-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

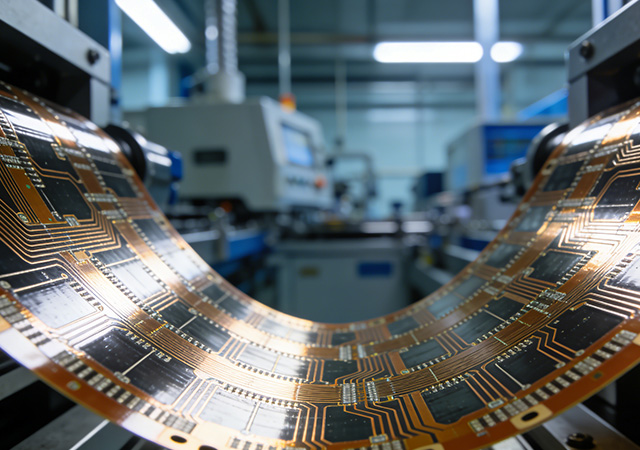

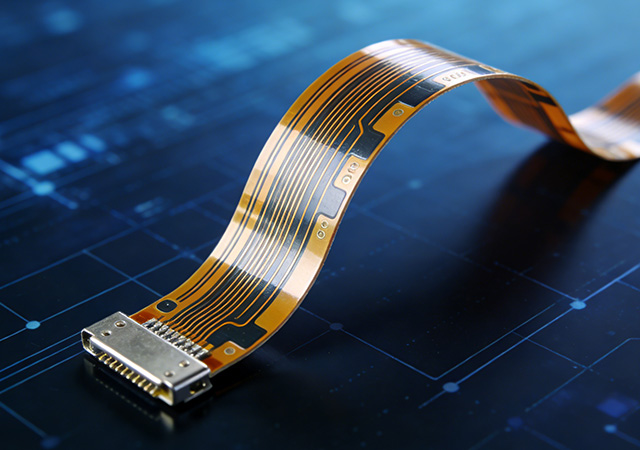

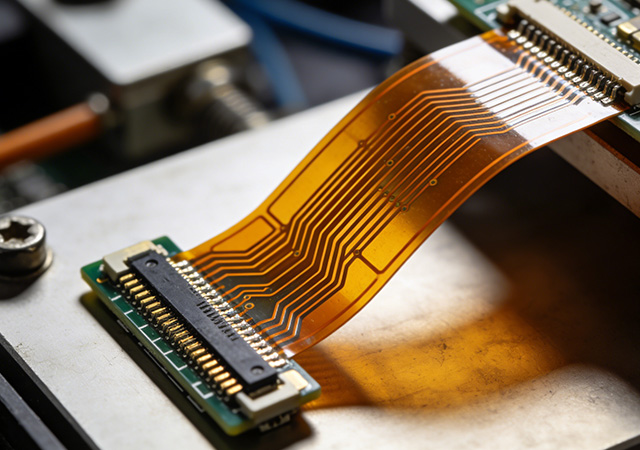

In the fast-paced electronic product development landscape, the ability to quickly validate design concepts and respond to market changes has become a key competitive advantage. Quick Turn Customize FPCB Service emerges as a critical enabler, addressing the core pain points of long lead times and inflexible solutions in traditional FPCB manufacturing. This service combines rapid turnaround capabilities with tailored design support, allowing electronic manufacturers and R&D teams to obtain customized flexible printed circuit boards (FPCBs) in a shortened timeframe without compromising quality. From small-batch prototyping to urgent production needs, Quick Turn Customize FPCB Service empowers innovators to accelerate product development cycles, reduce time-to-market, and gain an edge in the highly competitive electronics industry.

Flexible Printed Circuit Board (FPCB) has emerged as a transformative technology that is reshaping the landscape of modern electronics. Moving beyond the limitations of rigid printed circuit boards, FPCB’s inherent flexibility, miniaturization potential, and reliable electrical performance have made it a cornerstone of innovative product development across industries. From ultra-thin wearable devices that conform to the human body to complex flexible displays that redefine user interaction, FPCB is driving a paradigm shift in how electronic devices are designed, manufactured, and experienced. As the demand for smarter, more adaptive electronics continues to surge, FPCB’s role in enabling technological advancement becomes increasingly indispensable.

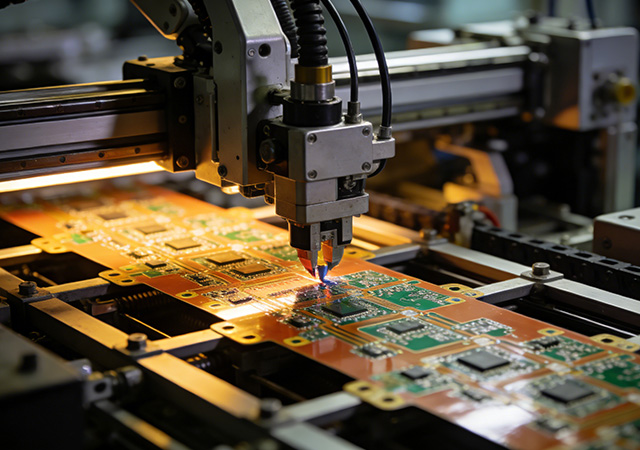

In the interconnected global electronics ecosystem, the role of an FPCB manufacturer extends far beyond component production—it serves as a critical link that bridges design innovation, production efficiency, and market accessibility. As flexible printed circuit boards (FPCBs) become ubiquitous in electronic devices ranging from consumer gadgets to industrial equipment, an FPCB manufacturer’s ability to deliver consistent, adaptable, and cost-effective solutions directly impacts the competitiveness of brands worldwide. Unlike niche specialized manufacturers, a versatile FPCB manufacturer caters to diverse market demands, integrating advanced production capabilities with flexible supply chain management to support both small-batch prototyping and large-scale mass production. This adaptability has made FPCB manufacturers indispensable partners for businesses navigating the fast-paced and ever-evolving electronics industry.

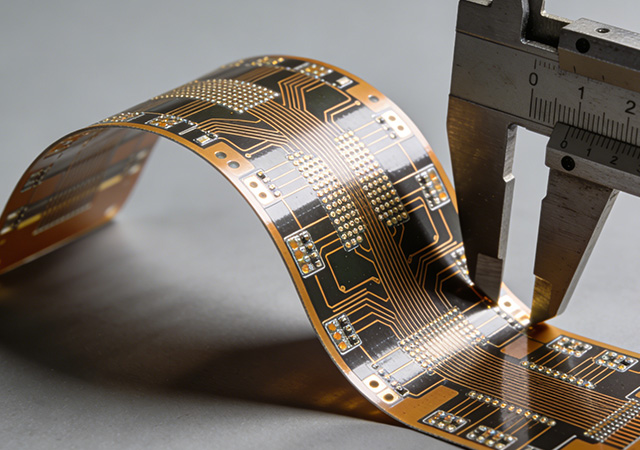

In the competitive landscape of high-end electronics, product reliability and performance consistency have become the core criteria for market success. Behind every trusted electronic device lies the solid support of a High Quality Flex FPCB Manufacturer. Unlike ordinary flex FPCB manufacturers that prioritize cost over quality, a High Quality Flex FPCB Manufacturer is committed to delivering flexible printed circuit boards that meet stringent quality standards, with stable electrical performance, excellent durability, and consistent batch-to-batch quality. From premium consumer electronics to industrial control systems and automotive electronics, these manufacturers provide the foundational components that ensure electronic products operate reliably in diverse scenarios. Their focus on quality runs through every link of production, making them indispensable strategic partners for brands pursuing long-term market competitiveness.

In the era of high-end electronics where miniaturization, high integration, and scenario-specific performance are paramount, the role of a Custom Precision FPCB Manufacturer has become increasingly pivotal. Unlike standard FPCB manufacturers that focus on mass-produced, off-the-shelf solutions, a Custom Precision FPCB Manufacturer specializes in delivering tailored flexible circuit boards that meet the unique precision requirements of complex electronic systems. From medical devices requiring ultra-miniature and biocompatible designs to aerospace electronics demanding extreme environmental resistance, these manufacturers bridge the gap between innovative product concepts and practical, high-precision manufacturing. Their ability to combine customized design flexibility with rigorous precision control makes them indispensable partners for industries pursuing technological breakthroughs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB