-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 27. 2026, 19:27:47

In the competitive landscape of electronics manufacturing, balancing high performance with cost-efficiency is a constant challenge. While FR4 has long been the industry standard, the CEM3 PCB (Composite Epoxy Material-3) has emerged as a powerhouse alternative, particularly for high-volume industrial applications.

For factory-scale buyers, the shift towards CEM3 pcb material is driven by its unique ability to offer FR4-like properties at a significantly lower price point. Whether you are developing consumer electronics, lighting solutions, or specialized computer peripherals, understanding the technical depth of CEM-3 is essential for optimizing your supply chain.

The most frequent question our engineering team at ApolloPCB receives is regarding cem3 vs fr4. While they may appear identical to the naked eye, their internal compositions are the key to their performance.

FR4: Composed of multiple layers of continuous woven glass cloth impregnated with epoxy resin.

CEM-3: Features a "sandwich" structure. It uses woven glass fabric for the surface layers but utilizes a non-woven "matte" glass fiber core impregnated with epoxy resin.

| Feature | FR4 PCB | CEM3 PCB |

| Mechanical Strength | High | Moderate-High |

| Machinability | Standard | Superior (Easier on Drills) |

| Thermal Conductivity | 0.25 - 0.30 W/mK | 0.20 - 0.28 W/mK |

| Cost | Baseline | 10% - 15% Lower |

| Application | Multilayer/Complex | Double-Sided/High Volume |

Choosing cem3 pcb material isn't just about saving money; it’s about choosing the right tool for the job. CEM-3 boards offer several technical advantages that often go overlooked by generalist manufacturers.

For power electronics and automotive parts, the Comparative Tracking Index (CTI) is vital. High CTI value cem3 (often reaching 600V) provides excellent resistance to electrical breakdown, making it safer for high-voltage applications compared to standard low-grade laminates.

Thermal expansion can ruin a precision device. Low CTE cem3 ensures that the board remains dimensionally stable during the soldering process and throughout its operational life, preventing cracks in solder joints or delamination.

Where exactly are CEM3 PCBs used? Their versatility makes them a staple in several high-growth industries.

The lighting industry is perhaps the largest consumer of CEM-3. Because LED light CEM3 substrates offer sufficient thermal dissipation and excellent reflectivity (when used with white solder masks), they are the preferred choice for LED Backlight CEM3 panels in televisions and monitors.

In the world of computer peripherals, the cem3 pcb keyboard is a gold standard for durability and cost. The material provides the necessary rigidity for tactile feedback while keeping the Bill of Materials (BOM) low for mass-market mechanical and membrane keyboards.

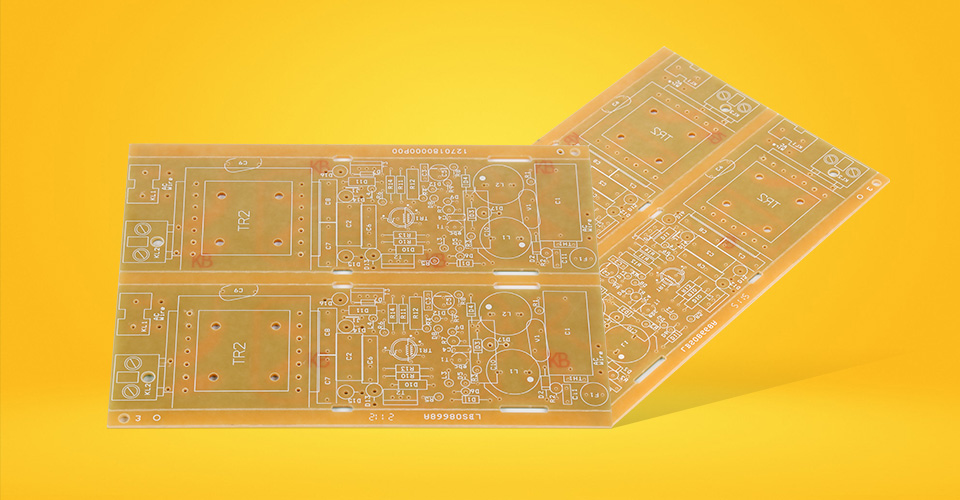

Understanding how to make pcb circuit board units using CEM-3 requires specialized equipment. Unlike FR4, the glass matte core in CEM-3 is much softer, which changes the fabrication dynamics.

Drilling: Because CEM-3 is less abrasive than FR4, drill bits last longer. However, precision is required to prevent "burring" on the matte core.

Punching: For very high volumes, CEM-3 can be punched rather than routed, which drastically reduces the unit cost for large-scale factory orders.

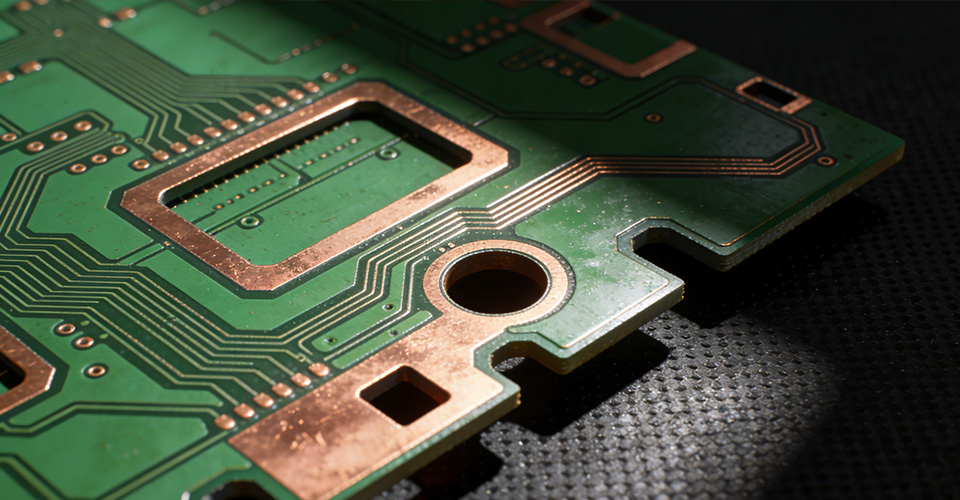

Hole Precision: At ApolloPCB, we can implement Counterbore holes in CEM3 PCB. This is critical for industrial interfaces where bolt heads must sit recessed within the board for a flush mechanical fit.

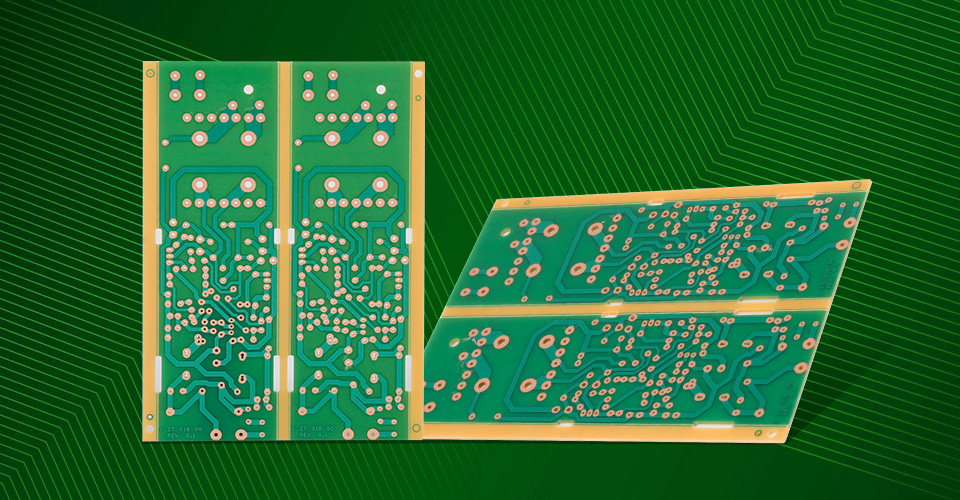

A successful product starts with a robust pcb design process. When designing for CEM-3, engineers must account for the material's slightly lower flexural strength compared to FR4.

Schematic Capture: Define your netlists and electrical constraints.

Stackup Definition: Select the appropriate thickness (standard 1.6mm is most common for CEM-3).

Component Placement: Ensure high-heat components are distributed to leverage the board's thermal properties.

Routing: Maintain trace widths that align with the slightly different dielectric constant of CEM-3.

In complex industrial assemblies, a single board is rarely enough. Understanding pcb to pcb connector types is essential for modular designs:

Board-to-Board Headers: Standard pin headers for vertical stacking.

Mezzanine Connectors: High-speed, low-profile connections.

Edge Connectors: Often used in cem3 pcb keyboard designs for ribbon cable interfaces.

Flex-to-Rigid: Connecting a CEM-3 motherboard to a flexible control panel.

As a premier CEM-3 PCB Manufacturer, ApolloPCB provides the bridge between high-end engineering and economical production. We specialize in:

Mass Customization: Delivering thousands of boards weekly with zero-defect quality control.

Advanced Machining: Specialized CNC capability for Counterbore holes and complex outlines.

Rapid Prototyping: While we handle factory-scale orders, we can also provide CEM-3 prototypes in as little as 3 days.

CEM3 is a composite material consisting of woven glass fabric surface layers and a non-woven glass core combined with epoxy resin. It is the most common cost-effective alternative to FR4.

CEM PCB stands for Composite Epoxy Material PCB. It refers to a family of substrates (CEM-1, CEM-2, CEM-3) that use different combinations of paper, woven glass, and epoxy to achieve specific mechanical and electrical properties.

Technically, all modern PCBs are referred to by their copper layers. A "3 layer" board is uncommon; usually, boards are even-numbered (2, 4, 6). However, in a material context, CEM-3 is often called a "3-ply" or "3-layered composite" because of its glass-matte-glass sandwich structure.

CEM-1 is a lower-grade composite than CEM-3. It uses a paper core instead of a glass matte core. While cheaper, it is only suitable for single-sided boards and cannot support plated-through holes (PTH) reliably, whereas ApolloPCB’s CEM-3 is perfect for double-sided PTH designs.

Absolutely. Our engineers provide a full DFM (Design for Manufacturability) review to help you transition from FR4 to CEM-3, ensuring you save on costs without sacrificing reliability.

Are you ready to switch to a more cost-effective substrate for your next industrial project? Partner with a factory that understands the technical nuances of CEM-3.

[Contact ApolloPCB for a Custom CEM3 PCB Quote and Technical Consultation]

Related Articles

CEM3-09HT Thermal Conductive PCB: Dual Advantages of High-Temp Resilience and Heat Dissipation

Countersink Holes in CEM3 PCB: Ensuring Structural Integrity and Assembly Precision

HA30 CEM3 Thermal Conductivity Specs: Guiding Heat Management in Mid-Tier Electronics

KB7150T High TG CEM3 Circuit Board: Reliable Performance for High-Temperature Electronics

LED Light CEM3 Circuit Board: Key Attributes and Applications in Modern Lighting Systems

Low CTE CEM3 Material for High Stability: Ensuring Precision in Dynamic Operational Environments

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB