-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 15. 2025, 20:09:43

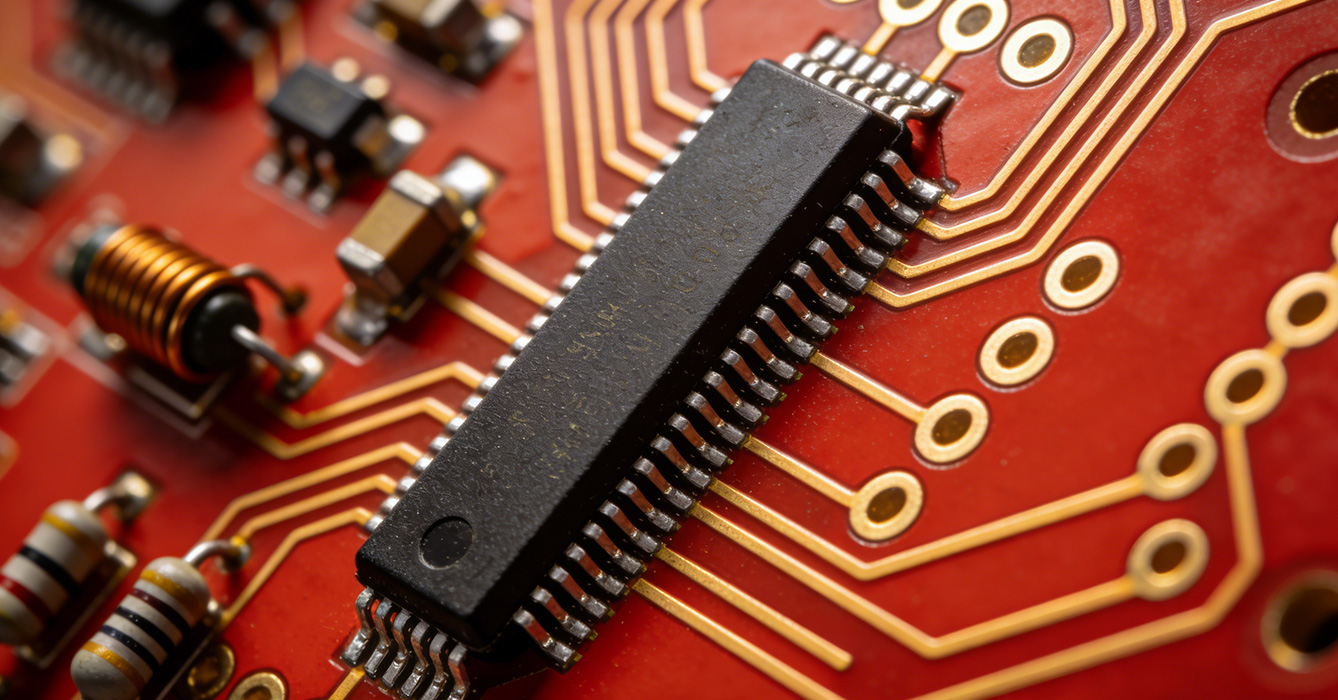

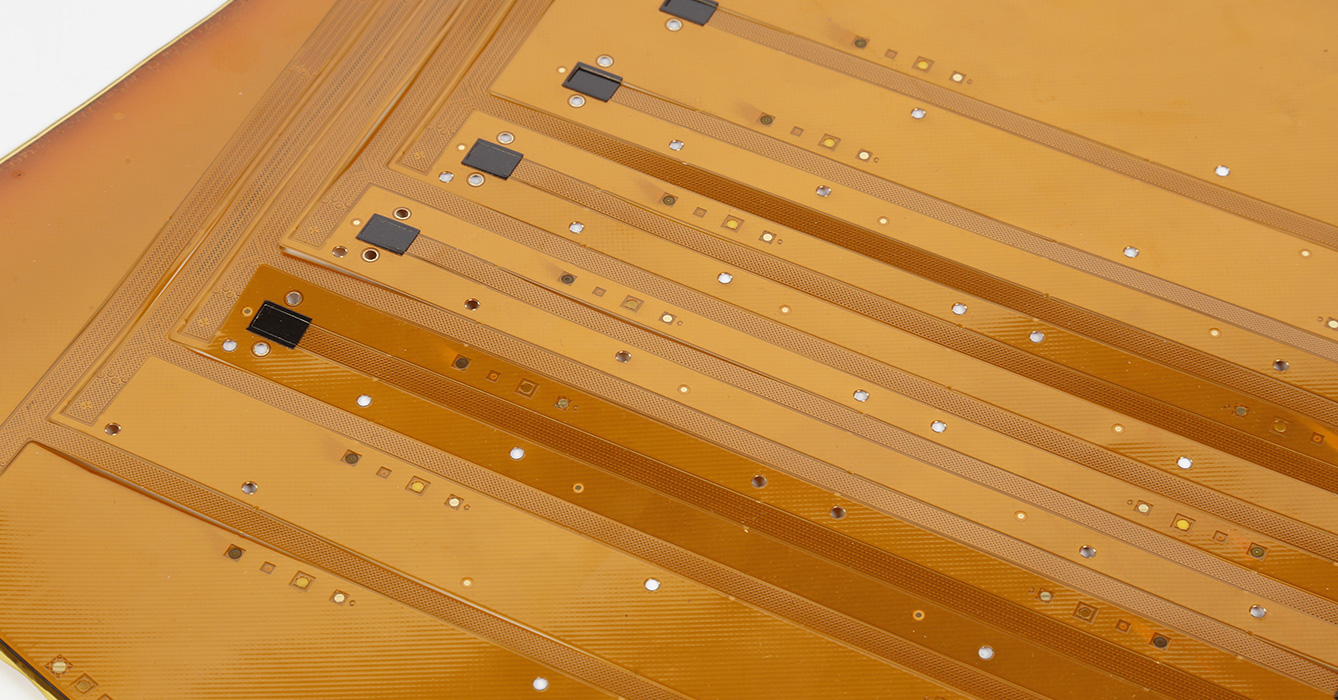

As electronic products evolve toward miniaturization, flexibility, and high performance, polyimide flexible printed circuits (FPCs) have become indispensable components in cutting-edge applications ranging from foldable electronics to aerospace systems. A professional Polyimide Flexible PCB Supplier distinguishes itself by mastering the synergy between polyimide material properties and FPC manufacturing processes, providing high-reliability, application-tailored solutions that leverage polyimide’s exceptional thermal stability, mechanical flexibility, and chemical resistance. Unlike generic FPC suppliers, these specialists deeply understand the unique requirements of polyimide-based circuits, ensuring seamless integration into products operating in harsh or demanding environments. For brands pursuing technological differentiation and product durability, partnering with a reputable Polyimide Flexible PCB Supplier is critical to unlocking the full potential of advanced electronic designs.

The competitive edge of a top Polyimide Flexible PCB Supplier lies in its ability to optimize the entire value chain through precise material selection and process control, tailored to polyimide’s intrinsic properties:

- Polyimide Material Customization & Sourcing: Leading suppliers establish strategic partnerships with high-quality polyimide material manufacturers, enabling access to specialized substrates—including high-temperature-resistant, low-dielectric, and transparent polyimide variants. They conduct rigorous material validation to ensure compatibility with FPC manufacturing processes, selecting options that balance flexibility, thermal endurance, and electrical performance based on client application needs. This material customization ensures the final FPCs meet the unique environmental and functional demands of target products.

- Precision Manufacturing Process Optimization: Polyimide’s unique physical properties require specialized manufacturing processes to avoid material damage and ensure circuit integrity. Suppliers optimize key processes such as laser etching, lamination, and curing, adapting parameters to polyimide’s thermal and mechanical characteristics. For example, they employ controlled-temperature lamination to maintain polyimide’s structural stability and use high-precision laser etching to create fine-pitch circuits without compromising the material’s flexibility. These process refinements guarantee consistent quality and performance across large-scale production.

- Advanced Quality Validation for Polyimide Circuits: Given the critical applications of polyimide FPCs, suppliers implement rigorous quality control systems tailored to polyimide’s performance attributes. This includes comprehensive testing for thermal endurance (to verify stability in extreme temperature ranges), flex endurance (to ensure reliability through repeated bending cycles), and electrical performance (to confirm signal integrity in high-frequency applications). Advanced automated inspection technologies are deployed to detect micro-defects, ensuring only flawless products reach clients.

Top Polyimide Flexible PCB Suppliers excel in developing targeted solutions for high-growth, high-demand industries, leveraging polyimide’s advantages to address sector-specific challenges:

- Foldable & Wearable Electronics: For foldable smartphones, tablets, and wearable health devices, suppliers design ultra-thin polyimide FPCs with exceptional flex endurance, capable of withstanding hundreds of thousands of bending cycles without performance degradation. These FPCs integrate seamlessly with flexible displays and miniaturized components, enabling sleek, lightweight product designs while ensuring stable signal transmission and power delivery.

- Aerospace & Defense Electronics: In aerospace applications—such as satellite systems and aircraft electronic components—suppliers provide polyimide FPCs that withstand extreme temperatures, radiation, and mechanical stress. These circuits meet stringent aerospace industry standards, using high-purity polyimide materials to ensure long-term reliability in harsh space and high-altitude environments, supporting critical mission-critical operations.

- 5G & High-Frequency Communications: For 5G base stations, millimeter-wave radar, and high-speed data transmission devices, suppliers develop low-dielectric polyimide FPCs that minimize signal loss. The polyimide material’s inherent low dielectric properties, combined with precision circuit design, enable efficient high-frequency signal transmission, supporting the performance requirements of next-generation communication technologies.

A professional Polyimide Flexible PCB Supplier goes beyond manufacturing, offering comprehensive end-to-end services and building resilient supply chains to support client success:

- Early-Stage Design Collaboration: Suppliers engage with clients in the early R&D phase, providing technical consultation on polyimide FPC design for manufacturability (DFM). They offer insights on material selection, circuit layout optimization, and thermal management, helping clients avoid design pitfalls and accelerate product development cycles.

- Vertical Integration & Supply Chain Security: Leading suppliers adopt vertical integration strategies, controlling key stages from polyimide material sourcing to FPC assembly. This integration ensures supply chain stability, reduces lead times, and enables tighter quality control. They also maintain strategic inventory of critical materials to mitigate risks from market fluctuations or supply disruptions.

- Post-Delivery Technical Support: Comprehensive after-sales support includes technical troubleshooting, performance validation assistance, and guidance on FPC installation and maintenance. Suppliers establish dedicated technical teams to address client queries promptly, ensuring the smooth integration of polyimide FPCs into final products and long-term operational reliability.

Forward-looking Polyimide Flexible PCB Suppliers are embracing emerging technologies to drive innovation and meet evolving market demands:

- Multifunctional Polyimide Integration: Innovation focuses on integrating additional functionalities—such as sensing, thermal management, and electromagnetic shielding—into polyimide FPCs. This creates smart, all-in-one solutions that reduce component count and enhance product miniaturization.

- Sustainable Manufacturing Practices: Suppliers are adopting eco-friendly processes, such as low-toxicity polyimide formulations and energy-efficient production technologies, aligning with global carbon neutrality goals. They also explore recyclable polyimide materials to reduce environmental impact.

- Advanced Packaging Compatibility: To support the trend toward high-density electronic packaging, suppliers are developing polyimide FPCs compatible with advanced packaging technologies such as chip-on-flex (COF) and system-in-package (SiP), enabling higher integration and performance in compact spaces.

In conclusion, a Polyimide Flexible PCB Supplier plays a pivotal role in enabling advanced electronic innovations by bridging polyimide material advantages with precision FPC manufacturing. Through material-process synergy, application-tailored solutions, and end-to-end support, these suppliers deliver high-reliability circuits that power next-generation products across industries. As demand for flexible, high-performance electronics continues to grow, the strategic value of partnering with a specialized Polyimide Flexible PCB Supplier will only increase, driving technological progress and market competitiveness for clients worldwide.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB