-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 27. 2025, 13:55:24

Printed Circuit Board (PCB) design is a complex process that involves several critical steps. One of these steps is the incorporation of counterbore holes. But what exactly are counterbore holes, and why are they important in PCB assembly? This article will explore the concept of counterbore holes, their applications, and how they fit into the broader scope of PCB design.

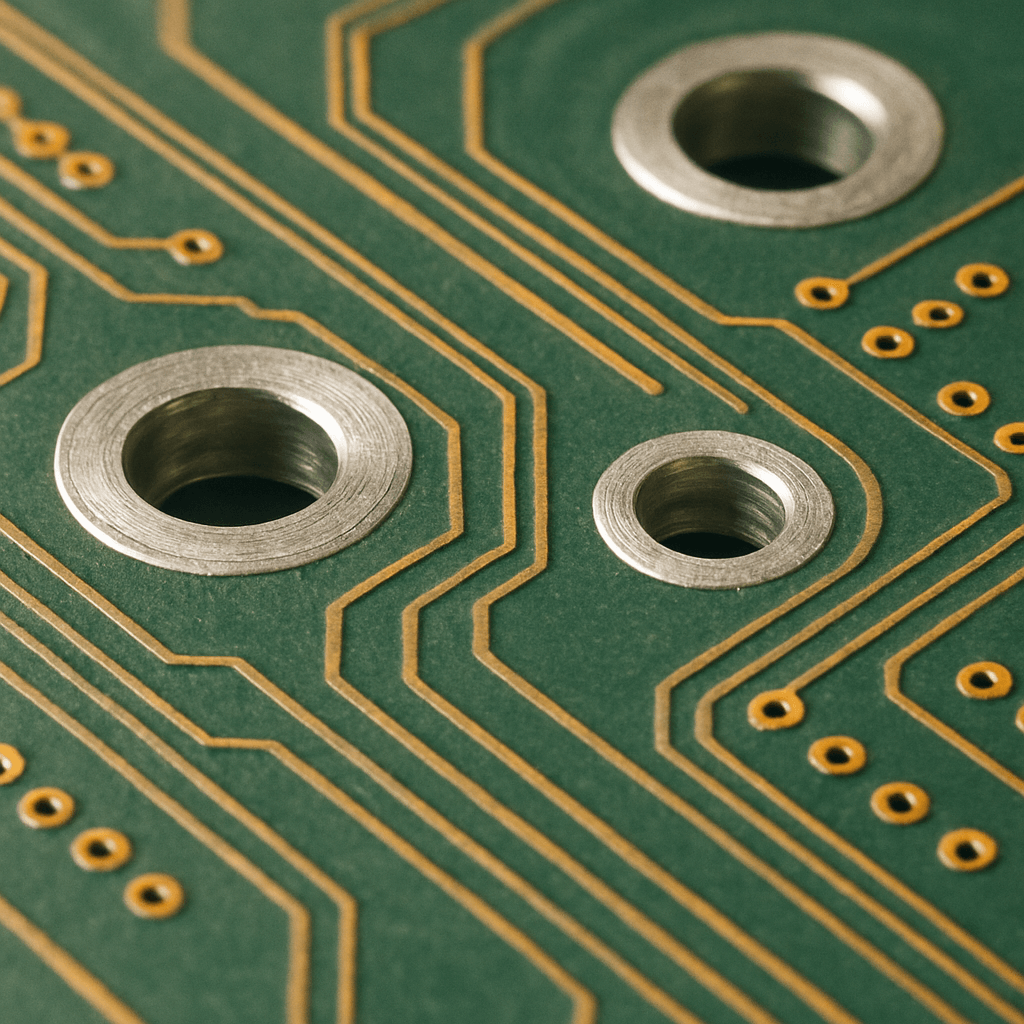

Counterbore holes are a type of hole that is larger at the top than at the bottom, creating a flat-bottomed, cylindrical recess. This design allows for the head of a screw or bolt to sit flush with or below the surface of the material, which is crucial in many electronic applications.

In PCB assembly, counterbore holes are often employed to accommodate fasteners, ensuring that components are securely attached without protruding above the board's surface. This is particularly important in applications where space is a premium, or where a smooth surface is required to prevent interference with other components or enclosures.

The use of counterbore holes in PCB design is not just about aesthetics or space-saving. It provides several functional benefits that are vital for the performance and reliability of electronic devices.

Secure Component Attachment: By allowing fasteners to sit flush with the PCB surface, counterbore holes help to securely attach components, minimizing the risk of movement or detachment during use.

Space Optimization: Counterbore holes contribute to efficient use of space on the PCB. This is especially beneficial in compact electronic devices where every millimeter counts.

Prevention of Short Circuits: Ensuring that fasteners do not protrude above the PCB surface helps prevent short circuits and protects sensitive electronic components.

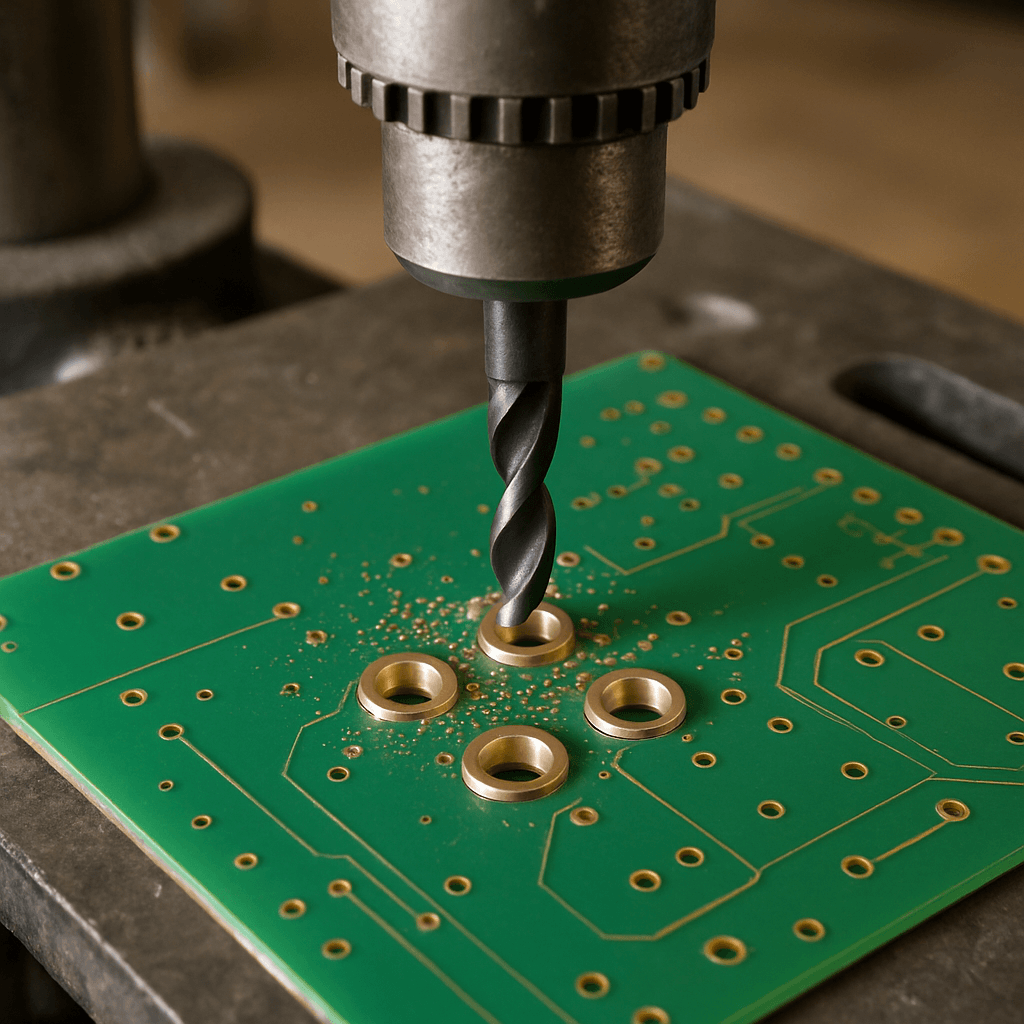

Creating counterbore holes in PCBs involves precise drilling and milling processes. These processes require specialized equipment and must adhere to stringent specifications to ensure accuracy and consistency.

The initial step in creating a counterbore hole is drilling. A drill press or CNC machine is typically used to create the hole to the required depth and diameter. The drill bit must be chosen carefully to match the specifications of the fastener that will be used.

Once the initial hole has been drilled, milling is used to create the counterbore. This involves removing additional material from the top section of the hole to create the cylindrical recess. Precision is key during this step, as any deviation can affect the fit and function of the fastener.

Counterbore holes are used in a wide range of PCB applications, from consumer electronics to industrial machinery. Here are some common scenarios where counterbore holes play a critical role:

Consumer Electronics: In smartphones and tablets, where space is limited, counterbore holes enable secure component fastening without compromising the sleek design.

Automotive Electronics: Counterbore holes are used to ensure that PCBs can withstand the vibrations and movements typical in automotive environments.

Medical Devices: In medical equipment, precision and reliability are paramount. Counterbore holes help maintain the integrity of PCBs, ensuring that devices function as intended.

Designing PCBs with counterbore holes requires careful planning and attention to detail. Here are some best practices to follow:

Before designing your PCB, it's essential to understand the specific requirements of your project. This includes knowing the size and type of fasteners you will use, as well as any space constraints or environmental factors that may affect your design.

Working closely with your PCB manufacturer can help ensure that your design is feasible and cost-effective. Manufacturers can provide valuable insights into the capabilities and limitations of their equipment, helping you optimize your design for production.

PCB design software can be a valuable tool in planning and executing your design. Many software packages offer features specifically for designing counterbore holes, allowing you to visualize and adjust your design before production.

Before moving to full-scale production, it's crucial to test prototypes of your PCB design. This allows you to identify any issues with your design and make necessary adjustments.

Counterbore holes are a critical component of PCB assembly, offering benefits such as secure component attachment, space optimization, and prevention of short circuits. By understanding the role of counterbore holes in PCB design and following best practices, you can create reliable and efficient PCBs for a wide range of applications.

Whether you're working on consumer electronics, automotive components, or medical devices, incorporating counterbore holes into your PCB design can enhance the functionality and performance of your final product. By paying attention to detail and collaborating with skilled manufacturers, you can ensure that your PCBs meet the highest standards of quality and reliability.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related News

PCB Assembly & Manufacturing Equipment Guide | ApolloPCB Solutions

Efficient PCB Assembly: Mastering Countersink Holes

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

Blind and Buried Vias in Aluminum PCBs: Elevating High-Frequency Circuit Design

Counterbore Holes in Sinkpad PCB: Key Considerations for Thermal-Mechanical Performance

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB