-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 28. 2026, 20:50:23

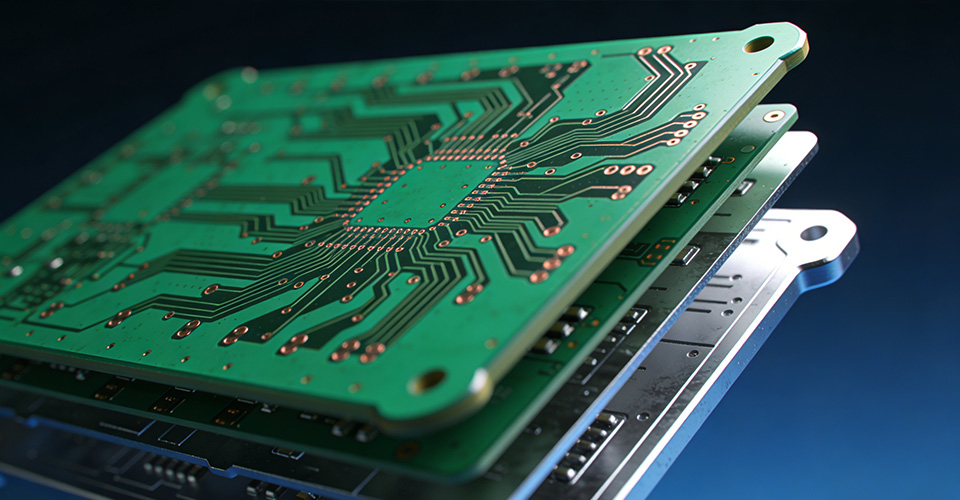

In the competitive landscape of industrial electronics, selecting the right substrate is a strategic decision that impacts both product reliability and the bottom line. While FR4 has long been the default choice, the CEM3 PCB (Composite Epoxy Material-3) has carved out a significant niche as a high-performance, cost-effective alternative.

For factory-scale buyers and engineers, the transition to CEM3 PCB is often driven by the need for FR4-like mechanical properties combined with superior machinability and competitive pricing. This comprehensive guide explores the technical intricacies of CEM3, its thermal capabilities, and its indispensable role in modern industrial applications.

A CEM3 PCB is a composite material consisting of woven glass fabric surface layers and a non-woven "matte" glass fiber core, all impregnated with an epoxy resin binder. This "sandwich" construction is what differentiates it from the continuous woven glass structure of FR4.

From a manufacturing perspective, the non-woven glass core makes the material softer than FR4. This leads to:

Reduced Tool Wear: Drill bits last significantly longer when processing CEM3.

Improved Punching Capabilities: For high-volume orders, CEM3 can be punched rather than routed, drastically lowering the unit cost for large-scale industrial projects.

Consistent Dielectric Properties: It maintains electrical insulation standards suitable for both double-sided and complex circuit designs.

One of the most critical factors for industrial electronics is how a board handles heat. In high-power environments, engineers often look for specialized grades like ST210G thermal conductivity CEM3.

Standard CEM3 typically offers a thermal conductivity of around 0.20 to 0.30 W/mK. However, advanced grades like ST210G are engineered to enhance heat dissipation.

Heat Dissipation: ST210G grade materials help bridge the gap between standard epoxy laminates and expensive metal-core PCBs.

Stability: This material ensures that components like MOSFETs and power regulators stay within their safe operating temperatures, preventing premature system failure.

At ApolloPCB, we utilize premium lamination processes to ensure that our CEM3 PCB products meet strict thermal dissipation requirements for industrial-grade power supplies and motor controllers.

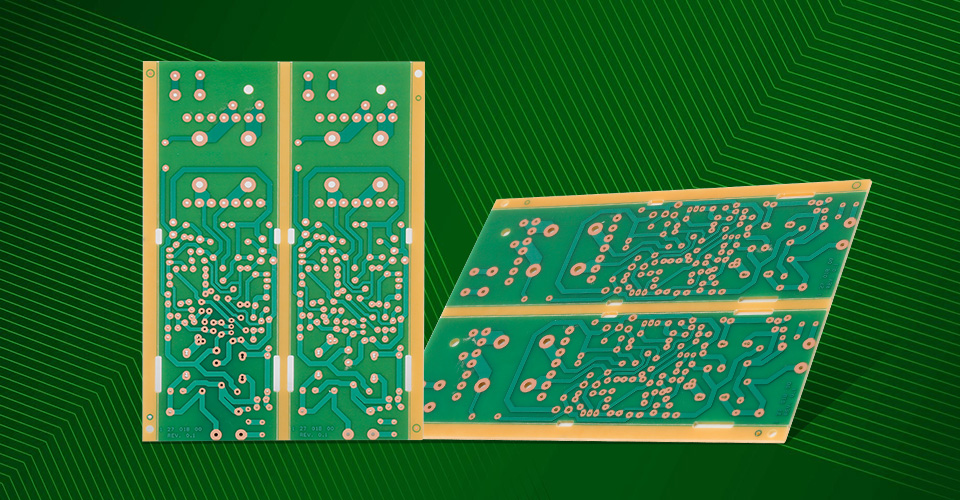

The most explosive growth for CEM3 substrates has been in the lighting sector. When it comes to LED light CEM3 applications, the material offers a unique synergy of cost and performance.

In general lighting (street lights, industrial high-bays), CEM3 provides the necessary rigidity and heat resistance to support high-lumen LED arrays. Because the material is naturally white/off-white, it aids in light reflectivity when combined with high-quality white solder masks.

For the consumer electronics and display industries, LED Backlight CEM3 is the gold standard.

Uniformity: It provides a stable platform for densely packed LEDs in TV and monitor backlights.

Cost Efficiency: Since backlight panels are often large, the per-square-inch savings of CEM3 over FR4 result in massive BOM (Bill of Materials) reductions for factories.

Reflectivity: ApolloPCB’s specialized LED Backlight boards are finished with high-reflectivity coatings to maximize light output efficiency.

In industrial environments, electrical safety is non-negotiable. This is where High CTI value cem3 becomes essential.

CTI is a measure of the electrical breakdown (tracking) properties of an insulating material.

Standard Grade: Most standard laminates have a CTI of 175V to 250V.

High CTI Value CEM3: These boards can reach a CTI of 600V or higher.

Why is this critical? In high-voltage applications or environments prone to moisture and dust (like industrial workshops), a high CTI prevents the formation of conductive paths on the board surface, eliminating the risk of fire and electrical shorts. ApolloPCB provides specialized High-CTI CEM3 solutions for rugged industrial controllers and automotive charging stations.

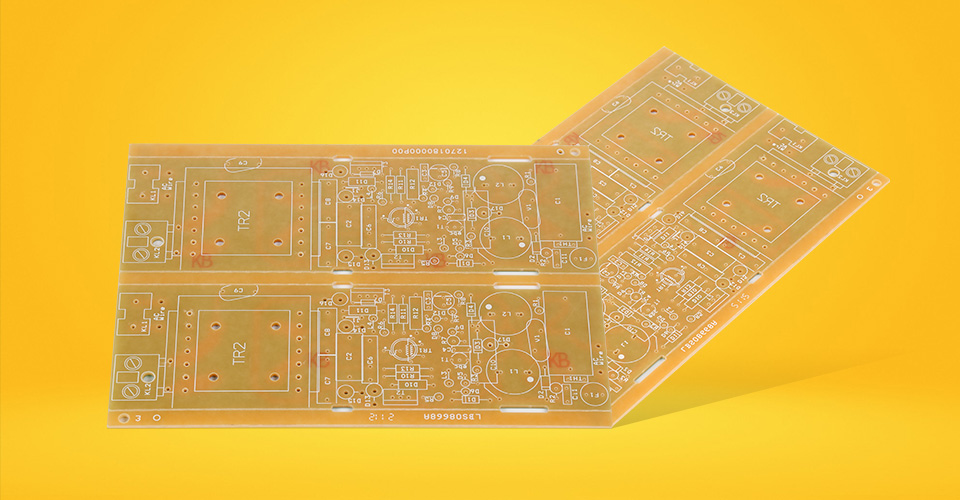

Producing a high-quality CEM3 PCB requires a nuanced understanding of the material's glass-matte core. Our factory process is optimized for:

Controlled Lamination: Ensuring the epoxy resin penetrates the non-woven glass core perfectly to prevent delamination.

Precision Drilling: Using specialized parameters to ensure clean hole walls for reliable plated-through-hole (PTH) connectivity.

Quality Inspection: Every batch undergoes thermal stress testing and CTI verification to ensure compliance with global industrial standards.

For procurement managers deciding between materials, this comparison is vital:

| Specification | Standard FR4 | CEM3 PCB |

| Substrate Construction | Woven Glass + Epoxy | Woven Glass + Matte Glass + Epoxy |

| Machinability | Hard (High tool wear) | Moderate (Low tool wear) |

| Cost | Baseline (100%) | 85% - 90% of FR4 cost |

| Thermal Conductivity | 0.25 - 0.30 W/mK | 0.20 - 0.35 W/mK (e.g., ST210G) |

| Typical Applications | Multilayer / High-Speed | Double-Sided / LED / Industrial |

A printed circuit board (PCB) is a rigid structure that mechanically supports and electrically connects electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. In the case of CEM3 PCB, that substrate is a composite of woven and non-woven glass.

The process of how to make pcb circuit board units at ApolloPCB involves several high-precision steps:

Design & DFM: Reviewing the Gerber files for manufacturability.

Lamination: Bonding the copper foil to the CEM3 or FR4 substrate.

Drilling: Creating vias and mounting holes.

Plating: Adding copper to the hole walls for interlayer conductivity.

Etching: Removing excess copper to define the circuit.

Solder Mask & Silkscreen: Applying protective coatings and identifying marks.

Testing: Final E-test and AOI (Automated Optical Inspection) to ensure 100% functionality.

While CEM3 is most commonly used for single and double-sided boards due to its matte core, it can be used in certain multilayer configurations where cost-saving is prioritized over extreme mechanical rigidity. However, for boards over 4 layers, ApolloPCB typically recommends FR4 or High-Tg materials.

With advanced materials like ST210G thermal conductivity CEM3, conductivity can reach up to 0.35 W/mK, making it highly effective for heat-generating industrial LED applications.

Choosing the right CEM3 PCB manufacturer is about more than just finding the lowest price—it's about ensuring your industrial equipment survives in the field. At ApolloPCB, we combine 20 years of manufacturing expertise with rigorous quality control to deliver CEM3 solutions that exceed expectations.

Whether you are looking for LED Backlight CEM3 panels or High CTI value cem3 for power electronics, our engineering team is ready to provide a full DFM review and a competitive quote.

[Contact ApolloPCB Today for a Technical Consultation on Your CEM3 Project]

Related Articles

CEM3-09HT Thermal Conductive PCB: Dual Advantages of High-Temp Resilience and Heat Dissipation

Countersink Holes in CEM3 PCB: Ensuring Structural Integrity and Assembly Precision

HA30 CEM3 Thermal Conductivity Specs: Guiding Heat Management in Mid-Tier Electronics

KB7150T High TG CEM3 Circuit Board: Reliable Performance for High-Temperature Electronics

LED Light CEM3 Circuit Board: Key Attributes and Applications in Modern Lighting Systems

Low CTE CEM3 Material for High Stability: Ensuring Precision in Dynamic Operational Environments

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB