-

- PCB TYPE

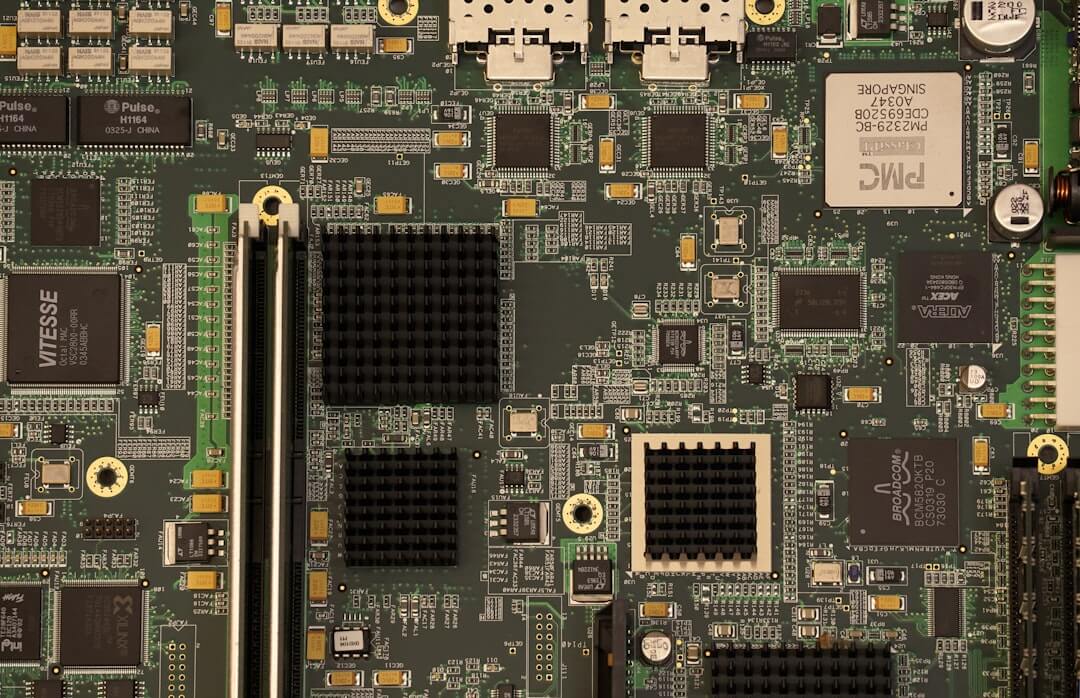

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 24. 2025, 18:05:32

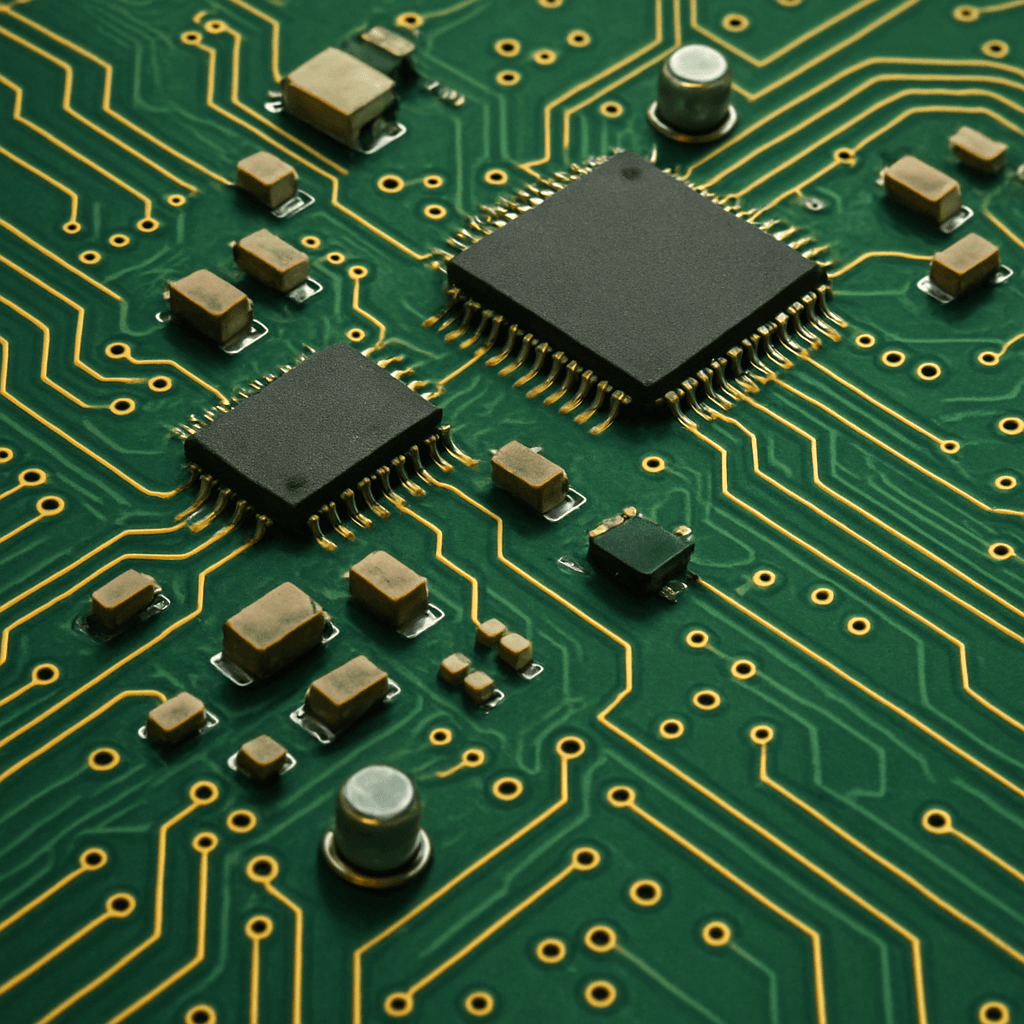

In the world of electronics, printed circuit boards (PCBs) are the backbone that holds everything together. Their design and assembly are crucial for the functionality and reliability of electronic devices. One specific technique that plays a vital role in PCB assembly is the precision countersink. But what is it, and why is it important?

In this article, we'll delve into the concept of precision countersink in PCB assembly, explore various PCB manufacturing methods, and discuss the techniques involved in PCB fabrication. Let's get started!

PCB manufacturing is a complex process that involves various methods to produce efficient and reliable circuit boards. These methods ensure that the PCB can handle the demands of the electronic components it supports. Let's look at some of the key PCB manufacturing methods:

The subtractive method is one of the most common PCB manufacturing techniques. It involves removing excess copper from a copper-clad board to create the desired circuit pattern. This is typically done through chemical etching, where a photoresist layer is applied to protect the areas of copper that need to remain.

Unlike the subtractive method, the additive method involves adding copper only where it is needed on the board. This process is more environmentally friendly as it reduces waste. It is often used in advanced PCB fabrication where precision is crucial.

The semi-additive method combines elements of both the subtractive and additive methods. It involves applying a thin layer of copper to the board and then adding more copper to create the circuit pattern. This method is known for its high precision and is used in complex PCB designs.

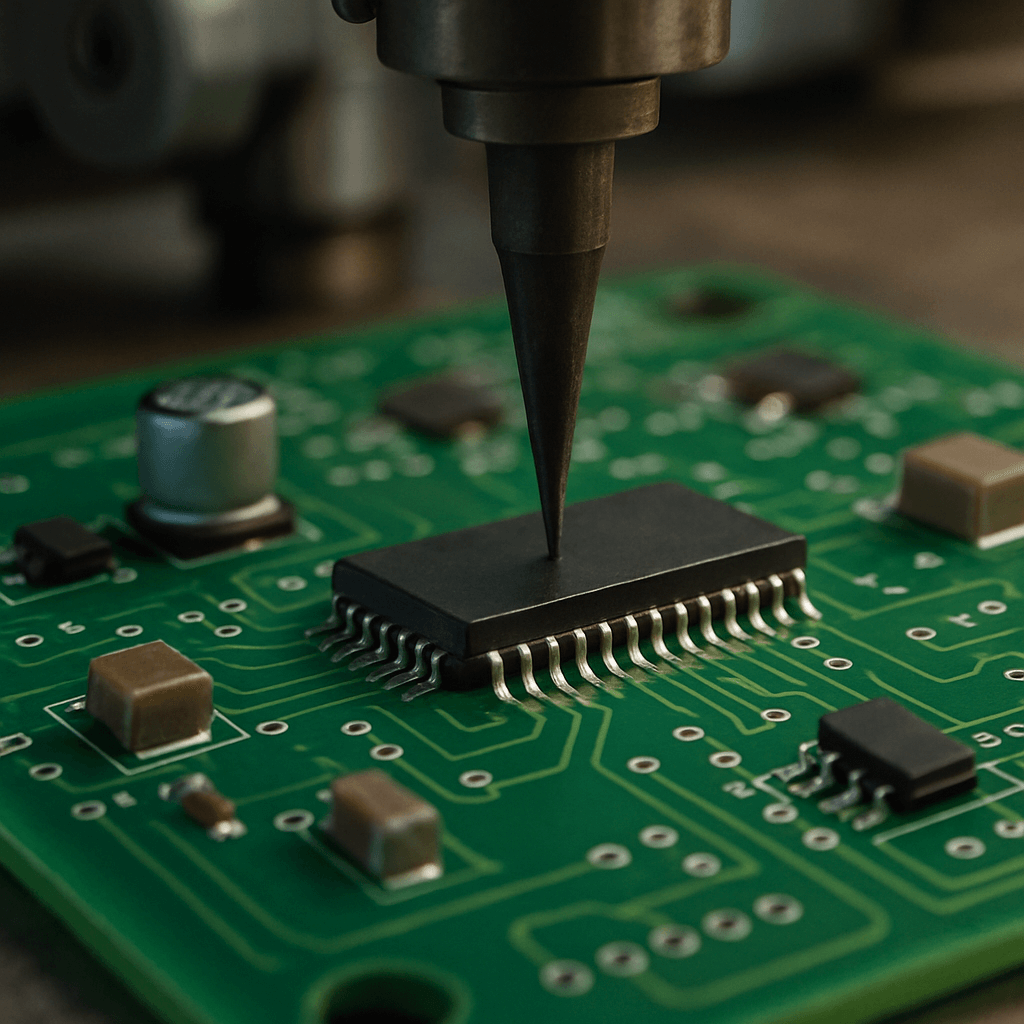

Precision countersink is a technique used in PCB assembly to ensure that screws or fasteners sit flush with the surface of the board. This is particularly important in applications where space is limited, and a smooth surface is required.

Countersinking involves creating a conical hole in the PCB that allows the head of a screw or fastener to sit below or flush with the surface. Precision countersink ensures that this process is carried out with high accuracy, reducing the risk of damaging the board or components.

Precision countersink is crucial for several reasons:

Space Optimization: In compact electronic devices, space is at a premium. Precision countersinking allows for efficient use of space by ensuring that fasteners do not protrude above the surface.

Aesthetic Appeal: A smooth, flush surface is often desirable in consumer electronics, where the appearance of the device is important.

Structural Integrity: Properly countersunk fasteners help maintain the structural integrity of the PCB by distributing stress evenly and reducing the risk of damage during assembly.

The fabrication of PCBs involves several intricate techniques that ensure the board functions as intended. Precision countersink is just one of these techniques. Let's explore some others:

Drilling is a fundamental step in PCB fabrication. Holes are drilled into the board to accommodate components and fasteners. Precision drilling ensures that holes are accurately placed and sized, which is critical for the assembly process.

Plating involves covering the drilled holes with a conductive material, typically copper. This creates a connection between different layers of the PCB. Proper plating ensures reliable electrical connections and is essential for the board's performance.

A solder mask is applied to protect the copper traces on the PCB from oxidation and to prevent solder bridges during assembly. The precision application of the solder mask is important to ensure that only the necessary areas are exposed for soldering.

The surface finish of a PCB plays a key role in its performance and longevity. It involves applying a protective layer over the copper traces to prevent corrosion. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

To achieve precision countersink in PCB assembly, several best practices should be followed:

Use the Right Tools: Precision countersinking requires specialized tools and equipment designed for PCB assembly. Using the right tools ensures accuracy and reduces the risk of damage.

Follow Design Guidelines: Adhering to design guidelines for countersinking, including hole size and depth specifications, is essential for achieving the desired results.

Regular Inspection: Regular inspection during the countersinking process helps identify any issues early and ensures that the final product meets quality standards.

Precision countersink in PCB assembly is a critical technique that contributes to the functionality and reliability of electronic devices. Understanding the various PCB manufacturing methods and fabrication techniques can help ensure the production of high-quality circuit boards.

By following best practices and using the right tools, you can achieve precision countersink and optimize the performance of your PCBs. Whether you're a seasoned professional or new to PCB assembly, mastering these techniques is key to success in the ever-evolving world of electronics.

Incorporate precision countersink in your PCB assembly process today and experience the benefits of efficient, reliable, and aesthetically pleasing circuit boards.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB