-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Leading pcb assembly manufacturer specializing in turnkey pcb assembly, custom FR4 pcb thickness, and flexible aluminum pcb for industrial factories

Looking for a reliable PCB manufacturer in China? ApolloPCB provides high-quality, ISO & UL certified PCB fabrication and assembly. 20+ years of expertise in industrial & medical electronics.

In the global electronics industry, selecting a reliable pcb manufacturer is a critical factor that directly impacts product quality, delivery timelines, and overall cost efficiency. From industrial automation and consumer electronics to automotive and communication systems, printed circuit boards form the backbone of modern electronic devices. As demand grows for higher performance and faster time-to-market, manufacturers worldwide increasingly rely on professional PCB partners with global production capabilities.

Comprehensive guide to CEM3 PCB for industrial apps. Learn about ST210G thermal conductivity, LED backlight CEM3, and High CTI value substrates from ApolloPCB.

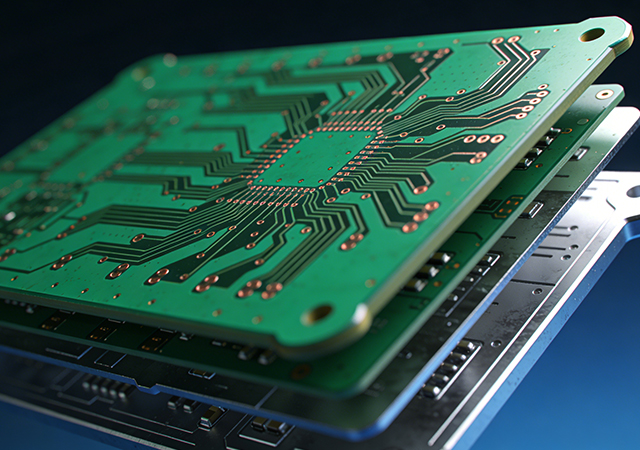

Selecting the right PCB material is a critical step in industrial electronics design. The substrate not only affects electrical performance but also determines mechanical stability, thermal behavior, manufacturability, and long-term reliability. Among commonly used rigid PCB materials, CEM3 PCB has gained widespread adoption in industrial electronics due to its balanced performance and cost-effectiveness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB