-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Feb 09. 2026, 12:56:14

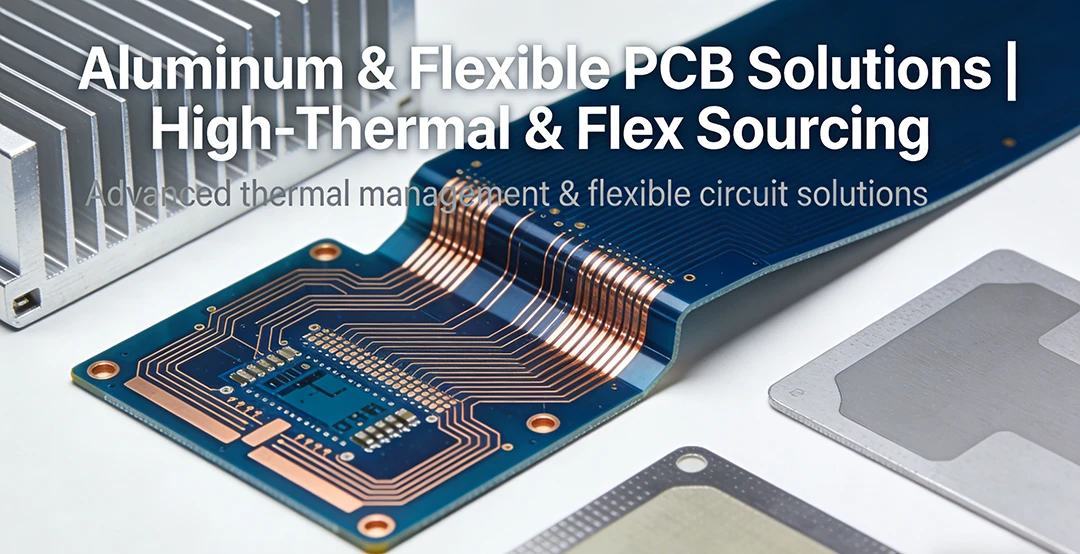

In the high-stakes world of industrial electronics, "standard" is no longer enough. As power densities rise and device footprints shrink, engineers at Tier-1 factories are moving away from traditional FR4 substrates in favor of specialized aluminum & flexible pcb solutions. These technologies address the two biggest hurdles in modern hardware: thermal dissipation and mechanical adaptability.

Whether you are developing high-lumen automotive lighting or aerospace-grade sensors, choosing the right aluminum pcb board or flexible pcb is a strategic decision that dictates your product’s lifespan and reliability.

An aluminum pcb, also known as a Metal Clad PCB (MCPCB), is the undisputed champion of heat management. Unlike standard fiberglass, the aluminum core pcb uses a thin layer of thermally conductive but electrically insulating dielectric to transfer heat away from the components into the metal base.

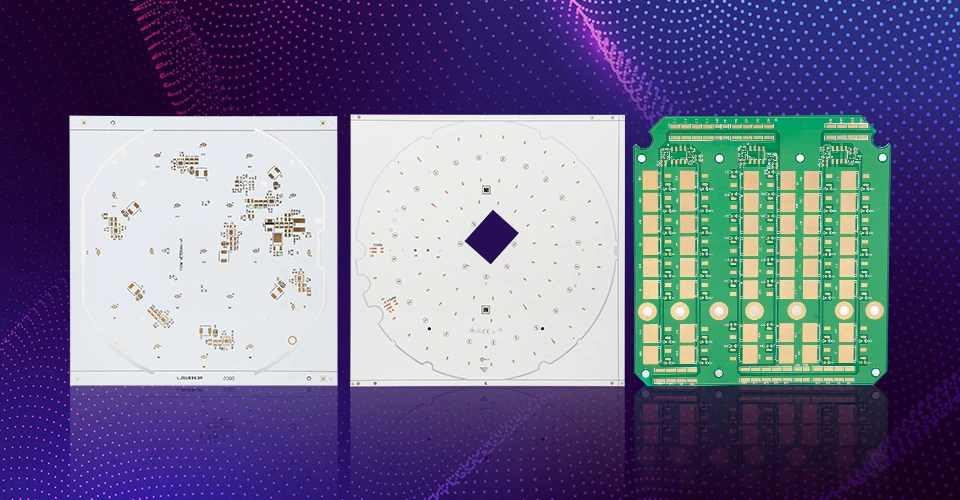

The lighting industry has been revolutionized by aluminum pcb for led applications. LEDs generate significant heat at the junction; if this heat isn't dissipated, the LED’s brightness will degrade, and its lifespan will plummet.

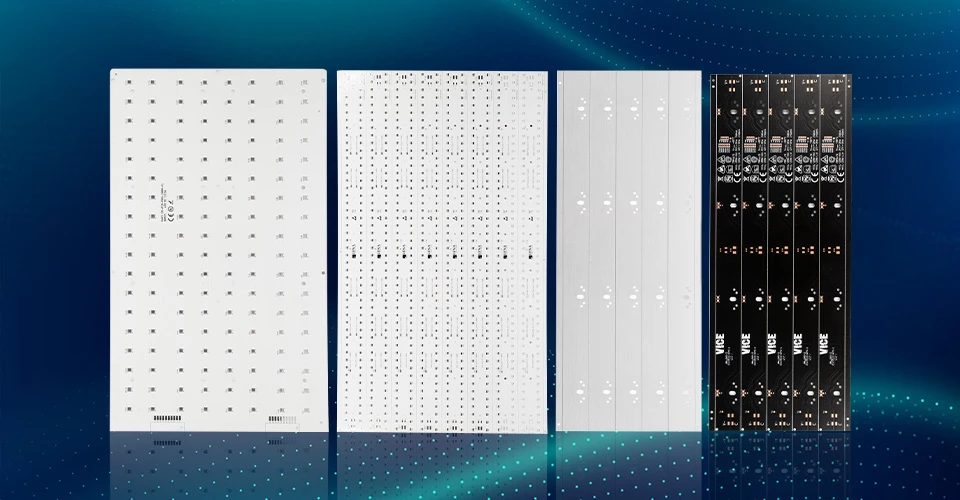

Dimensional Stability: Aluminum boards resist warping better than FR4 under extreme heat.

Cost-Effective Scalability: For mass-produced consumer and industrial lighting, aluminum pcb offers the best performance-to-price ratio.

If aluminum boards solve the problem of heat, the flexible pcb solves the problem of space. Utilizing polyimide (PI) or polyester (PET) films, a flexible pcb can be folded, twisted, and tucked into tight enclosures where a rigid board simply cannot go.

A successful flexible pcb design requires a departure from rigid thinking. Engineers must account for:

Bend Radius: Ensuring the copper traces don't fracture during repeated movement.

Stiffeners: Adding rigid sections (FR4 or Aluminum) to support heavy components while maintaining overall flexibility.

Static vs. Dynamic Flex: Determining if the board will be bent once during installation or millions of times during operation (e.g., a laptop hinge).

For complex industrial machinery, a rigid flex pcb design often provides the ultimate solution—combining the structural integrity of rigid boards with the connectivity of flex circuits, eliminating the need for bulky wire harnesses.

Sourcing is only half the battle. The true value for a factory-level client lies in a seamless pcb fabrication assembly process. Managing multiple vendors for fabrication, component sourcing, and assembly leads to "the blame game" when defects occur.

A professional pcb manufacturing service like ApolloPCB offers a turnkey approach:

DFM (Design for Manufacturability): We review your flexible pcb design to ensure the trace widths and pad placements are optimized for high-yield production.

Sourcing: Procuring genuine components that match the thermal demands of an aluminum pcb board.

Specialized Assembly: Flex pcb assembly requires precision tensioning and specialized carriers to prevent the thin substrate from stretching or warping in the reflow oven.

For high-volume factory orders, you need an aluminum pcb manufacturer that treats thermal conductivity as a science, not a guess. At ApolloPCB, we focus on:

Dielectric Integrity: Ensuring the insulating layer doesn't break down under high voltage.

Machining Precision: Providing clean edges and countersink holes for flush-mounting into industrial housings.

Flexible Circuit Board Prototype: Allowing you to test the mechanical limits of your design before committing to a 10,000-unit run.

| Feature | Aluminum PCB | Flexible PCB |

| Primary Benefit | Heat Dissipation | Space Saving / Weight Reduction |

| Substrate | Aluminum Alloy (5052/6061) | Polyimide (Kapton) |

| Flexibility | Rigid | High (Dynamic or Static) |

| Thermal Conductivity | High ($1.0 - 9.0\text{ W/m.K}$) | Low ($0.2 - 0.5\text{ W/m.K}$) |

| Typical Use Case | Power Supplies, LED Arrays | Wearables, Medical Sensors, Robotics |

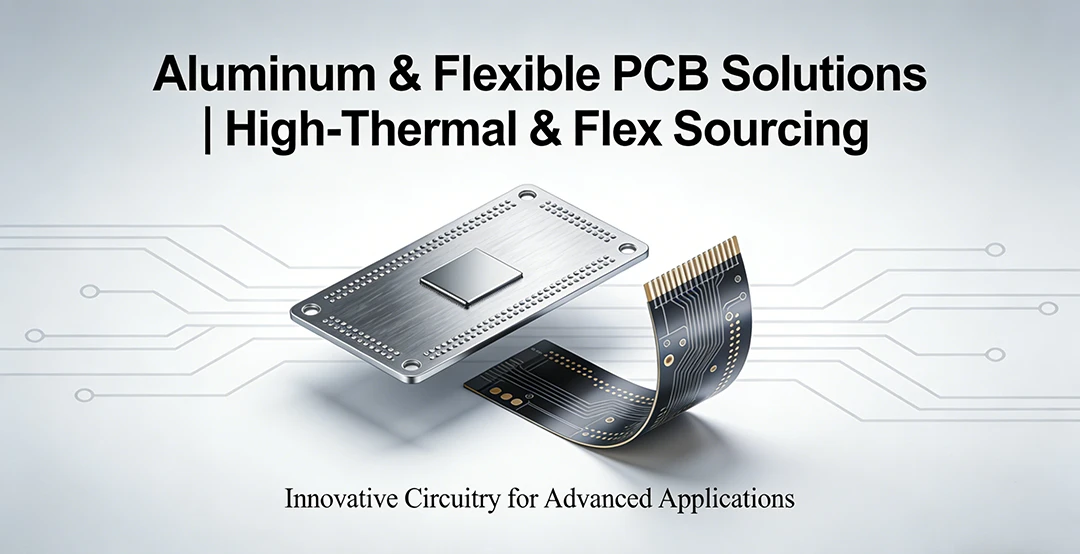

An emerging technology that factories are increasingly requesting is the flexible aluminum pcb. This hybrid uses specialized, thin aluminum alloys that can be bent (often only once) to fit a specific curved housing, such as an automotive headlight. It combines the thermal benefits of a pcb aluminum board with the form-factor benefits of a flex circuit.

An aluminium flex pcb is a hybrid board that uses a very thin aluminum foil or specialized alloy as a base, bonded to a flexible dielectric and copper layer. It is designed for applications requiring high heat dissipation in a non-planar (curved) environment.

Similar to the above, it is an aluminum pcb that has been scored or thinned in specific areas to allow for bending. It is primarily used to eliminate wires between two rigid aluminum sections.

Flex pcb assembly is more challenging because the material is "floppy." It requires rigid carriers (fixtures) to hold it flat during SMT placement and reflow. Rigid-flex pcb design assembly is slightly easier as the rigid sections provide built-in stability for the assembly machines.

Depending on the dielectric thickness and material grade, an aluminum pcb can support power densities exceeding $20\text{ W/cm}^2$, making it essential for high-current power converters.

Aluminum PCBs typically offer thermal resistance values that are 5 to 10 times lower than traditional FR-4 boards. While FR-4 acts as an insulator, the aluminum core pcb acts as a primary heat sink.

For ApolloPCB, the critical parameters are:

Lamination Pressure: To ensure no air bubbles in the dielectric.

Peel Strength: To ensure the copper doesn't delaminate from the metal base under thermal stress.

Surface Finish: Choosing the right finish (like OSP or ENIG) to ensure reliable solder joints on the metal substrate.

In the search for aluminum & flexible pcb solutions, price is a factor, but reliability is the priority. By partnering with a dedicated aluminum pcb manufacturer that understands the nuances of flexible circuit board prototype development and mass pcb fabrication assembly, you secure your product's future in the market.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related News

PCB Assembly & Manufacturing Equipment Guide | ApolloPCB Solutions

Aluminum PCB Manufacturer | High Thermal Conductivity MC-PCB Boards

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminum PCB: Benefits and Applications for High-Power Electronics

PCB Assembly & Manufacturing Costs Guide | Turnkey PCB & FPCB Solutions

FPC High Density Component Assembly: Powering Compact, High-Performance Flexible Electronics

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB