-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

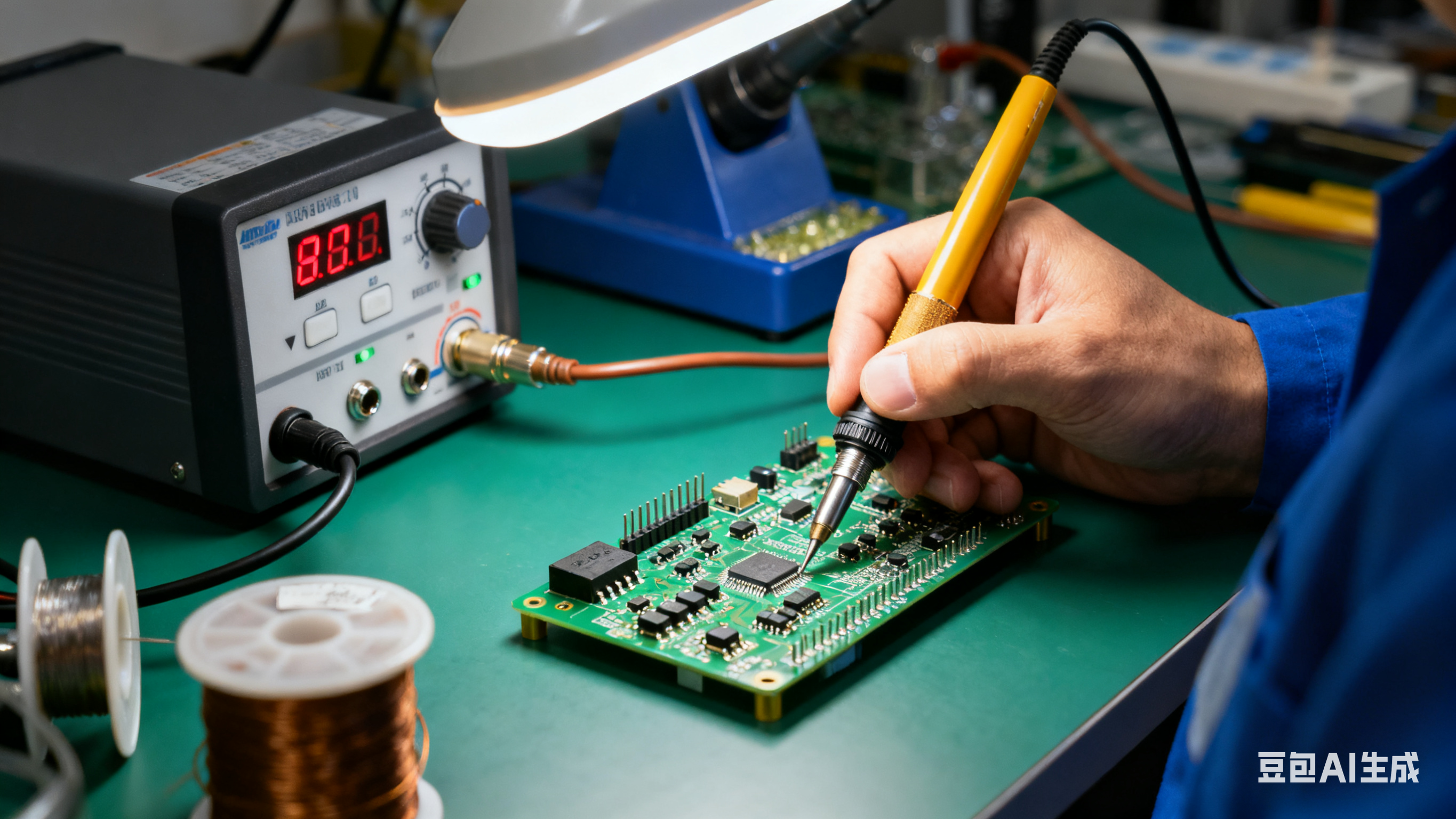

Urgent Quick Turn PCB Assembly represents a specialized subset of fast-track manufacturing, designed to address time-sensitive crises and unplanned demands that cannot wait for standard production timelines. Unlike scheduled quick-turn services, urgent assembly prioritizes immediate resource mobilization—often for scenarios where delays could lead to safety risks, significant financial losses, or mission failure. From emergency medical equipment repairs during public health crises to last-minute fixes for aerospace mission components, this service acts as a critical safety net for industries where “time is mission-critical.” This article explores the unique response frameworks, risk-mitigation strategies, targeted use cases, and operational agility that define urgent quick turn PCB assembly.

24-Hour Quick Turn PCB Assembly is a specialized service designed to deliver fully assembled PCBs in one day—addressing critical needs like emergency product repairs, rapid prototype validation, and time-sensitive market launches. Unlike standard PCB assembly (which typically takes 5–14 days), this fast-track solution prioritizes workflow efficiency without compromising compliance or performance. For industries ranging from aerospace (needing urgent avionics repairs) to startups (racing to test new IoT prototypes), 24-hour quick turn assembly is a lifeline that bridges gaps between urgent demand and production capacity. This article explores the operational frameworks that enable this speed, key quality safeguards,use cases, and how it supports agile decision-making in fast-paced electronics markets.

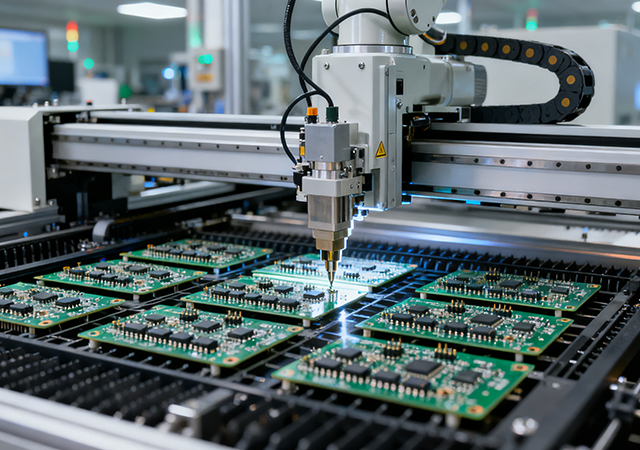

PCB Assembly remains the backbone of modern electronics, transforming bare circuit boards into functional components that power everything from smart appliances to aerospace systems. As technology evolves at an unprecedented pace, PCB assembly has shifted from a purely technical process to a strategic discipline—integrating emerging technologies, prioritizing quality at every stage, and building resilience against global disruptions. Today’s manufacturers must balance precision, speed, and adaptability to meet the demands of sectors like 5G, electric vehicles (EVs), and edge computing. This article explores the latest trends shaping PCB assembly, innovative quality assurance practices, and how the industry is fortifying itself against challenges, ensuring reliable production in a dynamic landscape.

Turnkey PCB Assembly has emerged as a transformative solution in electronics manufacturing, offering businesses a seamless, single-source approach to bringing PCB designs from concept to finished product. Unlike fragmented manufacturing models—where clients juggle component sourcing, assembly, testing, and logistics across multiple vendors—turnkey services consolidate every stage under one provider. This integration eliminates operational silos, reduces administrative burdens, and aligns production with business goals, whether that’s faster time-to-market, improved quality, or scalable growth. For companies navigating global supply chain complexities and evolving technical demands, turnkey PCB assembly is no longer a convenience but a strategic imperative to stay competitive.

Cost-Effective Turnkey PCB Assembly redefines value in electronics manufacturing by delivering end-to-end assembly services that prioritize budget efficiency without compromising quality or performance. Unlike generic turnkey solutions that may overcharge for unnecessary features, this specialized approach focuses on targeted cost optimization—aligning production processes, supply chain strategies, and service scopes with a client’s specific budget and technical needs. For businesses ranging from startups to mid-sized enterprises, cost-effective turnkey assembly eliminates the hidden expenses of fragmented production (e.g., component markup, rework costs, logistics delays) while ensuring reliable, compliant PCBs. This article explores the core strategies behind cost-effective turnkey services, their industry-specific applications, quality safeguards, and how they drive competitive advantage in price-sensitive markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB