-

- PCB TYPE

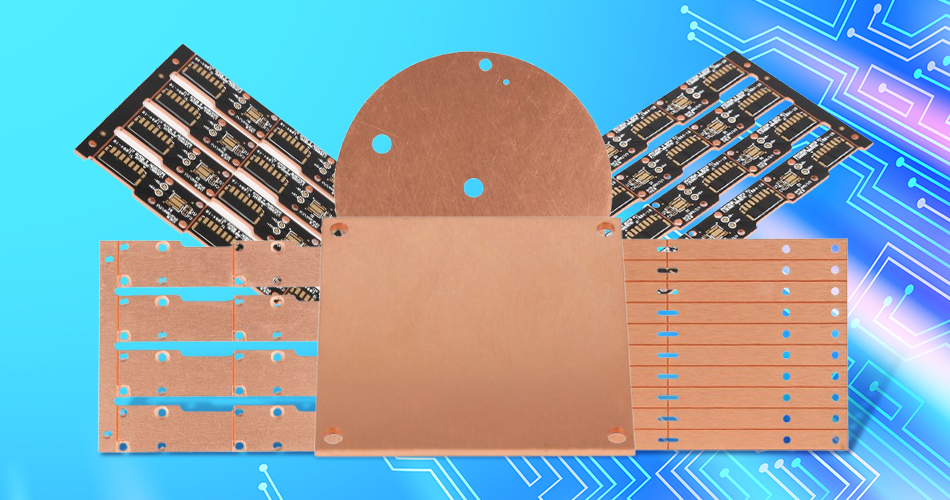

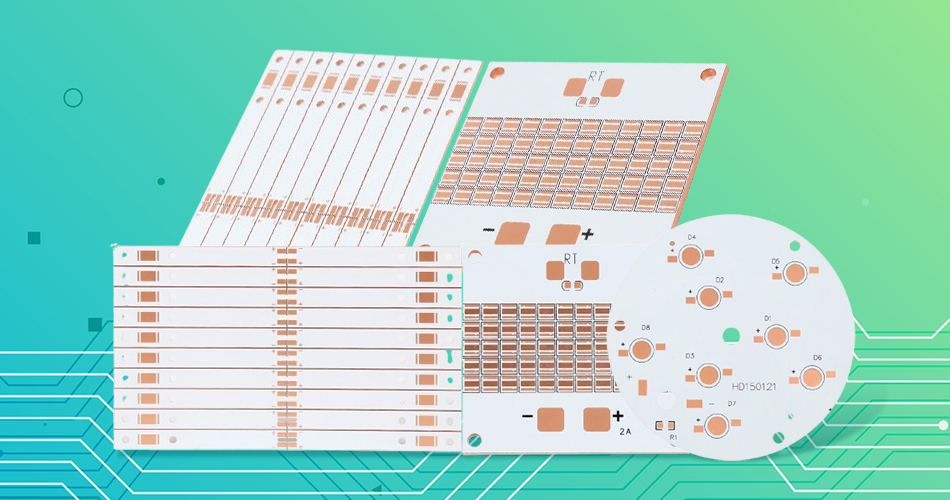

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 12. 2025, 11:05:47

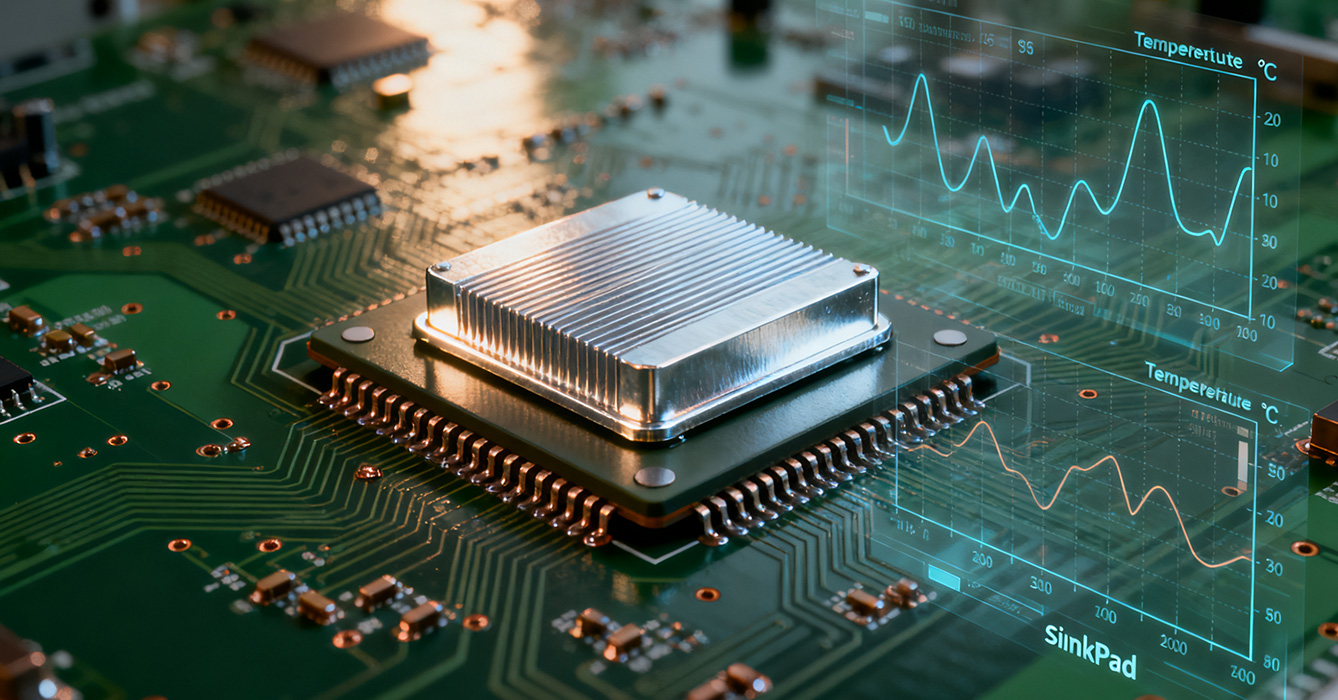

Sinkpad PCB emerges as a critical thermal management solution for electronics where balancing heat dissipation with design constraints—such as space, cost, and electrical compatibility—cannot be achieved with generic PCBs. Unlike standard thermal solutions that prioritize either heat transfer or form factor, a sinkpad PCB integrates a dedicated thermal pad (sinkpad) directly into the board’s architecture, enabling engineers to address application-specific thermal challenges without compromising other design goals. This flexibility makes it indispensable for devices ranging from compact consumer wearables to rugged industrial controllers, where one-size-fits-all thermal approaches fail. This article explores the key design tradeoffs in sinkpad PCB development, customization strategies for diverse use cases, performance validation methods tailored to real-world conditions, and emerging innovations that expand its applicability.

Engineers face three core tradeoffs when designing sinkpad PCBs, each requiring careful balancing to meet project goals:

The sinkpad’s role as a heat conductor conflicts with the need to isolate it from signal or power layers to prevent short circuits. To resolve this:

Insulating Layer Selection: Thin, high-temperature insulating materials (e.g., ceramic-filled prepreg or polyimide films) are used between the sinkpad and adjacent layers. These materials maintain electrical separation while enabling sufficient heat transfer—though thicker insulators boost isolation at the cost of slightly higher thermal resistance.

Selective Sinkpad Patterning: For mixed-signal PCBs, sinkpads are patterned to cover only high-power component areas, avoiding overlap with sensitive circuitry. This limits thermal transfer to critical zones while preserving signal integrity for low-noise components like sensors or microcontrollers.

High-performance sinkpad materials (e.g., solid copper or copper-tungsten composites) enhance heat dissipation but increase production costs. Cost-performance balance is achieved through:

Material Grading: Low-power applications (e.g., USB chargers) use thin copper-clad sinkpads bonded to standard FR-4 substrates, while high-power systems (e.g., industrial inverters) opt for aluminum-core sinkpads. This targets thermal performance to the application’s actual needs, avoiding over-engineering.

Standardized Sinkpad Templates: For high-volume production (e.g., smartphone power management PCBs), pre-designed sinkpad templates reduce tooling costs and lead times, while still allowing minor adjustments to fit specific component footprints.

Sinkpads add structural rigidity to PCBs, which is beneficial for industrial devices but problematic for flexible electronics (e.g., foldable wearables). To address this:

Flexible Sinkpad Composites: Thin copper-polyimide sinkpads are integrated into flexible PCBs, enabling bending while maintaining thermal conductivity. These composites sacrifice minimal rigidity compared to solid metal sinkpads but retain enough flexibility for foldable or curved designs.

Segmented Sinkpads: For partially flexible PCBs (e.g., automotive dashboard modules with rigid and flexible sections), sinkpads are split into segments connected by flexible hinges. This allows the flexible sections to bend without cracking the sinkpad, while rigid segments maintain thermal performance for high-power components.

Sinkpad PCBs are tailored to match the unique demands of three key sectors:

Industrial PCBs (e.g., motor drive controllers) operate in high-temperature, vibration-prone environments. Customizations include:

Reinforced Metal-Core Sinkpads: Aluminum or copper-core sinkpads with thickened edges resist vibration-induced damage, while conformal coatings protect against dust and moisture.

Integrated Heat Sink Mounts: Sinkpads are designed with pre-drilled holes to attach external heat sinks, creating a "dual-path" thermal solution for sustained high-power operation (e.g., 24/7 motor control).

Compact consumer devices (e.g., wireless earbuds, smartwatches) require miniaturized sinkpads:

Ultra-Thin Sinkpad Layers: 0.1–0.2mm copper sinkpads are integrated into 4-layer PCBs, adding minimal thickness while dissipating heat from small power ICs (e.g., battery chargers).

Enclosure-Coupled Sinkpads: Sinkpads are positioned to contact the device’s plastic or metal enclosure, using the enclosure as a secondary heat spreader. This eliminates the need for external heat sinks, preserving the device’s slim profile.

Automotive PCBs (e.g., EV battery management systems) face temperature extremes (-40°C to 125°C) and chemical exposure. Custom sinkpad features include:

Corrosion-Resistant Sinkpads: Nickel-plated copper sinkpads resist degradation from road salts or coolant leaks, ensuring long-term reliability.

Thermal Buffer Layers: Phase-change materials (PCMs) are applied between the sinkpad and high-power components (e.g., IGBTs), absorbing heat during peak operation (e.g., fast charging) to prevent temperature spikes.

Effective sinkpad PCB design requires validation beyond lab tests, focusing on real-world conditions:

Thermal Cycling Tests: PCBs undergo repeated temperature cycles (e.g., -40°C to 125°C) to simulate seasonal or operational temperature swings, ensuring the sinkpad maintains thermal performance without delaminating.

Vibration-Thermal Combined Testing: For automotive or industrial PCBs, tests combine thermal stress with vibration (e.g., 10–2000 Hz) to verify that sinkpads remain intact and thermally effective under harsh conditions.

In-Field Thermal Monitoring: Pilot production runs include embedded temperature sensors near sinkpads, collecting data during actual use to refine designs (e.g., adjusting sinkpad size for unexpected hotspots).

Two trends are expanding the capabilities of sinkpad PCBs:

AI-Optimized Sinkpad Layouts: Machine learning tools analyze component heat maps and design constraints (e.g., space, cost) to generate optimal sinkpad shapes and positions, reducing design time by 30–40% while improving thermal performance.

Sustainable Sinkpad Materials: Recycled copper and bio-based insulating layers are being integrated into sinkpad PCBs, aligning with industry sustainability goals without compromising thermal or electrical performance.

Sinkpad PCB design is defined by intentional tradeoffs and customization—balancing thermal performance with electrical isolation, cost, and form factor to meet the unique needs of each application. By tailoring materials, patterns, and structures to industrial, consumer, and automotive use cases, and validating performance under real-world conditions, sinkpad PCBs deliver targeted thermal solutions that generic PCBs cannot match. As electronics grow more compact and power-dense, the ability to navigate these design tradeoffs will keep sinkpad PCBs at the forefront of thermal management innovation, enabling reliable performance across diverse ecosystems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB