-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 15. 2025, 16:51:36

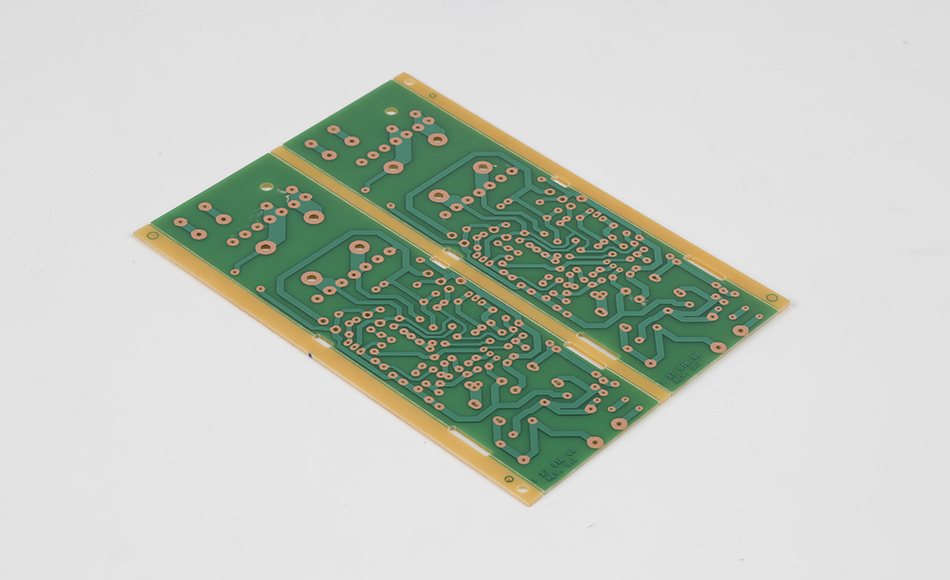

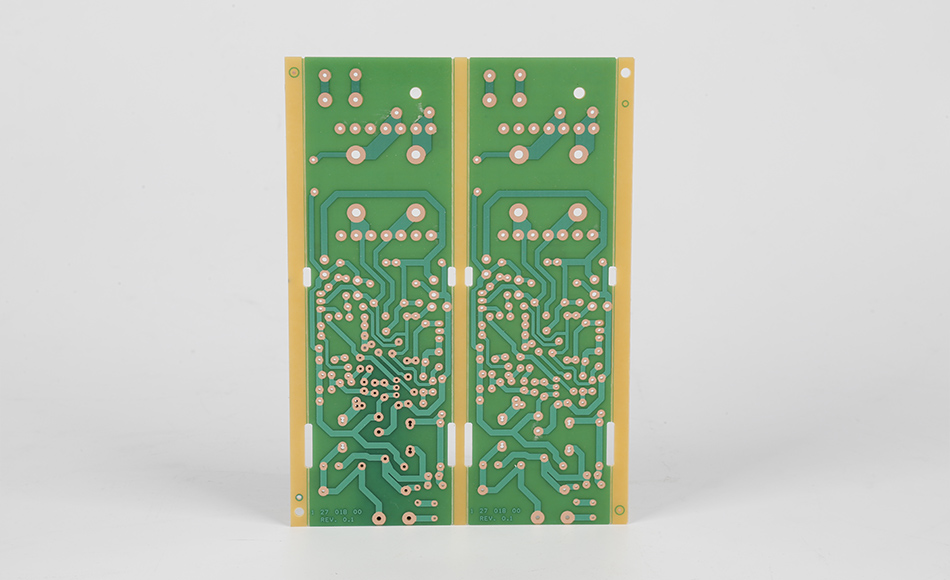

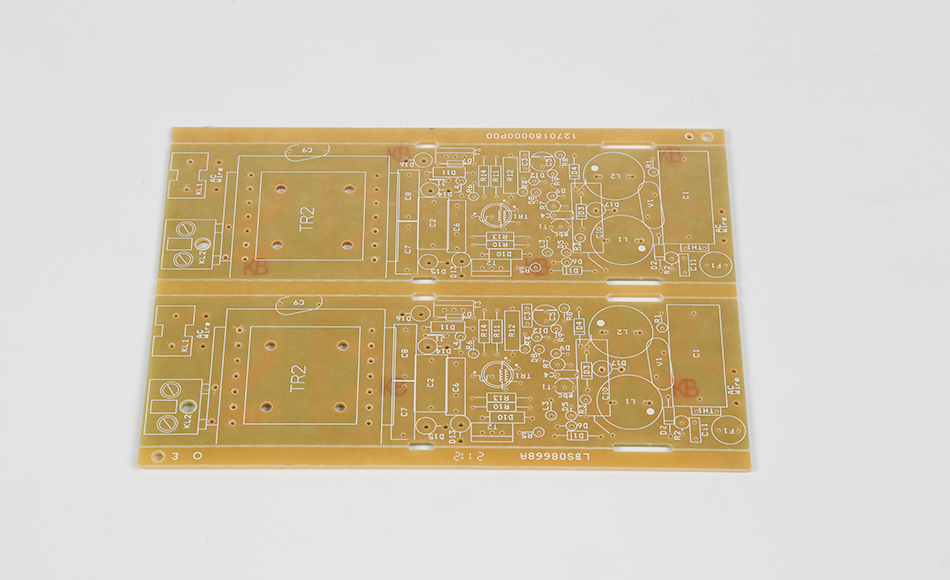

CEM3 PCB Material occupies a unique space in the electronics industry, offering a pragmatic blend of performance, affordability, and versatility that makes it a staple in countless devices. As a composite epoxy material, it bridges the gap between entry-level substrates and high-performance alternatives, providing sufficient mechanical strength, electrical insulation, and flame resistance for most general-purpose applications. Unlike specialized materials designed for extreme conditions, CEM3 is engineered for everyday use—powering everything from home appliances to light industrial controls—where reliability matters but excessive performance would only add unnecessary cost. This article explores the core attributes, material science, manufacturing nuances, and evolving role of CEM3 PCB material, highlighting why it remains a go-to choice for engineers seeking balance in design.

At its heart, CEM3 PCB Material is a masterclass in strategic material blending, combining epoxy resin and glass fibers to achieve targeted performance without over-engineering:

The matrix of CEM3 is a thermosetting epoxy resin, chosen for its exceptional adhesion, chemical resistance, and electrical insulation properties. This resin is formulated to cure into a rigid, cross-linked structure when exposed to heat and pressure, binding the reinforcement fibers into a unified substrate. Unlike the high-temperature epoxies used in FR4, CEM3’s resin prioritizes cost-effectiveness and flowability during manufacturing, ensuring it penetrates reinforcement fibers evenly and minimizes waste.

CEM3’s reinforcement system is a hybrid of two glass fiber forms, each contributing distinct benefits:

Non-woven glass mat: A dense, felt-like layer of randomly oriented glass fibers forms the core. This mat’s porous structure absorbs resin efficiently, reducing production time and ensuring uniform distribution. Its random fiber arrangement provides isotropic strength—consistent performance in all directions—critical for resisting warping during thermal cycling.

Woven glass fabric: Thin layers of woven glass fabric coat the non-woven core. Woven fabric adds directional rigidity, enhancing the material’s resistance to tearing during handling and providing a smooth surface for copper cladding. This combination of non-woven and woven fibers strikes a balance: the core ensures resin retention and isotropy, while the outer layers add structural integrity.

Thin copper foil is bonded to one or both sides of the CEM3 substrate to create conductive traces. The epoxy resin’s natural affinity for copper ensures strong adhesion, preventing delamination even during soldering and thermal cycling. This bond is critical for maintaining electrical continuity, as weak adhesion can lead to intermittent connections or complete failure in finished PCBs.

CEM3’s enduring popularity stems from a set of properties tailored to practical applications, avoiding the extremes of more specialized materials:

CEM3 offers sufficient flexural strength to support standard surface-mount and through-hole components, resisting deformation under the weight of parts like capacitors or small transformers. While not as rigid as FR4, its moderate flexibility is an advantage during manufacturing, allowing for easier cutting and shaping without cracking. This balance makes it ideal for low-volume production runs, where custom sizes and shapes are common.

The epoxy matrix provides excellent dielectric strength, ensuring minimal current leakage between adjacent copper traces in circuits operating at up to several hundred megahertz. This makes CEM3 suitable for low-to-moderate frequency applications, such as audio equipment, basic sensors, and household appliances, where signal integrity is important but not extreme. Its dielectric properties are stable across typical operating temperatures, avoiding the signal distortion that plagues lesser materials.

CEM3 is inherently flame-retardant, meeting UL94 V-0 standards—a critical safety feature for enclosed environments like homes and offices. This classification means it self-extinguishes within seconds when exposed to flame, reducing the risk of fire spread. Unlike early non-flame-retardant substrates, CEM3 achieves this without sacrificing other properties, making it a safe choice for consumer electronics.

CEM3 performs reliably in temperatures ranging from -30°C to 105°C, covering the operating range of most indoor and light industrial devices. While it softens slightly at higher temperatures (above its glass transition temperature, typically 120–130°C), it avoids the catastrophic failure seen in paper-based substrates. This thermal stability ensures consistent performance in devices like printers, which generate moderate heat during operation.

By using non-woven glass in its core, CEM3 reduces raw material costs compared to fully woven substrates like FR4. Its simplified manufacturing process—enabled by the non-woven mat’s resin absorption—further lowers production expenses. This cost advantage makes CEM3 accessible for high-volume consumer goods, where even small per-unit savings translate to significant overall value.

The production of CEM3 PCB Material is optimized for efficiency, leveraging its unique composition to streamline processes:

The first step involves saturating non-woven glass mat and woven glass fabric with epoxy resin to create prepreg—partially cured sheets. The non-woven mat’s porous structure absorbs resin quickly, reducing processing time, while the woven fabric requires precise resin control to maintain surface smoothness. This stage is critical: uneven resin distribution can lead to weak spots or electrical inconsistencies in the final substrate.

Prepreg layers are stacked with copper foil and subjected to heat (typically 150–180°C) and pressure in a hydraulic press. The heat cures the epoxy resin, forming strong chemical bonds between layers, while pressure ensures void-free adhesion. CEM3 requires lower pressure than FR4 due to its non-woven core, reducing energy consumption and equipment wear—a key factor in its cost advantage.

After lamination, the substrate undergoes cutting, drilling, and surface treatment. CEM3 drills cleanly with standard carbide tools, minimizing burrs and reducing the need for post-drilling cleaning. Its surface is treated to enhance copper adhesion, ensuring reliable trace formation during etching. These steps are designed to be compatible with standard PCB manufacturing lines, making CEM3 easy to integrate into existing production workflows.

CEM3 PCB Material is the backbone of devices that prioritize practicality over extreme performance, finding use in diverse sectors:

Home Appliances: Refrigerators, microwaves, and washing machines rely on CEM3 for their control boards. Its flame resistance and thermal stability ensure safe operation, while its cost-effectiveness keeps appliance prices accessible.

Audio Equipment: Speakers, radios, and amplifiers use CEM3 for signal routing. Its stable dielectric properties prevent audio distortion, and its rigidity supports compact component layouts.

Printers and Scanners: These devices depend on CEM3 to manage paper feeds, sensor inputs, and data processing. Its moderate flexibility withstands the vibrations of moving parts, while its electrical insulation prevents signal interference.

Copiers: CEM3’s durability ensures consistent performance in high-volume copying, where heat and mechanical stress are constant factors.

Sensor Modules: Temperature, humidity, and motion sensors use CEM3 for their circuit boards. Its isotropic strength resists the minor vibrations common in industrial settings, ensuring reliable data collection.

Basic Automation: Simple relay controllers and motor drives leverage CEM3’s cost efficiency, providing sufficient performance for low-power industrial systems without the expense of FR4.

CEM3 is widely used in automotive interior electronics, such as infotainment systems, climate controls, and seat sensors. Its flame resistance reduces fire risk in enclosed cabins, while its ability to withstand temperature swings (from cold starts to summer heat) ensures long-term reliability.

CEM3’s value becomes clear when compared to other PCB materials, each of which serves distinct niches:

FR4 uses woven glass fabric exclusively, offering higher mechanical strength and thermal resistance—ideal for high-power or high-frequency applications. However, it costs 30–50% more than CEM3, making it overkill for most consumer devices. CEM3 delivers 80% of FR4’s performance at 60% of the cost, a trade-off that makes sense for non-critical applications.

CEM1 uses paper reinforcement, making it cheaper but prone to moisture absorption and heat damage. It fails in humid environments or at temperatures above 80°C, limiting its use to low-cost, low-reliability devices. CEM3’s glass reinforcement eliminates these issues, justifying its modest price premium.

Older phenolic materials lack flame resistance and degrade quickly under heat, making them obsolete for modern electronics. CEM3’s flame retardancy and thermal stability have made it the natural successor, even in budget applications.

Flexible PCBs (e.g., polyimide-based) excel in curved or wearable devices but are expensive and less rigid. CEM3 is the better choice for flat, rigid designs, where its structure provides stable component mounting.

While CEM3 is a mature material, ongoing innovations are expanding its capabilities:

Environmental regulations are driving the development of halogen-free CEM3, which replaces brominated flame retardants with phosphorus or nitrogen-based alternatives. These formulations meet stricter eco-standards (e.g., EU RoHS) without sacrificing flame resistance, making CEM3 suitable for environmentally conscious markets.

New epoxy resins with higher glass transition temperatures (Tg 140°C+) are extending CEM3’s use into light industrial applications, such as small motor controllers, where moderate heat resistance is needed.

Producers are integrating recycled glass fibers into CEM3, reducing raw material costs and environmental impact. Some manufacturers also use bio-based epoxy resins derived from plant oils, lowering reliance on petroleum and appealing to green-focused brands.

CEM3 PCB Material is a testament to the power of balanced design. By prioritizing the properties that matter most for everyday applications—mechanical stability, electrical reliability, flame resistance, and affordability—it has earned its place as a workhorse of the electronics industry. Its hybrid structure, strategic resin formulation, and efficient manufacturing process make it a model of practical engineering, proving that sometimes “good enough” is exactly what’s needed. As regulations and sustainability goals evolve, CEM3 continues to adapt, ensuring it remains relevant in a market increasingly focused on value and responsibility. For engineers and manufacturers, CEM3 is more than a material—it’s a solution that makes innovation accessible.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB