-

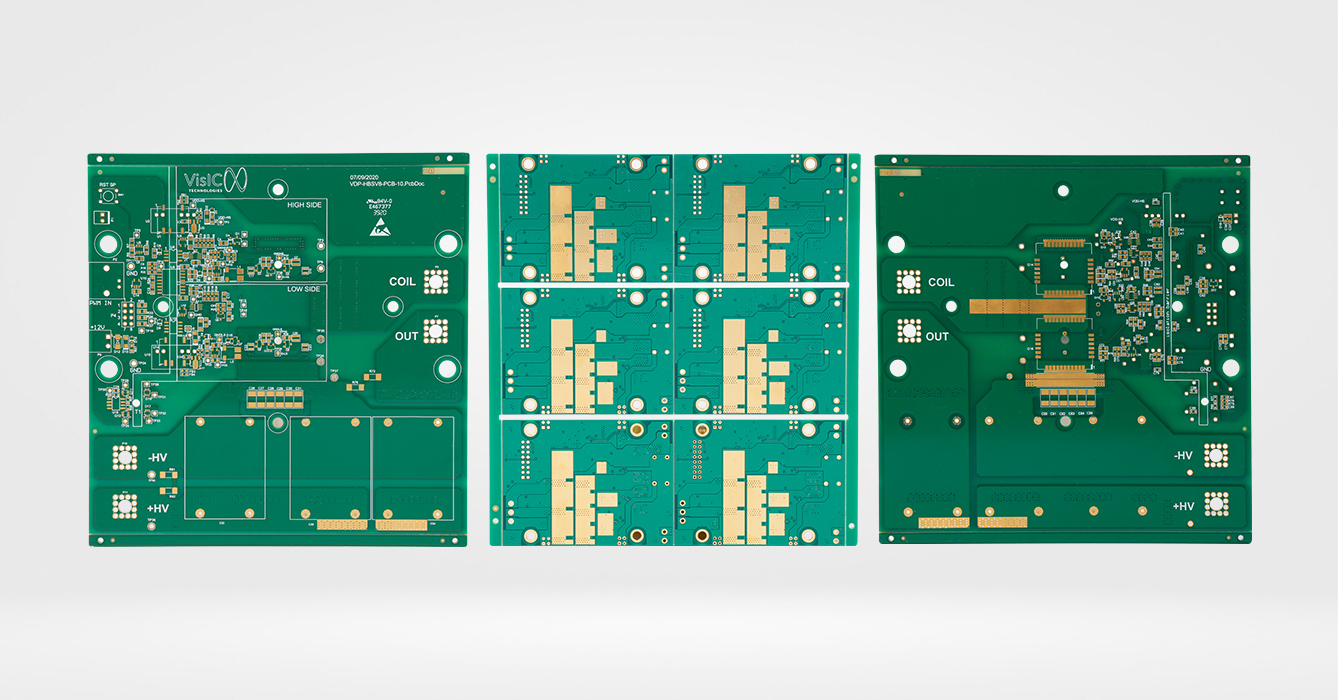

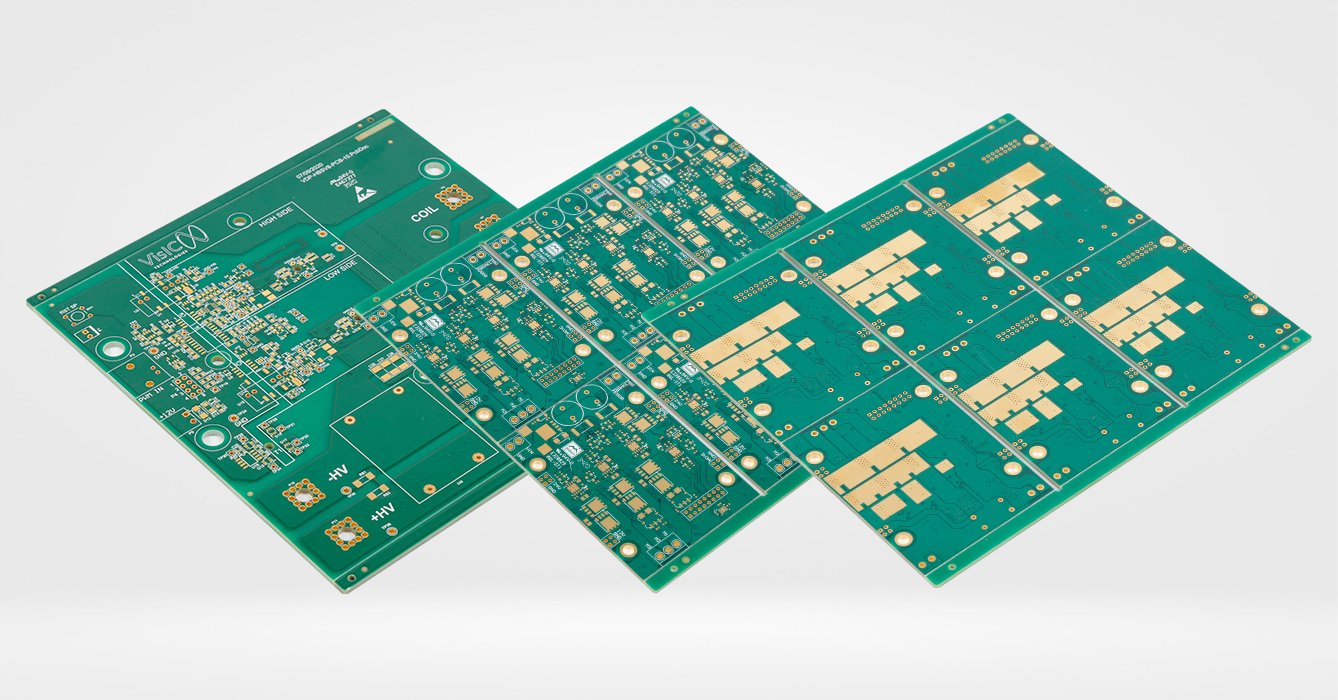

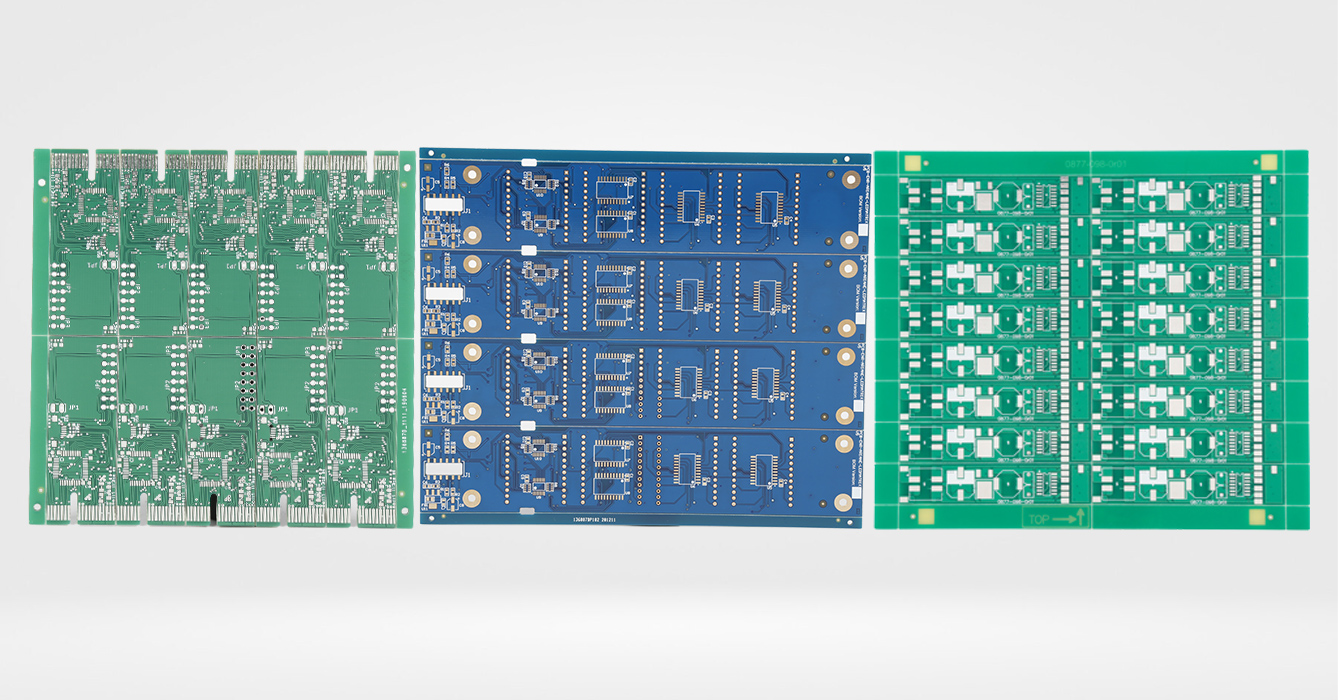

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 04. 2025, 11:48:10

In the realm of high-performance printed circuit boards (PCBs), Tg170 FR4 stands out as a critical material for applications demanding enhanced thermal stability. The Tg170 FR4 PCB datasheet PDF serves as an essential technical document, offering engineers and manufacturers precise insights into a laminate specifically engineered to withstand elevated temperatures without compromising structural or electrical integrity. Unlike standard FR4 with a glass transition temperature (Tg) of 130–140°C, Tg170 FR4 is formulated to maintain rigidity and performance up to 170°C, making it indispensable for industries such as automotive, industrial automation, and aerospace. This guide unpacks the technical nuances outlined in the Tg170 FR4 datasheet, from material composition to real-world application, empowering stakeholders to leverage its capabilities effectively.

At its core, Tg170 FR4 is a glass-reinforced epoxy laminate, but its distinction lies in a carefully modified resin system that elevates its glass transition temperature to 170°C. The "Tg" in its name refers to the critical temperature at which the epoxy resin shifts from a rigid, glassy state to a rubbery, flexible one—a transition that, if exceeded, can cause dimensional instability, reduced mechanical strength, and signal integrity issues in PCBs. The Tg170 FR4 datasheet PDF emphasizes that this higher Tg is not achieved through incremental adjustments but through a complete reformulation of the epoxy matrix.

Key to this formulation is the use of advanced epoxy resins, often blended with novolac hardeners, which form a more cross-linked molecular structure than standard bisphenol-A epoxies. This dense cross-linking resists thermal degradation, allowing the material to retain its mechanical and electrical properties at temperatures 30–40°C higher than standard FR4. The datasheet typically highlights that this resin system is paired with high-quality E-glass fiber reinforcement, often in tighter weaves (such as 2116 or 7628) to enhance dimensional stability—critical for maintaining layer alignment in multi-layer PCBs when exposed to thermal cycling.

Additives in Tg170 FR4 also differ from standard grades. The datasheet may note the inclusion of heat-resistant flame retardants, often phosphorus-based rather than brominated, to maintain flame retardancy (UL94 V-0 rating) at high temperatures without compromising Tg. Silica fillers are another key component, reducing the coefficient of thermal expansion (CTE) to minimize stress between the laminate and copper traces during temperature fluctuations—a detail particularly relevant for automotive underhood PCBs or industrial sensors exposed to wide temperature swings.

The Tg170 FR4 datasheet PDF provides a breakdown of its composition, emphasizing how each component contributes to its high-temperature performance:

Epoxy Resin System: As mentioned, Tg170 FR4 uses a modified epoxy blend, often incorporating novolac or dicyandiamide-based hardeners. These hardeners react with epoxy monomers to form a robust polymer network with stronger intermolecular bonds, resisting softening at elevated temperatures. The datasheet may specify that this resin system undergoes a longer curing cycle during manufacturing (typically 90–120 minutes at 180–200°C) to ensure full cross-linking—a process that, while increasing production time, is critical to achieving the 170°C Tg.

Glass Fiber Reinforcement: The datasheet highlights that Tg170 FR4 uses E-glass fibers with high tensile strength, woven into fabrics that balance mechanical rigidity and resin impregnation. Tighter weaves are preferred because they reduce resin-rich areas, which are more prone to thermal expansion. The fiber-to-resin ratio is also optimized: too much resin can increase CTE, while too little can reduce impact resistance. The datasheet often specifies a ratio of 55–60% glass fiber by weight, striking this balance.

Copper Foil: Like standard FR4, Tg170 FR4 uses electrodeposited (ED) or rolled copper foil, but the datasheet may note that thicker copper (1–2 oz) is more commonly paired with this material. This is because high-temperature applications often involve higher current densities, and thicker copper helps dissipate heat while reducing the risk of trace burnout. The datasheet may also highlight enhanced peel strength (the force required to separate copper from the laminate), typically 10–15% higher than standard FR4, due to improved resin adhesion—critical for preventing trace lifting during repeated soldering cycles.

Additives: Beyond flame retardants and silica fillers, the datasheet may mention coupling agents (e.g., amino silanes) that strengthen the bond between glass fibers and epoxy resin, reducing moisture absorption and improving delamination resistance at high temperatures. Some formulations include ceramic nanoparticles (e.g., alumina) to further enhance thermal conductivity, a feature valuable for heat-sensitive components like power transistors.

The Tg170 FR4 datasheet PDF devotes significant attention to thermal properties, as they define the material’s suitability for high-temperature environments:

Glass Transition Temperature (Tg): The datasheet confirms a Tg of 170°C, measured using differential scanning calorimetry (DSC) per IPC-TM-650 2.4.25. This ensures the material remains rigid in applications where operational temperatures reach 140–150°C, such as automotive engine control units (ECUs) or industrial ovens. Importantly, the datasheet may note that Tg is maintained even after prolonged exposure to high temperatures, with less than 5°C degradation after 1,000 hours at 150°C.

Decomposition Temperature (Td): Typically ≥340°C, significantly higher than standard FR4’s Td of 300°C. This means Tg170 FR4 can withstand lead-free soldering processes (peak temperatures ~260°C) with minimal resin degradation, reducing the risk of outgassing or blistering during assembly. The datasheet may include thermal gravimetric analysis (TGA) data showing that less than 5% weight loss occurs at 300°C, confirming its stability.

Thermal Conductivity: While not as high as metal-core PCBs, Tg170 FR4 offers improved thermal conductivity (0.3–0.4 W/m·K) compared to standard FR4 (0.2–0.3 W/m·K), thanks to ceramic fillers. This helps dissipate heat from high-power components, such as voltage regulators, reducing hotspots that can degrade performance.

Coefficient of Thermal Expansion (CTE): The datasheet emphasizes low CTE, particularly in the z-axis (thickness direction), which is critical for preventing via cracking during thermal cycling. Typical values are 50–70 ppm/°C below Tg and 180–220 ppm/°C above Tg—markedly lower than standard FR4’s z-axis CTE of 60–80 ppm/°C (below Tg). This reduction is achieved through silica fillers, which restrict resin expansion. The in-plane CTE (x/y axes) is 13–17 ppm/°C, closely matching copper’s CTE (17 ppm/°C) to minimize trace stress.

The Tg170 FR4 datasheet PDF details electrical properties that make it suitable for high-frequency and high-voltage applications, even under thermal stress:

Dielectric Constant (Dk): Typically 4.3–4.8 at 1 MHz, slightly higher than standard FR4 due to the modified resin system, but more stable across temperatures. The datasheet may show that Dk varies by less than 5% between 25°C and 150°C, ensuring consistent impedance control in high-speed designs. For RF applications, low-Dk variants of Tg170 FR4 are available, with Dk 3.9–4.2, as noted in specialized datasheets.

Dissipation Factor (Df): ≤0.025 at 1 MHz, with minimal increase at high temperatures (≤0.03 at 150°C). This low Df reduces signal loss in high-frequency circuits (e.g., 5G transceivers), making Tg170 FR4 suitable for telecommunications equipment operating in hot environments, such as outdoor base stations.

Dielectric Strength: ≥22 kV/mm, exceeding standard FR4’s 20 kV/mm, due to the dense resin cross-linking. This makes it ideal for high-voltage applications like power inverters, where insulation breakdown could cause catastrophic failure.

Insulation Resistance: Volume resistivity ≥10¹⁴ Ω·cm and surface resistivity ≥10¹³ Ω, even at 150°C—values that ensure minimal leakage current in humid or high-temperature conditions. The datasheet may include data from humidity tests (85°C/85% RH for 1,000 hours) showing less than a 10% drop in insulation resistance, confirming reliability in harsh environments.

The datasheet outlines mechanical properties that ensure Tg170 FR4 PCBs withstand manufacturing and operational stresses:

Tensile Strength: ≥420 MPa along the fiber direction, 5–10% higher than standard FR4, due to the stronger resin-fiber bond. This resistance to pulling forces is critical for PCBs mounted in vibrating environments, such as automotive engine bays or industrial machinery.

Flexural Strength: ≥550 MPa at room temperature and ≥350 MPa at 150°C, outperforming standard FR4’s flexural strength of ≥500 MPa (room temp) and ≥300 MPa (125°C). This ensures the laminate remains rigid even when exposed to bending forces at high temperatures, reducing the risk of board warpage.

Impact Resistance: Charpy impact strength ≥17 kJ/m², slightly higher than standard FR4, thanks to the tough resin matrix. This makes Tg170 FR4 less prone to cracking during handling or accidental drops, a valuable trait for field-deployed equipment.

Dimensional Stability: The datasheet highlights minimal post-curing shrinkage (≤0.15%) and low moisture-induced expansion (≤0.1% after 24-hour water immersion). This stability ensures multi-layer PCBs maintain alignment, even in humid, high-temperature environments, preventing short circuits or open traces.

The Tg170 FR4 datasheet PDF includes guidelines for manufacturing, as its unique properties require adjusted processes compared to standard FR4:

Lamination: Higher cure temperatures (180–200°C) and longer cycle times (90–120 minutes) are necessary to fully cross-link the resin. The datasheet may specify a pressure of 300–400 psi to ensure proper resin flow and fiber wetting, reducing voids that can weaken the laminate.

Drilling: Carbide drill bits with specialized geometries are recommended, as the dense resin matrix is harder than standard FR4. The datasheet may suggest slower feed rates (0.1–0.2 mm/rev) and higher spindle speeds (40,000–60,000 RPM) to minimize burring and resin smearing, which can impair via plating.

Soldering: Compatible with lead-free soldering (Sn-Ag-Cu alloys) with peak temperatures up to 260°C, but the datasheet may advise longer preheat cycles to prevent thermal shock. This gradual heating reduces stress between the laminate and components, lowering the risk of delamination.

Surface Finish: Compatible with all standard finishes (ENIG, HASL, OSP), but the datasheet may note that ENIG is preferred for high-temperature applications due to its superior oxidation resistance, ensuring solderability even after prolonged exposure to heat.

The Tg170 FR4 datasheet PDF references compliance with global standards, ensuring reliability across industries:

IPC-4101: Classified under Type 2 (high-performance) due to its Tg ≥170°C, meeting strict requirements for thermal and mechanical performance. The datasheet may include test results for IPC-TM-650 methods, such as thermal stress testing (28 cycles of -55°C to +125°C) with no delamination.

UL 94: Rated V-0 for flame retardancy, confirmed through vertical burn tests where specimens self-extinguish within 10 seconds. The datasheet may note that this rating is maintained even after thermal aging, a critical factor for safety-critical applications like medical devices.

RoHS and REACH Compliance: Free from restricted substances (e.g., lead, cadmium, brominated flame retardants in some formulations), aligning with environmental regulations in the EU, North America, and Asia.

Automotive Standards: Many Tg170 FR4 variants comply with IATF 16949, with datasheets including results from automotive-specific tests, such as 1,000-hour thermal cycling (-40°C to +150°C) to simulate underhood conditions.

The datasheet highlights applications that demand its high-temperature resilience:

Automotive Electronics: Engine control units (ECUs), transmission controllers, and underhood sensors rely on Tg170 FR4 to withstand ambient temperatures up to 150°C, as well as thermal spikes from nearby engines.

Industrial Automation: Motor drives, PLCs, and robotics controllers operating in factory environments with high ambient heat (e.g., near furnaces or ovens) benefit from its stability at 120–140°C.

Aerospace and Defense: Avionics systems, such as in-flight entertainment or engine monitoring, use Tg170 FR4 to resist temperature fluctuations during flight (from -55°C at altitude to 100°C on the ground).

Renewable Energy: Inverters for solar panels or wind turbines, which generate significant heat during operation, depend on its ability to maintain performance at 130–150°C.

While versatile, the Tg170 FR4 datasheet PDF acknowledges its limitations:

Cost: 20–30% more expensive than standard FR4 due to the advanced resin system and longer manufacturing cycles, making it overkill for low-temperature applications like consumer electronics.

Thermal Conductivity: Still lower than metal-core PCBs (1–2 W/m·K) or ceramic substrates, limiting its use in ultra-high-power applications (e.g., 200W+ LEDs).

Flexibility: Rigid by design, unsuitable for flexible PCBs, where polyimide laminates (Tg ≥250°C) are preferred.

The Tg170 FR4 PCB datasheet PDF is more than a technical reference—it is a blueprint for engineering reliability in high-temperature environments. By detailing the material’s composition, thermal, electrical, and mechanical properties, as well as manufacturing guidelines, the datasheet empowers engineers to select the right laminate for applications where standard FR4 would fail. From automotive underhood systems to industrial machinery, Tg170 FR4 bridges the gap between performance and cost, ensuring PCBs withstand the rigors of their operating environments. As technology advances, datasheets will continue to evolve, reflecting innovations in resin chemistry and reinforcement that push Tg170 FR4’s capabilities even further—solidifying its role as a cornerstone of high-performance electronics.

Related Articles

FR4 PCB Manufacturer | High Tg & Reliable PCB Material FR4 Solutions

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

LED Lighting FR4 PCB: Technical Foundations for Illumination Systems

FR4 PCB Manufacturer for Prototype and Mass Production

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

HDI Blind/Buried Vias FR4 PCB: High-Density Interconnect Solutions for Advanced Electronics

FR4 PCB Material Specification Sheet: A Comprehensive Technical Guide

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB