-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 19. 2025, 08:37:17

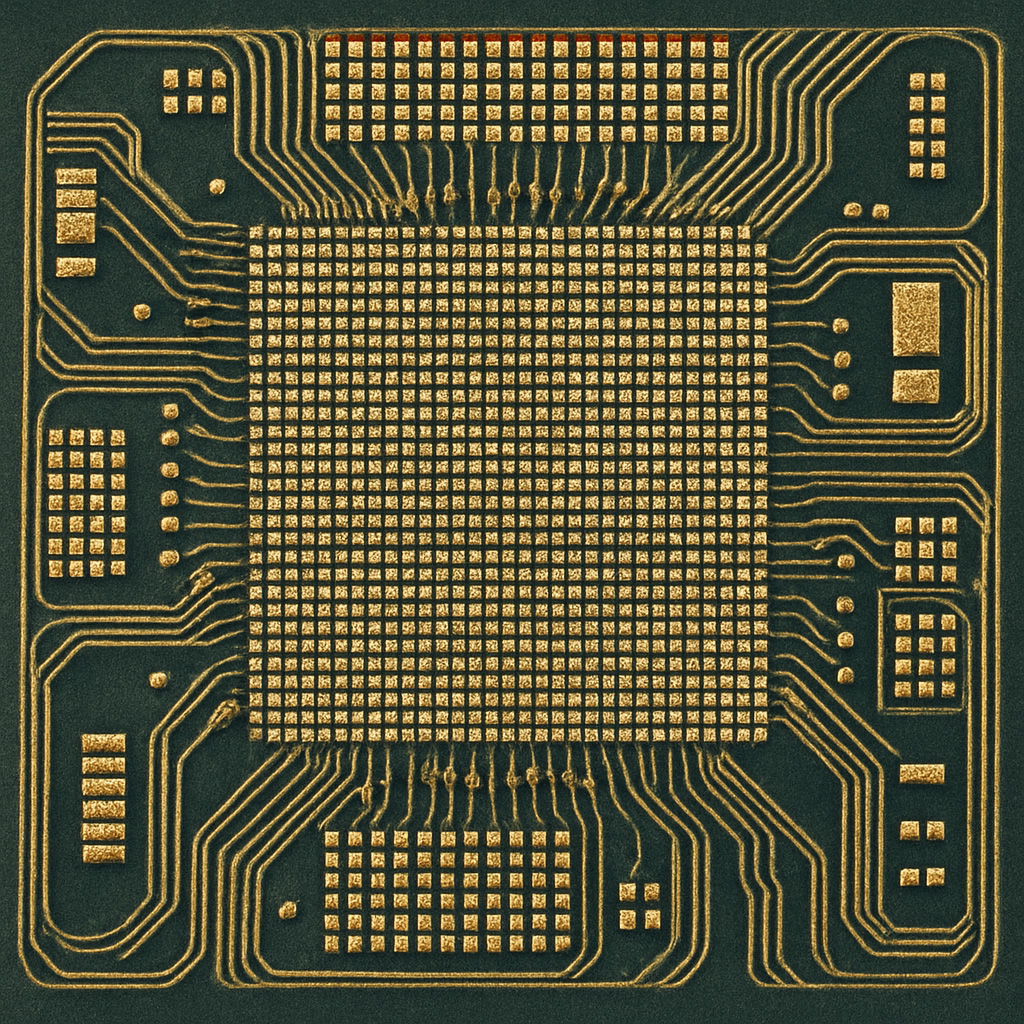

In the world of electronics, precision is key. High precision IC substrate PCBs (Printed Circuit Boards) are at the heart of modern electronic devices, enabling faster processing speeds, smaller form factors, and increased functionality. These components are indispensable in the development of advanced electronics, impacting everything from smartphones to complex computing systems. In this article, we will delve into the intricacies of high precision IC substrate PCBs, their manufacturing process, and their importance in the electronics industry.

IC (Integrated Circuit) substrate PCBs serve as the foundation for the assembly of ICs. They provide the necessary interconnections between the ICs and other components within an electronic device. High precision PCBs are specifically engineered to meet stringent requirements for accuracy and reliability, making them suitable for high-performance applications.

Miniaturization: With the trend towards smaller and more powerful devices, high precision PCBs are designed to support miniaturization. This involves creating complex circuitry in a compact space without compromising on performance.

High Density Interconnect (HDI): These PCBs utilize HDI technology to increase the number of connections per unit area. This allows for more components to be integrated into a smaller footprint.

Enhanced Thermal Management: Proper heat dissipation is crucial for maintaining the performance and longevity of electronic devices. High precision PCBs incorporate materials and designs that improve thermal management.

High Frequency Performance: These PCBs are optimized for high-frequency applications, ensuring minimal signal loss and interference.

Creating high precision IC substrate PCBs requires a meticulous manufacturing process that involves several steps to ensure quality and performance.

The process begins with the design and layout of the PCB. Engineers use computer-aided design (CAD) software to create detailed schematics of the circuit. This stage involves specifying the placement of components, routing of traces, and defining layer stack-ups.

Choosing the right materials is crucial for achieving the desired electrical and thermal properties. Common materials include FR-4 (a glass-reinforced epoxy laminate) and advanced substrates like BT (Bismaleimide Triazine) resin and polyimide.

Photolithography is used to transfer the circuit pattern onto the substrate. A photosensitive film, known as a photoresist, is applied to the substrate. The PCB is then exposed to ultraviolet light through a mask that defines the circuit pattern. This process creates a hardened image of the circuit on the substrate.

The next step is etching, where unwanted copper is removed from the substrate to reveal the circuit pattern. Chemicals such as ferric chloride or ammonium persulfate are used to dissolve the excess copper.

Drilling is performed to create holes for component leads and vias (connections between layers). These holes are then plated with copper to ensure electrical connectivity.

A solder mask is applied to the PCB to protect the traces from oxidation and prevent solder bridges during component assembly. The solder mask also enhances the board's durability and electrical insulation.

The surface finish is applied to the exposed copper areas to protect them from oxidation and ensure good solderability. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Rigorous testing is conducted to ensure that the PCB meets the required specifications. This includes electrical testing to verify connectivity and functional testing to assess performance under simulated conditions.

High precision IC substrate PCBs play a critical role in the advancement of technology. Their precision and reliability are crucial for the functionality of high-performance electronic devices. Here are some of the key benefits:

Increased Performance: High precision PCBs support faster data processing speeds and improved signal integrity, which are essential for modern electronic devices.

Space Efficiency: The ability to integrate more components into a smaller space allows for the development of compact and lightweight devices.

Enhanced Reliability: These PCBs are designed to withstand harsh environmental conditions, ensuring consistent performance over time.

Cost-Effectiveness: While the initial manufacturing cost may be higher, the durability and performance of high precision PCBs can lead to cost savings in the long run due to reduced failures and maintenance.

High precision PCBs are used in a variety of applications across different industries. Some of these include:

Consumer Electronics: Smartphones, tablets, and wearables rely on high precision PCBs for their compact designs and advanced functionalities.

Automotive Industry: Modern vehicles incorporate sophisticated electronic systems for navigation, entertainment, and safety, all of which depend on high precision PCBs.

Telecommunications: High-frequency communication devices require PCBs that can handle high data rates with minimal interference.

Medical Devices: Precision and reliability are paramount in medical equipment, making high precision PCBs essential for diagnostic and monitoring devices.

High precision IC substrate PCBs are indispensable components in the world of electronics. Their ability to support miniaturization, enhance performance, and improve reliability makes them vital for the development of advanced electronic devices. As technology continues to evolve, the demand for high precision PCBs will only increase, driving innovations in the manufacturing process and expanding their applications across various industries.

By understanding the intricacies of high precision IC substrate PCBs and their manufacturing process, businesses and engineers can make informed decisions that contribute to the success of their electronic products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB