-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Feb 10. 2026, 11:40:46

In the precision-driven world of electronics manufacturing, small dimensions lead to significant impacts. For factory procurement managers and hardware engineers, mastering the nuances of board dimensions and sourcing reliable production partners are the cornerstones of a successful product launch. As pcb thickness & assembly experts, we understand that whether you are developing high-speed networking gear or rugged industrial sensors, the physical parameters of your board dictate everything from mechanical fit to signal integrity.

Choosing a pcb assembly manufacturer who understands the relationship between standard fr4 pcb thickness and assembly yield is critical. This guide dives deep into the technical specifications of PCB substrates and the strategic advantages of modern assembly solutions.

The thickness of a printed circuit board is not merely a mechanical attribute; it is a critical variable in the electrical and thermal performance of the device. While many designers default to "standard" sizes, industrial-grade applications often require custom stackups to meet specific durability and conductivity goals.

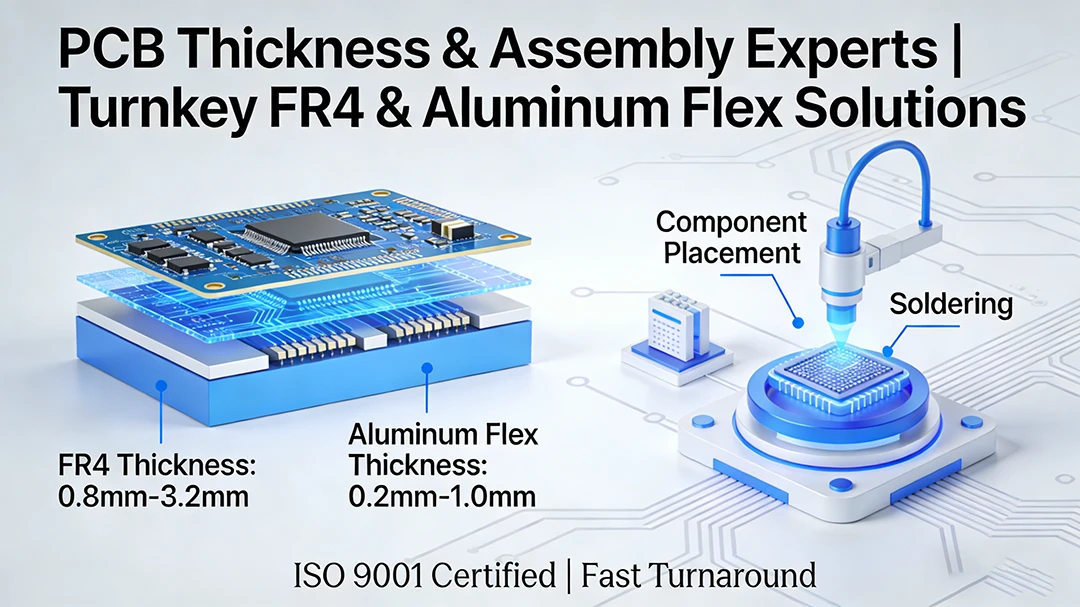

The most common material in the industry is FR4, a glass-reinforced epoxy laminate.

Standard FR4 PCB Thickness: The industry benchmark is $1.6\text{mm}$ ($0.062\text{ inches}$). This thickness provides an ideal balance of mechanical strength and weight for the majority of industrial controllers.

Thin Boards ($0.2\text{mm} - 0.8\text{mm}$): Frequently used in handheld devices or where weight is a primary constraint.

Thick Boards ($2.0\text{mm} - 3.2\text{mm}$): Necessary for high-layer-count backplanes or boards supporting heavy industrial components.

Beyond the core material, fr4 pcb copper thickness is a vital specification. Measured in ounces (oz), it determines the current-carrying capacity of the traces.

1 oz ($35\mu\text{m}$): Standard for signal traces.

2 oz - 4 oz: Used for power electronics to manage high current and improve heat dissipation.

For modern factories, the days of managing separate vendors for fabrication, component sourcing, and assembly are over. The industry has shifted toward turnkey pcb assembly to eliminate the "blame game" and streamline the supply chain.

A full turnkey pcb assembly service means the manufacturer handles everything:

PCB Fabrication: Manufacturing the bare board to your exact fr4 pcb thickness specifications.

Component Procurement: Sourcing parts from authorized distributors.

Assembly: Soldering components using high-speed SMT and through-hole lines.

Testing: AOI, X-ray, and functional testing.

By partnering with a turnkey pcb assembly specialist like ApolloPCB, factories reduce their administrative overhead and significantly decrease time-to-market.

As devices become more powerful, thermal management becomes more complex. This has led to the rise of hybrid solutions that combine the best of metal cores and flexible substrates.

An aluminum flex pcb (or flexible aluminum pcb) is a specialized board that utilizes a thin, bendable aluminum base bonded to a flexible dielectric. Unlike a rigid aluminum pcb board, the flexible aluminum pcb can be contoured to fit into non-planar housings, such as automotive headlights or curved LED displays.

Superior Cooling: Aluminum dissipates heat 5-10 times faster than FR4.

Space Optimization: The "flex" aspect allows the board to act as its own connector, reducing the need for bulky wire harnesses.

Vibration Resistance: The flexible nature of the substrate absorbs mechanical shock better than rigid metal boards.

Not all pcb assembly suppliers are equipped to handle the rigors of industrial-scale production. When evaluating a pcb assembly manufacturer, look for these key indicators of expertise:

Advanced Equipment: Do they have the SMT precision to handle 0201 components on thick $3.2\text{mm}$ boards?

Material Versatility: Can they transition from standard fr4 pcb thickness to specialized aluminum flex pcb projects seamlessly?

Proactive DFM: A true expert will review your Gerber files to ensure your fr4 pcb copper thickness is optimized for both manufacturing and electrical performance.

In the fast-moving tech sector, following pcb assembly news is vital. Trends like the shift toward "Halogen-Free" materials and the integration of AI in AOI (Automated Optical Inspection) are changing how pcb assembly suppliers operate. ApolloPCB remains at the forefront of these innovations, ensuring our clients receive the most reliable and modern solutions available.

Choosing the right thickness involves balancing three factors: mechanical requirements (will it fit the enclosure?), electrical requirements (impedance control often depends on thickness), and weight constraints. At ApolloPCB, we recommend $1.6\text{mm}$ for general industrial use, while high-frequency designs may require thinner substrates for better signal performance.

In high-speed designs, the distance between the signal layer and the reference plane (determined by the dielectric thickness) directly affects impedance. If the fr4 pcb thickness varies beyond tolerances, it can cause signal reflections and data loss.

Yes. For instance, in the aerospace and medical industries, IPC Class 3 standards often dictate minimum copper plating thickness in through-holes and specific board thickness tolerances to ensure survival in extreme environments.

For a 6-layer stackup, you should choose dielectric materials (Prepreg and Core) that maintain a symmetrical stackup. This prevents board warping during the reflow process. If you are using high-speed signals, materials with a low Dielectric Constant (Dk) like Rogers are often combined with FR4.

Mastering the complexities of fr4 pcb thickness, full turnkey pcb assembly, and specialized materials like flexible aluminum pcb is what sets world-class products apart. By choosing a pcb assembly manufacturer with deep technical expertise, you secure your product's performance and your factory's reputation.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related Blogs

Efficient PCB Assembly: Mastering Countersink Holes

Counterbore Holes in PCB Assembly: Essential Guide

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

Leading Flex & FR4 PCB Makers | Custom Fabrication & Assembly Meta

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB