-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 24. 2026, 21:09:21

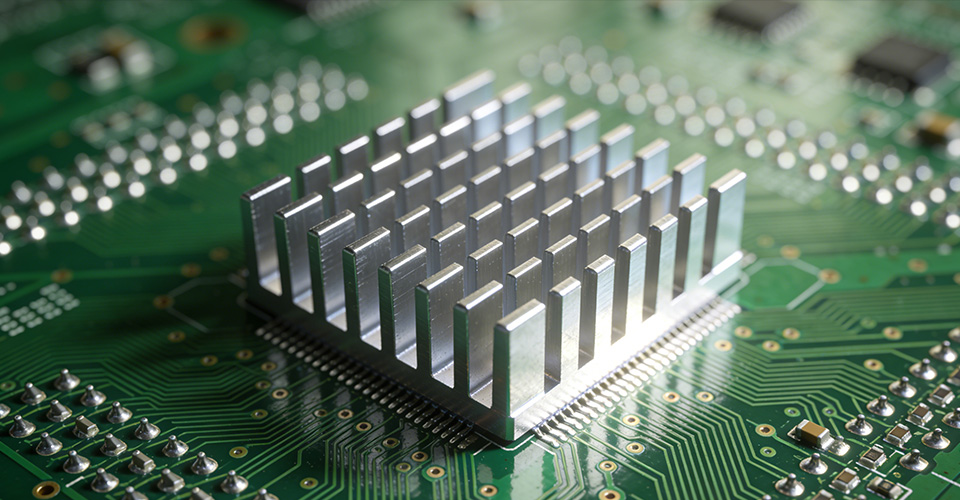

In the high-power electronics sector, heat is the ultimate enemy of longevity. As components become smaller and power densities increase, traditional FR4 substrates often fail to dissipate heat effectively. This is where the aluminum pcb becomes the industry standard.

For engineers and procurement managers at Tier-1 factories, choosing the right substrate is a strategic decision. Whether you are developing high-lumen LED arrays or automotive power converters, understanding the nuances of aluminum pcb boards is critical for product success.

The demand for aluminum pcb boards has skyrocketed due to their unparalleled thermal management capabilities. Unlike standard fiberglass, an aluminum-based substrate acts as a massive heat sink, drawing thermal energy away from sensitive semiconductors and dissipating it into the environment.

A typical aluminum pcb consists of three distinct layers:

The Circuit Layer: A copper foil layer (usually 1oz to 6oz) where your components are soldered.

The Dielectric Layer: The "secret sauce"—a thermally conductive but electrically insulating layer.

The Aluminum Base: The mechanical and thermal foundation, typically made of 5052 or 6061 alloy.

For factory-level buyers, the "price-per-piece" is only part of the equation. A true aluminum pcb manufacturer must offer consistency, material traceability, and advanced fabrication capabilities.

At ApolloPCB, we understand that a manufacturing defect in a 10,000-unit run can be catastrophic. That is why our facility focuses on:

Material Integrity: Ensuring the dielectric layer has consistent aluminum pcb Thermal Conductivity (ranging from 1.0 W/m.K to 9.0 W/m.K).

Scale: Handling everything from quick-turn prototypes to high-volume container shipments.

Compliance: Meeting UL, RoHS, and ISO 9001 standards for international markets.

In many industrial applications, the PCB is not just a circuit—it is part of the mechanical housing.

An aluminum box pcb setup refers to a design where the PCB is specifically engineered to slide into or bolt onto a metal housing. This is common in outdoor power supplies and industrial drivers.

When designing an enclosure case aluminum pcb, mechanical precision is paramount. Factories often require specific hole types to ensure a flush fit within the housing:

Countersink Holes in aluminum PCB: Essential for flat-head screws, ensuring the fastener sits flush with the board surface.

Counterbore Holes in aluminum PCB: Used for socket head cap screws, providing a recessed flat bottom for the bolt head.

While most people associate metal cores with simple designs, the technology has evolved significantly.

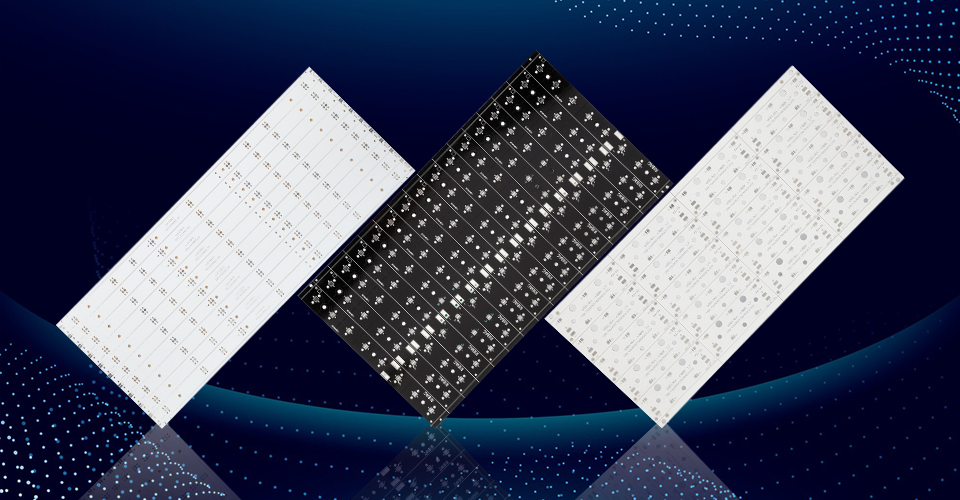

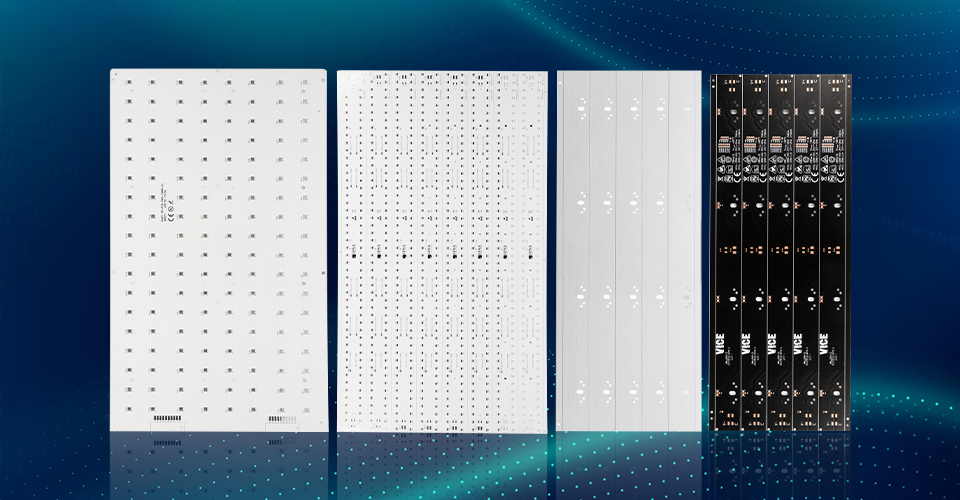

The most cost-effective solution, used widely in aluminum pcb led model light applications. It offers the most direct thermal path from the component to the metal base.

For complex circuitry requiring high-density interconnects, Multi-Layer aluminum pcb structures are used. These feature multiple copper layers separated by dielectric materials, all bonded to the aluminum core. This is common in high-end telecommunications and medical power modules.

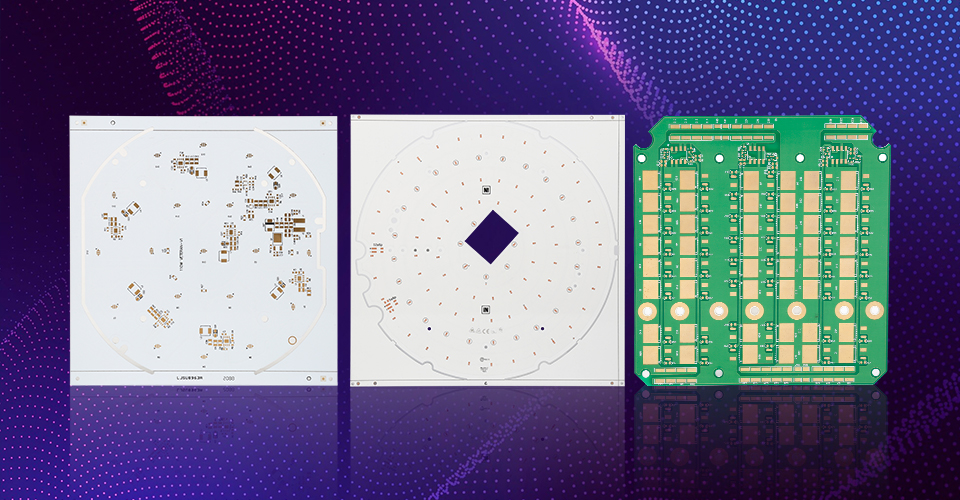

Innovation has led to the bendable aluminum pcb, which uses specialized alloys and thin dielectrics that allow the board to be shaped (e.g., for curved LED displays or automotive headlight housings) without fracturing the circuit.

Effective aluminum pcb design requires a departure from standard FR4 rules. To optimize your board for manufacturing, consider the following:

Thermal Expansion (CTE): Aluminum expands more than FR4. Ensure your surface-mount components (SMD) are placed to withstand thermal cycling stress.

Trace Clearance: Maintain adequate distance between traces and the board edge to prevent shorting to the metal base.

Halogen Free aluminum pcb: For eco-conscious markets (Europe/California), specify halogen-free materials to meet strict environmental regulations.

Soldermask: Use high-reflectivity white soldermask for round aluminum pcb led designs to maximize light output.

The aluminum clad pcb (also known as MCPCB or Metal Clad PCB) is the backbone of the lighting industry. In an aluminum pcb led model light, the thermal conductivity of the board directly impacts the "Lumen Depreciation"—the rate at which the light fades over time. By using high-quality aluminum substrates, you extend the life of the LED from 20,000 hours to over 50,000 hours.

When you search for the best aluminum pcb manufacturer, you are looking for more than a vendor; you are looking for a risk-mitigation partner.

Customization: From round aluminum pcb led for downlights to complex aluminum box pcb for EV chargers.

Advanced Machining: We utilize high-speed CNC routing to ensure clean edges and precise Countersink/Counterbore holes.

Speed: 24-hour express service for aluminum prototypes.

An aluminum PCB is a thermal management circuit board consisting of a thin layer of thermally conductive but electrically insulating dielectric material, laminated between a copper circuit layer and an aluminum metal base.

Standard PCBs (FR4) do not contain aluminum. Only Metal Core PCBs (MCPCBs) use aluminum, copper, or stainless steel as a base material to enhance heat dissipation.

The primary difference is Thermal Conductivity. FR4 has a rating of approximately 0.25 W/m.K, while aluminum pcb boards can reach up to 9.0 W/m.K. Aluminum is superior for heat, while FR4 is better for multi-layer complexity and lower costs in low-power apps.

Yes, PCBWay is a well-known Chinese prototype manufacturer. However, for factory-direct, high-volume industrial orders and specialized technical support for aluminum pcb design, partners like ApolloPCB offer more tailored B2B manufacturing services.

Standard hobbyist milling machines often struggle with aluminum due to its ductility. Professional aluminum pcb manufacturers use industrial CNC routers with specialized cooling systems to prevent burrs and ensure precision.

The aluminum pcb manufacturing process involves vacuum lamination of the copper, dielectric, and aluminum base, followed by UV exposure, etching, and mechanical drilling or CNC routing for the final shape.

While DIY methods exist, making a reliable aluminum PCB requires a high-pressure lamination press to ensure the dielectric layer is thin enough for heat transfer but strong enough for insulation. Professional fabrication is always recommended for industrial products.

Don't let heat compromise your product's performance. ApolloPCB provides professional DFM (Design for Manufacturability) reviews for all aluminum projects.

[Get a Free Quote & Thermal Analysis for Your Aluminum PCB Project Today]

Related Articles

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

GDM Aluminum Based CCL: A Versatile Foundation for Modern Electronics

Ventec Aluminum CCL Material Datasheet: A Paradigm of Thermal and Electrical Excellence

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminium-Based CCL: Innovations in High-Performance Copper Clad Laminates

Aluminum PCB: Benefits and Applications for High-Power Electronics

Thermal Via Aluminum PCB Structure: Design Principles for Enhanced Heat Dissipation

Countersink Holes PCB Manufacturer: Precision & Quality

Aluminum PCB: Benefits and Applications for High-Power Electronics

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB