-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

PCB Assembly is undergoing a paradigm shift as manufacturers embrace human-machine collaboration (HMC) to build adaptive production systems that balance precision, flexibility, and scalability. Unlike traditional assembly lines—where humans and machines operate in silos—modern PCB assembly integrates skilled technicians with advanced automation (cobots, AI-driven inspection tools) to address evolving industry challenges: from labor skill gaps to the rise of low-volume, high-mix production. This collaboration transforms PCB assembly from a rigid process into a dynamic ecosystem, where machines handle repetitive, high-precision tasks while humans oversee complex decision-making, troubleshooting, and design refinement. As electronics markets demand faster customization and shorter lead times, HMC-powered PCB assembly has become a competitive differentiator. This article explores the core dimensions of human-machine collaboration in PCB assembly, its role in enabling adaptive manufacturing

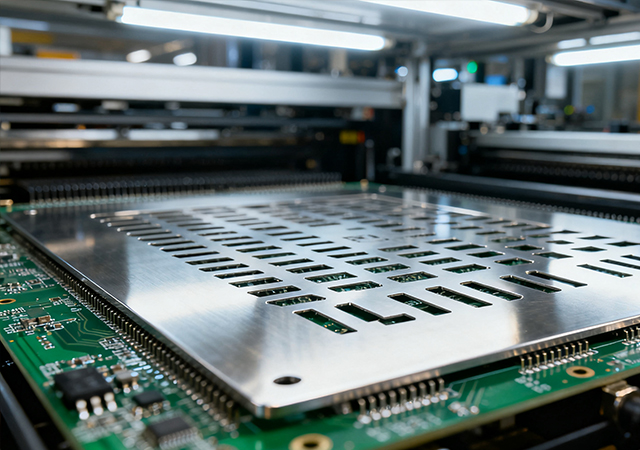

SMT Stencils are the foundational component of surface-mount technology (SMT) assembly, serving as the precision tool that deposits solder paste onto printed circuit boards (PCBs) to create electrical connections between components and pads. Often overlooked amid more complex assembly equipment, these thin, metal sheets play a make-or-break role in determining product quality—even minor flaws in stencil design or fabrication can lead to costly defects like solder bridging, insufficient paste, or tombstoning. As electronics evolve toward miniaturization, higher component density, and faster production cycles, the role of SMT stencils has grown from a simple "template" to a technically advanced solution that aligns with the demands of modern manufacturing. This article explores the technical evolution of SMT stencils, critical quality factors that define their performance, their impact on assembly efficiency, and how they adapt to emerging electronics trends.

Custom SMT Stencils Manufacturing is a specialized service that designs and produces surface-mount technology (SMT) stencils tailored to the unique requirements of specific PCB designs, production volumes, and component types. Unlike off-the-shelf standard stencils, custom solutions address the challenges of non-standard PCB layouts, niche components, and industry-specific constraints—from high-temperature automotive environments to space-constrained wearable devices. As electronics designs grow more diverse (e.g., flexible PCBs, mixed-component boards), custom SMT stencils have become essential for ensuring solder paste accuracy, reducing assembly defects, and aligning with production goals. This article explores the core workflow of custom SMT stencils manufacturing, key customization strategies, industry-specific applications, and how it drives efficiency in specialized electronics production.

A High-Precision SMT Stencils Maker plays a pivotal role in modern electronics manufacturing, as the quality of surface-mount technology (SMT) stencils directly impacts solder paste transfer efficiency, component placement accuracy, and final product reliability. Unlike standard stencil providers, high-precision makers specialize in crafting custom stencils tailored to the demands of dense PCB designs, miniaturized components, and high-volume production—catering to industries from consumer electronics to aerospace. These stencils act as the critical bridge between PCB design and assembly, ensuring precise deposition of solder paste onto PCB pads to form robust, consistent solder joints. As electronics grow more complex (with ultra-fine-pitch components and HDI PCBs), the expertise of a high-precision SMT stencils maker becomes indispensable for mitigating defects, reducing rework, and optimizing production yields. This article explores the core capabilities, quality standards, industry

PCB Assembly has transcended traditional manufacturing boundaries to become a nexus of digital collaboration and supply chain resilience—critical traits in today’s volatile electronics landscape. As global disruptions (component shortages, geopolitical shifts) and technical demands (higher density, faster prototyping) intensify, PCB assembly no longer hinges solely on precision soldering but on seamless integration of cross-functional teams, agile supply networks, and innovative technologies. This evolution empowers manufacturers to navigate uncertainties while delivering high-quality, on-time assemblies for applications ranging from automotive infotainment to industrial IoT gateways. This article explores how digital collaboration redefines workflow efficiency, strategies for building supply chain resilience, and emerging technologies shaping the next era of PCB assembly.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB