-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 01. 2025, 14:22:39

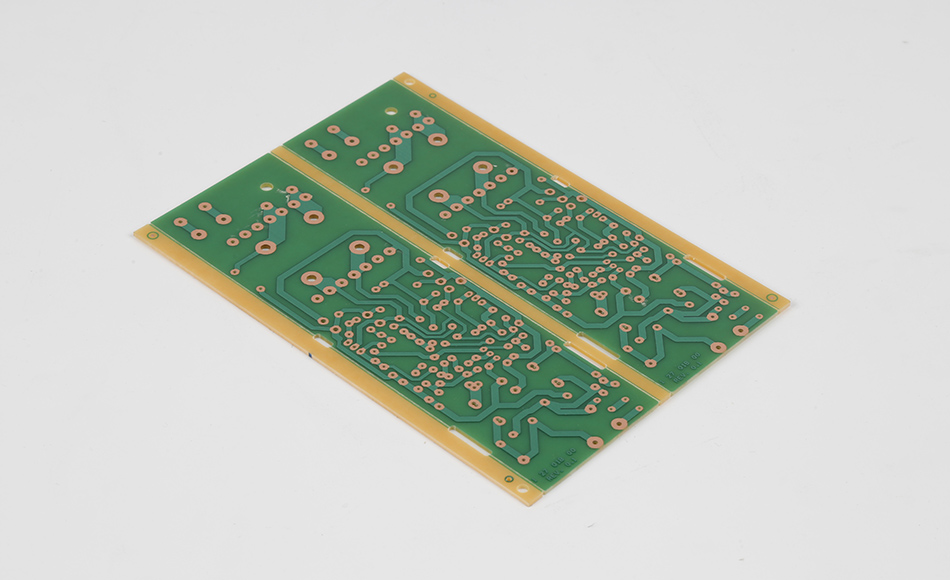

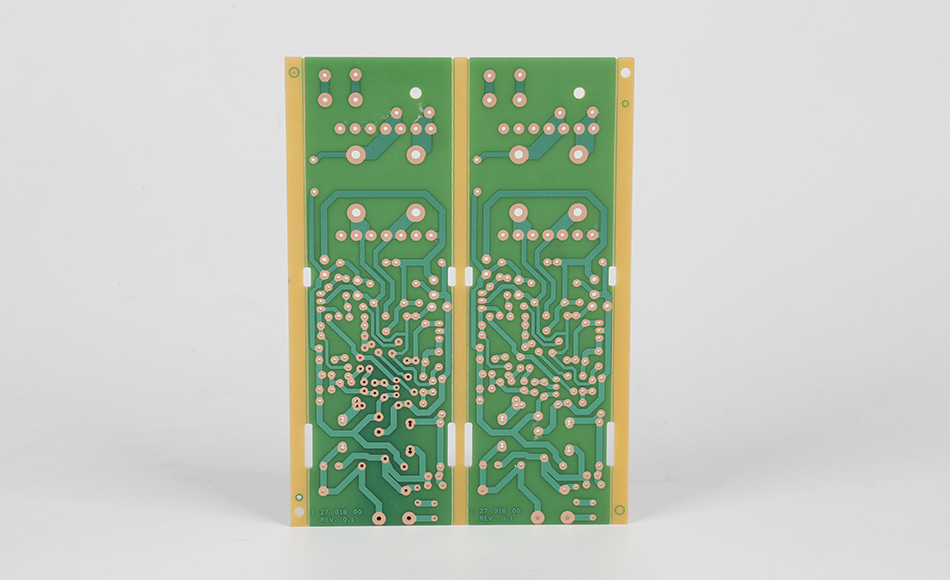

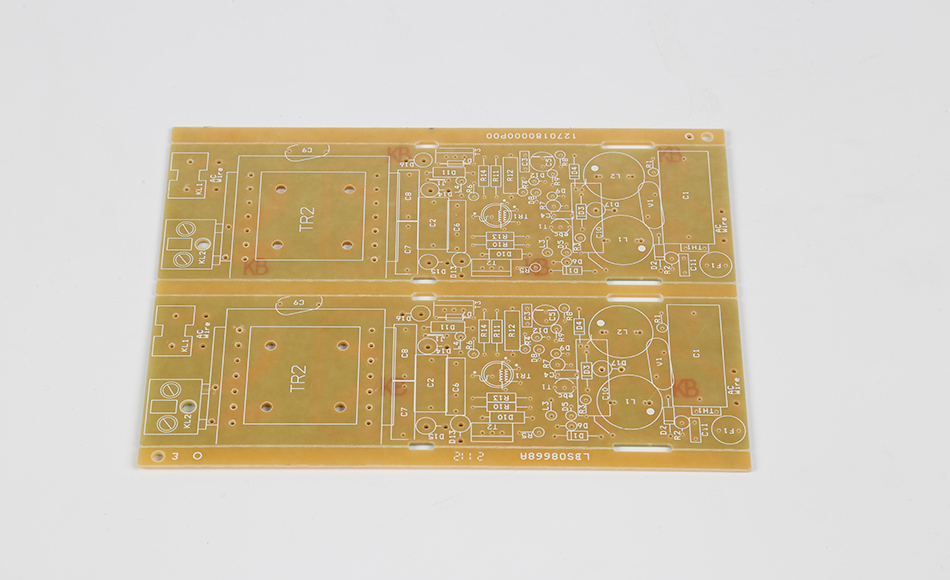

LED Light CEM3 Circuit Board serves as a critical substrate in modern lighting systems, bridging the gap between basic CEM1 boards (limited to low-power lighting) and high-cost FR4 or metal-core PCBs (overengineered for mid-tier applications). Designed to balance thermal management, electrical stability, and cost efficiency, it has become a staple in LED lighting—from residential bulbs and commercial downlights to industrial floodlights and outdoor street lamps.

Unlike substrates optimized for display backlighting or power electronics, LED Light CEM3 Circuit Boards are engineered for the unique demands of continuous LED operation: dissipating steady-state heat from high-power LEDs, ensuring uniform current distribution across multiple LED arrays, and withstanding diverse environmental stressors (moisture, UV radiation, temperature cycles). This specialization makes them indispensable for lighting manufacturers seeking reliable performance without premium costs.

This article explores the core attributes of LED Light CEM3 Circuit Boards, their tailored applications across lighting segments, design strategies to maximize efficiency, and emerging trends in smart lighting integration. It provides actionable insights for lighting engineers, product designers, and manufacturers aiming to develop durable, cost-effective LED systems.

LED Light CEM3 Circuit Boards differentiate themselves through three key attributes, each addressing critical challenges in LED lighting systems—ensuring longevity, performance consistency, and adaptability to diverse operating conditions.

LEDs generate steady-state heat during operation, and excess heat accelerates lumen depreciation (light output loss) and shortens lifespan. LED Light CEM3 Circuit Boards are engineered to mitigate this through:

Enhanced In-Plane Heat Spread: The woven glass fiber and epoxy matrix, reinforced with thermally conductive fillers (e.g., boron nitride), enables efficient heat distribution across the board surface. This reduces hot spots around high-power LEDs (1–5W), lowering junction temperatures by 10–15°C compared to standard CEM1 boards. For example, a 30W floodlight using a CEM3 circuit board maintained LED temperatures at 65°C, extending projected lifespan to 50,000 hours (vs. 30,000 hours with CEM1).

Thermal Stability Under Prolonged Use: The epoxy resin in LED Light CEM3 Circuit Boards is formulated to retain mechanical and electrical properties at sustained temperatures up to 105°C. This prevents board warping or insulation breakdown in fixtures operating 24/7 (e.g., industrial warehouse lighting), a common failure point for generic CEM boards.

Compatibility with Heat Sinks: The flat, uniform surface of CEM3 allows secure bonding with heat sinks or thermal pads, creating a direct thermal pathway from LEDs to ambient air. A street lamp design pairing CEM3 with an aluminum heat sink reduced system temperature by 20°C, meeting outdoor lighting durability standards.

LED lighting systems—especially multi-LED arrays (e.g., panel lights, troffers)—require stable current distribution to avoid uneven brightness or color shift. LED Light CEM3 Circuit Boards deliver this through:

Low-Impedance Trace Design: Optimized copper trace geometry (width, thickness) minimizes resistance variation across the board, ensuring each LED in an array receives consistent current (±2% tolerance). This reduces brightness mismatch in commercial downlights from 15% (with CEM1) to <5% (with CEM3).

Dielectric Stability: Tightly controlled dielectric constant (Dk) and low dielectric loss (Df) prevent signal interference in dimmable LED systems, where PWM (Pulse Width Modulation) signals regulate brightness. A dimmable residential bulb using CEM3 maintained flicker-free operation across all dimming levels, unlike CEM1 boards prone to signal distortion.

Insulation Resistance in Humid Environments: Moisture-resistant epoxy formulations preserve insulation resistance (>10¹³ Ω·cm) in damp settings (e.g., bathroom vanity lights, outdoor garden fixtures). This prevents leakage currents that cause LED flickering or premature failure.

LED lighting fixtures operate in diverse environments—from dry indoor spaces to rain-exposed outdoor poles—demanding robust substrate resilience. LED Light CEM3 Circuit Boards excel here through:

Vibration and Impact Resistance: The rigid epoxy-glass fiber composite withstands mechanical stress in portable lighting (e.g., work lights, emergency lanterns) or fixtures mounted on vibrating surfaces (e.g., factory machinery). Testing shows CEM3 boards survive 1,000 drop tests (1m height) with no trace damage, outperforming brittle FR4 in rugged applications.

UV and Chemical Resistance: For outdoor lighting (street lamps, parking lot fixtures), UV-stabilized resins prevent material yellowing and degradation from sunlight exposure. Additionally, chemical resistance to cleaning agents (e.g., in food processing facilities) ensures longevity in harsh industrial environments.

Dimensional Stability: Low coefficient of thermal expansion (CTE) minimizes board warping during temperature cycles (-40°C to 85°C), critical for fixtures with precision optical components (e.g., track lights, spotlights), where alignment affects beam accuracy.

LED Light CEM3 Circuit Boards adapt to diverse lighting applications, each with unique requirements—from compact residential bulbs to large-scale outdoor fixtures. Their versatility stems from the ability to balance performance and cost across use cases.

Indoor lighting (bulbs, downlights, panel lights) demands compact design, dimming compatibility, and low cost. LED Light CEM3 Circuit Boards meet these needs by:

Space-Efficient Layouts: Thin-core CEM3 (0.6–1.0mm) enables compact bulb designs (e.g., A19, PAR30) without sacrificing thermal performance. A 9W LED bulb using CEM3 fits standard sockets while housing 12 LEDs in a 30mm diameter board.

Dimming Circuit Integration: The stable dielectric properties of CEM3 support integrated dimming circuits (e.g., TRIAC, 0–10V), eliminating the need for separate control boards. A commercial downlight with integrated dimming on CEM3 reduced component count by 30% and assembly time by 25%.

Cost-Effectiveness for Mass Production: CEM3’s compatibility with high-speed SMT assembly (pick-and-place, reflow soldering) enables production of 100,000+ units/week at 20–30% lower cost than FR4, ideal for budget-friendly residential lighting lines.

Outdoor fixtures (street lamps, floodlights, landscape lighting) require resistance to rain, UV, and extreme temperatures. LED Light CEM3 Circuit Boards are optimized for this through:

Weatherproof Construction: Hydrophobic coatings and UV-stabilized resin protect CEM3 boards in IP65/IP66-rated fixtures (e.g., street lamps). A highway floodlight using treated CEM3 operated reliably through 2,000 hours of rain and snow exposure, with no corrosion or insulation loss.

High-Power LED Support: Thick copper traces (2–4oz) on CEM3 handle currents for high-power LEDs (5–10W per chip), enabling bright outdoor fixtures (e.g., 200W floodlights) without overheating. This avoids the need for metal-core PCBs, cutting costs by 40%.

Thermal Cycling Durability: CEM3’s ability to withstand -40°C to 85°C cycles prevents delamination in regions with extreme temperature swings. A northern European street lamp using CEM3 survived 500 winter-summer cycles with no performance degradation.

Industrial lighting (warehouse high bays, factory work lights) and specialty systems (grow lights,explosion-proff fixtures) demand ruggedness and performance consistency. LED Light CEM3 Circuit Boards deliver through:

Vibration Resistance for Industrial Environments: Reinforced trace bonding and thick copper (4oz) make CEM3 suitable for fixtures near machinery (e.g., factory work lights). A warehouse high bay light using CEM3 survived 10,000 hours of 10–500Hz vibration with no loose components.

Spectral Stability for Specialty Applications: In grow lights, CEM3’s stable electrical properties ensure consistent current to color-specific LEDs (e.g., 660nm red, 450nm blue), maintaining optimal plant growth wavelengths. A vertical farm using CEM3-based grow lights reported 10% higher crop yields due to uniform spectral output.

explosion-proff Compliance: For hazardous locations (e.g., oil refineries), CEM3’s flame-retardant properties (UL 94 V-0) and non-conductive matrix meet explosion-proff standards, avoiding sparks in explosive atmospheres.

Maximizing the performance of LED Light CEM3 Circuit Boards requires targeted design strategies, tailored to the unique demands of lighting applications—from thermal management to assembly efficiency.

Thermal Via Placement: Arrays of 0.3–0.5mm thermal vias under high-power LEDs (1W+) transfer heat from the top copper layer to the bottom, reducing junction temperatures by 15–20°C. A 50W floodlight with 3x3 via arrays per LED achieved 60°C junction temps (vs. 78°C without vias).

Copper Plane Design: Solid copper planes (2–4oz) on both board sides spread heat across the fixture, paired with strategic cutouts to avoid blocking optical elements (e.g., lenses, reflectors). A panel light using this design reduced hot spot temperatures by 12°C.

Heat Sink Integration: Direct bonding of CEM3 boards to aluminum heat sinks (using thermal adhesive with <0.5°C/W resistance) creates a continuous thermal path. A street lamp using this method cut system temperature by 25°C.

Current Path Equalization: Symmetric trace routing ensures each LED in an array receives identical current, reducing brightness variation. A 12-LED downlight with balanced routing achieved ±2% brightness uniformity, vs. ±8% with asymmetric designs.

Dimming Circuit Isolation: Separate ground planes for dimming circuits and LED arrays prevent noise interference in dimmable fixtures. A TRIAC-dimmable bulb using this isolation eliminated flicker at low brightness levels.

Overvoltage Protection Integration: Adding TVS (Transient Voltage Suppression) diodes directly on the CEM3 board protects LEDs from power surges (common in outdoor lighting). A storm-exposed street lamp with TVS diodes survived 300V surges with no LED damage.

Standardized Component Footprints: Using common LED footprints (e.g., 2835, 5050) reduces tooling changes between product lines. A lighting manufacturer using standardized footprints cut setup time by 40% when switching between bulb models.

Panelization for Mass Production: Grouping small CEM3 boards (e.g., bulb PCBs) into panels of 10–20 units streamlines SMT assembly, reducing per-unit processing time by 30%.

Test Point Integration: Adding test points for current, voltage, and thermal monitoring simplifies quality control, reducing inspection time by 25% for high-volume production runs.

As lighting systems evolve toward smart control and sustainability, LED Light CEM3 Circuit Boards are adapting to enable new capabilities—from IoT integration to eco-friendly manufacturing.

Sensor and Wireless Module Embedding: CEM3’s compatibility with small-form-factor sensors (ambient light, motion) and wireless chips (Bluetooth, Zigbee) enables smart fixtures (e.g., motion-sensing floodlights, app-controlled bulbs). A CEM3-based smart bulb with integrated motion sensor reduced energy use by 50% in field tests.

Power Over Ethernet (PoE) Support: Enhanced copper traces on CEM3 boards enable PoE lighting (e.g., office panel lights), combining power and data transmission over a single cable. This reduces wiring costs by 30% in commercial buildings.

Recycled Content: Incorporating 25–30% recycled glass fiber in CEM3 reduces carbon footprint by 20% without performance loss. A European lighting brand using recycled CEM3 achieved EU ECOLABEL certification, boosting green market appeal.

Bio-Based Epoxy Resins: Plant-derived epoxies (e.g., from castor oil) replace petroleum-based resins, improving biodegradability at end-of-life while retaining thermal stability. Testing shows bio-based CEM3 matches traditional versions in heat and moisture resistance.

Nano-Filler Enhancement: Adding graphene or carbon nanotubes to CEM3’s epoxy matrix increases thermal conductivity by 40–50%, enabling higher-power LEDs (10W+) without heat sinks. A prototype 300W floodlight using nano-enhanced CEM3 reduced weight by 25% vs. conventional designs.

LED Light CEM3 Circuit Board has emerged as a foundational technology in modern lighting, balancing thermal management, electrical uniformity, and cost efficiency across residential, outdoor, and industrial applications. Its ability to address the unique demands of LED lighting—from continuous heat dissipation to environmental resilience—makes it a preferred choice for manufacturers seeking reliable, scalable solutions.

Real-world applications demonstrate its impact: longer lifespans in outdoor fixtures, consistent performance in smart bulbs, and reduced costs in mass-produced residential lighting. By leveraging design strategies like thermal via optimization, current path equalization, and smart component integration, engineers can further unlock its potential.

As lighting evolves toward smart, sustainable systems, CEM3 circuit boards will continue to adapt—integrating sensors, using eco-friendly materials, and enhancing thermal performance. For the lighting industry, they represent a strategic blend of performance and practicality, enabling innovation without compromising affordability.

In a market where efficiency, durability, and cost are paramount, LED Light CEM3 Circuit Boards stand as a critical enabler, powering the next generation of advanced lighting solutions.

Related Articles

CEM3 PCB Material Guide: ST210G Thermal Conductivity & LED Solutions

CEM3 PCB Material Guide for Industrial Electronics Applications

CEM3 PCB Manufacturer | The Best Cost-Effective Alternative to FR4

CEM3 PCB Manufacturer for Cost-Effective Industrial Electronics

CEM3-09HT Thermal Conductive PCB: Dual Advantages of High-Temp Resilience and Heat Dissipation

Countersink Holes in CEM3 PCB: Ensuring Structural Integrity and Assembly Precision

KB7150T High TG CEM3 Circuit Board: Reliable Performance for High-Temperature Electronics

HA30 CEM3 Thermal Conductivity Specs: Guiding Heat Management in Mid-Tier Electronics

Low CTE CEM3 Material for High Stability: Ensuring Precision in Dynamic Operational Environments

ST210G CEM3 Thermal Performance: Optimizing Heat Management for High-Power Electronic Devices

Thermal CEM3: Balancing Heat Management and Practicality in Electronics Substrates

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB