-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Feb 02. 2026, 14:40:04

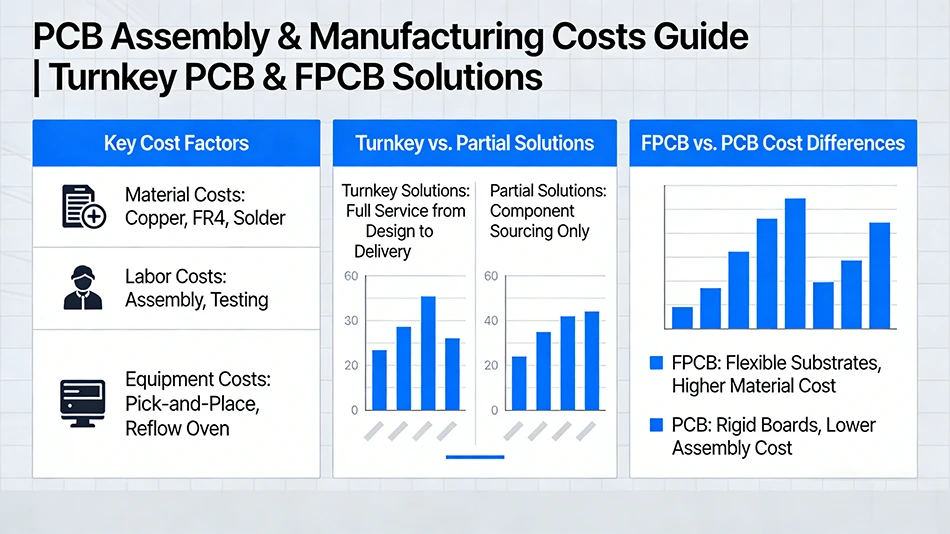

In the modern electronics landscape, the success of a product launch often hinges on one critical metric: the pcb assembly & manufacturing costs. For hardware startups and established industrial factories alike, understanding the price drivers behind pcb printed circuit board manufacturing is not just about saving pennies—it is about strategic resource allocation and ensuring supply chain longevity.

Whether you are scaling up a consumer gadget or developing high-reliability industrial controllers, the synergy between pcb fab and assembly determines your speed-to-market and your bottom line.

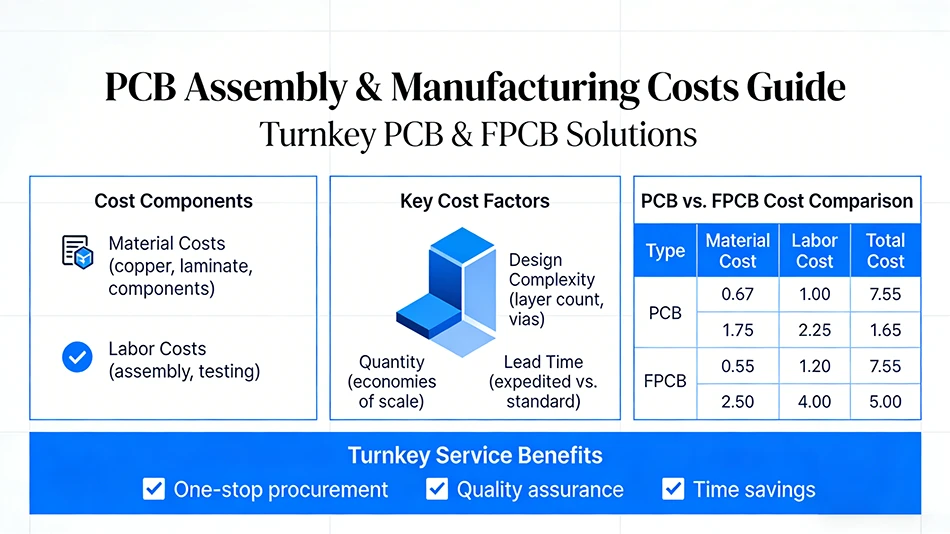

When a pcb assembler provides a quote, it is rarely a single number. It is a composite of several distinct phases. To optimize your pcbassembly and manufacturing budget, you must understand the cost centers.

This is the physical production of the substrate. Factors like layer count, material type (FR4, Aluminum, or Rogers), and surface finish (ENIG vs. OSP) are the primary drivers.

Often the largest part of the pcb board assembly budget. Sourcing genuine components from authorized distributors protects against failure but requires a pcb assembler with strong procurement networks.

This includes SMT (Surface Mount Technology) placement, Thru-Hole soldering, and manual inspection. For pcb manufacturing assembly, setup fees for stencils and pick-and-place programming are usually fixed, making larger runs more cost-effective per unit.

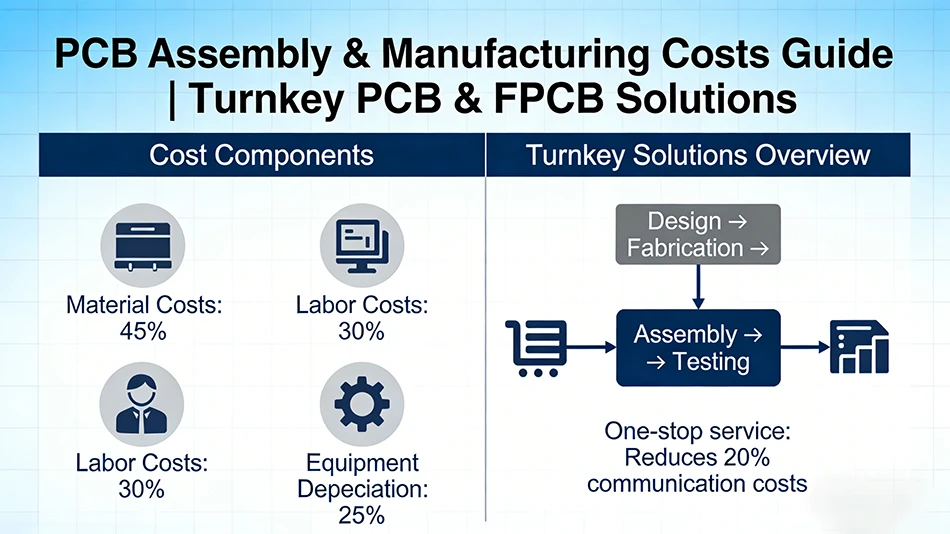

The traditional model of separating pcb printed circuit board manufacturing from the assembly house is dying. Modern factories prefer a "Turnkey" partner.

Choosing a unified partner for pcb manufacturing assembly reduces:

Shipping Costs: No need to ship bare boards across the country.

Lead Times: Seamless transition from the etching line to the SMT line.

Liability Gaps: If a board fails, a turnkey pcb assembler like ApolloPCB takes full responsibility, rather than the fabricator blaming the assembler and vice-versa.

As devices become smaller, thinner, and more ergonomic, flexible printed circuits (FPC) have moved from a niche technology to a mainstream requirement. However, these specialized boards come with a different cost structure.

A flexible printed circuit board fpcb definition refers to a patterned arrangement of printed circuitry and components that utilizes a flexible base material (usually Polyimide) with or without a flexible coverlay. Unlike rigid boards, FPCBs can bend, fold, and twist.

Why is flexible pcb cost generally higher than rigid boards?

Material Cost: Polyimide (PI) is significantly more expensive than standard FR4 epoxy glass.

Manufacturing Complexity: Flexible printed circuit manufacturers must use specialized handling equipment to prevent stretching or wrinkling during the pcb board manufacturing process.

Assembly Challenges: FPCBs require rigid "carriers" or stiffeners during SMT placement, which increases labor time.

Not all pcb manufacturing manufacturers can handle the delicacy of flex circuits. When evaluating flexible printed circuit manufacturers, look for:

Dimensional Stability: The ability to maintain trace alignment across thousands of units.

Stiffener Integration: Capability to add FR4 or Stainless Steel stiffeners for component support.

Customization: Experience in multi-layer flex and rigid-flex hybrids.

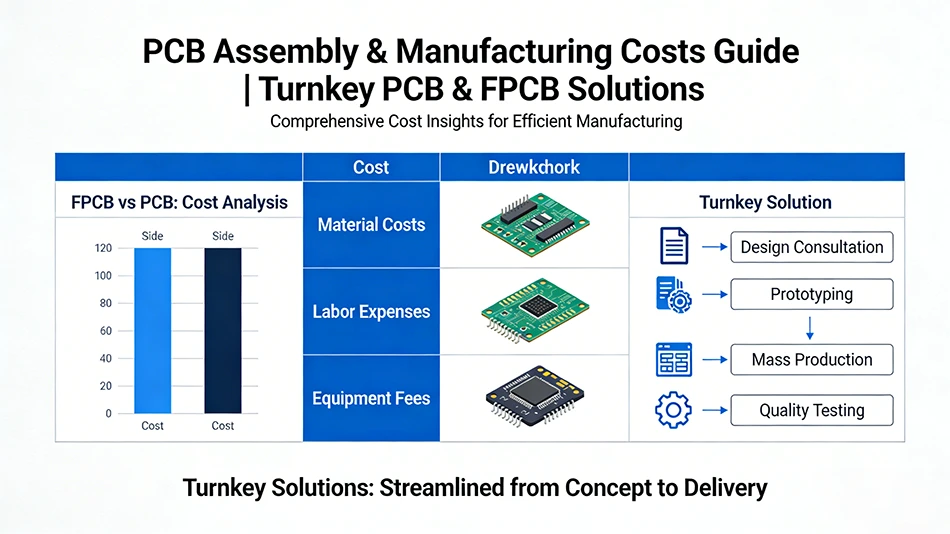

To better control pcb manufacturing assembly expenses, it is vital to understand the pcb manufacturing steps. Any deviation or "extra" step adds to the pcb board manufacturing process time.

DFM Check: Engineers review files to prevent errors.

Imaging & Etching: The circuit pattern is transferred to the copper.

Lamination: For multilayer boards, bonding layers under heat.

Drilling: Creating vias for interlayer connectivity.

Plating: Coating hole walls with copper.

Solder Mask & Silk Screen: Protecting traces and adding labels.

Final E-Test: Ensuring 100% electrical continuity.

Each of these pcb manufacturing steps is a point of optimization. For instance, reducing the number of different hole sizes can lower your drilling costs.

As a factory-scale buyer, you have several levers to pull to reduce your flexible pcb price and overall pcb fab and assembly spend.

Panelization: Maximize the number of boards per production sheet to reduce waste.

Component Standardization: Using common package sizes (e.g., 0603 instead of 0201) can reduce pcb board assembly complexity.

Order Volume: Moving from prototype pcb manufacturing to small-batch production (100+ units) significantly dilutes setup costs.

Lead Time Flexibility: Choosing a standard 10-day lead time instead of 24-hour "Quick-Turn" can save up to 50% on labor premiums.

At ApolloPCB, we have spent two decades refining our pcb board manufacturing process to offer the most competitive pcb assembly & manufacturing costs in the industry. We serve global industrial factories by combining the speed of a top Chinese pcb manufacturer with the precision required for medical and automotive grade electronics.

A pcb assembler is a specialized facility that takes bare printed circuit boards and populates them with electronic components (resistors, ICs, connectors) using SMT or Through-Hole technology. ApolloPCB acts as both the fabricator and the pcb assembler to provide a seamless turnkey solution.

At ApolloPCB, we handle the entire pcb assembly and manufacturing lifecycle. We utilize high-speed Siemens SMT lines, 3D AOI (Automated Optical Inspection), and X-Ray inspection for BGA components. Our experience spans from simple 2-layer boards to complex 32-layer industrial systems and high-precision flexible printed circuits.

While many "low cost" houses sacrifice quality, ApolloPCB maintains a low cost pcb assembly profile through automation and local component sourcing in the China ecosystem. This allows us to offer factory-direct pricing without the middleman markup found in Western brokers.

While assembly in the USA is convenient for local R&D, the flexible pcb price and labor costs are often 3x to 5x higher than sourcing from a top Chinese pcb manufacturer. Many US-based clients use ApolloPCB for their prototype pcb manufacturing to ensure that the transition to mass production is technically identical and cost-optimized from day one.

By optimizing your pcb assembly & manufacturing costs early in the design phase (using DFM), you can ensure high margins. Partnering with a manufacturer like ApolloPCB, who offers free design reviews, helps prevent the "hidden costs" of redesigns and field failures.

Managing pcb assembly & manufacturing costs is a science. From defining your flexible printed circuit board fpcb definition to selecting the right pcb assembler, every choice impacts your product's viability.

[Contact ApolloPCB Today for a Complete Cost Analysis and Turnkey Quote]

Related News

PCB Assembly & Manufacturing Costs Guide | Turnkey PCB & FPCB Solutions

Countersink Holes in Metal - Core PCBs: A Deep - Dive into Design, Manufacturing, and Applications

Counterbore Holes in Sinkpad PCB: Key Considerations for Thermal-Mechanical Performance

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB