-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

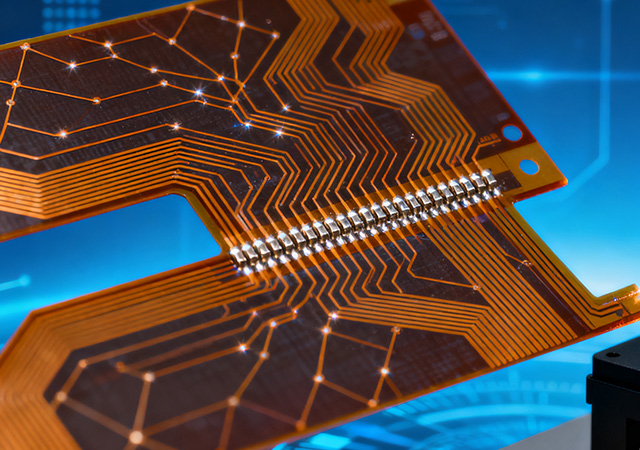

As high-end electronics continue to pursue miniaturization, high integration, and stable performance, the role of a professional HDI FPC Manufacturer has become increasingly vital in the global supply chain. An HDI FPC Manufacturer specializes in the design, development, and mass production of high-density interconnect flexible printed circuits (HDI FPCs), which are essential components for devices requiring compact layouts, high-speed signal transmission, and flexible installation. Unlike general FPC manufacturers, HDI FPC manufacturers possess specialized capabilities in balancing high-density routing with mechanical flexibility, ensuring that their products meet the stringent requirements of industries such as 5G communications, automotive electronics, and precision medical devices. For enterprises aiming to launch innovative electronic products, partnering with a reputable HDI FPC Manufacturer is a critical step to ensure production efficiency, product reliability, and market compe

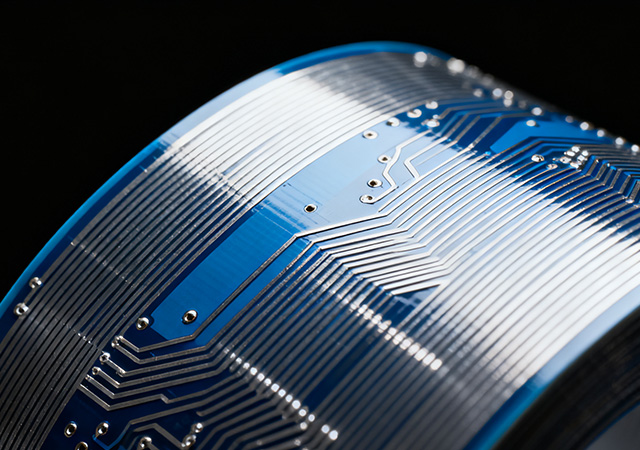

With the rapid evolution of electronic devices toward ultra-compact sizes, high-frequency operation, and multi-functional integration, the demand for high density interconnect (HDI) flexible printed circuits (FPCs) has become increasingly prominent. A professional High Density Interconnect FPC Producer serves as a core innovator in this field, specializing in the R&D and production of HDI FPCs that feature ultra-fine traces, micro vias, and advanced cross-layer interconnect structures. Unlike conventional FPC producers, these specialized providers possess in-depth expertise in resolving signal integrity issues, optimizing interconnect density, and adapting to diverse high-end application requirements. For brands engaged in 5G communications, autonomous driving, and precision medical devices, partnering with a reputable High Density Interconnect FPC Producer is crucial to realizing product innovation and maintaining market competitiveness.

As electronic devices evolve toward ultra-miniaturization, high integration, and high-frequency operation, the demand for flexible printed circuits (FPCs) with superior density and signal performance has surged. A professional 4 Layer HDI FPC Manufacturer emerges as a critical enabler in this landscape, specializing in the production of 4-layer high-density interconnect (HDI) FPCs that combine the flexibility of traditional FPCs with the high-density routing capabilities of HDI technology. Unlike standard FPC manufacturers, these specialized providers possess unique expertise in optimizing 4-layer stackups, fabricating micro blind/buried vias, and ensuring signal integrity—key requirements for powering next-generation electronic products. For brands in high-end consumer electronics, medical devices, and automotive ADAS, partnering with a reputable 4 Layer HDI FPC Manufacturer is essential to translating innovative designs into high-performance, reliable products.

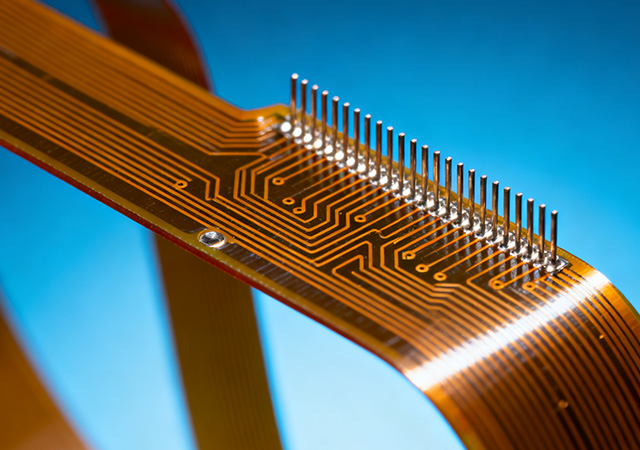

As the global electronics industry marches toward miniaturization, flexibility, and intelligence, the role of a professional FPC manufacturer has evolved from a mere component supplier to a core enabler of the flexible electronics ecosystem. An FPC manufacturer specializes in the research, development, and production of flexible printed circuits (FPCs)—key components that power a vast array of electronic devices by enabling seamless integration of functions in constrained spaces. Unlike generic circuit manufacturers, a dedicated FPC manufacturer possesses unique expertise in material science, precision manufacturing, and industry-specific compliance, ensuring that FPCs meet the rigorous performance and reliability requirements of diverse sectors. For electronics brands, system integrators, and innovators worldwide, partnering with a reputable FPC manufacturer is fundamental to building competitive products and advancing technological breakthroughs.

In the era of highly personalized and application-specific electronics, the role of a customize FPC manufacturer has become increasingly pivotal. Unlike one-size-fits-all FPC suppliers, a professional customize FPC manufacturer specializes in crafting flexible printed circuits (FPCs) that are precisely tailored to the unique design constraints, functional requirements, and operating environments of their clients’ products. From compact wearables to rugged industrial devices, these manufacturers bridge the gap between conceptual circuit design and practical implementation, empowering businesses across sectors to turn innovative ideas into high-performance electronic products. For companies seeking to differentiate their offerings and overcome complex engineering challenges, partnering with a skilled customize FPC manufacturer is a strategic move that enhances product value and accelerates market success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB