-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 05. 2026, 10:10:42

In the world of modern electronics, thermal management has become a paramount design consideration — especially as power densities rise and devices become more compact. Traditional PCB materials such as FR-4 struggle to dissipate heat efficiently in high-power environments, which can compromise performance and shorten product life. This is where metal core PCB solutions excel. With a metal substrate engineered to rapidly remove heat from critical components, MCPCBs offer both performance and reliability advantages that make them ideal for today’s demanding applications.

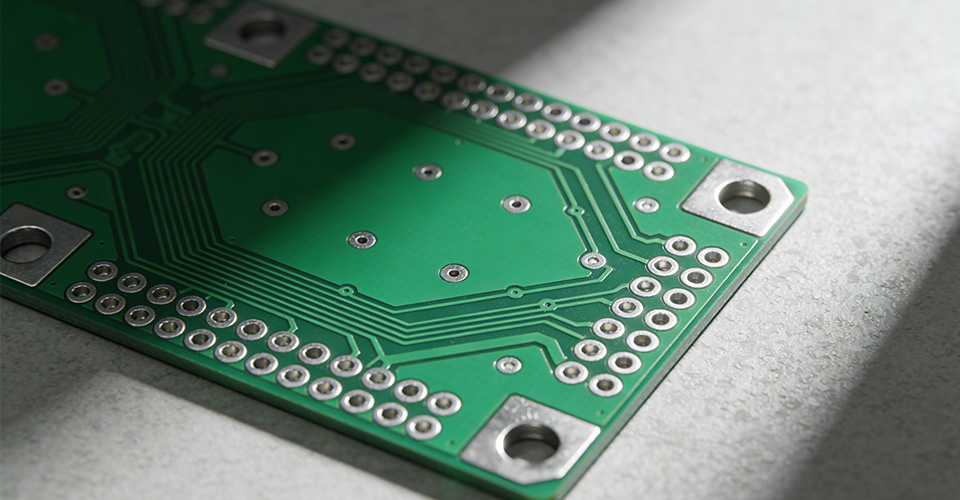

A metal core PCB, also called a Metal Core Printed Circuit Board (MCPCB), is a type of circuit board that incorporates a metal base layer — most commonly aluminum or copper — into its core structure. Unlike conventional fiberglass-based PCBs, the metal core acts as an integrated heat sink, rapidly spreading and dissipating heat generated by components during operation.

Structurally, a typical metal core PCB stack-up includes:

A copper circuit layer carrying electrical traces and components

A dielectric layer that is thermally conductive yet electrically insulating

A metal base (such as aluminum) that provides thermal transfer and mechanical support

This architecture dramatically improves thermal performance while maintaining the mechanical integrity necessary for industrial applications.

One of the defining benefits of metal core PCB technology is its ability to manage heat far more effectively than standard boards. The metal base acts as a thermal highway, conducting heat away from components such as LEDs, power converters, or motor drivers, which can otherwise reach damaging temperatures. This ensures consistent performance and prolongs service life.

Metal core boards are inherently robust. The metal substrate — particularly in aluminum core PCB variants — provides greater mechanical rigidity and resistance to warping compared to FR-4 boards, making them ideal for harsh operational environments.

Applications involving high currents or power densities benefit significantly from MCPCBs, as thermal issues are a major source of failure in such systems. Improved heat dissipation leads to better electrical stability and reduced component stress.

Aluminum, a common base metal in metal core PCB designs, is recyclable and environmentally friendly — an important consideration for sustainability-focused manufacturing.

Depending on the complexity of your application, designers might choose between several metal core PCB configurations:

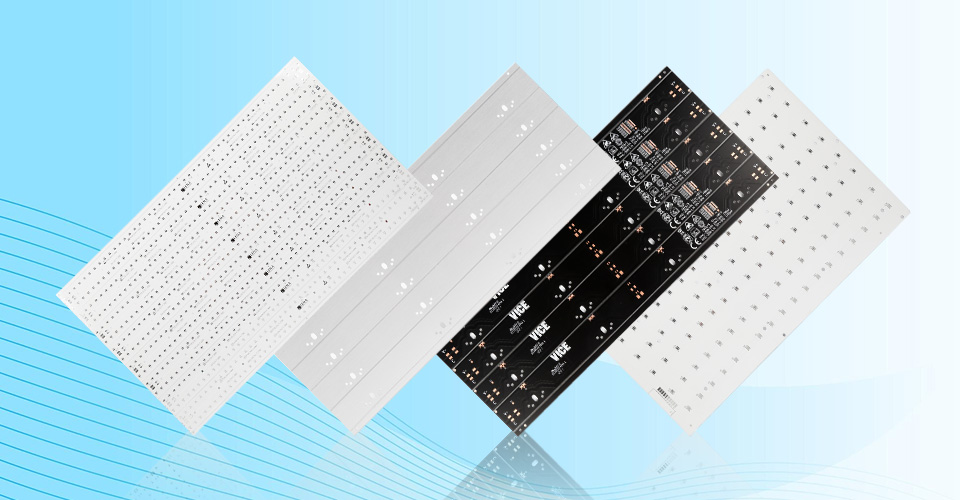

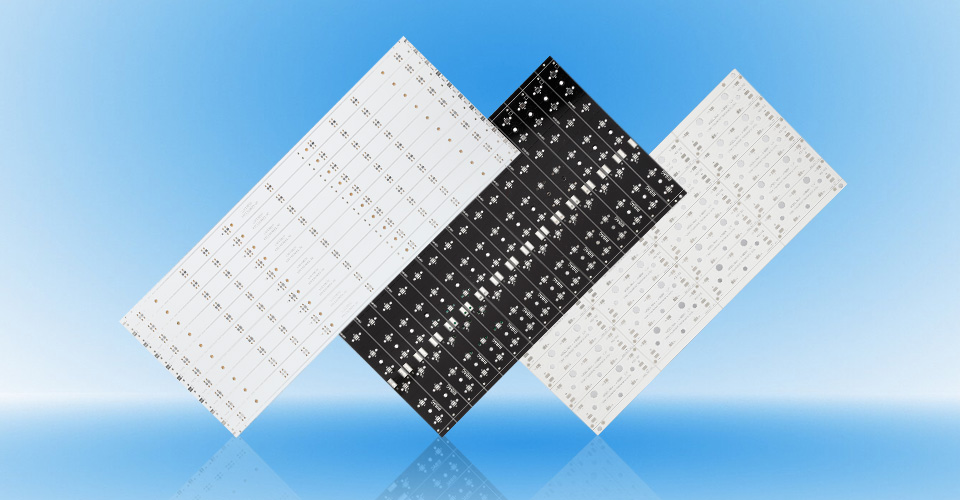

A Single Layer metal core PCB features a simple three-layer stack: copper, dielectric, and metal core. Its straightforward design delivers excellent heat transfer at a lower cost and with shorter lead times. This structure is widely used in LED lighting modules, power supplies, and motor controllers where thermal performance is critical, but signal routing complexity is moderate.

By contrast, a Multilayer metal core PCB integrates multiple copper layers separated by additional dielectric and insulation stacks. This allows for more intricate signal routing, better EMI performance, and improved impedance control, making it suitable for more complex electronics such as automotive modules, industrial controls, and advanced power electronics. While costs can be higher than single layer options, the performance benefits in high-density designs are often worth the investment.

A 2 layer metal core PCB is one specific configuration within the multilayer category. It provides two conductive copper layers with enhanced routing flexibility while still benefiting from the heat-dissipating properties of the metal base. This makes 2-layer solutions especially attractive for compact but thermally demanding designs.

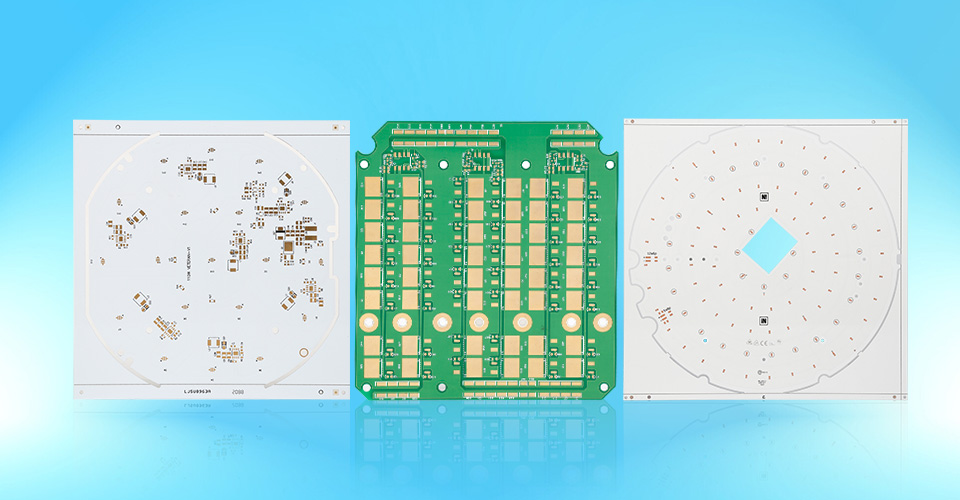

Among metal core options, aluminum core PCB stands out as the most widely adopted due to its balance of thermal performance, cost efficiency, and lightweight properties. Aluminum’s thermal conductivity allows effective heat spreading, keeping junction temperatures lower and improving reliability in LEDs, power converters, and renewable energy systems.

Compared to copper cores, aluminum is typically more economical and easier to machine, making it a preferred choice for many industrial applications where cost-to-performance is a deciding factor.

Because of their heat management capabilities and structural strength, metal core PCBs are essential in numerous sectors:

High-power LED systems generate heat that can degrade performance if not managed properly. Metal core boards efficiently draw heat away from LEDs, enhancing luminous efficiency and lifespan.

From dashboard systems to sensor modules and power converters, vehicles demand reliable boards that withstand thermal stress. MCPCBs are often integrated into electric vehicles (EVs) and advanced driver assistance systems (ADAS).

Power modules in energy systems, photovoltaic inverters, and motor drives rely on strong thermal solutions to maintain performance under heavy load. Metal core boards support these high-power environments.

Machinery and automation systems often operate in thermally challenging settings. Metal core PCB architectures provide the durability and heat resilience required.

The performance of metal core PCBs also depends on the quality of metal based laminates — composite materials that combine metal cores with copper circuitry and dielectric layers. Choosing laminates with optimal thermal conductivity and dielectric properties can significantly enhance heat transfer efficiency and mechanical reliability, especially in multilayer designs where thermal paths are more complex.

In summary, metal core PCB solutions deliver unmatched thermal management, structural durability, and performance for high-power and high-reliability electronic systems. Whether you need cost-effective Single Layer metal core pcb designs or advanced Multilayer metal core pcb configurations with intricate routing, MCPCBs — particularly aluminum core pcb variants — offer tangible benefits that directly translate to better product reliability and customer satisfaction.

By selecting the right materials and manufacturers with proven capabilities in metal based laminates and 2-layer or more complex metal core configurations, engineers can future-proof their designs for demanding applications.

Answer:

A Single Layer metal core PCB consists of a single copper circuit layer, a dielectric layer, and a metal base. Its simple design delivers excellent heat transfer at lower costs, making it ideal for high-power applications like LED lighting. This structure ensures improved heat dissipation and longer product life, especially when handling high-power levels.

Answer:

A Multilayer metal core PCB incorporates multiple copper layers and dielectric materials, offering more complex signal routing and better performance for high-frequency designs. It is suitable for electronics requiring better signal integrity, like automotive systems and communications equipment. On the other hand, Single Layer metal core PCB is better for simpler, high-power applications with less complex routing needs.

Answer:

Aluminum core PCB is a popular choice due to its excellent thermal conductivity, cost-effectiveness, and light weight. It is commonly used in LED lighting and power conversion systems, offering reliable heat dissipation and performance at a lower cost compared to copper-based PCBs.

Answer:

Metal based laminates are composite materials combining metal cores with copper and dielectric layers. These laminates enhance thermal conductivity, ensuring effective heat transfer and improving the mechanical stability of the PCB. High-quality laminates are crucial for ensuring the longevity and efficiency of Single Layer metal core PCB and Multilayer metal core PCB designs.

Answer:

2 layer metal core PCB configurations are ideal for compact, thermally demanding designs that require moderate signal complexity. Common applications include power supplies, LED lighting, automotive electronics, and other high-power systems. These PCBs provide a balanced combination of heat dissipation, electrical performance, and routing flexibility.

Related Articles:

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB