-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 21. 2025, 14:21:34

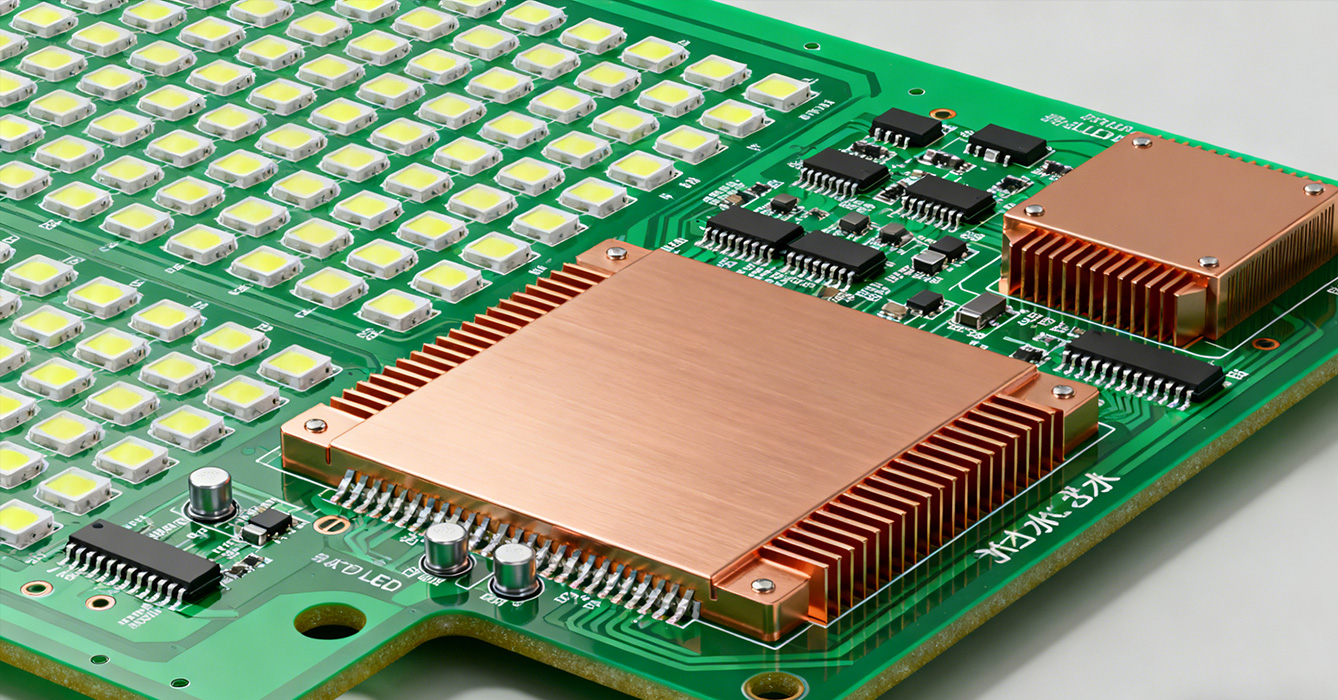

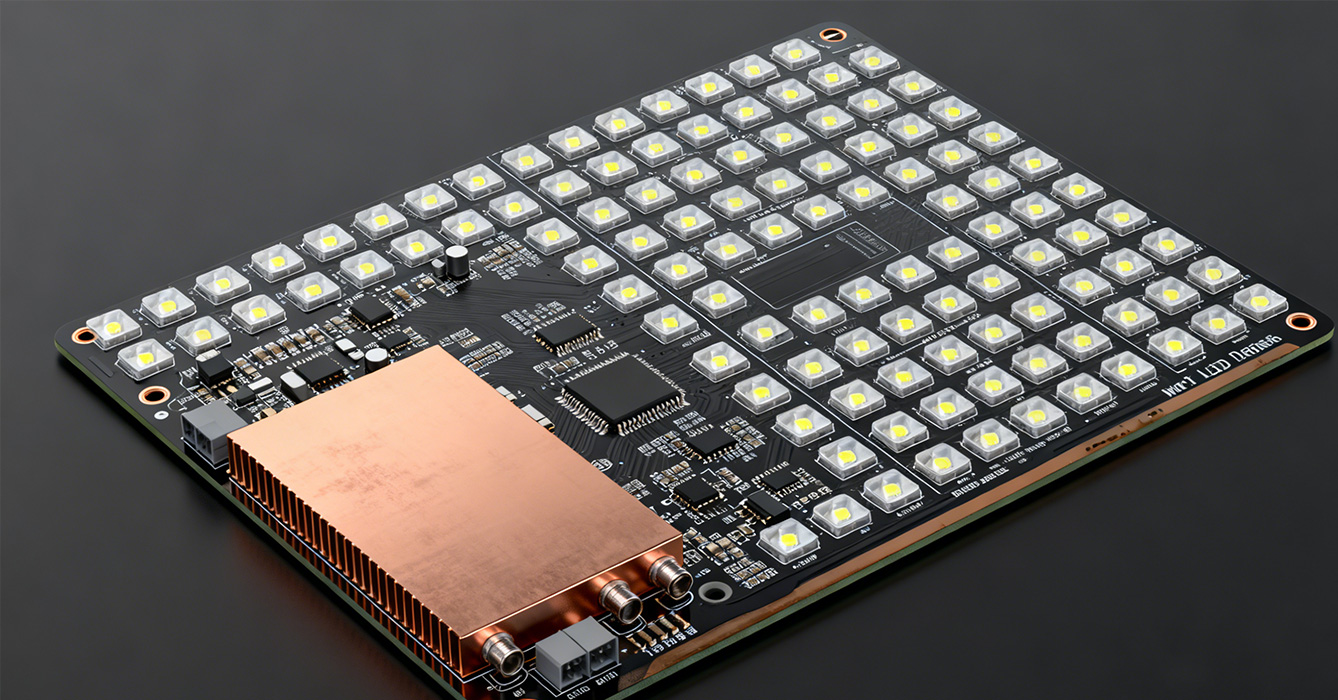

LED Lighting Sinkpad PCB stands as a foundational component in modern illumination systems, addressing the unique thermal and mechanical demands of LED technology. Unlike generic PCBs, this specialized solution is engineered to manage the concentrated heat generated by LED chips— a critical factor that directly impacts lumen maintenance, energy efficiency, and lifespan. As LED lighting evolves toward higher power densities, smaller form factors, and diverse applications (from residential downlights to industrial high-bays), LED Lighting Sinkpad PCB has become indispensable for unlocking the full potential of energy-efficient illumination. This article explores the illumination-specific design considerations, material optimizations, application-driven innovations, and performance validation of LED Lighting Sinkpad PCB, highlighting its role in shaping reliable, sustainable lighting solutions.

LED Lighting Sinkpad PCB design is tailored to the unique operating characteristics of LED systems, balancing thermal efficiency with form factor and application requirements.

LEDs convert only 20-30% of energy into light, with the rest dissipated as heat—concentrated in a small chip area. LED Lighting Sinkpad PCB addresses this by optimizing thermal paths for illumination scenarios:

Direct Chip-to-Sinkpad Contact: For high-power LEDs (30W+), the sinkpad’s metal core is precision-aligned with the LED’s thermal pad, eliminating intermediate layers to minimize thermal resistance. This direct path ensures heat is rapidly transferred away from the junction, preventing lumen depreciation.

Size-Scaled Heat Spreading: Compact fixtures (e.g., residential bulbs) use slim, disc-shaped sinkpads that match the LED’s footprint, while high-bay lights employ extended sinkpad structures with radial heat channels to cover larger areas. This scaling ensures thermal efficiency without compromising fixture design.

Passive Cooling Synergy: Sinkpad geometries are integrated with fixture housings to leverage natural convection—critical for lighting applications where active cooling (fans) is impractical due to noise or size constraints.

LED Lighting Sinkpad PCB is designed to adapt to the diverse form factors of modern lighting:

Low-Profile Designs: For slim fixtures like panel lights and track lights, sinkpad PCBs use thin-gauge metal cores (1-2mm) with optimized copper pour patterns, maintaining thermal performance while enabling sleek aesthetics.

Conformal Compatibility: Flexible sinkpad PCBs (using polyimide substrates) conform to curved surfaces, supporting innovative designs such as automotive headlight strips and architectural contour lighting.

Component Integration: Sinkpad layers are engineered to accommodate LED drivers, resistors, and connectors in a single board, reducing fixture complexity and assembly costs—key for mass-produced lighting products.

LED Lighting Sinkpad PCB must withstand the specific environmental stresses of lighting applications:

Outdoor Lighting: Sinkpad cores and finishes (e.g., anodized aluminum, ENEPIG plating) resist UV radiation, moisture, and temperature cycling (-40°C to 65°C), ensuring long-term performance in street lights and floodlights.

Indoor Commercial Spaces: Humidity-resistant dielectrics and corrosion-proof traces address the stable but high-usage environments of offices, retail stores, and hospitals, where lighting operates 12+ hours daily.

Materials and manufacturing processes for LED Lighting Sinkpad PCB are optimized to balance performance, cost, and scalability—critical for the competitive lighting market.

Aluminum Core Dominance: For mid-to-high-power LED lighting (10-50W), aluminum-core sinkpads offer a cost-effective balance of thermal conductivity (237 W/(m·K)) and weight, making them ideal for mass-produced fixtures like downlights and street lights.

Copper Core for High-Power Needs: High-bay lights and industrial lighting (50W+) use copper-core sinkpads to handle higher thermal loads, leveraging copper’s superior conductivity (401 W/(m·K)) to maintain lower junction temperatures.

Hybrid Composites for Specialized Use: Ceramic-aluminum hybrids are used in extreme-temperature applications (e.g., industrial process lighting), combining thermal stability with dielectric strength to withstand 150°C+ operating conditions.

Precision Etching for Fine Traces: LED Lighting Sinkpad PCB requires narrow electrical traces (0.2-0.5mm) to fit compact fixtures, using controlled etching processes to maintain trace integrity while preserving the sinkpad’s thermal path.

Solder Mask Optimization: Clear solder mask is applied to sinkpad surfaces (except LED mounting areas) to enhance heat dissipation and protect against environmental damage, without interfering with thermal transfer.

Scalable Production: Manufacturers use automated assembly lines for LED Lighting Sinkpad PCB, ensuring consistent quality for high-volume lighting applications—critical for meeting the demands of residential and commercial construction projects.

LED Lighting Sinkpad PCB must meet strict illumination-specific standards to ensure reliability and energy efficiency.

Lumen Maintenance Validation: Sinkpad performance is tested alongside LEDs per IES LM-80 standards, tracking lumen output over 6,000+ hours to ensure ≥90% retention—directly linking thermal management to lighting performance.

Thermal Cyclic Testing: Simulates seasonal temperature changes for outdoor lighting, subjecting sinkpad PCBs to 500+ cycles of -40°C to 85°C to verify structural integrity and thermal consistency.

Energy Efficiency Benchmarking: Tests per ENERGY STAR requirements measure lumens per watt (lm/W) with the sinkpad installed, ensuring the design contributes to the fixture’s energy-saving claims.

IES LM-80: Mandates thermal management requirements for LED modules, ensuring sinkpad PCBs maintain junction temperatures within safe limits to preserve lifespan.

ENERGY STAR: Requires LED fixtures with sinkpad PCBs to achieve minimum lm/W ratios (e.g., ≥80 lm/W for residential bulbs), validating energy efficiency.

RoHS/REACH: Restricts hazardous substances in sinkpad materials, aligning with global lighting industry sustainability mandates and enabling market access in Europe and North America.

High-Bay Lights: Copper-core sinkpad PCBs dissipate heat from 100W+ LEDs in warehouses and factories, maintaining 50,000+ hours of operation with minimal lumen loss.

Retail Track Lights: Low-profile aluminum sinkpads enable slim designs while cooling 30-50W LEDs, preserving color consistency (Δu'v' ≤0.005) critical for product displays.

Street Lights: Corrosion-resistant sinkpad PCBs with extended heat spreading structures handle 50-200W LEDs, enduring rain, UV, and temperature fluctuations for 100,000+ hours.

Landscape Lighting: Flexible sinkpad PCBs conform to curved fixtures, cooling 10-30W LEDs while withstanding moisture and soil contact.

LED Bulbs: Compact aluminum sinkpads fit within standard bulb envelopes, cooling 5-20W LEDs to extend lifespan beyond 25,000 hours.

Smart Downlights: Sinkpad PCBs integrate with wireless modules and dimming circuits, balancing thermal management with electrical integration for connected home systems.

Integrated Sensing: Sinkpad PCBs will embed low-power temperature sensors to enable adaptive dimming, adjusting LED output based on thermal conditions to maximize efficiency.

Eco-Friendly Materials: Recycled aluminum cores and bio-based dielectrics will become standard, reducing the carbon footprint of LED lighting systems.

Miniaturized High-Power Designs: Advanced thermal engineering will enable smaller sinkpad PCBs for high-power LEDs, supporting ultra-compact fixtures for urban and architectural applications.

LED Lighting Sinkpad PCB is a specialized, application-driven technology that unlocks the reliability and efficiency of modern LED illumination. By tailoring thermal paths, materials, and form factors to the unique needs of lighting systems—from compact residential bulbs to industrial high-bays—this solution addresses the core challenge of heat management in LEDs. Compliance with illumination-specific standards ensures performance consistency, while scalable manufacturing supports mass-market accessibility. As LED lighting continues to dominate the global illumination market, LED Lighting Sinkpad PCB will remain a critical enabler, driving innovations in energy efficiency, design flexibility, and sustainability for a brighter, greener future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB