-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 06. 2026, 16:55:31

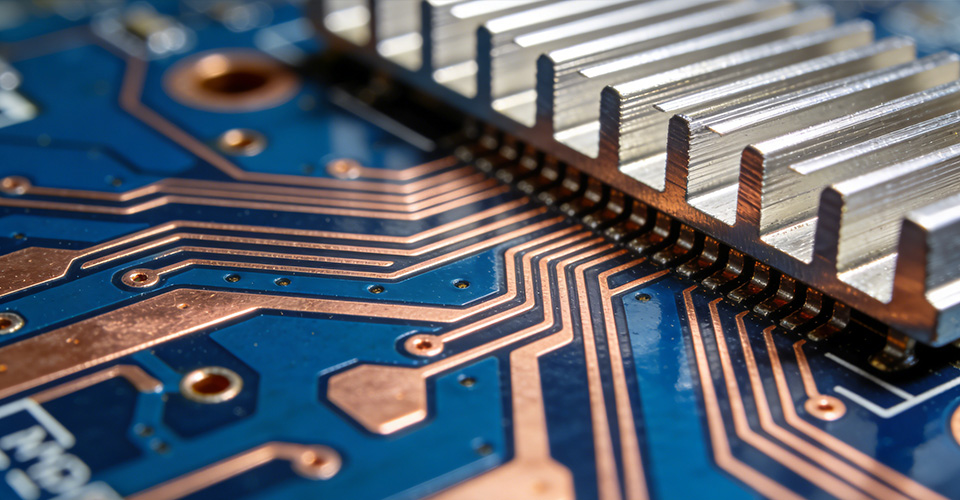

In modern electronics, thermal management has become a crucial aspect of device design, especially as the demand for compact and high-performance systems grows. Traditional PCBs made of FR-4 materials struggle to manage heat effectively, especially in high-power applications. This is where metal core PCBs (MCPCBs) excel, providing superior heat dissipation, improved reliability, and mechanical strength. In this article, we explore the key advantages of metal core PCB technology and its diverse applications in industries like LED lighting, automotive electronics, and more.

A metal core PCB is a type of printed circuit board that incorporates a metal base layer, typically made of aluminum or copper, beneath the conductive layers. This metal core serves as a heat sink, efficiently drawing heat away from sensitive components and ensuring that the PCB can perform reliably even under high thermal stress. The structure of a metal core PCB typically consists of three layers:

Copper Circuit Layer: This layer contains the electrical traces and components of the PCB.

Dielectric Layer: A thermally conductive layer that prevents electrical short circuits while allowing heat to pass through.

Metal Base Layer: Usually aluminum core PCB or copper core PCB, which provides thermal management and mechanical support.

This design ensures that the PCB can handle high temperatures without compromising the performance or longevity of the components.

The primary benefit of metal core PCBs is their ability to manage heat much more effectively than traditional FR-4 PCBs. The metal base layer conducts heat away from critical components, preventing overheating and maintaining optimal operational temperatures. This is especially beneficial in high-power applications like LED lighting and automotive electronics, where heat buildup can significantly impact performance.

Metal core PCBs provide additional mechanical strength due to the metal base. This makes them more durable and resistant to physical stress. The enhanced strength of aluminum core PCBs or copper core PCBs is crucial in environments where PCBs must endure harsh conditions, such as in automotive or industrial applications.

With better thermal management and mechanical strength, metal core PCBs offer greater reliability and longer operational lifespans. They are less likely to suffer from issues related to thermal stress, such as component degradation or board warping, making them ideal for mission-critical applications.

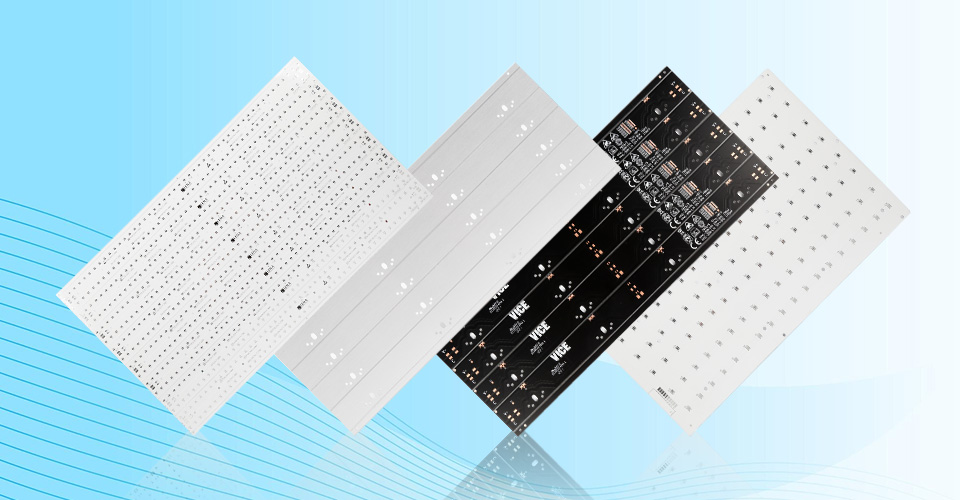

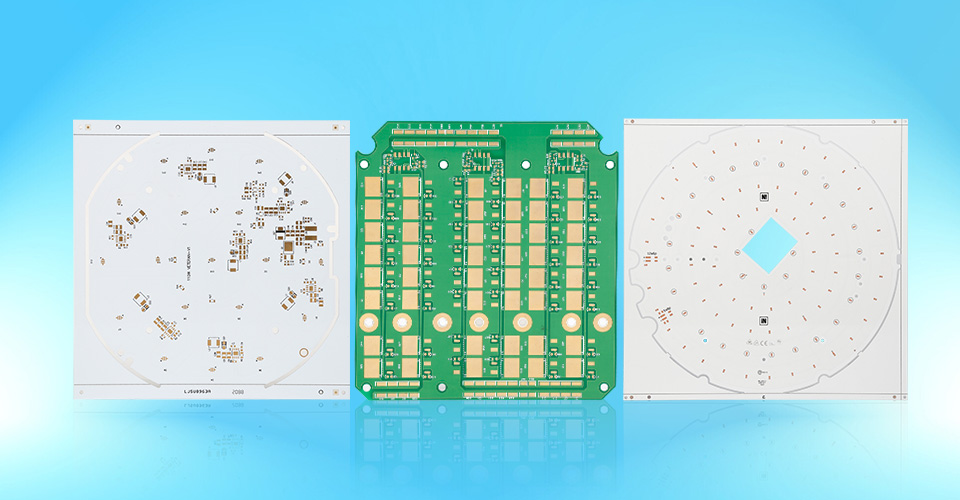

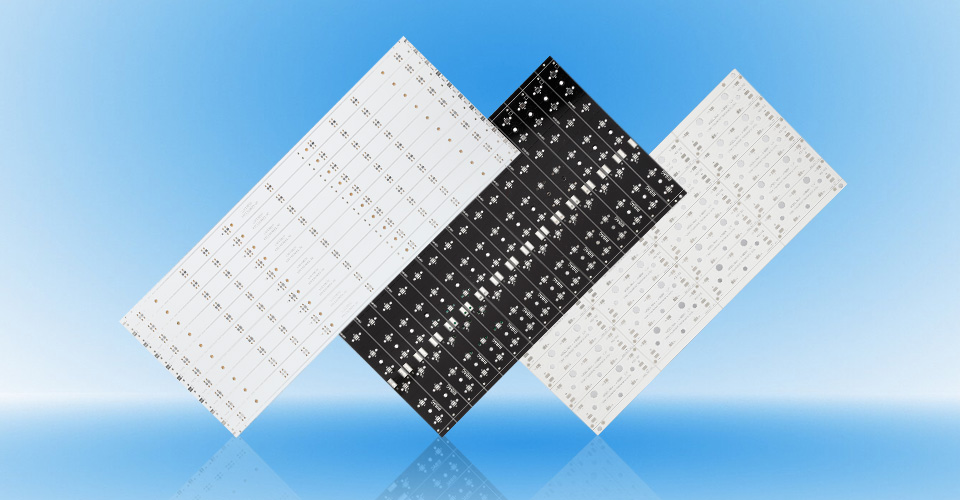

One of the most common applications for metal core PCB is in LED lighting systems. LEDs generate significant heat, and if not properly dissipated, they can fail prematurely. LED lighting metal core PCBs draw heat away from the LED components, maintaining performance and extending their lifespan. This is crucial in applications such as street lighting, automotive lighting, and large-scale display systems where high power is used.

In automotive electronics, heat management and durability are essential. Metal core PCBs are used in power electronics, LED headlights, sensors, and control systems in vehicles. These boards can handle high temperatures under the hood, providing the necessary reliability and mechanical support for automotive applications. Moreover, the metal core offers increased resistance to vibrations and shocks typically encountered in automotive environments.

In addition to basic heat dissipation, metal core PCBs can be designed with advanced features that enhance their functionality:

Countersink holes are used to allow fasteners or screws to sit flush with the surface of the PCB. This is especially important in applications where secure mechanical assembly is required. Countersink holes in metal core PCBs ensure that components are tightly secured, improving the overall reliability of the product.

Similar to countersink holes, counterbore holes create a space where fasteners sit at a specific depth. This helps prevent mechanical stress and ensures that the PCB maintains its integrity during assembly and operation. The use of counterbore holes in metal core PCBs is common in applications where precise connections are needed, such as in automotive electronics or power supply systems.

Blind vias connect the outer layer to one or more inner layers, while buried vias are entirely contained within the inner layers of the PCB. These vias allow for complex circuit designs, enabling the creation of multilayer metal core PCBs that provide more functionality in a smaller footprint. Blind and buried vias are commonly used in high-density designs where space is limited, such as in telecommunications or medical devices.

When considering metal core PCBs for your project, keep in mind the following benefits:

Superior Thermal Performance: Efficient heat dissipation ensures reliable operation, even in high-power systems.

Enhanced Durability: The metal core adds mechanical strength, making the PCB more robust and resistant to physical stress.

Longevity: Metal core PCBs offer improved reliability and longer lifespans, reducing the need for frequent maintenance or replacement.

Design Flexibility: Advanced features such as countersink and counterbore holes, as well as blind and buried vias, allow for customized and efficient designs.

Metal core PCBs are essential in industries where heat management, reliability, and mechanical strength are critical. From LED lighting to automotive electronics, their superior thermal performance and durability make them ideal for a variety of high-performance applications. Whether you're designing high-power LED systems or automotive control units, metal core PCB technology ensures that your products are reliable, efficient, and long-lasting.

For your next project, consider incorporating metal core PCB technology to take advantage of its many benefits. Work with an experienced PCB manufacturer to find the best solutions for your specific needs.

Answer:

LED lighting metal core PCB is specifically designed for high-power LED applications. The metal core helps dissipate the heat generated by LEDs, preventing overheating and ensuring the LEDs perform optimally over a long period. This results in improved lifespan and efficiency in applications such as street lighting, automotive headlights, and industrial lighting.

Answer:

Countersink holes in metal core PCB designs ensure that screws or other fasteners sit flush with the surface of the board. This is essential for applications where secure and precise mounting is required, ensuring that components are properly assembled and reducing the risk of mechanical failure.

Answer:

Counterbore holes create a recess for fasteners to sit at a specific depth, while countersink holes allow fasteners to sit flush with the surface. Both types of holes help in securing components to the PCB and are critical in applications requiring strong mechanical connections and precise assembly.

Answer:

Blind vias connect the outer layer to an inner layer of the PCB, while buried vias connect only inner layers. These vias are used in multilayer metal core PCBs to create compact and efficient circuit paths, enabling complex designs in high-density applications such as telecommunications and medical electronics.

Answer:

Automotive PCBs need to endure high temperatures, vibrations, and physical stress. Metal core PCBs provide the necessary heat dissipation and mechanical strength to ensure reliable operation in harsh automotive environments. These boards are used in power electronics, sensors, and control systems in vehicles, ensuring that they perform reliably even under extreme conditions.

Related Articles:

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB