-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

In the fast-paced electronics industry, the demand for flexible, high-performance printed circuits (FPCs) that align with unique product designs and production scales is ever-growing. An OEM FPC Customization Services Provider emerges as a vital strategic partner, offering end-to-end tailored solutions that bridge the gap between conceptual circuit design and large-scale, consistent production. Unlike standard FPC suppliers, these providers specialize in understanding OEMs’ specific requirements—from technical specifications to branding integration and supply chain scalability—delivering customized FPCs that power a wide range of electronic devices. For OEMs across consumer electronics, automotive, medical, and industrial sectors, partnering with a reputable OEM FPC Customization Services Provider is key to enhancing product competitiveness, streamlining production, and accelerating time-to-market.

The wearable technology sector is defined by its relentless pursuit of miniaturization, comfort, and uncompromised performance—attributes that place immense demands on the underlying electronic components. A specialized Customized FPC Manufacturer for Wearables emerges as a critical partner in this ecosystem, delivering flexible printed circuits (FPCs) tailored to the unique constraints of wearable devices. Unlike generic FPC suppliers, these manufacturers combine deep expertise in wearable design requirements with agile customization capabilities, creating circuits that conform to ergonomic shapes, withstand repeated bending, and integrate seamlessly with sensors, batteries, and other compact components. For wearable brands and innovators, partnering with a dedicated customized FPC manufacturer is not just a supply chain decision; it’s a strategic enabler of products that resonate with consumers and stand out in a competitive market.

As high-power electronics evolve toward greater miniaturization, higher energy density, and more demanding operating environments, thermal management has become a defining constraint for innovation. Sinkpad PCB emerges as a pivotal solution, redefining how heat is managed in compact, power-dense systems by integrating dedicated thermal sink structures directly into the circuit board architecture. Unlike conventional PCBs that rely on external cooling solutions or passive thermal pads, Sinkpad PCB unifies electrical functionality and thermal dissipation into a single, streamlined design—enabling breakthroughs in industries from renewable energy to industrial automation and beyond. For engineers and manufacturers, this technology is not just a component upgrade; it’s a strategic enabler of next-generation devices that balance performance, size, and reliability.

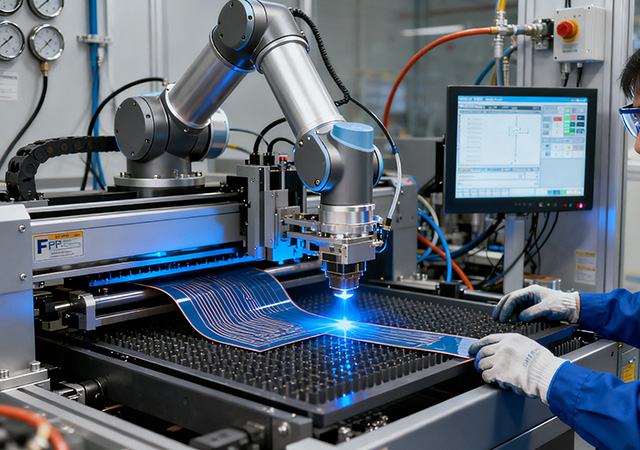

Flexible Printed Circuit (FPC) Fabrication has emerged as a transformative technology in modern electronics, redefining how devices are designed, manufactured, and deployed. Unlike rigid PCBs that limit form factor and placement, FPC fabrication produces lightweight, bendable circuits that adapt to complex shapes, tight spaces, and dynamic environments. This versatility makes FPCs indispensable for a wide range of applications—from wearables that conform to the human body to aerospace components that fit into curved structures. Beyond flexibility, FPC fabrication prioritizes efficiency, reliability, and adaptability, supporting the industry’s shift toward miniaturized, connected, and sustainable electronics. For engineers, manufacturers, and innovators, FPC fabrication is more than a manufacturing process; it’s a catalyst for reimagining what electronic devices can achieve.

In the era of miniaturized, high-performance electronics, the demand for flexible printed circuits (FPCs) with exceptional precision has never been greater. The High Precision FPC Fabrication Process stands as a cornerstone technology, enabling the production of FPCs that meet the strict tolerances, signal integrity, and mechanical reliability required for cutting-edge devices. Unlike standard FPC fabrication, which prioritizes cost or speed, this specialized process focuses on meticulous control over every manufacturing step—from material selection to final assembly—delivering circuits that perform flawlessly in applications where even minor deviations can cause system failure. For industries ranging from aerospace to medical devices and consumer electronics, this process is the backbone of innovation, enabling designs that push the boundaries of what’s possible with flexible electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB