-

- PCB TYPE

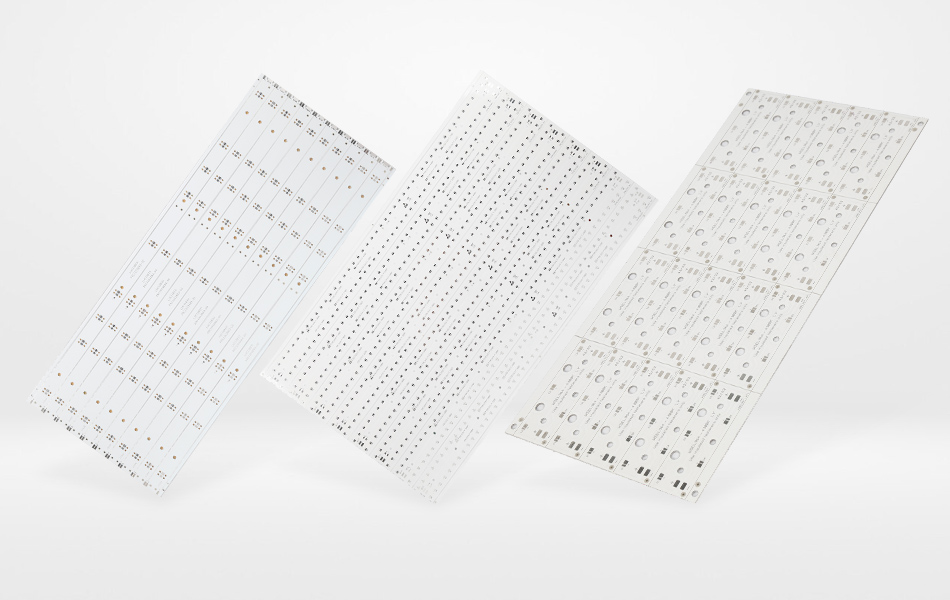

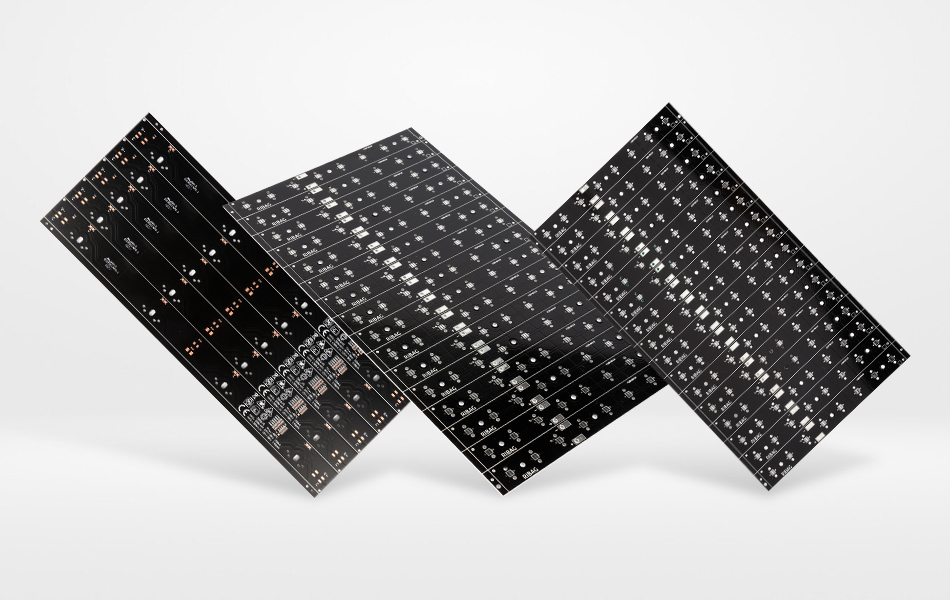

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 09. 2025, 15:33:47

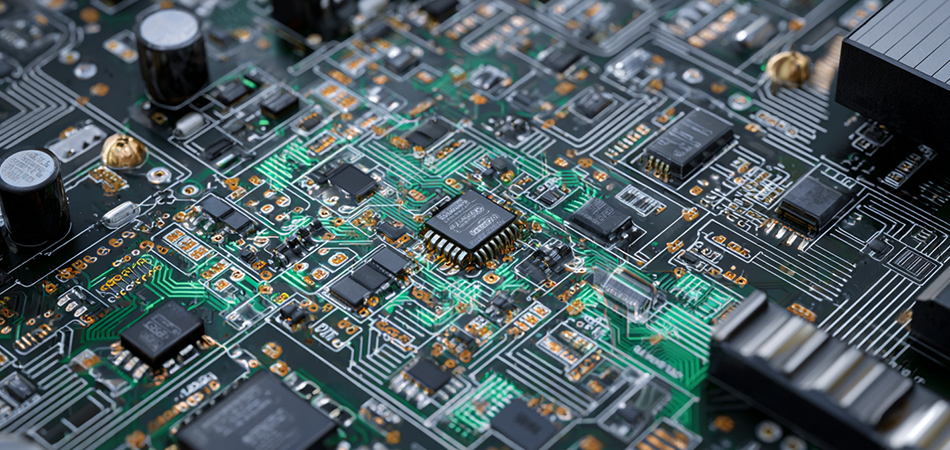

In the fast-paced evolution of electronic engineering, aluminum printed circuit boards (PCBs) have emerged as a transformative technology, offering a unique combination of thermal efficiency, mechanical robustness, and design versatility. These PCBs leverage the inherent properties of aluminum to address the critical challenges of heat management, compact form factors, and reliable operation in diverse environments, making them indispensable across industries from lighting to aerospace. This article provides a comprehensive overview of aluminum PCBs, exploring their material science, design principles, manufacturing processes, industrial applications, and emerging trends, while highlighting their role in enabling the next generation of high-performance electronics.

The Foundation of Aluminum PCBs: Material Science

Aluminum Substrate: A Multifunctional Core

The aluminum substrate lies at the heart of these PCBs, serving as a foundational layer with distinct advantages:

Exceptional Thermal Conductivity: Aluminum’s high thermal conductivity allows for rapid dissipation of heat generated by power-hungry components, preventing thermal stress and ensuring stable operation. This is particularly crucial for devices where overheating could lead to performance degradation or component failure.

Mechanical Resilience: Aluminum alloys offer a favorable strength-to-weight ratio, making them resistant to bending, vibrations, and shocks. This mechanical durability is essential for applications in harsh environments, such as automotive, industrial, and aerospace systems.

Cost-Effective Formability: Aluminum’s malleability enables the creation of complex shapes and thin profiles, accommodating the compact designs demanded by modern electronics while maintaining structural integrity.

Dielectric Layers: Balancing Insulation and Heat Transfer

The dielectric layer in aluminum PCBs plays a dual role, separating the aluminum substrate from copper conductive layers while facilitating heat transfer:

Electrical Insulation: Ensures no short circuits between the aluminum core and copper traces, maintaining the integrity of electrical signals.

Thermal Interface: High-quality dielectric materials, such as ceramic-filled epoxies or polyimides, enhance heat transfer from components to the aluminum substrate, optimizing thermal management without compromising electrical performance.

Copper Layers: Conductive Pathways for Signal and Power

Copper, with its low electrical resistance, forms the conductive layers of aluminum PCBs:

Signal Traces: Designed to carry low-current signals with minimal loss, critical for high-frequency applications such as wireless communication and sensor networks.

Power Traces: Thicker copper foils are used for power distribution, reducing resistance and heat generation in high-current paths, the crucial in power electronics and motor control systems.

Design Principles for Aluminum PCBs

Thermal Management: The Critical Design Focus

Effective heat dissipation is the cornerstone of aluminum PCB design, involving strategic component placement and thermal pathway optimization:

Component Placement: Heat-generating components like power transistors, LEDs, and microprocessors are positioned to maximize contact with the aluminum substrate, allowing direct heat transfer. Thermal vias, which connect copper layers to the aluminum core, are strategically placed to create efficient heat dissipation paths.

Heat Sink Integration: The aluminum substrate can act as a natural heat sink, or it can be paired with external heat sinks for enhanced cooling. This is particularly important in high-power applications where maintaining optimal component temperatures is essential for longevity and performance.

Electrical Design: Signal Integrity and Power Efficiency

Trace Routing: High-speed signals are routed to minimize interference, with controlled impedance traces ensuring signal integrity in applications such as high-frequency data transmission. Power traces are designed to handle current loads efficiently, reducing voltage drops and energy loss.

Ground Plane Design: A solid ground plane on one or both sides of the PCB provides a stable reference for signals, reducing electromagnetic interference (EMI) and improving noise immunity in mixed-signal circuits.

Mechanical Design: Durability and Form Factor

Substrate Thickness: Tailored to application needs, with thinner substrates enabling compact, lightweight designs for portable devices and thicker substrates providing enhanced heat capacity for industrial power modules.

Mounting Solutions: Reinforced mounting holes and mechanical fixtures ensure the PCB remains secure in vibration-prone environments, while conformal coatings protect against moisture, dust, and chemical contaminants in harsh operating conditions.

Manufacturing Processes for Aluminum PCBs

Substrate Preparation

Material Cutting: Aluminum substrates are precision-cut using CNC milling or laser cutting to exact dimensions, followed by surface treatments to enhance the adhesion of dielectric layers and improve corrosion resistance.

Surface Treatment: Processes such as degreasing and micro-etching prepare the aluminum surface for lamination, ensuring a strong bond with dielectric materials and optimal thermal conductivity.

Layer Lamination

Dielectric Bonding: High-pressure lamination processes bond dielectric layers to the aluminum substrate, creating a stable base for copper layers. This step is critical for maintaining thermal and electrical performance, with automated presses controlling temperature and pressure to ensure uniform bonding.

Copper Layer Fabrication

Foil Lamination: Electrolytic copper foil is laminated to the dielectric layers, followed by photolithography or laser direct imaging (LDI) to transfer circuit patterns. LDI is particularly useful for fine-pitch traces in high-density designs, ensuring precise feature sizes and spacing.

Chemical Etching: Unwanted copper is removed using chemical etching, with post-etch inspection via automated optical inspection (AOI) to ensure trace integrity and eliminate defects.

Surface Finishing

Protective Coatings: Surface finishes such as electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), or hot air solder leveling (HASL) are applied to copper traces to enhance solderability and corrosion resistance, depending on the application’s requirements.

Industrial Applications of Aluminum PCBs

LED Lighting Systems

Commercial and Residential Lighting: Aluminum PCBs are widely used in LED panels, downlights, and linear fixtures, efficiently dissipating heat from LED arrays to maintain consistent light output and extend lifespan. Their formability allows for custom shapes in architectural lighting, while their thermal efficiency is crucial for high-brightness applications.

Automotive Lighting: In headlamps, taillights, and interior lighting, aluminum PCBs enable compact designs with reliable heat management, even in the temperature-sensitive environment of vehicle interiors.

Power Electronics

Power Supplies and Inverters: Aluminum PCBs handle the high currents and heat generated by power semiconductors in inverters for renewable energy systems and DC-DC converters, ensuring efficient power conversion and stable operation.

Battery Management Systems (BMS): Used in electric vehicles and energy storage systems to monitor and control battery cells, with thermal management critical to preventing thermal runaway and ensuring safety.

Automotive Electronics

Engine Control Units (ECUs): Operate reliably in the harsh environment of engine bays, with aluminum’s thermal and mechanical properties resisting high temperatures, vibrations, and moisture.

Advanced Driver-Assistance Systems (ADAS): Support high-speed data processing and sensor integration in ADAS modules, with aluminum PCBs enabling compact layouts and efficient heat dissipation from image processors and radar components.

Consumer Electronics

Portable Devices: Laptops, tablets, and gaming consoles use aluminum PCBs to manage heat from high-performance processors, enabling slim designs without compromising performance.

Wearable Technology: Smartwatches and fitness trackers rely on lightweight aluminum PCBs to integrate sensors, batteries, and wireless modules in compact form factors, balancing thermal efficiency with comfortable wear.

Industrial Control and Automation

Motor Drives and Robotics: Aluminum PCBs withstand the vibrations and high temperatures of industrial environments, supporting reliable operation of motor control circuits and robotic controllers.

Process Control Systems: Used in sensors and control panels for real-time monitoring in manufacturing plants, with conformal coatings protecting against dust and moisture.

Aerospace and Defense

Avionics Systems: Critical for navigation and communication modules in aircraft, where aluminum PCBs provide lightweight, high-reliability solutions that can withstand extreme temperatures and mechanical stress.

Military Electronics: Used in ruggedized devices such as portable radios and missile systems, combining thermal stability with resistance to shock and vibration.

Emerging Trends in Aluminum PCB Technology

Miniaturization and High-Density Integration

Microvia Technology: Laser-drilled microvias and fine-pitch traces enable high-density interconnects in compact devices such as IoT sensors and 5G modules, where every millimeter of board space is valuable.

3D Packaging: Aluminum PCBs facilitate vertical integration of components, creating 3D systems with enhanced thermal and electrical performance, ideal for advanced mobile devices and embedded systems.

Sustainable Manufacturing Practices

Eco-Friendly Materials: The industry is moving towards recycled aluminum substrates and water-based dielectric adhesives, reducing the environmental footprint while maintaining performance.

Energy-Efficient Processes: Low-temperature lamination and lead-free surface finishes align with global sustainability goals, ensuring aluminum PCBs are produced with minimal environmental impact.

Advanced Thermal Solutions

Hybrid Substrates: Composite materials combining aluminum with high-thermal-conductivity layers such as graphite or carbon fiber enhance heat dissipation, enabling higher power densities in applications like 5G power amplifiers and high-performance computing.

Phase-Change Materials (PCM): Integration of PCMs with aluminum PCBs provides passive thermal regulation, absorbing and releasing heat to maintain component temperatures within tight ranges in extreme environments.

Automation and Digital Design Tools

AI-Powered Design: Machine learning algorithms optimize component placement and thermal via routing, reducing design time and improving thermal performance in complex layouts.

Robotic Assembly: High-precision robotic systems ensure accurate component placement and soldering, improving yield in high-volume production and enabling micro-pitch applications.

Conclusion

Aluminum PCBs have revolutionized the electronics industry by offering a robust solution to the challenges of heat management, mechanical durability, and design flexibility. Their ability to support a wide range of applications, from everyday consumer devices to critical aerospace systems, highlights their versatility and importance in modern electronics. As technology continues to advance towards miniaturization, sustainability, and higher power densities, aluminum PCBs will evolve through material innovation, advanced manufacturing techniques, and 智能化 design tools. For engineers and designers, leveraging the unique advantages of aluminum PCBs is essential for creating reliable, efficient, and future-ready electronic systems that meet the demands of an increasingly connected and performance-driven world. By combining the natural strengths of aluminum with cutting-edge engineering, these PCBs are set to remain a cornerstone of high-performance electronics for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB