C) compared to standard FR4 (0.2–0.3% at the same temperature), minimizing stress on solder joints and vias—a critical consideration for high-reliability designs.

Mechanical Strength Retention: At 150°C, High Tg180 FR4 retains 70–75% of its room-temperature flexural strength (≥500 MPa), whereas standard FR4 retains only 50–60%. This strength ensures the PCB withstands vibration and mechanical loads even in high-heat conditions, guiding designers to use larger, heavier components without risking board warpage.

Electrical Performance at Elevated Temperatures: The dielectric constant (Dk) of High Tg180 FR4 remains stable (4.4–4.8 at 1 MHz) across 25°C to 150°C, with a maximum variation of 3%—half that of standard FR4. This stability is vital for maintaining impedance control in high-speed designs (e.g., 10 Gbps Ethernet) operating in hot environments, where signal reflection and loss could otherwise compromise functionality.

Chemical Resistance: The dense resin matrix of High Tg180 FR4 resists degradation from industrial fluids, automotive oils, and cleaning agents—an attribute that influences design choices such as conformal coating requirements (often reduced or eliminated) and component encapsulation strategies.

Designing with High Tg180 FR4 requires intentionality to leverage its thermal resilience while addressing its unique characteristics:

Layer Stackup Optimization: High Tg180 FR4’s rigidity allows for thicker core materials (≥0.2 mm) and more layers (up to 20+) without sacrificing flatness—a benefit for complex designs requiring multiple power and ground planes. Designers often incorporate additional ground planes (every 2–3 signal layers) to enhance heat spreading and reduce EMI, which becomes more pronounced at high temperatures.

Trace Routing and Impedance Control: The material’s stable Dk at high temperatures enables tighter impedance tolerances (±5% vs. ±10% for standard FR4). For high-frequency signals (5–10 GHz), designers use controlled-impedance traces with width/thickness ratios optimized for High Tg180’s Dk, reducing the need for post-manufacturing tuning. Trace spacing is also increased by 10–15% compared to standard FR4 designs to minimize crosstalk, which intensifies with temperature.

Component Placement: Heat-generating components (e.g., power MOSFETs, voltage regulators) are strategically placed near board edges or thermal vias to exploit High Tg180’s improved thermal conductivity (0.3–0.4 W/m·K). Unlike standard FR4, where clustering hot components risks localized softening, High Tg180’s stability allows for denser placement, reducing board size in space-constrained applications like automotive ECUs.

Via Design: Z-axis thermal expansion is a critical concern in high-temperature cycling. High Tg180 FR4’s lower z-axis CTE (50–70 ppm/°C below Tg) allows for smaller vias (≤0.3 mm) with tighter pitch (≤0.8 mm) compared to standard FR4. Designers often specify filled and capped vias to enhance thermal conductivity and prevent resin outgassing during soldering, a common issue in high-Tg materials due to their longer curing cycles.

While High Tg180 FR4 inherently resists heat-induced degradation, effective thermal management design ensures components operate within their safe temperature ranges:

Thermal Vias: Placing arrays of thermal vias (0.2–0.3 mm diameter) beneath high-power components creates pathways for heat to dissipate from the top layer to internal ground planes. High Tg180’s compatibility with conductive epoxy filling enhances this transfer, with thermal resistance reduced by 20–30% compared to standard FR4 designs.

Copper Weight Selection: Thicker copper (2–4 oz) is used for power traces and ground planes, leveraging its higher thermal conductivity to spread heat. High Tg180’s stronger resin-copper adhesion (peel strength ≥1.1 N/mm) prevents trace lifting, even with repeated thermal cycling—allowing designers to use heavier copper without reliability tradeoffs.

Heat Sinks and Thermal Pads: Mechanical attachment of heat sinks directly to the PCB is simplified by High Tg180’s rigidity, which resists warpage under the pressure of mounting hardware. Thermal interface materials (TIMs) with high-temperature ratings (≥200°C) are paired with the laminate to ensure efficient heat transfer, as standard TIMs may degrade at the temperatures High Tg180 PCBs endure.

Layout for Convection: Designs incorporate strategic gaps between components and routed air channels to facilitate natural convection. High Tg180’s stability allows for these gaps to be narrower (≤2 mm) than in standard FR4 designs, maximizing component density without impairing cooling.

Design choices must align with High Tg180’s unique manufacturing requirements to avoid defects:

Lamination Parameters: High Tg180 requires higher cure temperatures (190–210°C) and longer press cycles (120–150 minutes) than standard FR4 to fully cross-link its resin. Designers specify thicker prepreg layers (≥0.05 mm) to ensure sufficient resin flow during lamination, preventing voids in high-density areas with fine-pitch components.

Soldering Processes: Lead-free soldering with peak temperatures up to 260°C is compatible with High Tg180 FR4, but designers must specify longer preheat profiles (60–90 seconds at 150–180°C) to reduce thermal shock. This slower ramp-up minimizes stress between the laminate and components, a critical consideration for BGA or CSP devices with large thermal masses.

Drilling and Routing: The dense resin matrix of High Tg180 FR4 requires carbide drill bits with enhanced wear resistance, operated at lower speeds (20,000–40,000 RPM) than standard FR4. Designers avoid tight-radius corners in routing (minimum radius ≥0.5 mm) to prevent laminate chipping, which is more common in high-Tg materials due to their increased brittleness.

Surface Finish Compatibility: ENIG (Electroless Nickel Immersion Gold) is preferred over HASL for High Tg180 PCBs, as its flat profile and high-temperature oxidation resistance ensure reliable solder joints after repeated thermal cycles. Designers specify thicker nickel layers (≥5 μm) to enhance adhesion, particularly in automotive applications with strict reliability requirements.

High Tg180 FR4 PCB designs must adhere to stringent standards to validate their performance in extreme environments:

IPC-4101/41: Classifies High Tg180 FR4 under Type 3 (ultra-high performance), requiring Tg ≥180°C and compliance with thermal cycling tests (-55°C to +125°C for 28 cycles) without delamination.

AEC-Q200 Grade 0: For automotive applications, designs must meet this standard, which mandates operation from -40°C to +150°C for 1,000 hours. High Tg180 FR4’s stability ensures compliance, particularly in tests measuring solder joint integrity and via reliability.

UL 94 V-0: High Tg180 formulations retain flame retardancy even after thermal aging, a requirement for industrial and aerospace applications. Designers verify this through vertical burn tests on samples exposed to 150°C for 1,000 hours.

MIL-PRF-31032: For military and aerospace designs, High Tg180 PCBs must pass thermal vacuum testing and radiation exposure (≥100 kRad), with designers incorporating additional ground planes to enhance shielding against EMI, which becomes more problematic at high temperatures.

Rigorous testing ensures High Tg180 designs meet their performance claims:

Thermal Cycling and Shock: PCBs are subjected to 1,000 cycles of -55°C to +150°C, with post-test inspection using X-ray and AOI to detect via cracks or delamination. High Tg180 designs typically exhibit <5% failure rates, compared to 15–20% for standard FR4 in the same test.

High-Temperature Operating Life (HTOL): Components mounted on High Tg180 PCBs undergo 1,000 hours of operation at 150°C, with electrical performance monitored to ensure no degradation. This validates the design’s ability to withstand sustained heat in end-use environments.

Mechanical Stress Testing: Vibration testing (20–2,000 Hz, 20 g RMS) combined with elevated temperatures (125°C) simulates automotive or aerospace conditions, ensuring the PCB retains structural integrity. High Tg180’s rigidity reduces resonance-related failures compared to standard FR4.

Signal Integrity at High Temperatures: Network analyzers measure insertion loss and return loss at 150°C, confirming that High Tg180’s stable Dk maintains signal integrity in high-speed designs. This testing is critical for 5G base station PCBs operating in outdoor enclosures with extreme temperature swings.

High Tg180 FR4 PCB Design is indispensable in applications where sustained high temperatures are unavoidable:

Automotive Underhood Electronics: Engine control units (ECUs), transmission controllers, and battery management systems (BMS) in electric vehicles (EVs) operate at 120–150°C. High Tg180 designs prevent solder joint fatigue and via cracking, extending service life beyond 150,000 miles.

Industrial Furnace Controls: PCBs in furnace temperature regulators and sensor interfaces endure ambient temperatures up to 160°C. High Tg180’s stability ensures accurate signal processing, preventing costly process deviations in manufacturing.

Aerospace Avionics: In-flight engine monitoring systems and hydraulic control PCBs experience temperature swings from -55°C (altitude) to +100°C (ground operation). High Tg180 designs resist delamination, a critical failure mode in pressurized cabin environments.

Oil and Gas Downhole Tools: PCBs in logging tools operate at 150–170°C in deep wells. High Tg180’s chemical resistance and thermal stability ensure reliable data transmission, even in contact with harsh drilling fluids.

While High Tg180 FR4 offers significant advantages, designers must navigate key limitations:

Cost: High Tg180 PCBs are 30–50% more expensive than standard FR4 due to specialized resins and extended manufacturing cycles. This limits their use to high-reliability applications where failure costs outweigh material expenses.

Brittleness: The dense resin matrix increases brittleness, making the PCB more prone to cracking during handling. Designers mitigate this by specifying rounded board edges, avoiding thin unsupported sections, and using reinforced mounting holes.

Thermal Conductivity: While better than standard FR4, High Tg180’s thermal conductivity (0.3–0.4 W/m·K) is still lower than metal-core PCBs (1–2 W/m·K). For ultra-high-power applications (e.g., 200W+ inverters), designers combine High Tg180 with thermal vias and heat sinks, or specify hybrid designs with metal cores.

Advancements in material science and design tools continue to expand the capabilities of High Tg180 FR4:

Nano-Reinforced Resins: Adding graphene or carbon nanotubes to the epoxy matrix increases thermal conductivity (up to 0.6 W/m·K) while maintaining Tg 180°C, reducing the need for thermal vias in mid-power designs.

AI-Driven Thermal Simulation: Machine learning algorithms optimize component placement and via arrays in High Tg180 designs, predicting hotspots with 90% accuracy and reducing prototyping cycles by 30%.

Sustainable Formulations: Bio-based novolac epoxies derived from plant oils are being integrated into High Tg180 FR4, reducing carbon footprints without sacrificing thermal performance—aligning with EU and US sustainability mandates.

3D-Printed High Tg180 Structures: Experimental additive manufacturing processes use high-Tg epoxy inks to print complex geometries (e.g., integrated heat sinks), enabling designs that were impractical with traditional lamination.

High Tg180 FR4 PCB Design represents a critical intersection of material science and engineering intent, enabling electronics to thrive in environments once considered too harsh for standard FR4. By leveraging the material’s elevated Tg, stable electrical properties, and mechanical resilience, designers can create PCBs that withstand sustained high temperatures, thermal cycling, and chemical exposure—key requirements for automotive, industrial, and aerospace applications. While cost and brittleness pose challenges, the long-term reliability benefits make High Tg180 FR4 an indispensable choice for mission-critical systems. As material innovations and design tools advance, High Tg180 FR4 PCB Design will continue to push the boundaries of what’s possible in extreme thermal environments, ensuring electronics keep pace with the demands of modern technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB