-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 27. 2026, 19:18:31

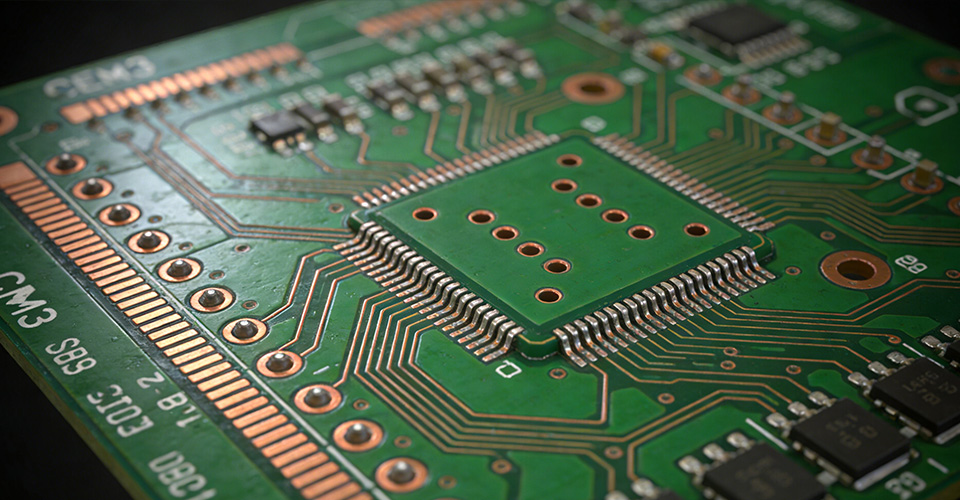

Choosing the right PCB substrate is a fundamental decision in industrial electronics design. The material directly affects electrical performance, mechanical reliability, thermal behavior, and overall production cost. Among various rigid PCB materials, CEM3 PCB is widely recognized as a cost-effective and reliable solution for industrial electronics applications where balanced performance and manufacturability are required.

This guide explores the structure, properties, thermal performance, and common material grades of CEM3 PCB, helping industrial manufacturers select the most suitable laminate for their projects.

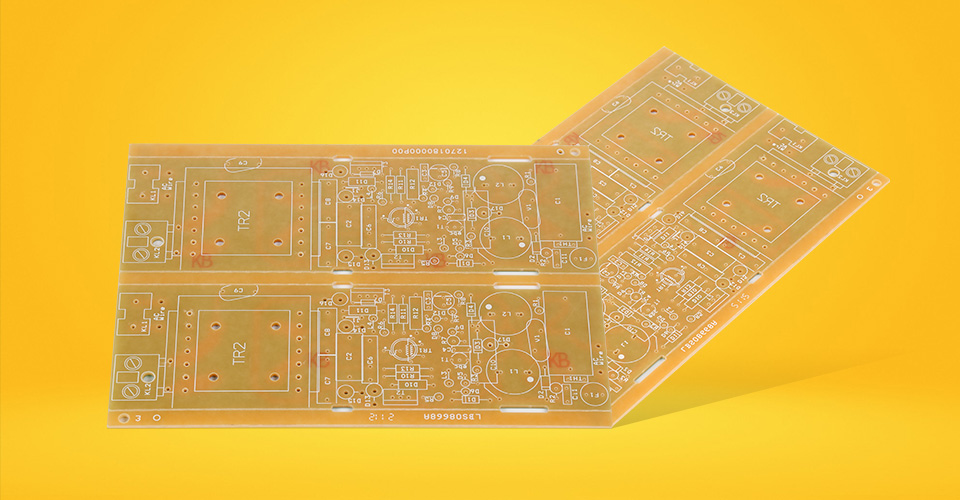

CEM3 PCB is a composite epoxy laminate made from a non-woven glass fiber core combined with woven glass fabric surfaces. Compared with traditional paper-based laminates, CEM3 provides improved mechanical strength and electrical insulation. Compared with FR-4, it offers a more economical alternative for medium-performance applications.

CEM3 PCB is commonly used for:

Double-sided rigid PCBs

Medium-density industrial electronics

Cost-sensitive mass production projects

Thanks to its smooth surface and stable structure, CEM3 PCB is compatible with through-hole assembly and SMT processes, making it suitable for a wide range of industrial electronics.

From a manufacturing and application perspective, CEM3 PCB offers several important advantages:

CEM3 PCB typically has lower material and processing costs compared with FR-4, helping manufacturers control BOM and production expenses.

The glass fiber composite structure provides sufficient rigidity and strength for industrial assemblies and mechanical fastening.

CEM3 PCB delivers consistent dielectric performance suitable for low- to medium-frequency industrial electronics.

CEM3 laminates are easy to drill, route, and plate, supporting stable yields in volume production.

Thermal management is increasingly important in industrial electronics, especially in power control and lighting applications. While standard CEM3 PCB provides moderate thermal performance, enhanced options are available.

HA30 THERMAL CONDUCTIVITY CEM3 is designed with thermally conductive fillers to improve heat dissipation. This material is commonly used in:

LED driver boards

Power supply and power conversion circuits

Industrial control systems with elevated heat density

HA30 THERMAL CONDUCTIVITY CEM3 allows manufacturers to improve thermal performance while maintaining the cost advantages of CEM3 PCB.

Different industrial applications demand different performance levels. Several specialized CEM3 PCB grades are widely used in the market.

CEM-3-09HT CEM3 PCB is formulated for improved heat resistance and stability at higher operating temperatures. It is well suited for:

Industrial control electronics

Power management systems

Applications with frequent thermal cycling

This grade balances cost, thermal reliability, and manufacturability.

KB7150T CEM3 PCB is known for its stable quality and consistent electrical properties. It is commonly applied in:

Industrial interface boards

Control panels

Consumer-grade industrial electronics

KB7150T CEM3 PCB offers reliable performance for medium-volume production and standard industrial requirements.

Panasonic R-1787 CEM3 is a premium CEM3 laminate recognized for excellent material consistency and strict quality control. It is often selected for:

High-reliability industrial electronics

Applications requiring stable long-term performance

Projects with strict material brand specifications

Panasonic R-1787 CEM3 is ideal for customers who prioritize material traceability and consistent manufacturing quality.

When compared with other rigid PCB substrates, CEM3 PCB occupies a practical middle ground:

Lower cost than FR-4 and metal core PCBs

Better mechanical and electrical performance than paper-based laminates

Suitable for many industrial applications that do not require extreme thermal or high-frequency performance

This makes CEM3 PCB a preferred option for industrial manufacturers seeking a balance between performance and cost.

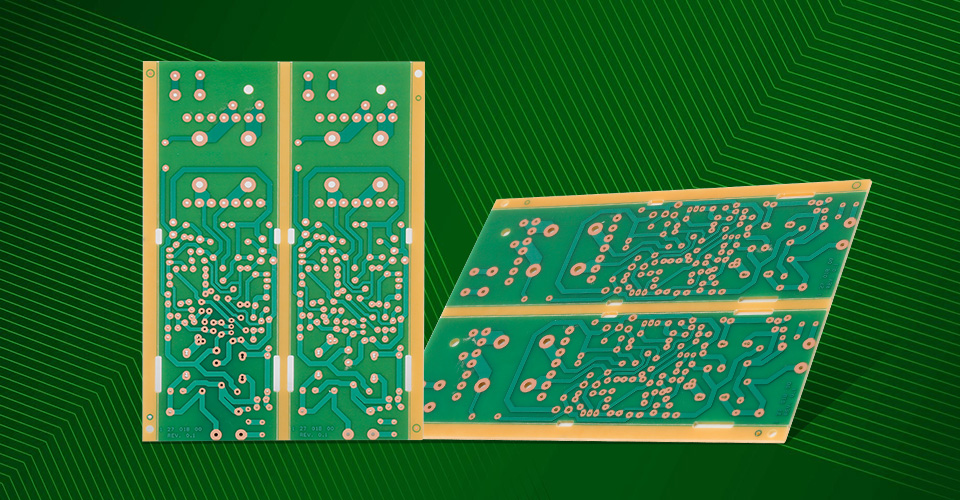

Thanks to its balanced characteristics, CEM3 PCB is widely used in:

Industrial automation and control systems

Power distribution and relay boards

LED lighting control electronics

Embedded industrial devices

Consumer industrial equipment

Enhanced grades such as HA30 THERMAL CONDUCTIVITY CEM3 or CEM-3-09HT CEM3 PCB extend CEM3’s usability into more demanding thermal environments.

A qualified CEM3 PCB manufacturer can provide:

Multiple CEM3 material options, including branded laminates

Engineering support for material selection

Strict quality inspection and process control

Stable production from prototype to mass manufacturing

This ensures consistent product quality and reduces long-term manufacturing risk.

CEM3 PCB offers a strong balance of cost efficiency, mechanical stability, and electrical insulation. It is ideal for industrial electronics that require reliable performance without the higher cost of premium laminates.

CEM-3-09HT CEM3 PCB is recommended for applications operating at higher temperatures or experiencing frequent thermal cycling. It provides improved heat resistance compared with standard CEM3 PCB.

KB7150T CEM3 PCB is valued for its consistent quality, stable electrical properties, and reliable manufacturability. It is commonly used in industrial control boards and interface electronics.

HA30 THERMAL CONDUCTIVITY CEM3 improves heat dissipation by enhancing the thermal conductivity of the laminate. This makes it suitable for LED drivers, power supplies, and industrial electronics with higher heat density.

Yes. Panasonic R-1787 CEM3 offers excellent material consistency, traceability, and long-term stability. It is often chosen for high-reliability industrial electronics where quality assurance is critical.

Related Articles

CEM3 PCB Manufacturer | The Best Cost-Effective Alternative to FR4

CEM3-09HT Thermal Conductive PCB: Dual Advantages of High-Temp Resilience and Heat Dissipation

Countersink Holes in CEM3 PCB: Ensuring Structural Integrity and Assembly Precision

HA30 CEM3 Thermal Conductivity Specs: Guiding Heat Management in Mid-Tier Electronics

KB7150T High TG CEM3 Circuit Board: Reliable Performance for High-Temperature Electronics

LED Light CEM3 Circuit Board: Key Attributes and Applications in Modern Lighting Systems

Low CTE CEM3 Material for High Stability: Ensuring Precision in Dynamic Operational Environments

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB