-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 08. 2025, 14:18:05

A leading China-based PCB supplier stands at the intersection of global electronics demand and advanced manufacturing capability, delivering critical circuit board solutions to industries spanning automotive, consumer electronics, renewable energy, and aerospace. Beyond manufacturing, these suppliers act as end-to-end partners, integrating design collaboration, supply chain resilience, and quality assurance to meet the complex needs of international clients. As the world’s largest producer of PCBs, China’s leading suppliers combine scale, technological innovation, and cost efficiency to drive the electronics ecosystem—enabling faster time-to-market, higher performance, and greater reliability for products worldwide.

In an era of supply chain volatility and rapid technological change, these suppliers distinguish themselves through their ability to adapt: investing in R&D, expanding global footprint, and adhering to stringent international standards. This article explores the defining characteristics of leading China-based PCB suppliers, their industry-specific solutions, global market strategies, sustainability initiatives, and key factors for businesses seeking to partner with them.

Leading China-based PCB suppliers leverage a unique combination of capabilities that position them as preferred partners for global electronics brands, blending technical expertise with operational excellence.

Vertical Integration: Many top suppliers control key stages of the production chain, from raw material sourcing (copper foil, substrates) to final assembly, reducing dependency on external vendors and mitigating supply disruptions. This integration enables faster response to material shortages or design changes.

Scalable Production Networks: With multiple manufacturing facilities across China and increasingly overseas, these suppliers can scale production from prototypes to millions of units, supported by centralized planning systems that optimize resource allocation and reduce lead times.

Diversified Sourcing Strategies: To counter geopolitical risks, leading suppliers maintain relationships with alternative material providers globally, ensuring continuity even amid regional disruptions. This agility was critical during recent global chip shortages, where suppliers reconfigured production to prioritize high-priority orders.

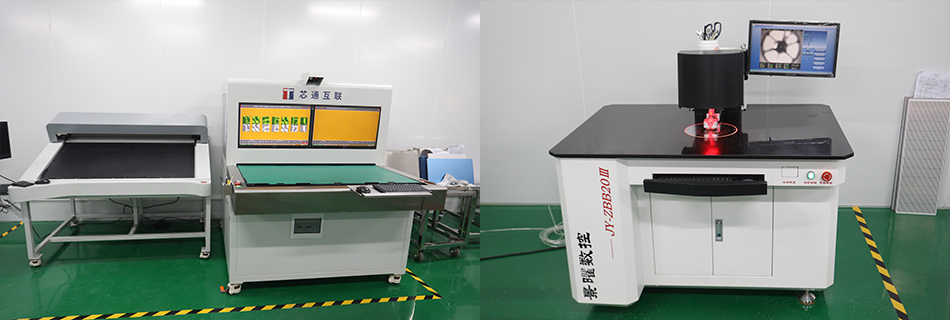

Cutting-Edge Manufacturing Technologies: Investment in high-precision equipment—such as laser drilling systems, automated optical inspection (AOI) machines, and 5G-compatible production lines—enables these suppliers to produce complex PCBs, including HDI (High-Density Interconnect), rigid-flex, and high-frequency designs.

R&D Focus: In-house research teams collaborate with academic institutions and clients to develop next-gen PCB solutions, such as low-loss substrates for 6G applications, thermally conductive materials for EV power modules, and lightweight designs for drones.

Design for Excellence (DFX) Support: Engineers work with clients early in the design phase to optimize PCBs for manufacturability, cost, and performance. This includes recommendations on layer stackups, trace routing, and material selection to align with end-use requirements.

International Certifications: Leading suppliers hold certifications such as ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), and UL, demonstrating adherence to global quality and safety standards. Regular third-party audits ensure ongoing compliance.

Rigorous Testing Protocols: Implementing comprehensive testing, including thermal cycling, vibration testing, and signal integrity analysis, to validate PCB performance under real-world conditions. X-ray inspection and in-circuit testing (ICT) ensure defect rates remain below industry averages (often <0.01%).

Traceability Systems: Digital platforms track every PCB from raw material to delivery, recording production parameters, inspection results, and material origins. This transparency is critical for industries like aerospace and medical, where full accountability is mandatory.

Leading China-based PCB suppliers tailor their offerings to address the unique demands of key industries, ensuring PCBs meet sector-specific performance and regulatory requirements.

EV and ADAS Focus: Suppliers specialize in PCBs for electric vehicle (EV) powertrains, battery management systems (BMS), and advanced driver-assistance systems (ADAS). These PCBs require high-temperature resistance (up to 150°C), thick copper traces for high current, and EMI shielding to prevent interference with sensors.

Functional Safety Compliance: Production processes align with ISO 26262 (ASIL B-D) to minimize failure risks in safety-critical systems. Suppliers often provide detailed failure mode and effects analysis (FMEA) reports to support client certification efforts.

High-Volume Efficiency: With automotive production runs exceeding 100,000 units, suppliers use automated lines and statistical process control (SPC) to maintain consistency, achieving yields above 99.5% for mature designs.

Example: A leading supplier partnered with a European automaker to develop BMS PCBs for EVs. The solution included high-Tg FR-4 substrates, 3oz copper traces, and conformal coating for moisture resistance. Rigorous testing—including 10,000 thermal cycles—ensured reliability, with zero field failures reported over 500,000 units.

High-Frequency Performance: PCBs for 5G base stations and routers require low dielectric loss and stable impedance control. Suppliers use specialized substrates (e.g., PTFE composites) and precision machining to achieve signal integrity at frequencies up to 40GHz.

Compact Design Support: As 5G equipment shrinks in size, suppliers deliver HDI PCBs with micro-vias (≤0.1mm) and sequential lamination, enabling higher component density without sacrificing performance.

Mass Production Speed: To meet the rapid rollout of 5G infrastructure, suppliers have optimized production lines to reduce cycle times for high-volume PCB orders, often delivering within 7–10 days for repeat designs.

Cleanroom Manufacturing: PCBs for implantable devices, diagnostic equipment, and surgical tools are produced in Class 7/8 cleanrooms to prevent contamination, with strict protocols for handling and packaging.

Biocompatibility: Using materials certified for medical use (e.g., USP Class VI substrates) and ensuring PCBs resist bodily fluids or sterilization processes (autoclaving, ethylene oxide).

Regulatory Documentation: Supporting clients with detailed test data, material certificates, and compliance reports to streamline FDA, CE, and CFDA submissions.

Case Study: A China-based supplier developed PCBs for a portable ultrasound device, incorporating low-noise traces and EMI shielding to enhance image clarity. The supplier provided full documentation, including biocompatibility test results, enabling the client to secure FDA approval six months ahead of schedule.

To maintain their leadership, top China-based PCB suppliers are expanding beyond domestic borders, adopting strategies that enhance their global relevance and client proximity.

Regional Production Facilities: Establishing factories in Southeast Asia, Mexico, and Eastern Europe to reduce shipping costs, shorten lead times, and navigate trade barriers. These facilities mirror domestic quality standards and are staffed by locally trained engineers.

Proximity to Key Markets: Locating plants near automotive clusters in Europe or tech hubs in the U.S. allows suppliers to collaborate more closely with clients, facilitating faster prototyping and just-in-time delivery.

Dedicated Account Teams: Assigning cross-functional teams (engineering, logistics, quality) to major clients ensures personalized support, with regular on-site visits and 24/7 communication channels for urgent issues.

Joint Development Projects: Collaborating with clients on long-term R&D initiatives, such as next-gen PCB materials for quantum computing or flexible electronics for wearables. These partnerships often include shared intellectual property agreements.

Cloud-Based Platforms: Clients access real-time production data, order status, and test reports via secure portals, enabling transparency and proactive decision-making. Some suppliers integrate with client ERP systems for seamless data exchange.

Predictive Analytics: Using AI to forecast demand, optimize inventory, and identify potential production bottlenecks, reducing lead time variability and improving on-time delivery rates (often exceeding 98%).

Leading China-based PCB suppliers are prioritizing sustainability to align with global environmental goals and client ESG (Environmental, Social, Governance) requirements.

Energy Efficiency: Investing in solar-powered factories, energy-efficient equipment, and heat recovery systems to reduce carbon emissions. Some suppliers have achieved 30% renewable energy usage in their operations.

Waste Reduction: Implementing closed-loop systems for etching chemicals and water recycling, cutting hazardous waste by up to 50%. Scrap copper is recycled internally, with recovery rates exceeding 95%.

Low-Impact Materials: Phasing out halogenated substrates and lead-based solders in favor of eco-friendly alternatives, complying with RoHS, REACH, and California’s Prop 65.

Carbon Mapping: Conducting lifecycle assessments (LCAs) to measure emissions across the supply chain, from raw material extraction to shipping. This data is used to set reduction targets (e.g., 50% lower emissions by 2030).

Sustainable Logistics: Partnering with green shipping providers and optimizing delivery routes to minimize transportation emissions. Some suppliers offer carbon-neutral shipping options for clients.

Worker Welfare: Ensuring safe working conditions, fair wages, and professional development programs, with certifications such as SA8000 (social accountability) demonstrating commitment to ethical labor practices.

Community Engagement: Investing in local communities near manufacturing sites through education programs, environmental cleanups, and healthcare initiatives, strengthening social license to operate.

Businesses seeking to partner with a leading China-based PCB supplier should evaluate potential partners based on factors that align with their technical needs, operational requirements, and long-term goals.

Capability Matching: Verify the supplier’s expertise in your industry (e.g., automotive, medical) and ability to produce your specific PCB type (e.g., HDI, rigid-flex). Request case studies or references from similar clients.

R&D Capacity: Assess the supplier’s investment in innovation, including patents, partnerships with research institutions, and ability to develop custom solutions for emerging technologies.

Supply Chain Resilience: Inquire about contingency plans for material shortages, geopolitical disruptions, or natural disasters. A robust supplier will have diversified sourcing and production options.

Scalability: Ensure the supplier can handle your volume requirements, from prototypes to mass production, with flexible lead times. Ask about maximum monthly output and historical on-time delivery rates.

Certifications and Audits: Confirm the supplier holds relevant industry certifications and allows third-party audits. Request access to quality reports, including defect rates and corrective action processes.

Testing Capabilities: Evaluate the breadth of testing services, ensuring they align with your product’s requirements (e.g., thermal, mechanical, electrical testing).

Cultural Compatibility: Assess the supplier’s ability to communicate effectively in English and understand Western business practices, including deadlines, documentation, and dispute resolution.

Technical Support: Look for suppliers offering proactive DFM feedback, design optimization, and post-delivery technical assistance to address issues quickly.

Leading China-based PCB suppliers have evolved from cost-focused manufacturers to strategic partners, driving innovation and resilience in the global electronics supply chain. Their combination of technical excellence, scalable production, and commitment to quality positions them as critical enablers of industries ranging from automotive electrification to 5G deployment.

By prioritizing sustainability, expanding global footprint, and fostering collaborative client relationships, these suppliers are well-equipped to meet the demands of a rapidly changing market. For businesses seeking reliable, high-performance PCB solutions, partnering with a leading China-based supplier offers access to cutting-edge technology, supply chain stability, and the agility to navigate industry disruptions.

As electronics continue to advance—becoming more connected, efficient, and integrated into daily life—the role of these suppliers will only grow, underscoring their importance as architects of the next generation of technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB