-

- PCB TYPE

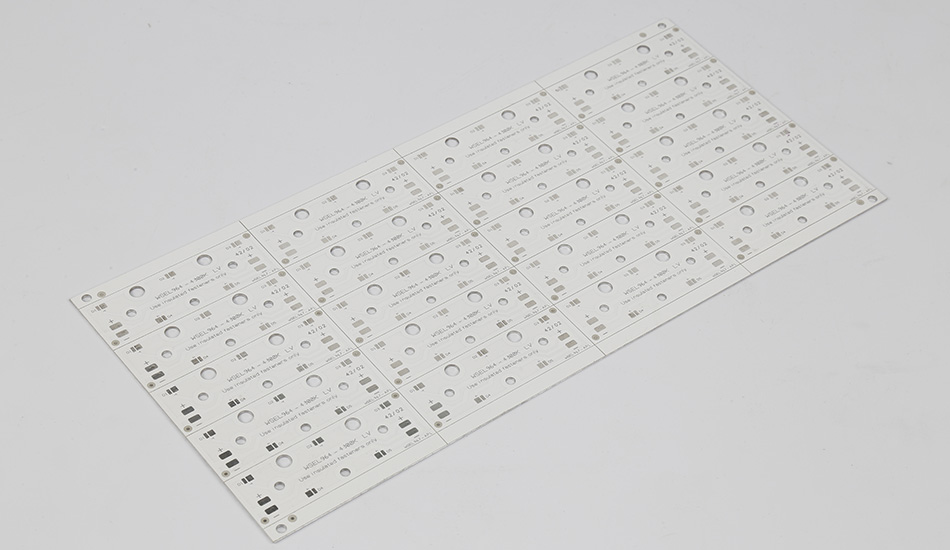

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 10. 2025, 10:20:13

In the dynamic landscape of modern lighting technology, LED lighting has emerged as a dominant force, offering energy - efficiency, long lifespan, and environmental friendliness. At the heart of high - performance LED lighting systems lies the Metal Core Printed Circuit Board (PCB). These specialized PCBs are engineered to address the unique challenges associated with LED operation, particularly heat management, ensuring optimal performance and reliability. This article delves into the world of LED Lighting Metal Core PCBs, exploring their structure, benefits, applications, design considerations, manufacturing processes, and future trends.

What is an LED Lighting Metal Core PCB?

An LED Lighting Metal Core PCB is a type of printed circuit board designed specifically for LED lighting applications. Unlike traditional PCBs with organic substrates, it incorporates a metal core, typically made of aluminum or copper. This metal core serves as both a mechanical support and an efficient heat - dissipation medium. On top of the metal core, there is an insulating layer that provides electrical isolation while facilitating heat transfer. The copper layer, where the LEDs and other components are mounted, is situated above the insulating layer, forming the electrical circuit for the lighting system. This unique structure enables the PCB to handle the electrical requirements of LEDs while effectively managing the significant heat generated during their operation.

Structure and Components

Metal Core:

Aluminum vs. Copper: Aluminum is a popular choice for the metal core due to its cost - effectiveness, lightweight nature, and adequate thermal conductivity. It can efficiently spread heat across its surface, helping to maintain lower operating temperatures for LEDs. Copper, on the other hand, offers superior thermal conductivity, making it ideal for high - power LED applications where maximum heat dissipation is crucial. However, copper is more expensive, which may influence the choice depending on the project's budget and thermal requirements.

Heat - Sinking Function: The metal core acts as a large heat sink, absorbing the heat produced by the LEDs. Heat is transferred from the LEDs through the copper traces and the insulating layer to the metal core, which then dissipates the heat into the surrounding environment. This process is essential for preventing overheating, which can lead to a decrease in LED performance, color shift, and reduced lifespan.

Insulating Layer: Positioned between the metal core and the copper layer, the insulating layer is a thermally conductive dielectric material. Its primary function is to electrically isolate the metal core from the electrical components on the PCB, preventing short - circuits. At the same time, it allows heat to pass through, albeit at a controlled rate. The thickness and material properties of the insulating layer are carefully selected to balance electrical insulation and thermal conductivity, ensuring optimal performance.

Copper Layer: This is the layer where the LEDs, drivers, and other electronic components are mounted. The copper layer contains the conductive traces that form the electrical circuit, providing power to the LEDs and enabling signal transmission. The design of the copper traces must consider factors such as current - carrying capacity, electrical resistance, and signal integrity to ensure reliable operation of the LED lighting system.

Advantages

Efficient Thermal Management: The most significant advantage of LED Lighting Metal Core PCBs is their ability to manage heat effectively. LEDs generate a substantial amount of heat during operation, and if not dissipated quickly, it can cause a decline in light output and a reduction in lifespan. The metal core PCB's design allows for rapid heat transfer away from the LEDs, maintaining them at an optimal operating temperature. This not only ensures consistent light quality but also extends the overall lifespan of the LED lighting system.

Mechanical Robustness: The metal core provides enhanced mechanical strength to the PCB. LED lighting fixtures may be subject to various mechanical stresses, such as vibrations, shocks, and physical impacts during installation or operation. Metal core PCBs can withstand these stresses better than traditional PCBs, reducing the risk of component damage or PCB failure. This makes them suitable for a wide range of applications, including outdoor and industrial lighting, where reliability is crucial.

Cost - Effectiveness in the Long Run: Although LED Lighting Metal Core PCBs may have a higher upfront cost compared to some traditional PCBs, they offer long - term cost savings. Their efficient thermal management reduces the likelihood of LED failures due to overheating, minimizing the need for frequent component replacements. Additionally, the longer lifespan of the LEDs and the PCB itself means lower maintenance costs over time, resulting in a better return on investment.

Design Flexibility: These PCBs offer a high degree of design flexibility. They can be customized in terms of size, shape, and the layout of components to meet the specific requirements of different LED lighting applications. Whether it's a simple linear LED strip or a complex circular lighting fixture, the design of the metal core PCB can be tailored accordingly. This flexibility also allows for the integration of additional features, such as dimming capabilities or electromagnetic interference (EMI) shielding.

Applications

Outdoor Lighting: In outdoor applications such as streetlights, floodlights, and landscape lighting, LED Lighting Metal Core PCBs are widely used. Outdoor environments expose the PCBs to varying temperatures, humidity, and physical impacts. The thermal and mechanical properties of metal core PCBs ensure reliable operation, providing consistent and bright illumination even in harsh conditions. For example, in streetlights, the efficient heat dissipation helps maintain the performance of high - power LEDs over long periods, reducing maintenance frequency.

Automotive Lighting: In the automotive industry, LED lighting is becoming increasingly popular for headlights, taillights, and interior lighting. Metal core PCBs are essential in automotive lighting systems due to their ability to withstand the vibrations and temperature fluctuations inside a vehicle. They ensure the stable operation of LEDs, providing reliable lighting for safety - critical applications such as headlights.

Commercial and Industrial Lighting: In commercial buildings, offices, factories, and warehouses, LED Lighting Metal Core PCBs are used to create energy - efficient and bright lighting solutions. In industrial settings, where high - power LEDs are often required, the thermal management capabilities of these PCBs are crucial for preventing overheating and ensuring the longevity of the lighting system. In commercial spaces, the design flexibility allows for customized lighting designs to meet aesthetic and functional requirements.

Indoor Decorative Lighting: For indoor decorative lighting applications, such as accent lighting, cove lighting, and LED - illuminated signs, Metal Core PCBs enable the creation of unique and visually appealing lighting effects. Their ability to handle heat effectively and be customized in shape and size makes them suitable for integrating into various interior design concepts.

Design Considerations

Thermal Design:

Component Placement: When designing an LED Lighting Metal Core PCB, the placement of heat - generating components, especially LEDs, is crucial. LEDs should be positioned to maximize heat transfer to the metal core. Placing them directly over areas with good thermal contact and avoiding overcrowding can prevent hotspots. Thermal vias, which are small holes filled with a conductive material, can be used to enhance heat transfer between the copper layer and the metal core.

Insulating Layer Selection: The choice of insulating layer material and its thickness significantly impacts thermal performance. A material with higher thermal conductivity will facilitate better heat transfer but must also maintain sufficient electrical insulation. Designers need to carefully balance these factors based on the specific requirements of the LED lighting application.

Electrical Design:

Trace Width and Spacing: Determining the appropriate trace width and spacing on the copper layer is essential for electrical performance. Wider traces are needed for higher - current applications to minimize resistance and prevent overheating. Adequate spacing between traces is necessary to avoid electrical short - circuits, especially in high - voltage or high - frequency applications.

Power Distribution and Grounding: A well - designed power distribution network and grounding system are critical for the stable operation of the LED lighting system. The metal core can be used as a ground plane to improve grounding and reduce electromagnetic interference. Properly routing power traces and ensuring a low - impedance path for power delivery to the LEDs are also important considerations.

Mechanical Design:

Board Shape and Size: The shape and size of the PCB should be designed to fit the intended LED lighting fixture. Consideration should be given to factors such as the available space, the number and arrangement of LEDs, and the mechanical constraints of the installation. Unusual or complex board shapes may require additional design considerations to ensure mechanical integrity.

Mounting and Fastening: Ensuring secure mounting of the PCB is important to prevent vibrations and movement during operation, which can affect the performance of the LEDs. Designers need to consider appropriate mounting holes, brackets, or adhesive bonding methods based on the application requirements.

Manufacturing Processes

Layer Preparation: The manufacturing process starts with the preparation of the individual layers. The metal core is cleaned thoroughly to remove contaminants, and its surface may be treated to enhance adhesion. The insulating layer material, often in the form of a film or liquid resin, is prepared and applied to the metal core. The copper foil for the copper layer is also cleaned and treated to improve bonding with the insulating layer.

Lamination: The prepared layers, including the metal core, insulating layer, and copper foil, are laminated together using heat and pressure. The heat softens the insulating material, allowing it to flow and bond the layers, while the pressure ensures a uniform and strong laminate structure.

Circuit Imaging and Etching: Photolithography is used to transfer the circuit design onto the copper layer. A photosensitive resist is applied, exposed to light through a mask, and developed. The unprotected copper is then etched away, leaving the desired conductive traces.

Drilling and Plating: Holes are drilled for component leads, vias, and mounting. After drilling, the holes are plated with copper to create electrical connections between layers and enhance the mechanical strength of the holes.

Surface Finishing: The final step is surface finishing, which protects the copper traces from oxidation and provides a suitable surface for soldering components. Common surface finishes include hot - air solder leveling, electroless nickel immersion gold, and organic solderability preservative.

Challenges and Solutions

Cost: The cost of LED Lighting Metal Core PCBs can be a barrier for some applications. The use of specialized materials, such as the metal core and thermally conductive insulating layers, along with more complex manufacturing processes, contributes to the higher price. To address this, manufacturers are exploring cost - effective materials and optimizing manufacturing processes. For example, using alternative insulating materials with similar performance at a lower cost or improving production efficiency to reduce waste.

Thermal Expansion Mismatch: Different materials in the PCB, such as the metal core, insulating layer, and copper layer, have different coefficients of thermal expansion. This can lead to thermal stress and potential delamination or cracking during temperature changes. Solutions include selecting materials with compatible thermal expansion coefficients and using thermal interface materials to reduce stress and improve heat transfer.

Lighting Uniformity: Ensuring uniform light output across an LED array can be challenging. Variations in LED characteristics, heat distribution, and electrical connections can cause uneven lighting. To overcome this, careful selection and binning of LEDs, optimizing the PCB layout for even heat dissipation, and using diffusers or optical lenses can help achieve more uniform lighting.

Future Trends

Miniaturization and High - Density Integration: As the demand for smaller and more compact LED lighting products grows, there will be a trend towards miniaturizing Metal Core PCBs. This will involve developing thinner layers, smaller vias, and more precise component placement to enable higher - density integration of LEDs and other components.

Integration with Smart Technologies: LED Lighting Metal Core PCBs are likely to be integrated with smart lighting technologies, such as sensors, wireless communication modules, and microcontrollers. This will enable features like remote control, dimming, color - changing, and energy - consumption monitoring, making LED lighting systems more intelligent and energy - efficient.

Sustainable Manufacturing: With the increasing focus on environmental sustainability, there will be a push for more eco - friendly manufacturing processes for Metal Core PCBs. This may include using recycled materials, reducing waste during production, and implementing energy - efficient manufacturing techniques.

Conclusion

LED Lighting Metal Core PCBs are integral to the success of modern LED lighting systems. Their unique structure and properties make them well - equipped to handle the challenges of heat management, mechanical stress, and electrical performance. While they face certain challenges, ongoing advancements in design, manufacturing, and materials are continuously improving their capabilities. As the lighting industry continues to evolve, LED Lighting Metal Core PCBs will play an increasingly important role in shaping the future of energy - efficient, reliable, and intelligent lighting solutions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB