-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 15. 2025, 16:57:35

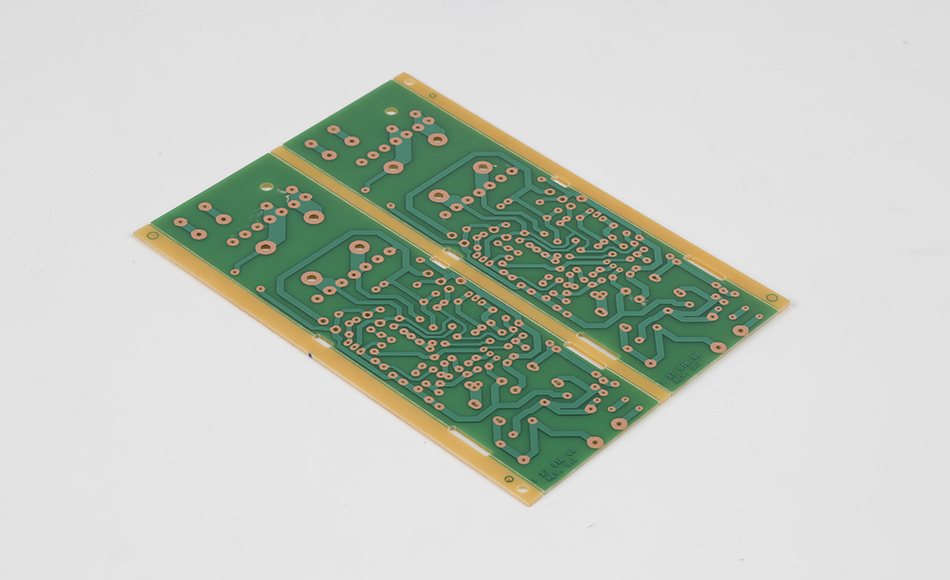

CEM3 PCB stands as a cornerstone of practical electronics design, embodying a philosophy of balanced performance that has made it indispensable across industries. Unlike high-performance PCBs tailored for extreme environments, CEM3 PCBs are engineered to deliver reliable functionality at an accessible cost, making them the backbone of devices ranging from household appliances to light industrial controls. By leveraging the unique properties of Composite Epoxy Material-3 (CEM3)—a hybrid substrate of epoxy resin and glass fibers—these PCBs strike a critical balance: sufficient mechanical strength to support components, stable electrical performance for standard circuits, and flame resistance for safety, all without the premium price tag of specialized alternatives. This article explores the design principles, assembly considerations, application versatility, and future trends of CEM3 PCBs, illustrating why they remain a preferred choice for engineers prioritizing value and reliability.

Designing with CEM3 PCB requires a nuanced understanding of the material’s capabilities, ensuring that circuits are optimized for its unique properties without over-engineering:

CEM3 PCBs excel in single and double-layer designs, where their mechanical stability and insulation properties align with the demands of low-to-moderate component density. While multi-layer CEM3 PCBs are feasible, they are typically limited to 4 layers due to the non-woven glass core’s slightly lower rigidity compared to FR4. This makes them ideal for applications like sensor interfaces or basic control modules, where signal paths are straightforward and layer count is minimal. Engineers often opt for CEM3 in these scenarios to avoid the unnecessary cost of FR4, which would offer unused performance headroom.

For circuits operating at frequencies up to several hundred megahertz—common in consumer electronics and office equipment—CEM3 PCBs maintain reliable signal integrity. Their epoxy matrix provides stable dielectric properties, minimizing crosstalk between adjacent traces. However, designers must account for CEM3’s slightly higher dielectric loss compared to FR4 when routing high-speed signals, opting for wider traces or increased spacing to mitigate signal degradation. This careful balancing act ensures that CEM3 PCBs perform adequately in applications like audio amplifiers or printer control boards, where signal fidelity matters but extreme frequencies are not a factor.

CEM3 PCBs support both through-hole and surface-mount components, but their load-bearing capacity is best suited for standard-weight parts. Heavy components, such as large transformers or heat sinks, require additional mechanical support—like mounting brackets—to prevent substrate warping over time. Heat-generating components, such as power transistors, should be limited to those dissipating less than 5 watts, as CEM3’s thermal conductivity is lower than FR4’s, making it less effective at spreading heat. By matching component selection to CEM3’s capabilities, engineers avoid premature failure while keeping costs in check.

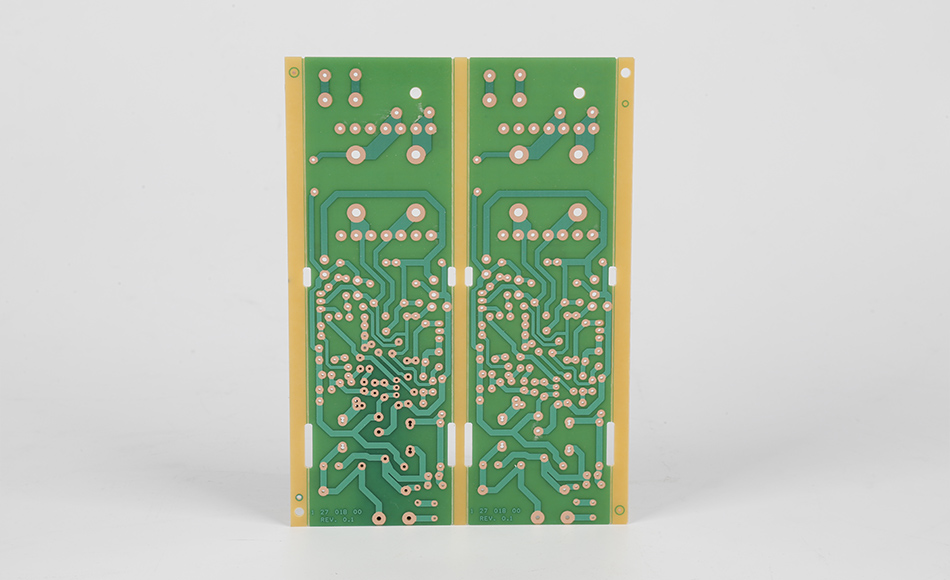

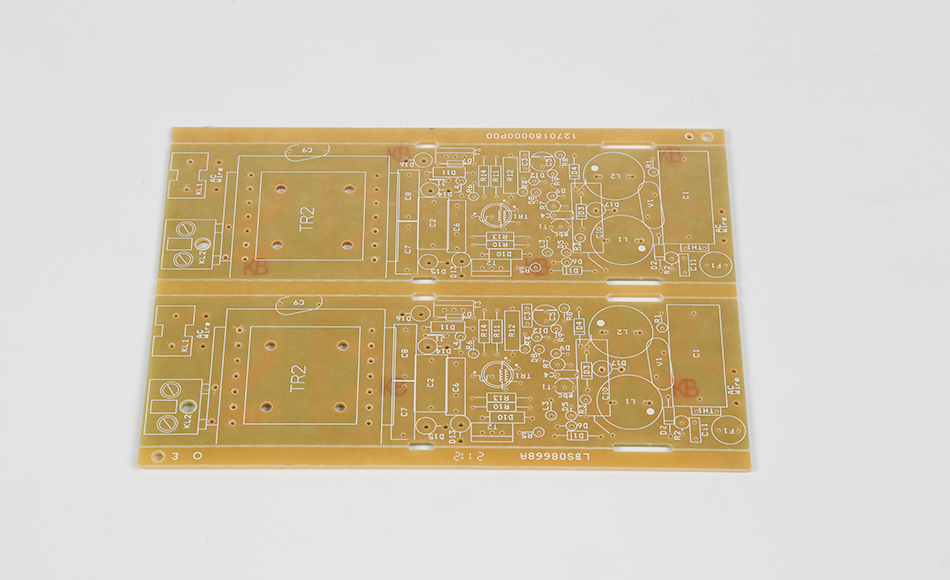

The manufacturing process of CEM3 PCB is optimized for efficiency, leveraging the material’s unique composition to streamline production without compromising quality:

CEM3 PCBs integrate seamlessly into existing PCB assembly lines, requiring minimal adjustments to standard workflows:

Soldering: Both reflow and wave soldering processes work effectively with CEM3, as the material withstands short-term exposure to soldering temperatures (240–260°C) without delamination. However, prolonged heat exposure—such as repeated rework—should be avoided to prevent resin degradation.

Drilling and Routing: CEM3’s hybrid glass structure drills cleanly with standard carbide tools, reducing burr formation and simplifying post-processing. This is particularly advantageous for low-volume production, where manual drilling may be used.

Surface Finishes: Common finishes like HASL (Hot Air Solder Leveling) and OSP (Organic Solderability Preservative) adhere reliably to CEM3’s copper cladding, ensuring long-term solderability and corrosion resistance.

These compatibilities make CEM3 PCBs accessible to manufacturers of all sizes, from small-scale prototyping shops to large-scale production facilities.

To ensure reliability, CEM3 PCB manufacturing incorporates targeted quality checks:

Visual Inspection: Automated optical inspection (AOI) systems detect defects like incomplete etching, solder mask misalignment, or delamination, which can compromise performance.

Electrical Testing: Flying probe testers verify continuity and insulation resistance, ensuring that traces and vias meet design specifications.

Thermal Cycling Tests: Samples are subjected to temperature cycles (-30°C to 105°C) to simulate real-world operating conditions, validating the material’s resistance to thermal stress.

These measures ensure that CEM3 PCBs meet industry standards for reliability, even in demanding applications.

CEM3 PCB delivers consistent performance across a range of applications, proving its versatility in diverse operating environments:

In devices like microwaves, televisions, and home audio systems, CEM3 PCBs serve as the control hub, managing functions from power regulation to user interface inputs. Their flame resistance (UL94 V-0 rating) is critical for safety in enclosed household spaces, while their cost-effectiveness allows manufacturers to include advanced features without raising prices. For example, a smart refrigerator’s temperature control PCB relies on CEM3 to handle sensor inputs and relay commands to cooling systems, operating reliably in the appliance’s moderate temperature environment.

Printers, scanners, and copiers depend on CEM3 PCBs for their mechanical and electrical stability. These devices experience constant vibration from moving parts (e.g., paper rollers) and moderate heat from motors, making CEM3’s flexibility and thermal tolerance valuable. A printer’s main control PCB, for instance, uses CEM3 to coordinate print head movement, ink delivery, and data processing, withstanding the device’s operational stresses without performance degradation.

In industrial sensors, basic automation controllers, and low-power motor drives, CEM3 PCBs balance durability and cost. They resist dust, minor chemical exposure, and vibration—common in factory settings—while supporting the low-frequency signals used in these systems. A humidity sensor deployed in a warehouse, for example, uses a CEM3 PCB to process analog readings and transmit data wirelessly, maintaining accuracy even in fluctuating environmental conditions.

CEM3 PCBs are widely used in automotive cabin electronics, such as infotainment systems, climate controls, and seat adjustment modules. Their ability to withstand temperature swings (from cold starts to summer heat) and resist automotive fluids (e.g., cleaning agents) ensures long-term reliability. Unlike underhood components, which require high-temperature FR4, cabin electronics operate within CEM3’s performance range, making it a cost-effective choice for manufacturers.

CEM3 PCB occupies a unique niche in the market, offering distinct advantages over other PCB types in specific scenarios:

FR4 PCBs provide higher mechanical strength, thermal resistance, and high-frequency performance, but at a 30–50% price premium. CEM3 PCBs are preferable for applications where these extreme properties are unnecessary—such as home appliances—delivering sufficient performance at a lower cost. For example, a toaster’s control PCB functions reliably with CEM3, whereas FR4 would add unnecessary expense without improving functionality.

CEM1 PCBs use paper-based cores, making them cheaper but prone to moisture absorption and heat damage. They fail in humid environments or at temperatures above 80°C, limiting their use to low-reliability devices like disposable electronics. CEM3 PCBs, with their glass reinforcement, offer superior durability, justifying their modest price increase for long-lived products like office printers.

Flexible PCBs (polyimide-based) excel in curved or wearable designs but are expensive and less rigid. CEM3 PCBs are better suited for flat, rigid applications—such as control panels—where their structure provides stable component mounting and easier assembly.

Metal-core PCBs (MCPCBs) dissipate heat effectively but are heavier and more costly. They are reserved for high-power applications like LED drivers, while CEM3 PCBs suffice for low-heat devices like remote controls.

Recent advancements are expanding the utility of CEM3 PCB, ensuring its relevance in evolving electronics markets:

Environmental regulations (e.g., EU RoHS) are driving adoption of halogen-free CEM3 PCBs, which replace brominated flame retardants with phosphorus-based alternatives. These PCBs maintain UL94 V-0 flame resistance while reducing toxic emissions during combustion, making them suitable for eco-conscious markets like Europe and North America.

New formulations with glass transition temperatures (Tg) of 140°C+ extend CEM3’s use into light industrial applications, such as small motor controllers, where moderate heat resistance is required. These variants retain CEM3’s cost advantage while narrowing the performance gap with FR4.

Producers are integrating recycled glass fibers and bio-based epoxy resins into CEM3 PCBs, reducing environmental impact. These sustainable variants appeal to brands prioritizing circular economy goals, such as consumer electronics companies aiming for carbon-neutral production.

CEM3 PCB exemplifies practical engineering, proving that balance—rather than extreme performance—is often the key to successful electronic design. By leveraging the unique properties of CEM3 material, these PCBs deliver reliable functionality, safety, and affordability across a wide range of applications, from home appliances to automotive interiors. Their compatibility with standard manufacturing processes and ongoing innovations—like halogen-free formulations and high-Tg variants—ensure they remain relevant in a market increasingly focused on value and sustainability. For engineers and manufacturers, CEM3 PCBs are more than a component; they are a strategic choice that enables accessible, reliable electronics without unnecessary compromise. As technology evolves, CEM3 PCBs will continue to adapt, solidifying their role as a foundational element of modern electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB