-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 16. 2025, 19:31:03

Printed Circuit Boards (PCBs) are at the heart of almost every electronic device. From smartphones to kitchen appliances, PCBs make these gadgets function. But how exactly do these intricate boards come to life? Let's dive into the PCB assembly process and unravel the steps involved in creating these essential components.

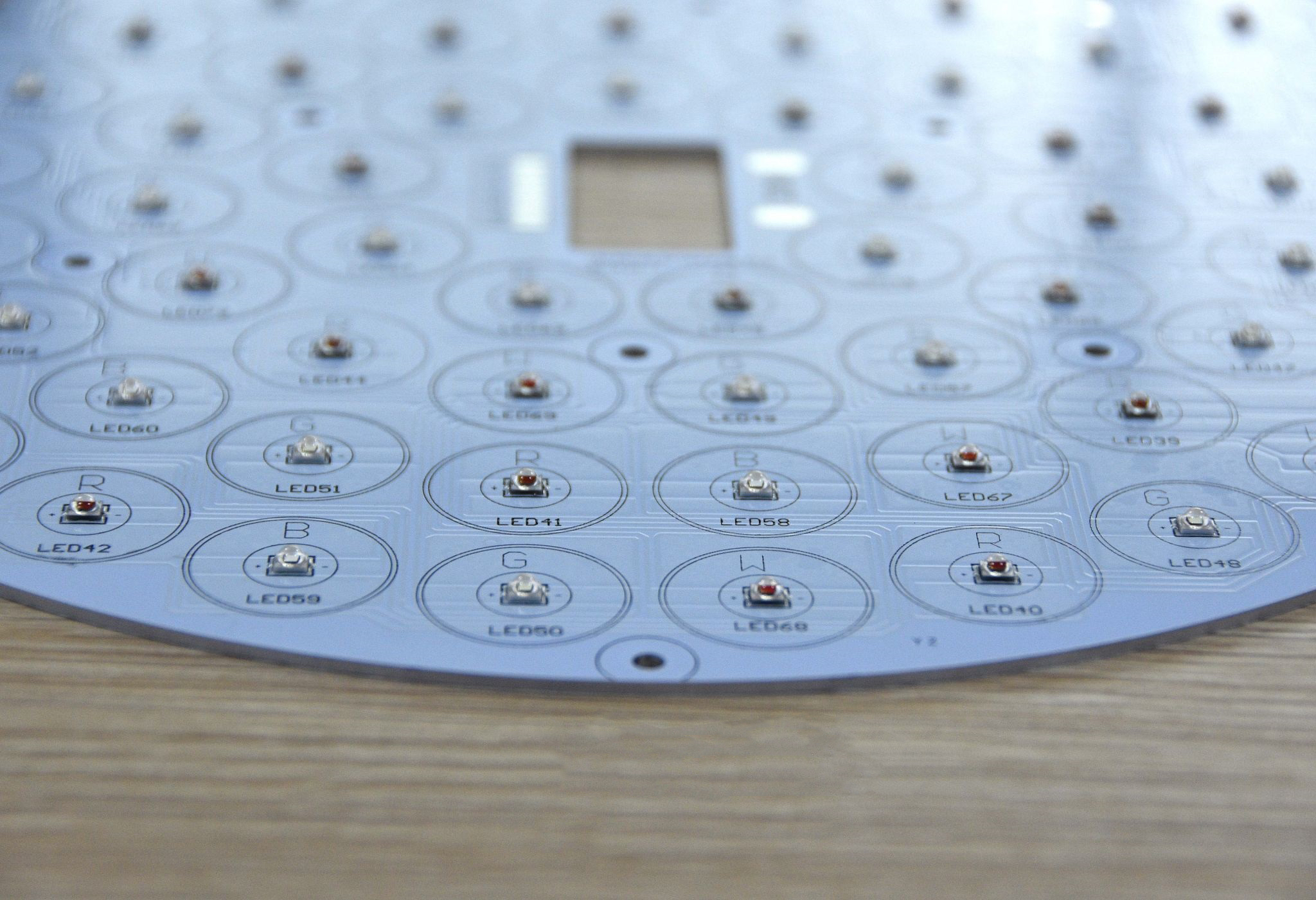

PCB assembly, often referred to as PCBA, is the process of mounting electronic components onto a PCB. This is distinct from PCB manufacturing, which involves creating the board itself. The assembly process transforms a simple board into a functioning electronic circuit by adding components like resistors, capacitors, and integrated circuits.

The assembly of a PCB involves several key steps, each crucial to ensuring the final product functions as intended. Here’s a breakdown of the process:

The first step in PCB assembly is applying solder paste to the board. This paste is a mixture of tiny solder balls and flux, which helps the solder melt and bond. The solder paste is applied to areas where components will be mounted, using a stencil to ensure precision.

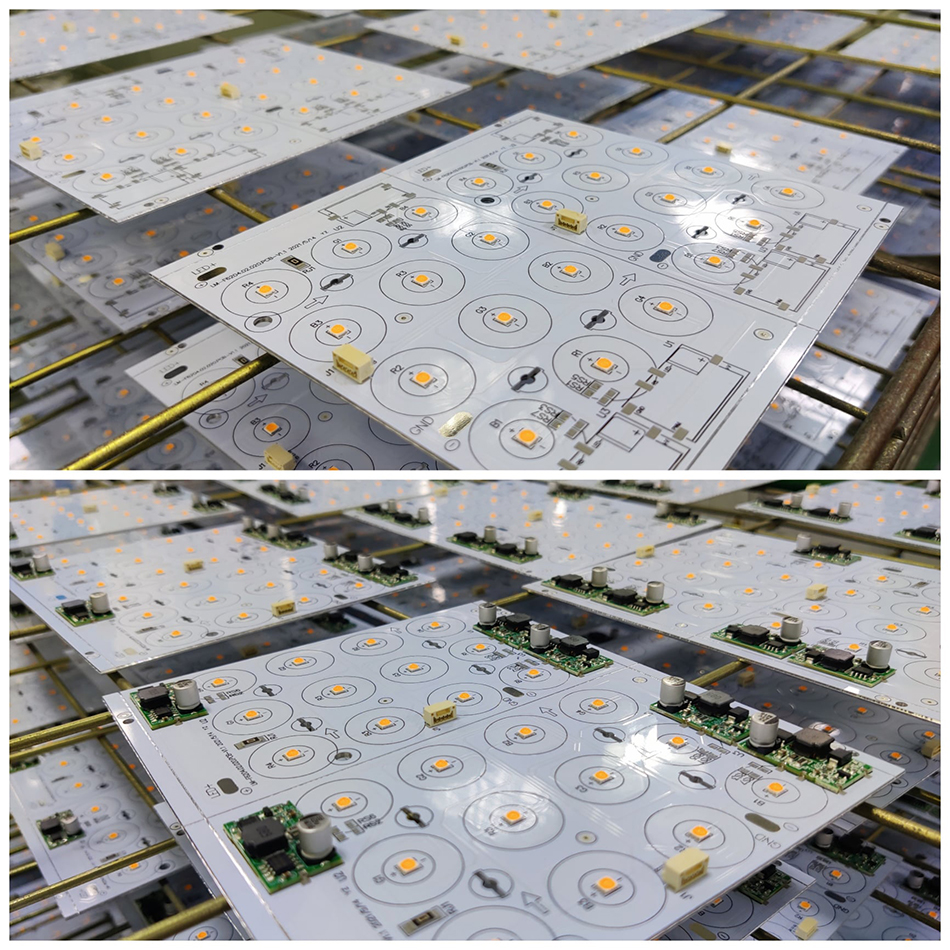

Once the solder paste is applied, it's time to place the components. This is often done using a pick-and-place machine, which accurately positions each component onto the board. These machines are incredibly precise, ensuring each component is placed exactly where it needs to be.

With components in place, the board goes through a reflow oven. This oven heats the board to a temperature that melts the solder paste, causing it to solidify and form permanent bonds between the components and the board. This step is crucial for ensuring the electrical connections are secure.

After reflow soldering, the board undergoes inspection to ensure all components are correctly placed and secured. Automated Optical Inspection (AOI) systems are often used for this step, scanning the board for any defects or misalignments. If any issues are detected, they are corrected before moving on.

For boards that include through-hole components, these are inserted manually or with the help of automated machines. Through-hole components have leads that pass through holes on the PCB and are soldered on the opposite side, providing strong mechanical bonds.

For through-hole components, the board may undergo wave soldering. In this process, the bottom of the board is passed over a wave of molten solder, which solders the component leads to the board. This method ensures reliable connections and is efficient for mass production.

The final step in PCB assembly is a thorough inspection and testing of the completed board. Functional tests are performed to verify that the board operates as intended. This may involve testing electrical connections, functionality, and even stress testing to ensure reliability.

Before assembly can begin, the PCB must be designed. PCB design involves creating a blueprint for the board, detailing where each component will be placed and how they will be connected. Designers use specialized software to create these layouts, ensuring the board will function correctly once assembled.

A key aspect of PCB design is Design for Manufacturability (DFM). This involves designing the board in a way that minimizes potential manufacturing issues. By considering factors like component placement, trace routing, and layer stacking, designers can create boards that are easier and more cost-effective to produce.

It's important to distinguish between PCB manufacturing and PCB assembly. PCB manufacturing involves creating the bare board, which includes the substrate, copper layers, and any drilled holes or cutouts. This process is typically handled by specialized manufacturers.

PCB assembly, on the other hand, involves adding the electronic components to the manufactured board. While some companies handle both manufacturing and assembly, others specialize in one or the other.

When looking for a PCB assembly partner, consider factors like experience, quality control processes, and technological capabilities. A reliable partner will have a track record of delivering high-quality assemblies on time and within budget.

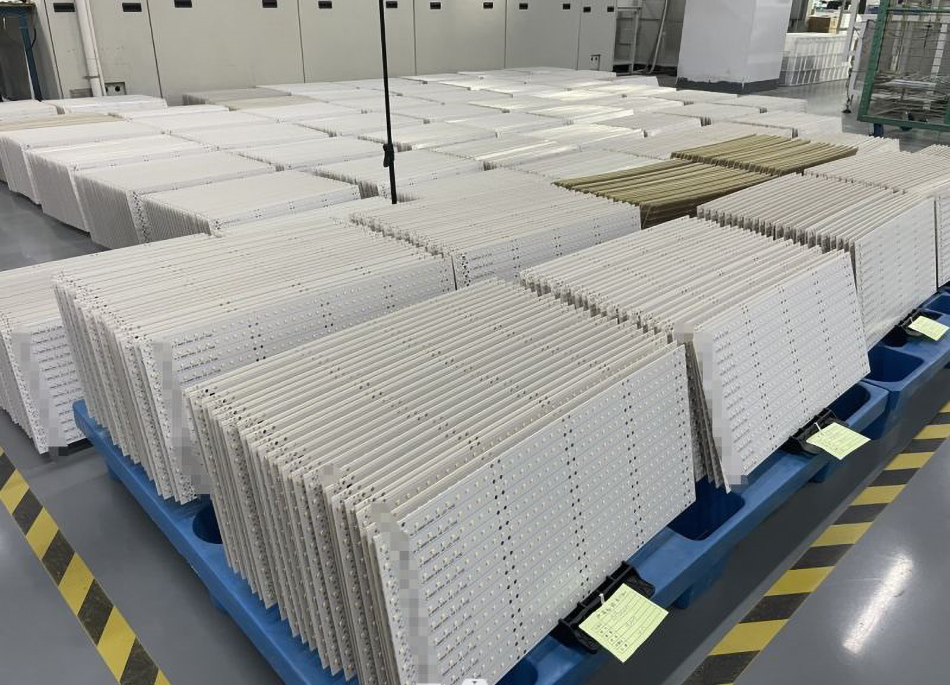

For startups or small-scale projects, prototyping and small batch production are essential. Look for assembly partners who offer these services, allowing you to test and refine your designs before committing to larger production runs.

Ensure your assembly partner adheres to industry standards and holds relevant certifications, such as ISO 9001 or IPC standards. This guarantees they follow best practices and deliver products that meet quality expectations.

Understanding the PCB assembly process is crucial for anyone involved in electronics design or manufacturing. From solder paste application to final testing, each step plays a vital role in creating functional and reliable electronic devices. By working with experienced partners and focusing on quality from design to assembly, you can ensure your PCBs meet the demands of today’s technology-driven world.

Embarking on a PCB assembly project can be daunting, but with the right knowledge and partners, it becomes a manageable and rewarding endeavor. Whether you’re producing a single prototype or gearing up for mass production, understanding these processes will help you achieve success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB