-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Feb 07. 2026, 17:33:06

The quality of an electronic product is only as good as the machinery that builds it. For industrial factories and hardware engineers, understanding the synergy between pcb assembly & manufacturing equipment is the key to ensuring high yield, reliability, and cost-efficiency. In an era where circuits are becoming smaller and more complex, the reliance on high-precision pcb assemblies has never been greater.

At ApolloPCB, we believe that transparency in the pcb assembly process helps our partners make better design decisions. This guide explores the sophisticated world of the pcb board manufacturing machine, the nuances of pcb smt assembly, and how specialized materials like aluminum nitride pcb are processed using state-of-the-art technology.

The journey from a digital Gerber file to a physical board involves a series of high-tech stages. Each pcb board manufacturing machine in a modern facility serves a specific, critical purpose.

The first step in manufacturing pcb assembly starts with creating the circuit pattern. Traditional film masking is being replaced by LDI machines, which use laser beams to "draw" the circuit directly onto the photoresist-coated laminate. This ensures the ultra-fine trace widths required for high-density designs.

Whether you are working with standard FR4 or a rogers fr4 pcb, mechanical precision is paramount. Automated drilling machines create vias and mounting holes with micron-level accuracy. For industrial clients requiring Countersink or Counterbore holes, these CNC machines are programmed to create recessed profiles for flush screw mounting.

Before a board ever reaches the assembly line, it must pass through an AOI pcb manufacturing machine. By comparing the physical board against the digital design, these machines detect "shorts," "opens," and "width violations" that the human eye would miss.

Once the bare board is fabricated, it moves to the assembly phase. PCB SMT assembly (Surface Mount Technology) is the standard for modern high-performance electronics.

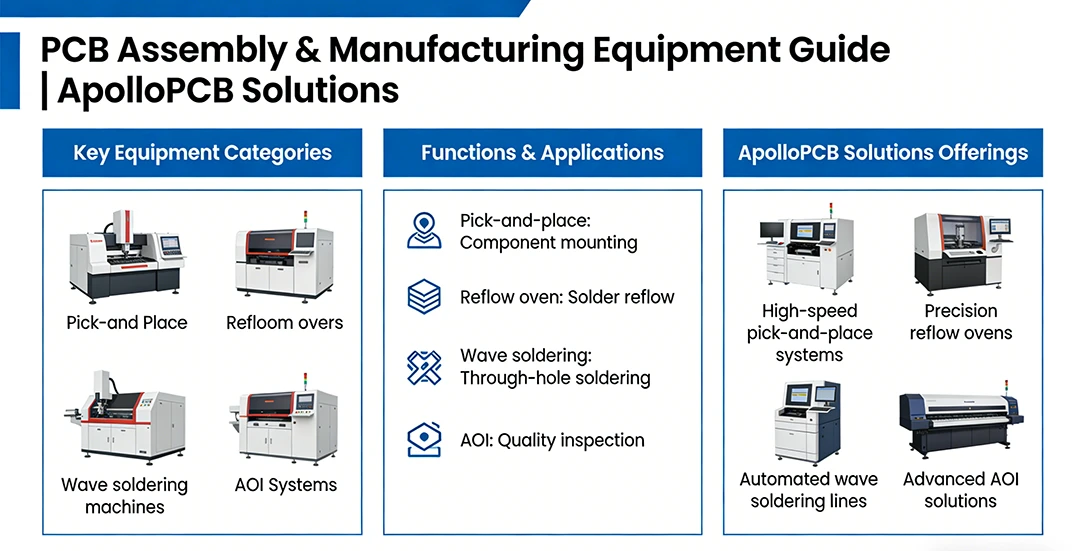

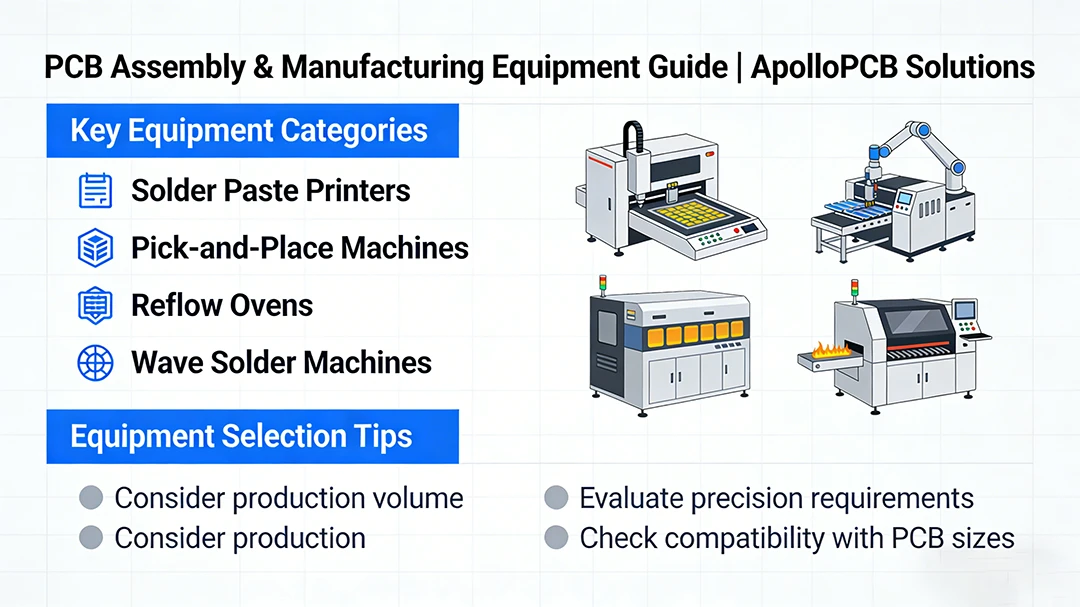

A world-class pcb smt assembly line consists of several integrated machines:

Solder Paste Printer: Uses a high-precision stencil to apply solder paste onto the SMD pads.

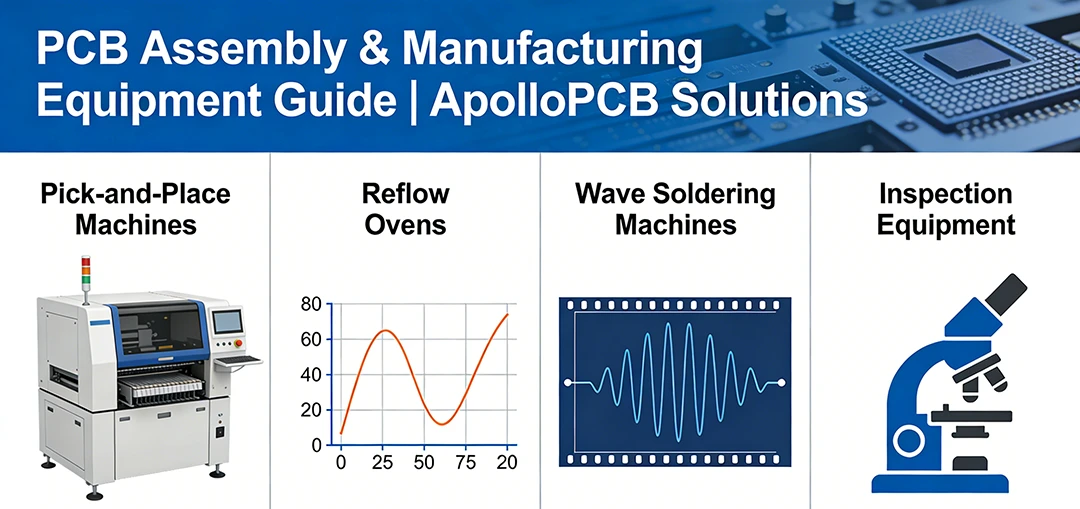

Pick-and-Place Machine: The heart of surface mount pcb assembly. These robotic arms can place thousands of components per hour with staggering speed and precision.

Reflow Oven: Where the board is heated to melt the solder and create permanent electrical bonds.

For complex pcb assemblies, such as those containing BGAs (Ball Grid Arrays), standard AOI is not enough. Leading manufacturers utilize 3D X-Ray Inspection to look through the components and verify the integrity of hidden solder joints.

Industrial and aerospace applications often demand materials that go beyond standard FR4. The pcb assembly & manufacturing equipment must be calibrated differently to handle these substrates.

For extreme thermal management, the aluminum nitride pcb is the gold standard. Unlike aluminum-core boards, aluminum nitride ceramic pcb offers high thermal conductivity (170-230 W/mK) while remaining an electrical insulator.

Processing: AlN is brittle and requires specialized laser cutting and diamond-bit drilling tools to prevent cracking.

Applications: High-power LEDs, RF wireless systems, and power electronics.

Rogers fr4 pcb designs (often called Hybrid Stackups) combine Rogers' high-frequency materials with standard FR4. This allows engineers to place high-speed RF signals on the Rogers layers while keeping the cost down by using FR4 for the remaining layers. Processing these requires precise control during the lamination phase to manage the different Coefficients of Thermal Expansion (CTE).

A common hurdle for procurement managers is understanding the pcb manufacturing machine price and how it correlates to the per-unit cost.

The investment in a single high-end SMT line can exceed $1 million. When you request a quote, the pcb fabrication cost includes:

Machine Depreciation: The high cost of the pcb board manufacturing machine is spread across millions of units.

Setup and Tooling: The labor involved in programming the pick-and-place machine and creating solder stencils.

Maintenance and Calibration: Ensuring the reflow oven maintains an exact thermal profile.

By partnering with an established leader like ApolloPCB, factories benefit from our massive economies of scale, allowing us to offer "Tier 1" equipment precision at a competitive mid-market price point.

To ensure the reliability of your pcb assemblies, ApolloPCB follows a rigorous 8-step pcb assembly process:

DFM Review: Engineering check of the design files.

Solder Paste Printing: Using high-tension stencils.

Component Placement: High-speed pcb smt assembly.

Reflow Soldering: Utilizing multi-zone nitrogen reflow ovens.

AOI & X-Ray: Verification of all solder joints.

Through-Hole Soldering: Selective or wave soldering for heavy components.

Functional Testing (FCT): Verifying the board performs its intended task.

Final Quality Audit: A visual and mechanical final check before shipping.

PCB assembly (PCBA) is the process of soldering electronic components onto a fabricated printed circuit board. This transforms a non-functional board into a complete electronic device.

Look for a partner that owns their own pcb board manufacturing machine fleet. Brokers often outsource, which leads to quality gaps. Check for ISO 9001 and UL certifications, and ensure they have experience with your specific material (e.g., aluminum nitride ceramic pcb).

The cost is calculated based on the board size, layer count, material type (Standard vs. Rogers), and the complexity of the pcb assembly process (number of SMD pads).

For small prototypes, costs can range from $50–$500. For mass production at ApolloPCB, the per-unit cost drops significantly, often to just a few dollars, depending on the BOM (Bill of Materials) complexity.

High-end reflow ovens with more heating zones (e.g., 10-zone ovens) and nitrogen-inerting capabilities cost significantly more but provide superior soldering quality for complex pcb assemblies, reducing the risk of cold solder joints or oxidation.

The world of pcb assembly & manufacturing equipment is one of constant evolution. At ApolloPCB, we continuously invest in the latest pcb manufacturing machines to ensure that our clients receive the most reliable pcb assemblies on the market. Whether you are innovating with aluminum nitride pcb or scaling a rogers fr4 pcb project, our facility is equipped to bring your vision to life.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related News

Counterbore Holes in PCB Assembly: Essential Guide

Efficient PCB Assembly: Mastering Countersink Holes

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

Blind and Buried Vias in Aluminum PCBs: Elevating High-Frequency Circuit Design

Counterbore Holes in Sinkpad PCB: Key Considerations for Thermal-Mechanical Performance

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB