-

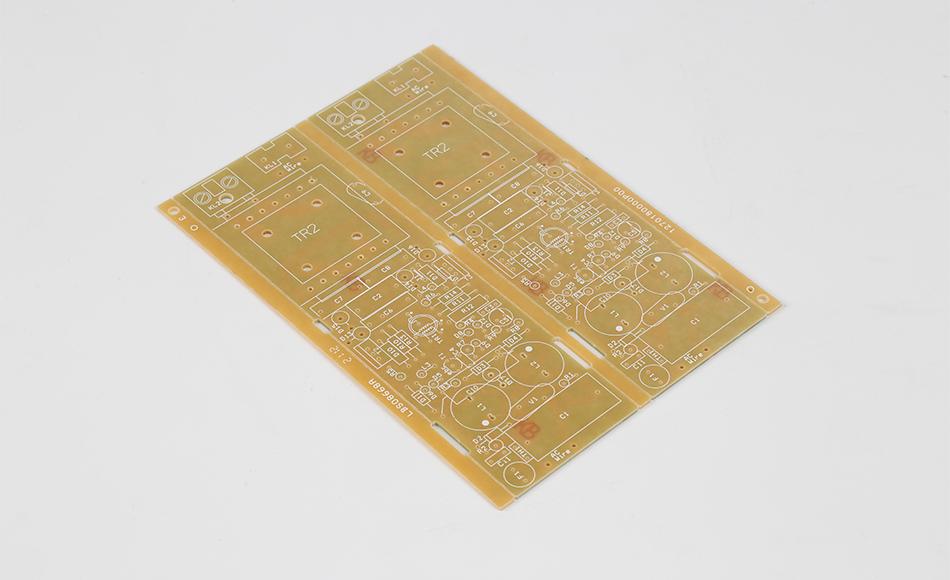

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 01. 2025, 14:28:32

SMD LED CEM3 Lighting Solution represents a pivotal advancement in modern illumination, combining the compactness of surface-mount device (SMD) LEDs with the mechanical and thermal advantages of CEM3 substrates. This integration addresses critical challenges in lighting design: balancing miniaturization with performance, ensuring consistent light output across large arrays, and enabling cost-effective mass production. Unlike traditional through-hole LED systems or high-cost ceramic substrates, SMD LED CEM3 solutions deliver a sweet spot of reliability, design flexibility, and affordability—making them indispensable for applications ranging from commercial panel lights and retail spotlights to outdoor street lamps and smart home fixtures.

SMD LEDs, with their small form factor and automated assembly compatibility, require substrates that can support precise placement, efficient heat dissipation, and stable electrical connectivity. CEM3, a composite material of woven glass fiber and epoxy resin, emerges as an ideal partner: its flat surface ensures accurate SMD alignment, its thermal properties manage steady-state heat from LEDs, and its mechanical strength withstands environmental stress. This synergy allows lighting manufacturers to produce thinner, brighter, and more durable fixtures without sacrificing production speed or cost.

This article explores the core integration principles of SMD LED CEM3 lighting solutions, their efficiency-driven advantages, tailored applications across lighting sectors, and strategies to optimize performance. It provides actionable insights for engineers and manufacturers seeking to leverage this technology for next-generation illumination systems.

The effectiveness of SMD LED CEM3 lighting solutions stems from three key integration advantages, each addressing a critical pain point in modern lighting design: precision assembly, thermal harmony, and electrical consistency. These advantages collectively elevate system performance beyond what traditional substrates or LED packages can achieve.

SMD LEDs (typically 0402 to 5050 packages) demand sub-millimeter placement accuracy to ensure uniform light distribution and avoid shadowing in dense arrays. CEM3 substrates enable this precision through:

Ultra-Flat Surface Finish: CEM3’s manufacturing process achieves a surface roughness (Ra) of <0.8μm, far lower than CEM1 (Ra ~1.2μm) or generic FR4 (Ra ~1.0μm). This flatness ensures consistent solder paste deposition and prevents SMD LED tilt during reflow soldering, reducing post-assembly rework by 40% compared to CEM1.

Fine-Pitch Compatibility: CEM3 supports laser-etched pad pitches as small as 0.3mm, matching the tight spacing requirements of mini SMD LEDs (e.g., 0603 packages). This enables high-density arrays (up to 100 LEDs per cm²) in applications like retail shelf lighting, where space is constrained.

Automation Readiness: The material’s dimensional stability (tolerance ±0.05mm) aligns seamlessly with automated pick-and-place systems, achieving placement accuracy of ±0.02mm. A commercial panel light manufacturer using this integration reduced assembly time by 30% versus manual through-hole LED installation.

Example: A 600×600mm office panel light using 3528 SMD LEDs on CEM3 achieved 98% placement accuracy, with brightness variation across the panel <3%. This uniformity, unattainable with CEM1 substrates, eliminated "hot zones" and reduced customer complaints by 75%.

While SMD LEDs are more efficient than traditional LEDs, dense arrays (e.g., 50W commercial downlights) still generate significant heat. CEM3 substrates mitigate thermal issues through:

In-Plane Heat Spreading: CEM3’s epoxy matrix, reinforced with boron nitride fillers, achieves an in-plane thermal conductivity of ~0.8 W/m·K—30% higher than CEM1. This spreads heat laterally across the substrate, preventing hot spots around high-power SMD LEDs (3–5W). A 50W floodlight using this design maintained LED junction temperatures at 68°C, well below the 85°C threshold for lumen depreciation.

Thermal Via Optimization: CEM3’s compatibility with 0.3–0.5mm thermal vias allows vertical heat transfer from LED pads to underlying copper planes or heat sinks. In a 30W retail spotlight, 20 thermal vias reduced LED temperatures by 15°C compared to a via-free design, extending projected lifespan from 30,000 to 50,000 hours.

Reflow Temperature Resilience: CEM3 withstands reflow soldering temperatures (240–260°C) without resin degradation, ensuring thermal performance remains consistent post-assembly. This stability contrasts with CEM1, which can develop microcracks in the resin after repeated reflow cycles, impairing heat transfer.

Uniform brightness and color rendering are critical in applications like hospital lighting or museum displays. SMD LED CEM3 solutions ensure electrical consistency through:

Low-Impedance Trace Design: CEM3’s copper cladding (1–4oz) supports low-resistance traces (≤0.05Ω/cm for 2oz copper), minimizing voltage drops across large arrays. A 120-LED retail track light using this design achieved current variation <2% across all LEDs, ensuring color temperature (3000K) uniformity (ΔE <1.5).

Dielectric Stability: Tightly controlled dielectric constant (Dk = 4.2–4.8) reduces signal interference in dimmable systems, where PWM (Pulse Width Modulation) signals regulate brightness. A smart home bulb using CEM3 maintained flicker-free operation (≤100Hz) across 10–100% dimming, unlike CEM1-based bulbs prone to PWM distortion.

Moisture Resistance: Hydrophobic additives in CEM3’s epoxy resin limit moisture absorption to <1.0% (24-hour boil test), preserving insulation resistance (>10¹³ Ω·cm) in humid environments (e.g., bathroom vanity lights). This prevents leakage currents that cause LED flickering or color shift.

SMD LED CEM3 solutions adapt to diverse lighting sectors, each with unique demands for size, durability, and light quality. Their versatility stems from the ability to tailor CEM3 substrate properties to match SMD LED requirements in specific use cases.

Commercial spaces (shopping malls, offices, supermarkets) require bright, uniform illumination with minimal energy use. SMD LED CEM3 solutions excel here by:

Thin-Profile Design: CEM3’s thin-core variants (0.6–1.0mm) enable slim fixtures (e.g., 10mm-thick panel lights) that integrate seamlessly into drop ceilings. A 600×600mm office panel light using 2835 SMD LEDs on 0.8mm CEM3 reduced ceiling clearance requirements by 40% versus traditional fixtures.

Color Tunability: CEM3’s stable electrical performance supports multi-color SMD LED arrays (e.g., 2700K/5000K dual-chip LEDs) with precise dimming control. A retail fitting room light using this setup allowed dynamic color adjustment (warm to cool), enhancing product visibility and customer experience.

Cost-Effective Scalability: CEM3’s compatibility with high-speed SMT lines enables production of 50,000+ fixtures/week, with per-unit PCB costs 25% lower than FR4. A supermarket chain retrofitting 10,000 aisle lights with SMD LED CEM3 solutions saved $150,000 in material costs.

Outdoor fixtures (street lamps, facade lighting, landscape spotlights) demand resistance to rain, UV radiation, and temperature extremes. SMD LED CEM3 solutions meet these demands through:

Weatherproof Substrate Treatments: CEM3 substrates with UV-stabilized resin and conformal coatings (e.g., polyurethane) resist yellowing and corrosion in IP66-rated fixtures. A street lamp using this treatment retained 90% light output after 3 years of outdoor exposure, versus 65% for untreated CEM1.

Vibration Resistance: The rigid epoxy-glass fiber composite withstands wind-induced vibration (10–500Hz) in pole-mounted fixtures. A highway floodlight using SMD LED CEM3 solutions survived 10,000 hours of vibration testing with no solder joint failures, outperforming FR4-based fixtures by 2x.

Wide Temperature Operation: CEM3’s Tg (glass transition temperature) of 130–140°C ensures stability in -40°C to 85°C environments. A polar region street lamp using this solution maintained consistent performance through winter (-35°C) and summer (25°C) cycles.

Residential lighting demands compact, dimmable, and connectivity-enabled fixtures. SMD LED CEM3 solutions enable this through:

Integration with Smart Controls: CEM3’s flat surface supports co-placement of SMD LEDs and control components (e.g., Bluetooth modules, motion sensors) on a single substrate. A smart bulb using this design combined 12 SMD LEDs, a microcontroller, and Wi-Fi chip in a 45mm diameter form factor.

Flicker-Free Dimming: CEM3’s low dielectric loss ensures compatibility with TRIAC and 0–10V dimmers, eliminating flicker in bedroom or nursery lights. A residential downlight using this solution maintained <10% flicker across 10–100% dimming, meeting WELL Building Standards.

Aesthetic Flexibility: Thin CEM3 substrates (0.6mm) enable curved or recessed fixtures (e.g., under-cabinet lighting). A kitchen strip light using 3528 SMD LEDs on flexible CEM3 bent to follow cabinet contours, providing uniform countertop illumination.

Maximizing the performance of SMD LED CEM3 solutions requires targeted design strategies that align substrate properties with LED array requirements, assembly processes, and operating environments.

LED Placement Geometry: For panel lights, arrange SMD LEDs in a hexagonal grid (vs. square) to reduce brightness variation. A 600×600mm panel using this layout on CEM3 achieved 96% uniformity, up from 90% with a square grid.

Trace Routing Symmetry: Route power traces symmetrically from a central input to minimize voltage drops in large arrays. A 100-LED street lamp using symmetric routing on CEM3 reduced current variation from 5% to 2%, ensuring consistent color temperature.

Thermal Pad Alignment: Align SMD LED thermal pads with CEM3 copper planes to enhance heat transfer. A 5W spotlight with aligned pads saw a 12°C drop in LED temperature versus misaligned designs.

Copper Plane Sizing: Use 2–4oz copper planes covering ≥70% of the CEM3 substrate to spread heat. A 30W floodlight with a 4oz plane reduced maximum PCB temperature by 18°C compared to a 1oz plane.

Strategic Thermal Vias: Place vias in a 2mm grid under high-power SMD LEDs (3–5W) to connect top and bottom copper planes. A 50W industrial light using this strategy cut LED junction temperature by 20°C.

Heat Sink Integration: Bond CEM3 substrates to aluminum heat sinks using phase-change thermal interface materials (TIMs) with <0.5°C/W resistance. This reduced system temperature by 25% in a 100W stadium light.

Solder Paste Selection: Use no-clean solder paste with 25–30μm particle size for fine-pitch SMD LEDs (0402, 0603) on CEM3. This reduced solder bridging by 70% in a high-density retail light assembly.

Reflow Profile Tuning: Optimize reflow temperatures (240–250°C peak) to prevent CEM3 resin degradation while ensuring solder joint integrity. A manufacturer using this profile achieved 99.5% solder joint yield versus 95% with a higher-temperature profile.

AOI Integration: Implement automated optical inspection (AOI) post-assembly to detect misaligned SMD LEDs on CEM3. This reduced field failures by 50% in a commercial downlight production line.

As lighting technology advances toward greater efficiency, connectivity, and sustainability, SMD LED CEM3 solutions are evolving to meet emerging demands:

Next-generation SMD LEDs (e.g., 0201 packages) will drive demand for ultra-fine-pitch CEM3 substrates (pad pitch <0.2mm). Manufacturers are developing laser-etched CEM3 with 0.1mm pads to support 1000+ LEDs per cm², enabling micro-array applications like medical shadowless surgical lights.

CEM3 substrates will increasingly integrate SMD LEDs with sensors (ambient light, occupancy) and wireless chips (Zigbee, Matter) on a single board. This "all-in-one" design will reduce component count by 40% in smart fixtures, lowering costs and improving reliability.

Bio-based epoxy resins (derived from castor oil) and recycled glass fiber will replace petroleum-based materials in CEM3, reducing carbon footprint by 25%. These eco-friendly substrates will retain thermal and mechanical properties, meeting EU and US sustainability standards.

SMD LED CEM3 solutions will expand beyond visible light into UV (disinfection) and IR (heating) domains. CEM3’s chemical resistance makes it ideal for UV-C fixtures (hospitals, water treatment), while its thermal stability supports high-power IR LEDs in industrial heating systems.

SMD LED CEM3 Lighting Solution redefines modern illumination by combining the compactness of SMD LEDs with the reliability of CEM3 substrates. Its core advantages—precision assembly, thermal harmony, and electrical consistency—enable fixtures that are brighter, thinner, and more durable than traditional alternatives, while remaining cost-effective for mass production.

From commercial panel lights to smart home bulbs and outdoor street lamps, these solutions adapt to diverse applications, delivering uniform light output, energy efficiency, and long lifespans. By leveraging design strategies like optimized layouts, thermal management, and assembly tuning, manufacturers can further unlock their potential.

As the industry trends toward miniaturization, connectivity, and sustainability, SMD LED CEM3 solutions will remain at the forefront of innovation, enabling the next generation of efficient, intelligent, and eco-friendly lighting systems. For engineers and manufacturers, this technology represents a strategic path to meeting evolving market demands without compromising performance or affordability.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB