In today’s electronics industry, thermal management is a critical factor for ensuring the efficiency and longevity of high-power devices. Traditional PCBs, made of materials like FR-4, often struggle to handle the heat generated by power-sensitive components. This is where aluminum PCBs come in. With their superior thermal conductivity, mechanical strength, and cost-effectiveness, aluminum PCBs have become the go-to choice for a wide range of high-power electronic applications, particularly in LED lighting and power electronics.

What is an Aluminum PCB?

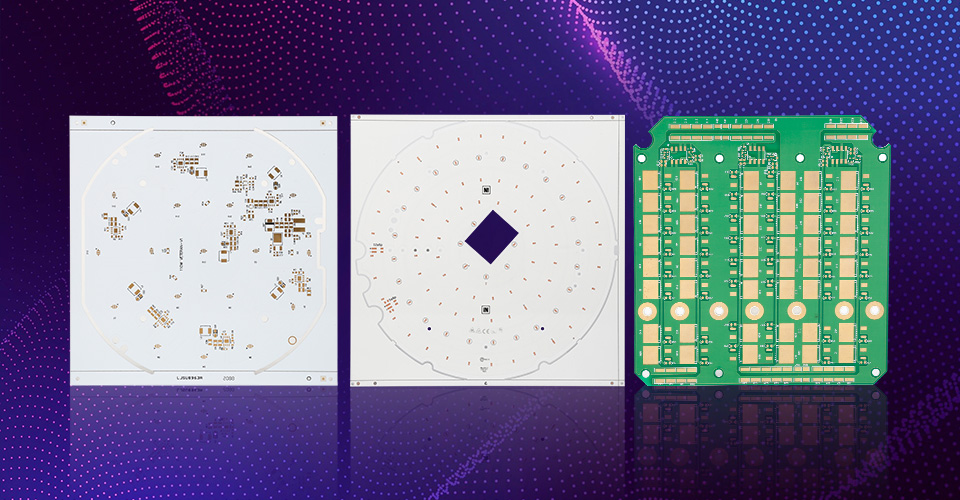

An aluminum PCB is a type of metal-core PCB that uses aluminum as the base material. It consists of three primary layers:

Copper Circuit Layer: The conductive layer where the circuit is etched.

Dielectric Layer: An insulating layer that allows heat to pass through while electrically isolating the copper from the aluminum.

Aluminum Base Layer: The base layer provides superior thermal conductivity and mechanical support, making it ideal for heat dissipation.

The use of aluminum as the base material ensures that aluminum PCBs can effectively dissipate heat, preventing components from overheating and ensuring reliable performance even under heavy loads.

Key Benefits of Aluminum PCB

1. Superior Thermal Conductivity

The main advantage of aluminum PCBs is their exceptional thermal conductivity. The aluminum base layer serves as a highly efficient heat sink, drawing heat away from sensitive components like LEDs and power devices. This makes aluminum PCBs an ideal solution for LED lighting applications, where managing heat is essential for maintaining performance and extending the lifespan of the LEDs.

2. Enhanced Durability and Strength

Aluminum PCBs are known for their mechanical strength. The aluminum base not only helps with heat dissipation but also adds durability, making the board more resilient to physical stress. This is especially important in industries where the PCB is exposed to vibrations or harsh environmental conditions, such as in automotive or industrial applications.

3. Cost-Effectiveness

Compared to copper-based PCBs, aluminum PCBs are more cost-effective while still offering excellent thermal management and mechanical properties. The affordability of aluminum PCBs makes them a popular choice for manufacturers looking to balance performance and cost in high-power electronics.

4. Reliability and Long Lifespan

With better heat dissipation and improved mechanical strength, aluminum PCBs offer higher reliability and a longer operational life. This is particularly important in high-power electronics where component failure due to heat is a significant risk. The longer lifespan of aluminum PCBs helps reduce maintenance costs and improves overall system reliability.

Applications of Aluminum PCB

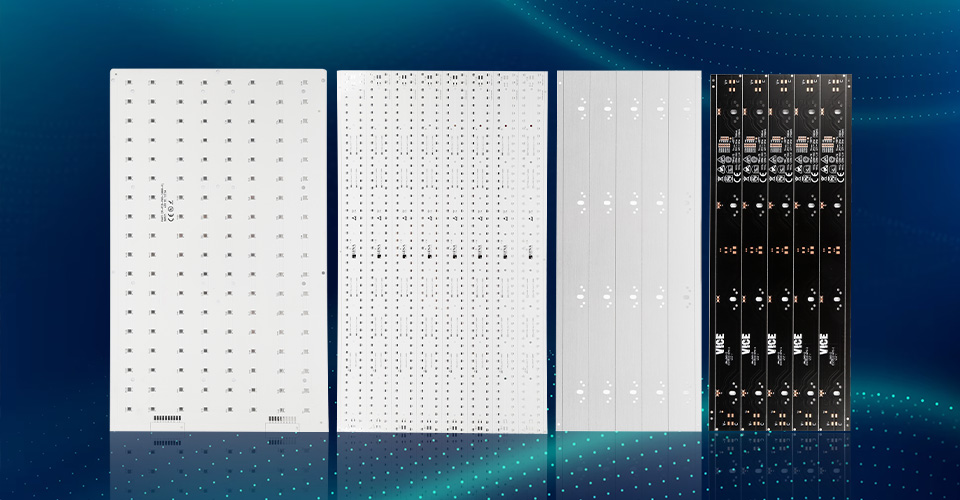

LED Lighting

LED light aluminum PCBs are one of the most common applications of aluminum PCBs. LEDs generate significant heat during operation, and without effective heat dissipation, their performance can degrade, leading to shorter lifespans. Aluminum PCBs for LED lighting help manage this heat by conducting it away from the LED components, ensuring that the LEDs operate at their optimal temperature for extended periods. These PCBs are widely used in LED light aluminum PCB models, from streetlights to automotive headlights and industrial lighting systems.

Automotive Electronics

Aluminum PCBs are also essential in automotive applications. They are used in power control units, sensors, LED lighting, and other electronic systems that require efficient heat dissipation. The aluminum PCB's ability to withstand high temperatures and vibrations makes it a reliable choice for automotive electronics that operate under harsh conditions.

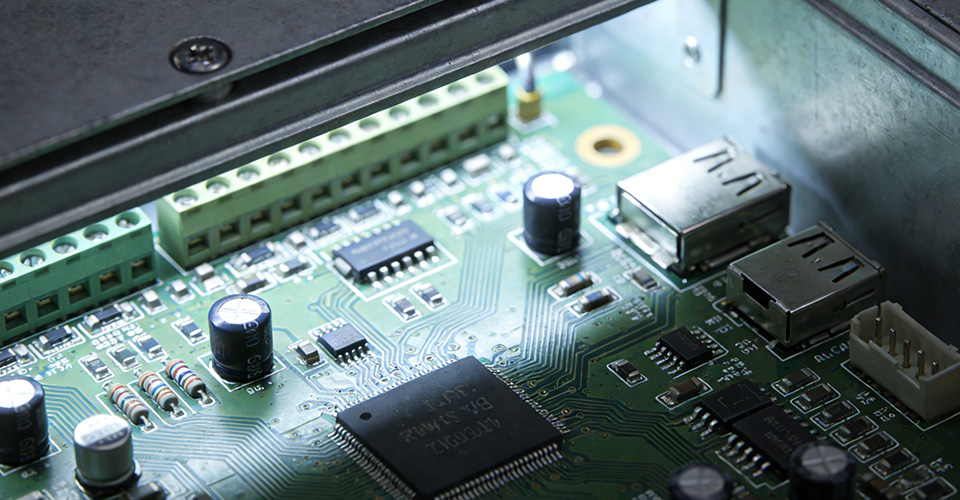

Power Electronics

Power devices such as power supplies, converters, and inverters require robust thermal management to operate efficiently. Aluminum PCBs are used in these power electronics to ensure that excess heat is quickly dissipated, preventing overheating and ensuring stable performance.

Advanced Features in Aluminum PCB Design

Countersink Holes in Aluminum PCB

In some designs, countersink holes in aluminum PCBs are used to allow screws or other fasteners to sit flush with the surface of the PCB. This feature is especially useful in applications where the PCB needs to be securely mounted to another surface or when the assembly process requires precise and compact designs. Countersink holes are typically used in high-density applications, such as LED light aluminum PCB models, where space and mounting are key considerations.

Counterbore Holes in Aluminum PCB

Similar to countersink holes, counterbore holes in aluminum PCBs are used for mounting components and ensuring that fasteners are positioned at the correct depth. Counterbore holes provide additional precision and help secure components more tightly, preventing mechanical stress on the board and improving overall reliability. This is critical for high-performance aluminum PCBs, particularly in LED lighting applications where stability is essential.

LED Light Aluminum PCB

For LED light aluminum PCBs, precise hole and via placement is key to ensuring that the heat from the LEDs is dissipated effectively and that the electrical signals are routed properly. The combination of copper-clad laminate and aluminum-based PCBs allows for both efficient thermal management and reliable electrical performance. These LED light aluminum PCBs are commonly used in energy-efficient lighting systems that require low maintenance and high performance over long periods.

Key Considerations When Choosing Aluminum PCBs

1. Thermal Requirements

Since aluminum PCBs are primarily used for heat-sensitive applications, it’s important to evaluate the thermal conductivity requirements of your application. If your device generates significant heat, choosing an aluminum PCB with higher thermal conductivity ensures that heat is dissipated efficiently.

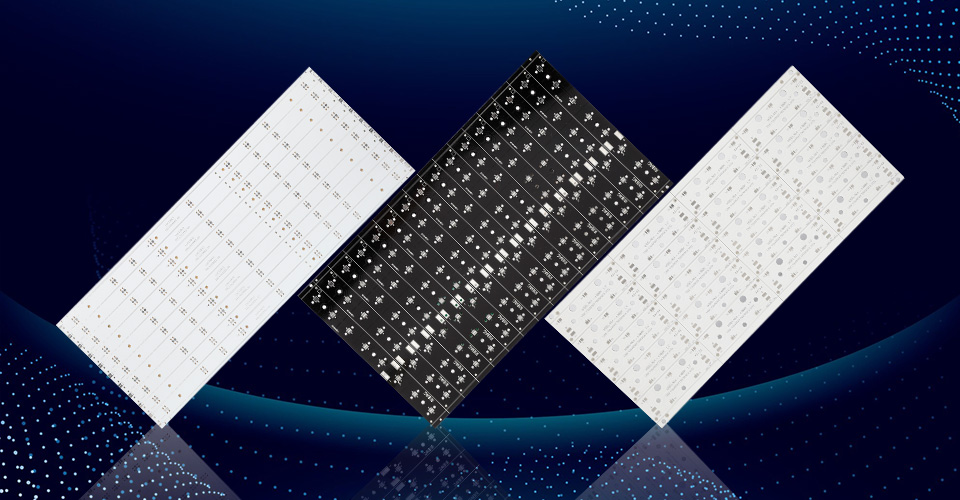

2. Design Complexity

For simple applications, Single Layer aluminum PCBs may be sufficient, but for more complex circuits that require multi-layer routing, a Multi-Layer aluminum PCB is required. The complexity of the circuit should guide your choice between single-layer or multi-layer designs.

3. Mechanical Strength

Consider the mechanical stresses that the PCB will be exposed to. For more robust applications, bendable aluminum PCBs or multi-layer aluminum PCBs offer the flexibility and durability needed for high-performance environments, such as automotive or industrial applications.

4. Cost Considerations

While aluminum PCBs offer significant advantages in thermal conductivity and mechanical strength, it is important to evaluate the cost in relation to your budget. Aluminum PCBs are generally more affordable than copper-based PCBs, but selecting the right material (such as copper-clad laminate) will depend on your specific design needs.

Conclusion

Aluminum PCBs provide outstanding benefits for high-power electronics, from LED lighting systems to automotive electronics and power devices. Their superior thermal conductivity, enhanced durability, and cost-effectiveness make them the ideal solution for applications requiring reliable heat management and mechanical strength. Whether you're designing a Single Layer aluminum PCB for a simple application or a Multi-Layer aluminum PCB for a complex power system, aluminum PCBs offer unmatched performance and reliability.

By understanding the key features, applications, and considerations, you can make an informed decision when selecting aluminum PCBs for your next project, ensuring optimal performance and longevity for your electronic systems.

Frequently Asked Questions

1. What is the advantage of using aluminum PCBs for LED lighting?

Answer:

Aluminum PCBs are ideal for LED lighting because they offer excellent thermal conductivity, helping to dissipate the heat generated by the LEDs. This improves the lifespan and performance of the LEDs, ensuring they operate efficiently over extended periods.

2. How do countersink and counterbore holes benefit aluminum PCBs?

Answer:

Countersink and counterbore holes in aluminum PCBs help secure components more precisely, ensuring the PCB remains stable during operation. They are commonly used in applications like LED light aluminum PCBs, where accurate mounting is crucial for optimal performance.

3. What is the difference between Single Layer and Multi-Layer aluminum PCBs?

Answer:

Single Layer aluminum PCBs are used for simpler circuits and applications requiring minimal routing, while Multi-Layer aluminum PCBs allow for more complex designs with multiple copper layers, ideal for high-density circuits in power electronics and automotive applications.

4. What are bendable aluminum PCBs?

Answer:

Bendable aluminum PCBs are flexible PCBs made from aluminum that can be shaped to fit specific designs or compact spaces. They are especially useful in applications like wearable electronics or automotive systems, where space constraints require flexibility in PCB design.

5. How do LED light aluminum PCBs improve performance in lighting systems?

Answer:

LED light aluminum PCBs enhance lighting performance by efficiently dissipating heat, preventing LEDs from overheating, and maintaining optimal operating conditions. This results in improved efficiency, longer lifespan, and better overall performance in energy-efficient lighting systems.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related News

Aluminum & Flexible PCB Solutions | High-Thermal & Flex Sourcing

Aluminum PCB Manufacturer | High Thermal Conductivity MC-PCB Boards

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

GDM Aluminum Based CCL: A Versatile Foundation for Modern Electronics

Ventec Aluminum CCL Material Datasheet: A Paradigm of Thermal and Electrical Excellence

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminium-Based CCL: Innovations in High-Performance Copper Clad Laminates

Thermal Via Aluminum PCB Structure: Design Principles for Enhanced Heat Dissipation

Countersink Holes PCB Manufacturer: Precision & Quality

Whatsapp 0086 755 29438407

Whatsapp 0086 755 29438407 Mail info@apollopcb.com

Mail info@apollopcb.com  Tel 0086 755 29438407

Tel 0086 755 29438407