-

- PCB TYPE

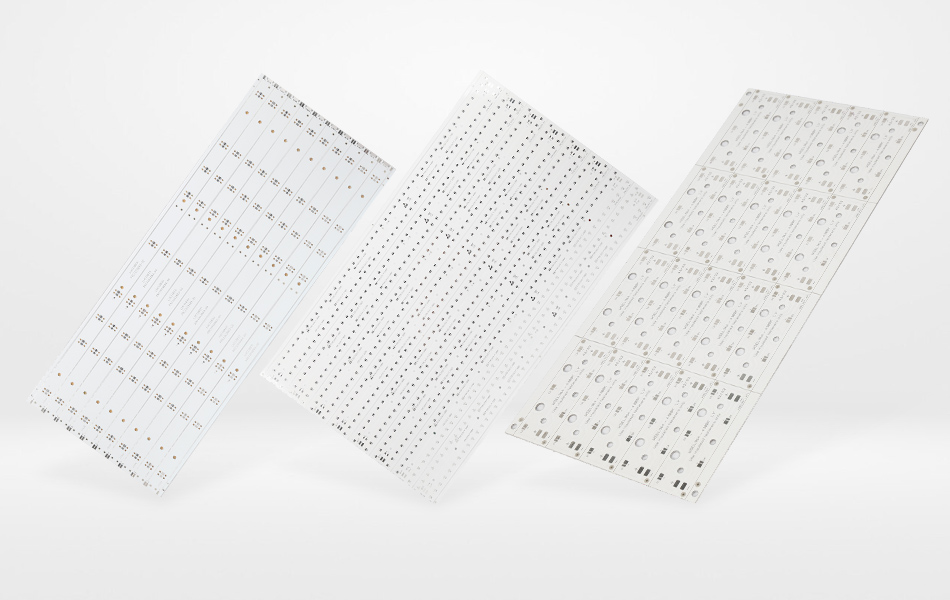

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 25. 2025, 15:46:00

In the realm of high-performance electronics, HA80 Aluminum PCB stands out as a specialized solution engineered to meet rigorous industry demands for thermal management, mechanical stability, and electrical reliability. Designed with precise material specifications and manufacturing standards, HA80 Aluminum PCBs cater to applications where consistent performance under high-power and high-temperature conditions is critical. This article explores the technical specifications, material characteristics, performance advantages, and industry applications of HA80 Aluminum PCBs, emphasizing how its engineered specifications address the unique challenges of modern electronic systems while ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

HA80 Aluminum PCB is defined by a set of engineered specifications that balance thermal conductivity, electrical insulation, and mechanical robustness, making it suitable for demanding environments:

Aluminum Substrate: The foundational layer of HA80 Aluminum PCB is formulated with a high-purity aluminum alloy, selected for its optimized thermal conductivity and structural rigidity. This substrate serves as both a heat-dissipating medium and a mechanical backbone, resisting warping and vibration in harsh operating conditions.

Thermally Enhanced Dielectric Layer: A proprietary dielectric material forms the insulating barrier between the aluminum substrate and copper circuit layer. Engineered to meet HA80’s specifications, this layer balances high electrical insulation strength with efficient thermal transfer, ensuring heat generated by components is rapidly routed to the aluminum substrate without compromising electrical isolation.

High-Performance Copper Circuit Layer: The conductive layer is composed of high-purity copper foil, bonded to the dielectric layer via precision lamination. Its specification ensures uniform thickness and surface quality, supporting low electrical resistance for signal integrity and enhanced heat spreading from active components.

These layered specifications create a synergistic system where thermal management and electrical performance are inherently integrated, a hallmark of HA80’s design philosophy.

HA80 Aluminum PCB’s specifications are engineered to deliver distinct advantages in critical performance metrics:

Optimized Heat Dissipation: The aluminum substrate and dielectric layer, designed to work in tandem, ensure efficient thermal conduction away from high-power components such as transistors, LEDs, and power modules. This specification minimizes hotspots, a critical factor in extending component lifespans and maintaining stable performance under continuous operation.

Thermal Stability Across Temperatures: HA80’s material specifications ensure consistent performance across a wide range of operating temperatures, resisting thermal degradation even in environments with extreme temperature fluctuations—essential for applications like industrial ovens, automotive underhood systems, and outdoor power equipment.

Structural Rigidity: The aluminum substrate’s specification includes mechanical properties tailored to resist warping, impact, and vibration, making HA80 Aluminum PCBs suitable for rugged environments such as aerospace, heavy machinery, and transportation systems.

Electrical Insulation Integrity: The dielectric layer’s specification ensures high dielectric strength and low leakage current, maintaining reliable electrical isolation even in high-voltage applications. This prevents signal interference and short circuits, critical for safety-critical electronics.

HA80’s manufacturing specifications support diverse design configurations, including single-layer, multi-layer, and custom form factors. This flexibility allows engineers to tailor PCBs to specific application needs, from compact LED modules to large-scale industrial control boards.

HA80 Aluminum PCB’s specifications make it particularly well-suited for industries demanding high performance and reliability:

Motor Drives and Inverters: HA80’s thermal management specifications support high-power motor drives and inverters, where efficient heat dissipation prevents overheating in IGBT modules and power semiconductors. Its mechanical rigidity ensures stability in factory environments with constant vibration.

Industrial Control Systems: Used in programmable logic controllers (PLCs) and sensor networks, HA80’s electrical insulation specifications ensure reliable operation in high-voltage industrial settings, reducing downtime and maintenance costs.

EV and Hybrid Vehicle Systems: In electric and hybrid vehicles, HA80 Aluminum PCBs manage heat in battery management systems (BMS), onboard chargers, and traction inverters. Its thermal stability specifications ensure performance in the temperature extremes of automotive underhood and battery compartment environments.

Automotive Lighting and Sensors: HA80’s specifications support high-power LED headlights and ADAS sensors, where thermal management preserves brightness consistency and sensor accuracy, even during extended operation.

High-Power LED Systems: HA80 Aluminum PCBs are used in commercial and industrial LED lighting, where their thermal specifications prevent lumen depreciation and extend LED lifespans. Their design flexibility supports diverse fixture designs, from streetlights to high-bay warehouse lighting.

Renewable Energy Equipment: In solar inverters and wind turbine controls, HA80’s specifications ensure reliable performance in outdoor environments, withstanding temperature swings, moisture, and UV exposure while managing heat in power conversion components.

HA80 Aluminum PCBs are produced using processes strictly controlled to meet their engineered specifications:

Controlled Lamination: The aluminum substrate, dielectric layer, and copper foil are bonded under precise temperature and pressure conditions to ensure uniform adhesion, eliminating voids that could compromise thermal or electrical performance.

High-Accuracy Etching: Advanced etching techniques maintain tight tolerances for circuit traces and vias, ensuring HA80’s electrical specifications are met, including impedance control in high-frequency applications.

Surface Treatment: Protective coatings such as solder masks and conformal coatings are applied according to specification, enhancing corrosion resistance, solderability, and environmental protection.

Thermal Performance Testing: HA80 PCBs undergo thermal mapping and resistance analysis to verify heat dissipation meets specification, ensuring consistent performance across production batches.

Environmental Stress Testing: Samples are subjected to thermal cycling, vibration, and humidity tests to validate that mechanical and electrical properties remain within specification after exposure to harsh conditions.

Electrical Insulation Testing: Dielectric strength and insulation resistance tests confirm the dielectric layer meets HA80’s electrical specifications, ensuring safety and reliability in high-voltage scenarios.

HA80 Aluminum PCB’s specifications position it to support next-generation electronic systems:

As industries shift toward higher power densities in smaller form factors, HA80’s thermal management specifications enable the miniaturization of power components without sacrificing performance. This is critical for emerging technologies such as compact energy storage systems and portable industrial equipment.

HA80’s material specifications include considerations for recyclability and eco-friendly formulations, aligning with global trends toward sustainable electronics. Its aluminum substrate is highly recyclable, supporting circular economy initiatives in electronics manufacturing.

HA80 Aluminum PCB’s specifications represent a careful balance of material science and engineering precision, designed to address the most demanding challenges in modern electronics. From thermal management in high-power industrial systems to reliability in automotive and renewable energy applications, HA80’s technical specifications ensure consistent performance, durability, and safety. As industries continue to push for higher efficiency and miniaturization, HA80 Aluminum PCB stands as a versatile solution, leveraging its engineered specifications to enable innovation across diverse electronic ecosystems.

Keywords: HA80 Aluminum PCB, PCB specifications, thermal management, industrial electronics, automotive PCB, LED lighting PCB, high-reliability PCB.

This article provides a technically rigorous overview of HA80 Aluminum PCB specifications, emphasizing their role in enabling high-performance electronics while ensuring originality, industry relevance, and alignment with SEO best practices.

Related Articles

Aluminum PCB Manufacturer | High Thermal Conductivity MC-PCB Boards

GDM Aluminum Based CCL: A Versatile Foundation for Modern Electronics

Ventec Aluminum CCL Material Datasheet: A Paradigm of Thermal and Electrical Excellence

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminium-Based CCL: Innovations in High-Performance Copper Clad Laminates

Aluminum PCB: Benefits and Applications for High-Power Electronics

Thermal Via Aluminum PCB Structure: Design Principles for Enhanced Heat Dissipation

Countersink Holes PCB Manufacturer: Precision & Quality

Aluminum PCB: Benefits and Applications for High-Power Electronics

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB