-

- PCB TYPE

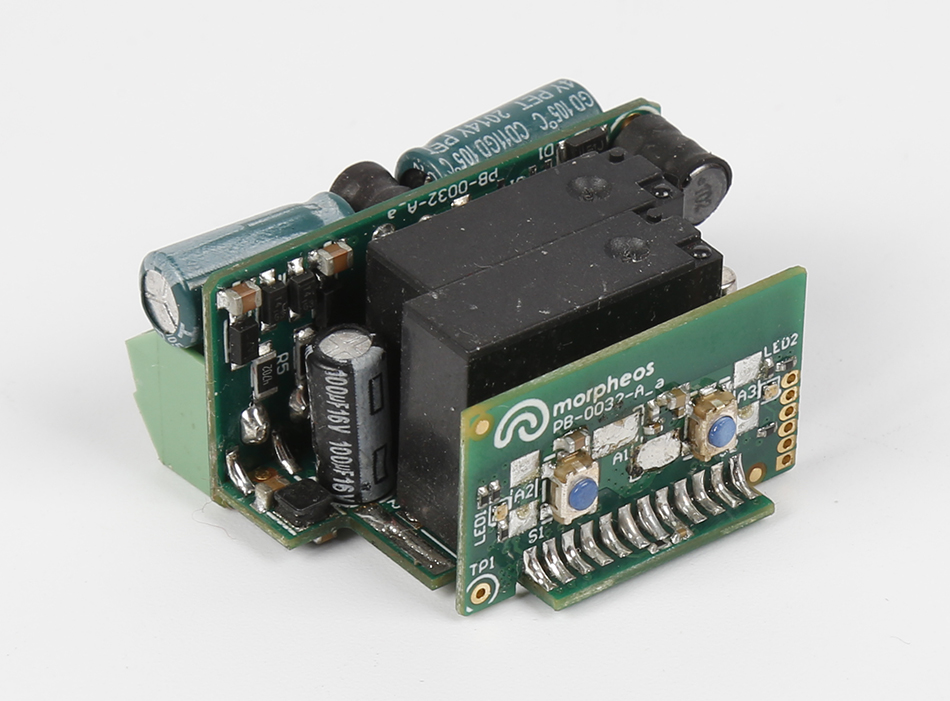

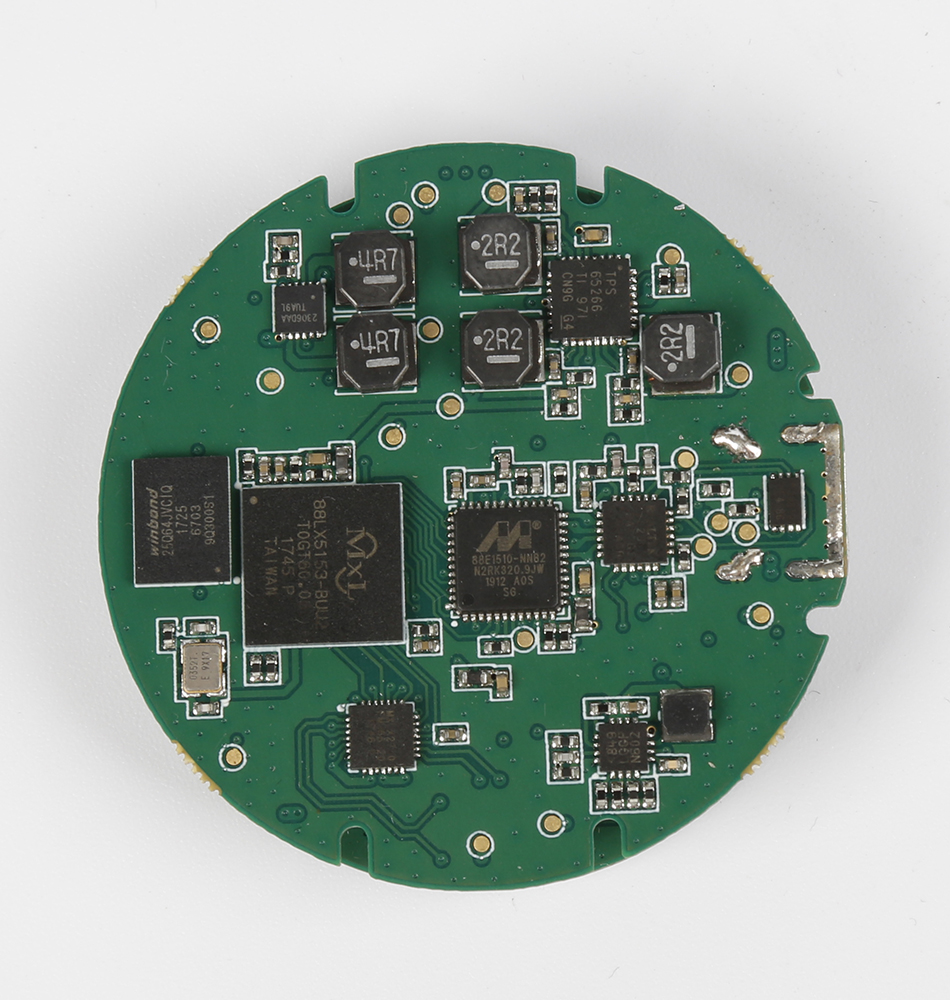

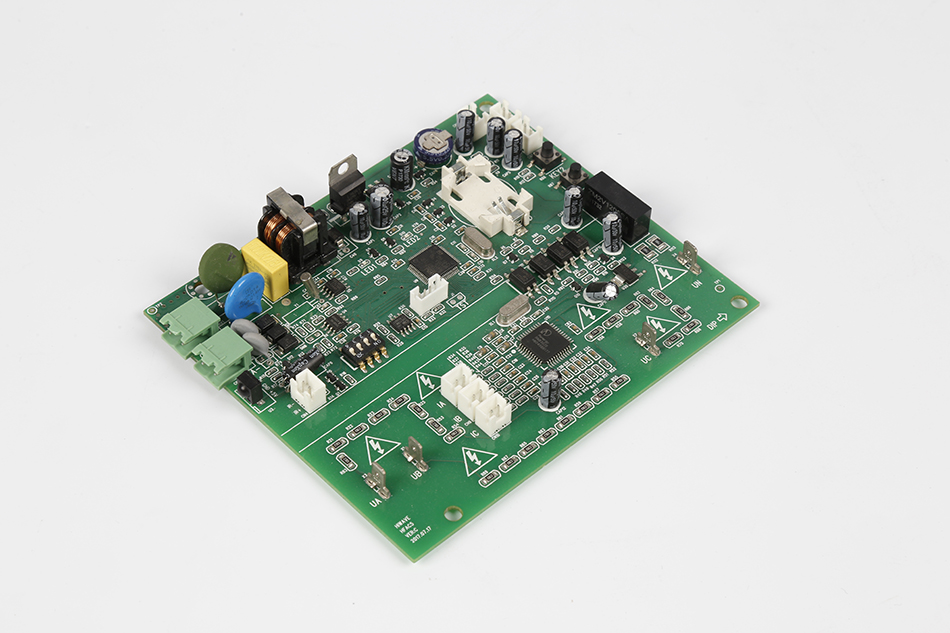

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 05. 2025, 13:37:17

Urgent Quick Turn PCB Assembly represents a specialized subset of fast-track manufacturing, designed to address time-sensitive crises and unplanned demands that cannot wait for standard production timelines. Unlike scheduled quick-turn services, urgent assembly prioritizes immediate resource mobilization—often for scenarios where delays could lead to safety risks, significant financial losses, or mission failure. From emergency medical equipment repairs during public health crises to last-minute fixes for aerospace mission components, this service acts as a critical safety net for industries where “time is mission-critical.” This article explores the unique response frameworks, risk-mitigation strategies, targeted use cases, and operational agility that define urgent quick turn PCB assembly.

Urgent quick turn assembly relies on dynamic, demand-driven systems to accelerate production without sacrificing control:

- Real-Time Demand Triage: Providers use a priority scoring system to assess urgency—factoring in safety impact (e.g., medical devices), financial risk (e.g., industrial downtime), and mission criticality (e.g., military). This triage ensures resources are allocated to the most pressing orders first, avoiding bottlenecks.

- Dynamic Resource Allocation: Unlike fixed quick-turn lines, urgent services redirect flexible production cells—pausing non-critical orders temporarily to free up pick-and-place machines, reflow ovens, and skilled technicians. This “surge capacity” model lets providers scale response to sudden spikes in urgent demand.

- Emergency Supply Chain Activation: For hard-to-source components, providers activate pre-negotiated “emergency access” agreements with distributors, enabling after-hours deliveries and priority access to limited stock. Some even maintain a “critical component reserve” for high-risk industries like aerospace and healthcare.

Urgency demands stricter risk controls to avoid compounding crises with defective assemblies:

Testing focuses on “mission-critical” parameters first: e.g., for a medical ventilator PCB, functional testing of power regulation and sensor connectivity takes precedence, with secondary checks (like cosmetic flaws) deferred to post-deployment. This ensures the assembly meets safety requirements before delivery.

Digital compliance logs are updated in real time, capturing material certifications, test results, and technician sign-offs. This documentation is shared with clients immediately, ensuring traceability even in urgent handoffs—critical for industries like aviation where regulatory audits are mandatory.

If a design has manufacturability issues, engineers offer “emergency redesign alternatives” (e.g., substituting a unavailable component with a functionally equivalent, pre-qualified part) within hours. This balances speed with design integrity, avoiding rushed fixes that cause long-term failures.

After natural disasters (e.g., earthquakes, hurricanes), urgent PCB assembly repairs communication equipment (radios, satellite terminals) and medical devices (portable defibrillators) for first responders. For example, following a flood, a quick-turn provider might deliver 50 repaired communication PCBs in 12 hours to restore emergency radio networks.

Military missions and satellite launches often face last-minute PCB failures. Urgent assembly providers support these scenarios with “flight-ready” assemblies that meet MIL-STD-883 standards, delivering replacements for avionics or guidance system PCBs within hours to keep missions on track.

During pandemics or medical supply shortages, urgent assembly scales production of critical device PCBs—such as oxygen concentrators or diagnostic test readers. Providers work with regulators to expedite compliance, ensuring assemblies meet FDA or CE standards while cutting delivery times by 70% compared to normal production.

The biggest challenge is balancing speed with communication—ensuring clients understand trade-offs (e.g., component substitutions). Future solutions include AI-powered “urgency simulators” that predict timeline impacts of design changes, and blockchain-enabled component tracking for instant provenance verification. Additionally, “mobile quick-turn labs” (equipped with compact assembly equipment) will deploy to disaster zones for on-site repairs.

Urgent Quick Turn PCB Assembly is not just about speed—it’s about controlled, responsible rapid response in high-stakes scenarios. By combining dynamic resource allocation, targeted quality checks, and emergency supply chain partnerships, providers deliver assemblies that keep critical systems running when failure is not an option. As industries face increasing volatility, this service will remain an indispensable tool for resilience, turning crises into manageable challenges through agility and expertise.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB